Driving shaft fine-tuning connecting taper sleeve

A transmission shaft and connecting cone technology, applied in the field of transmission shaft precision adjustment devices, to achieve the effects of improving assembly accuracy and transmission accuracy, prolonging service life, and simple and reliable actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

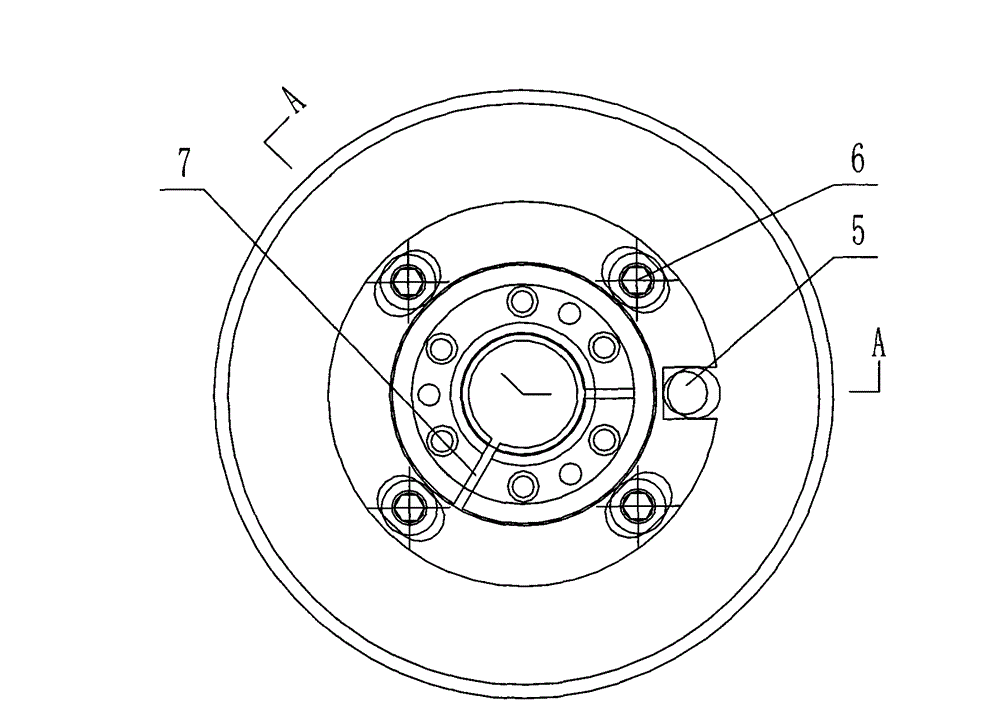

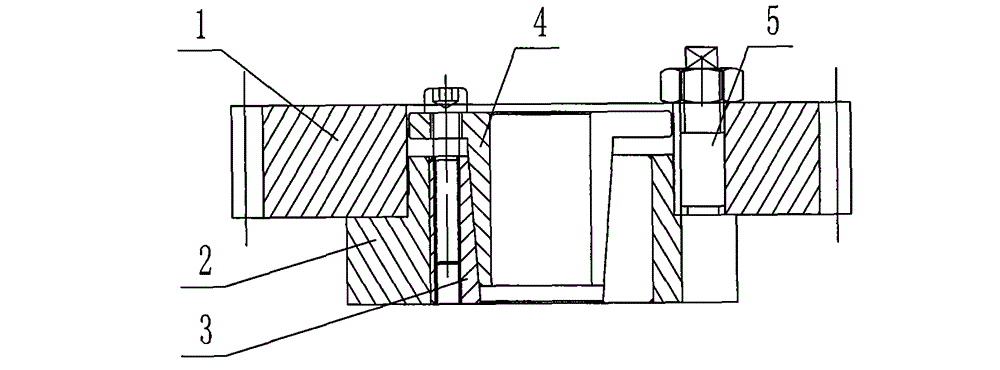

[0012] Such as Figure 1-2 As shown, the transmission shaft fine-tuning connection taper sleeve described in the embodiment of the present invention is installed on the gear shaft, including the transmission gear adjustment seat 2, the circular transmission shaft fixing cone seat 3 assembled inside the transmission gear adjustment seat 2, the transmission shaft The transmission shaft fixed taper sleeve 4 inside the fixed cone seat 3, the transmission gear adjustment seat 2 is connected with the transmission gear 1 through the eccentric shaft 5, the transmission shaft fixed taper seat 3 cooperates with the transmission shaft fixed taper sleeve 4 through the cone surface, and Connect and fix with screw 6.

[0013] Taper sleeve devices 3 and 4 are two parts with a taper of 8.4 degrees that are pressed against each other to play the role of frictional fixation. There are six 12.9-grade screws to pull the taper sleeve parts against each other. Because the drive shaft fixing taper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com