A Lithium battery combined core film driving device

A membrane device and lithium battery technology, which is applied in the field of lithium-ion batteries, can solve problems such as welding explosion points, scratches entering the shell, and affecting the welding of the top cover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

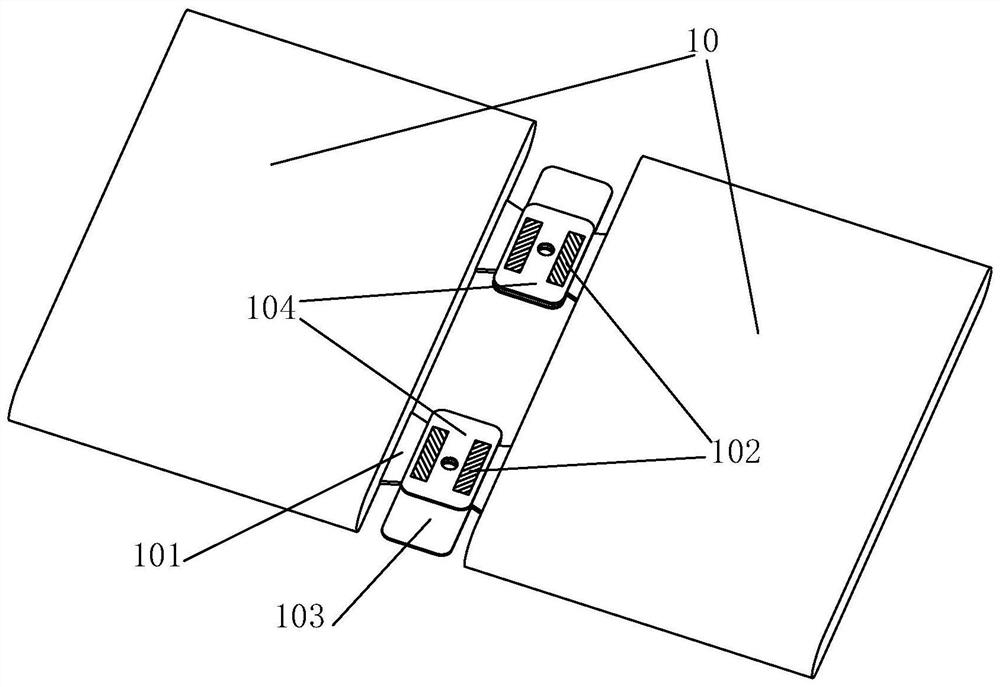

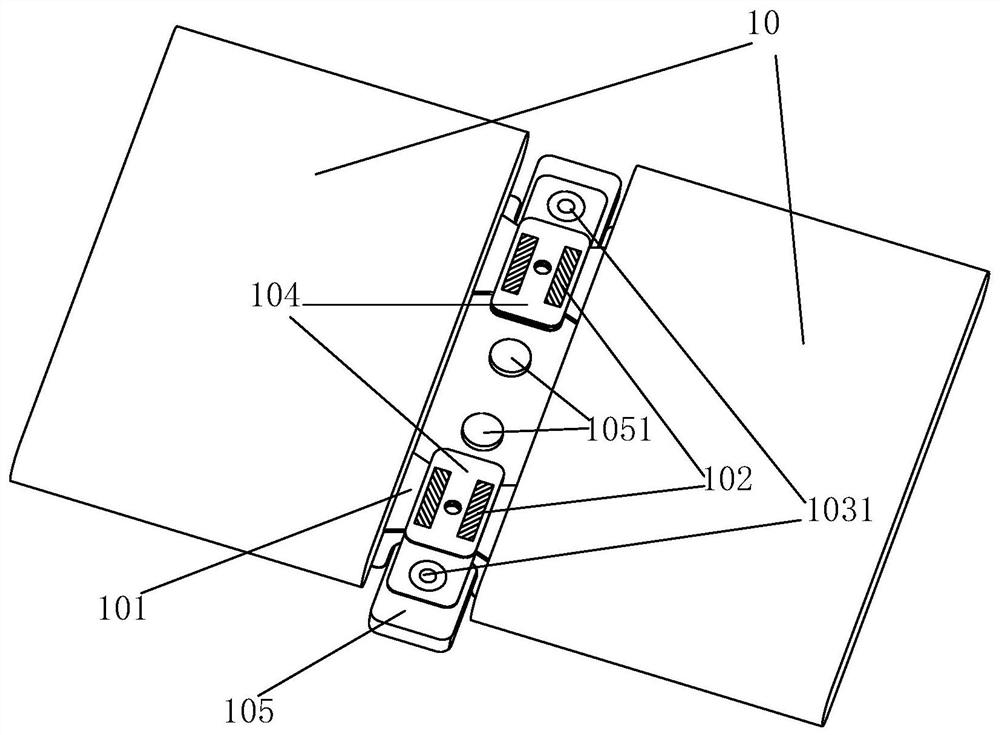

[0024] combined with Figure 1-10 The present invention is further described:

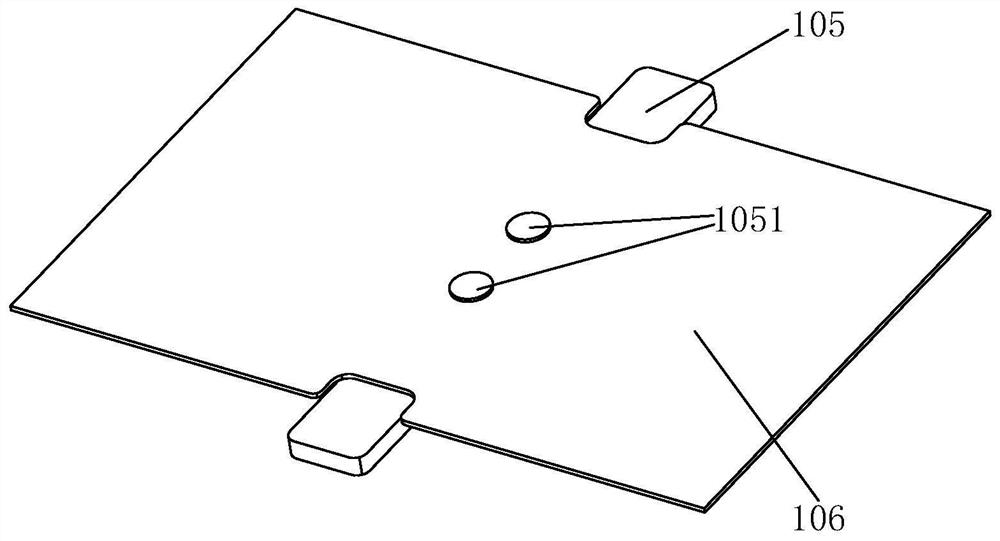

[0025] A lithium battery core-combining film removal device, including a core-combining assembly 40, and a support assembly 50, the support assembly 50 includes a support block 501 for supporting the cover plate 105, and the core-combining assembly 40 includes The composite core board 401 on both sides of the length direction of the block 501, the film catcher conveyor belt 403 is arranged on the board surface of the composite core board 401, and the driving direction of the film catcher conveyor belt 403 is in line with the support block 501 The length direction is vertical.

[0026] In the initial state, the composite core board 401 is in a flattened state. At this time, the cover plate 105 is first fixedly arranged on the support block 501, and the insulating film 106 and the cover board 105 are spread on the film conveyor belt on the composite core board 401 in cooperation. 403, the welded tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com