Driving method of ejector pin rod and negative pressure jacking type photovoltaic module laminating machine

A photovoltaic module and jack-up technology, applied in the field of solar lamination equipment, can solve problems such as battery module damage, battery module offset, ejection speed and poor time consistency, so as to save manpower and material resources, improve consistency, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiment:

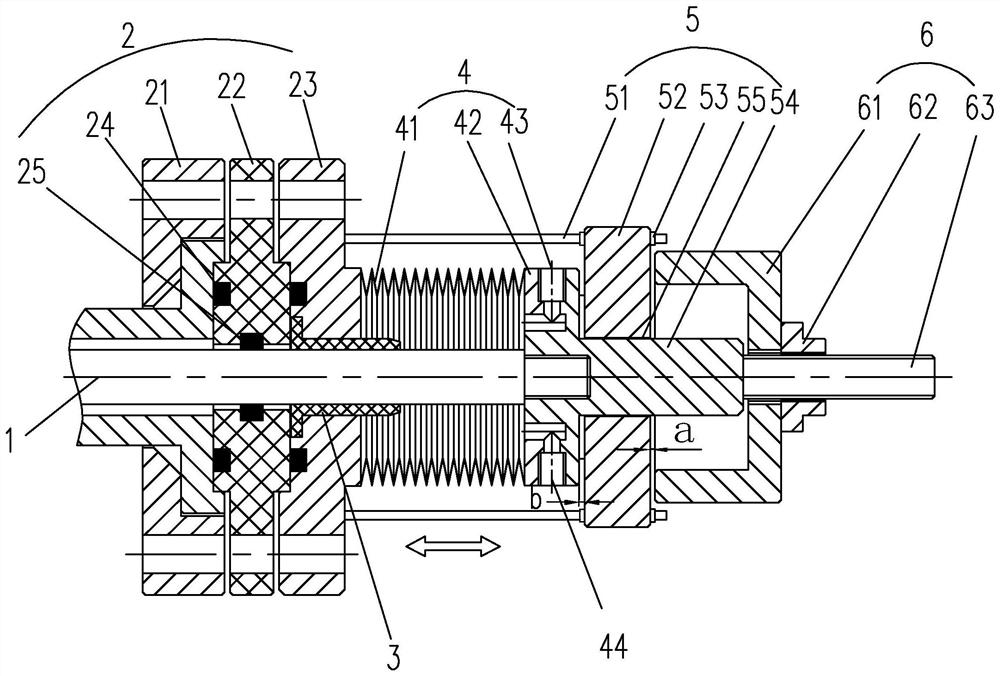

[0022] Such as figure 1 As shown, the present invention provides a negative pressure jacking photovoltaic module laminator, which includes a thimble rod 1, a connecting flange 2, and a drive mechanism 4 for driving the thimble rod up and down. The driving device includes a telescopic tube 41, a bottom plate 42, and a pumping and inflating device (not shown in the figure). One end of the telescopic tube 41 is in sealing connection with the connecting flange 2, and the other end is in sealing connection with the bottom plate 42. 41 is fixedly connected on the device main body. The inner chamber of the telescopic tube 41 communicates with the pumping and inflating device. When the pumping and inflating device pumps and inflates the telescopic tube 41, the tube shrinks or expands, thereby driving the bottom plate 42 to reciprocate along the axial direction of the telescopic tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com