A negative pressure conveying bin bottom retrieving device

A technology of reclaiming device and conveying bin, applied in valve device, transportation and packaging, loading/unloading, etc., can solve the problems of high abrasion and energy loss, time-consuming and laborious installation, complicated pipeline connection, etc., and achieve fast and convenient installation. The effect of expanding the number of pipes and increasing the number of material pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

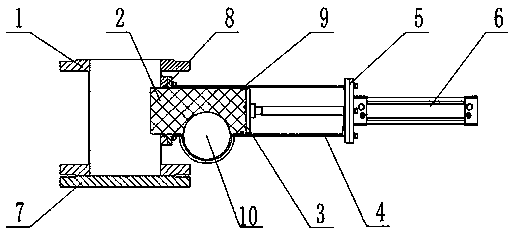

[0021] like Figure 3-5 As shown, the main body connection pipe 1 of the reclaimer is directly connected to the bottom of the silo, and is connected to the valve body 4 on the side. 50%. A columnar valve core 2 is arranged inside the valve body, and a semicircular notch is provided at the rear end of the columnar valve core 2, which is connected with the executive cylinder 6 through the connecting lever 3, and the cylinder 6 is connected with the valve body pipe through the mounting plate 5. A sealing ring 8 is fixedly installed at the connection between the valve body 4 and the connecting pipe 1. When the cylindrical valve core 2 is in the closed state, the sealing ring 8 is installed. The space between the inner walls of the body 4 is always in a sealed state.

Embodiment 2

[0023] If the reclaimer is in the cut-off state of work, such as image 3 As shown, the valve stem of the actuator cylinder 6 is stretched out, driving the columnar valve core 2 to run to the front end of the valve body. At this time, the columnar valve core 2 completely fills the material channel inside the valve body and is kept sealed by the sealing ring 8. The material cannot flow from the connecting pipe 1. Enter the delivery pipe 10, but the semicircular notch of the cylindrical valve core 2 just runs to the intersection of the delivery pipe 10, maintaining a complete circular delivery section, without affecting the delivery of the delivery pipe 10.

Embodiment 3

[0025] If the reclaimer is in the working open state, such as Figure 4 As shown, the valve stem of the actuator cylinder 6 is retracted, driving the columnar valve core 2 to run to the rear end of the valve body. Under the action of negative pressure, it enters the delivery pipe 10 from the joint 1. The columnar spool 2 drives the sealing ring 9 and moves with the spool, so that the space between the rear end of the columnar spool 2 and the inner wall of the valve body 4 is always in a sealed state.

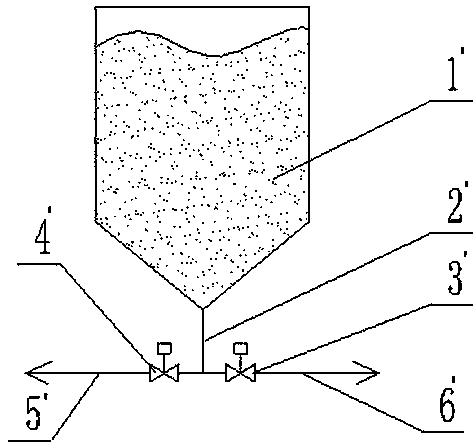

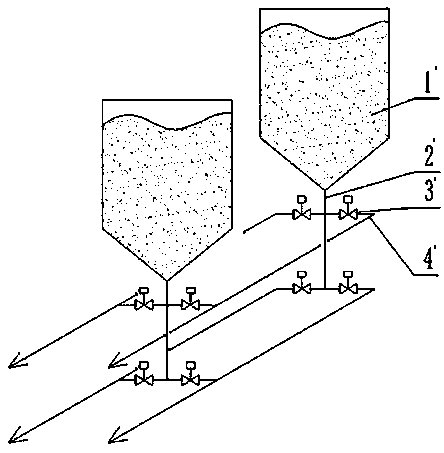

[0026] The above is a detailed description of the structure and working form of the single-group negative pressure conveying bin bottom reclaiming device. In practical applications, when retrieving materials from multiple bins and multi-channel material tubes, the extended application of the reclaimer is as follows: Figure 6-7 shown. The reclaimer can adopt a one-to-two form of 180° layout on both sides, and realize it by stacking up and down. This structure has the advanta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com