High-speed wire double production line swinging wire separation device

A technology for high-speed wire rods and line dividing devices, which is applied in the directions of guiding/positioning/aligning devices, metal processing equipment, metal rolling, etc. Long operation cycle and other problems, to achieve the effect of improving maintenance performance, simple operation and reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

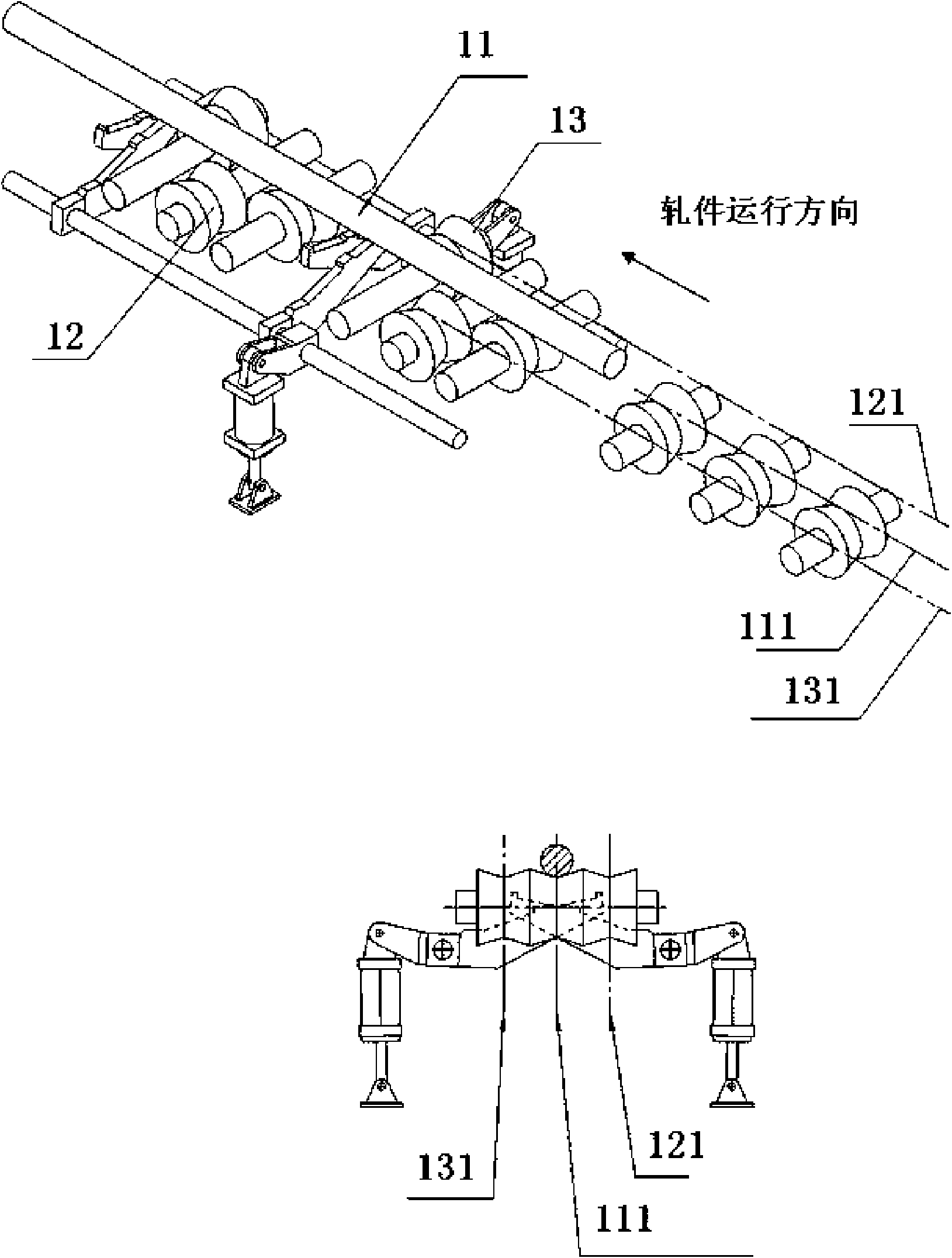

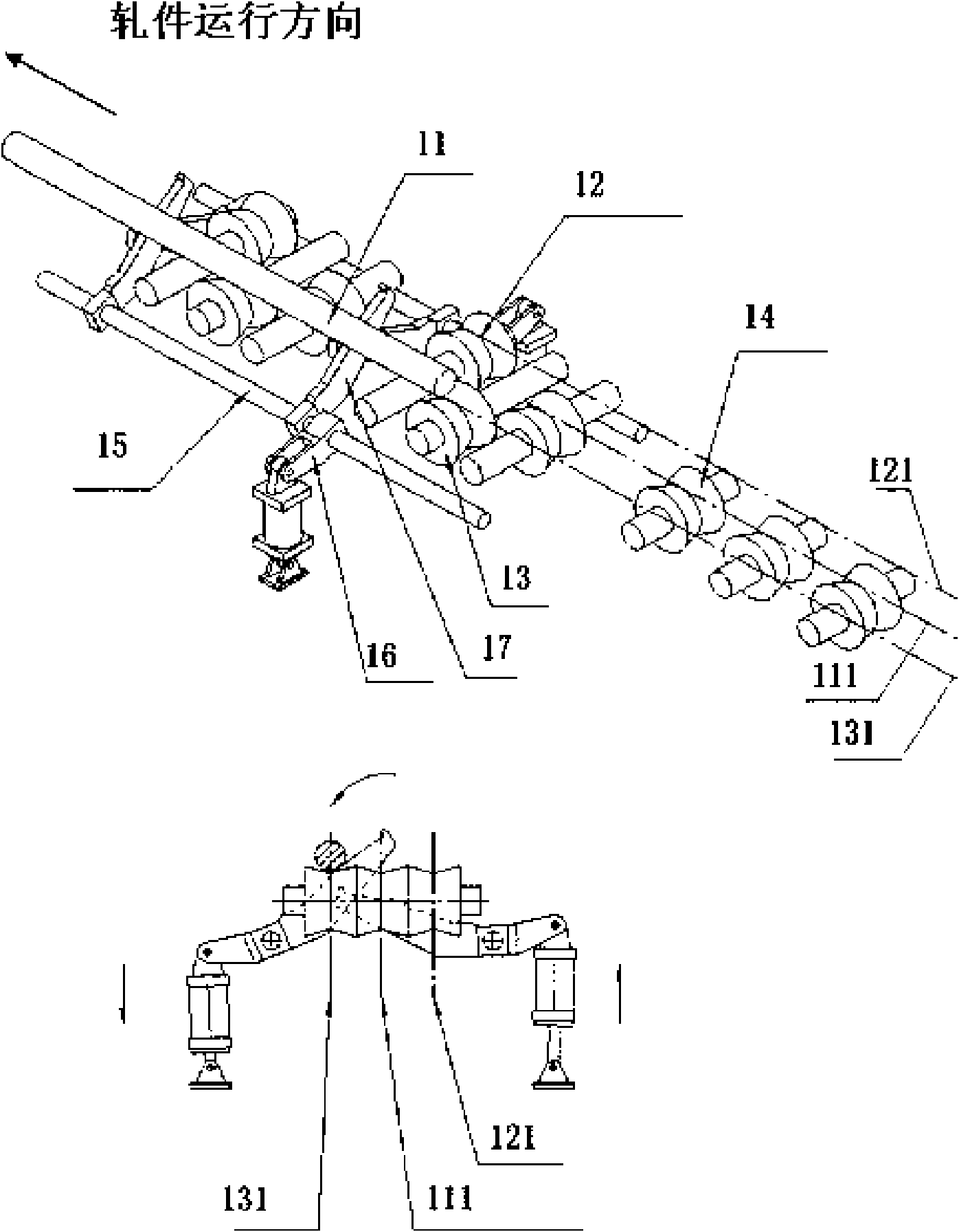

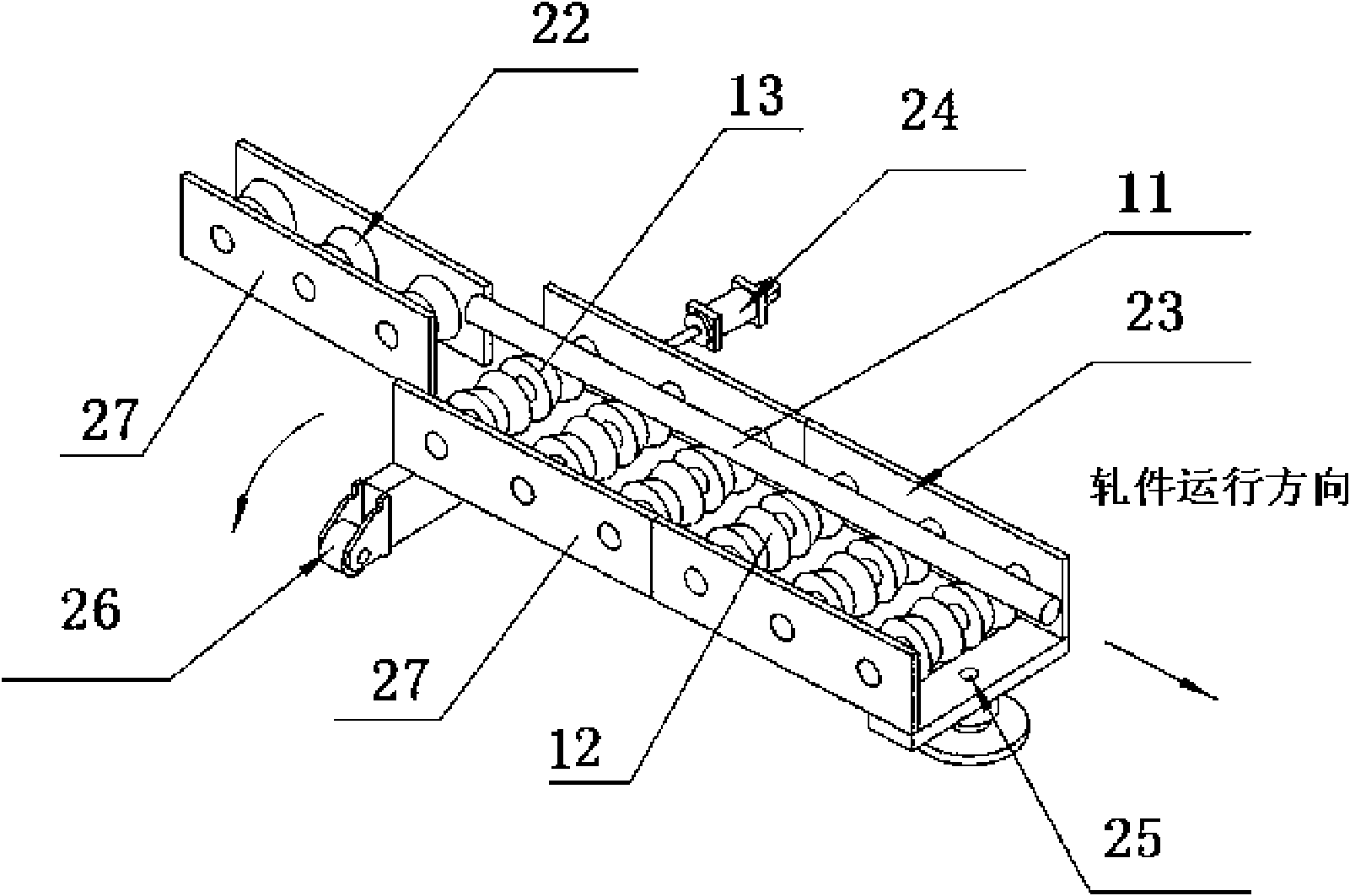

[0043] Combine below Figure 3 to Figure 5 , the present invention is further described:

[0044] Such as image 3 As shown, a high-speed wire double production line swing-type wire separation device includes a single-wire output roller table 22 and a double-wire input roller table 23. The double-wire input roller table 23 is composed of two roller tables, at least including A-line roller table 12 and Line B roller table 13, single-line output roller table 22 is fixed, and the input end of the double-line input roller table 23 is driven by the roller table swing device, and the circular swing connects the entrances of each roller table of the double-line input roller table 23 with the single-line output roller table in turn. 22 docking, to accept the rolling piece that single-line output roller table 22 sends out. Carrying out in this way, swinging again and again, can distribute the rolling piece 11 to the different roller tables of the double-line input roller table 23, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com