Load switch for magnesium electrolysis

A technology of load switch and magnesium electrolysis, applied in electrical switches, high-voltage/high-current switches, circuits, etc., can solve the problems of easy corrosion of pneumatic pipes, high maintenance costs, and high investment costs, and achieve simple and reliable operation mechanism, low cost, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

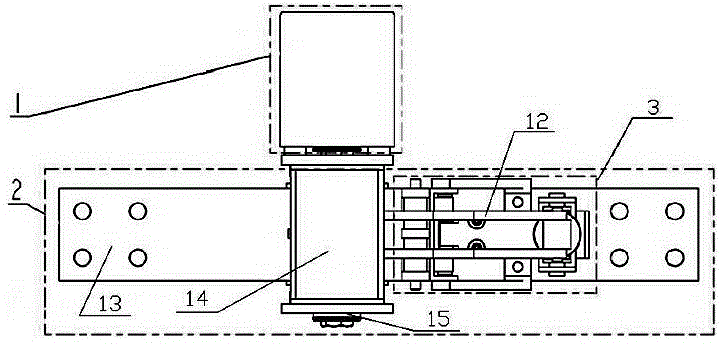

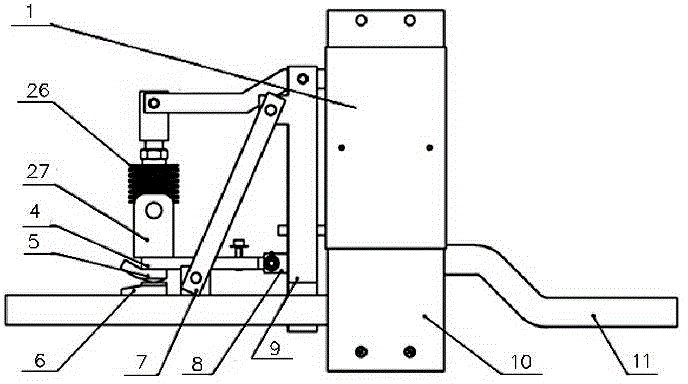

[0029] In this example, see Figure 1 to Figure 5 As shown, a load switch for magnesium electrolysis of the present invention includes a main switch 2, a drive motor 1 installed on one side of the main switch 2, and an air type arc extinguishing system 3 connected in parallel with the main switch 2 ;

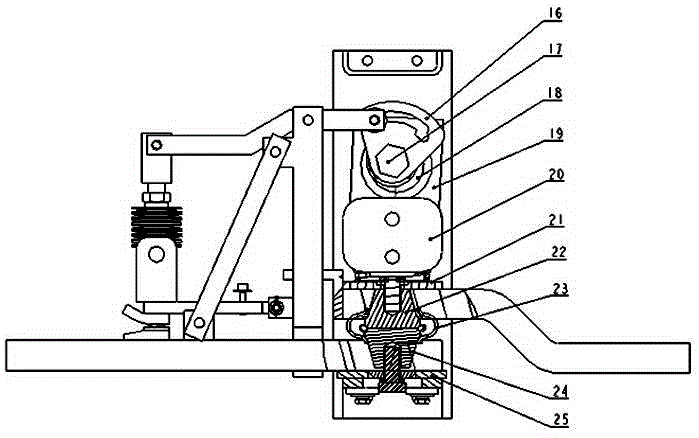

[0030] The main switch 2 is provided with a main switch frame 10, a lifting frame 20 installed in the main switch frame 10, a soft connection 11 installed on the lifting frame 20, and a hard copper welded at both ends of the soft connection 11. row 13, and the main contact system arranged on the hard copper row 13 and the soft connection 11, and the cam rotation mechanism 19 linked with the lifting frame 20, and the hexagonal shaft 17 fixed together with the drive motor 1, The cam rotation mechanism 19 is installed on the hexagonal shaft 17, and the main switch frame 10 is a stainless steel anti-corrosion frame;

[0031] The main contact system is provided with a contact sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com