Motor and bearing supporting structure

A technology of bearing support and bearing, which is applied in the direction of casing/housing/support, structural connection, electrical components, etc., can solve problems such as difficult control of dimensional stability, shortened product life, and stuck, so as to improve product reliability and Efficiency, expanding design margin, and avoiding the effect of axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A bearing support structure according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

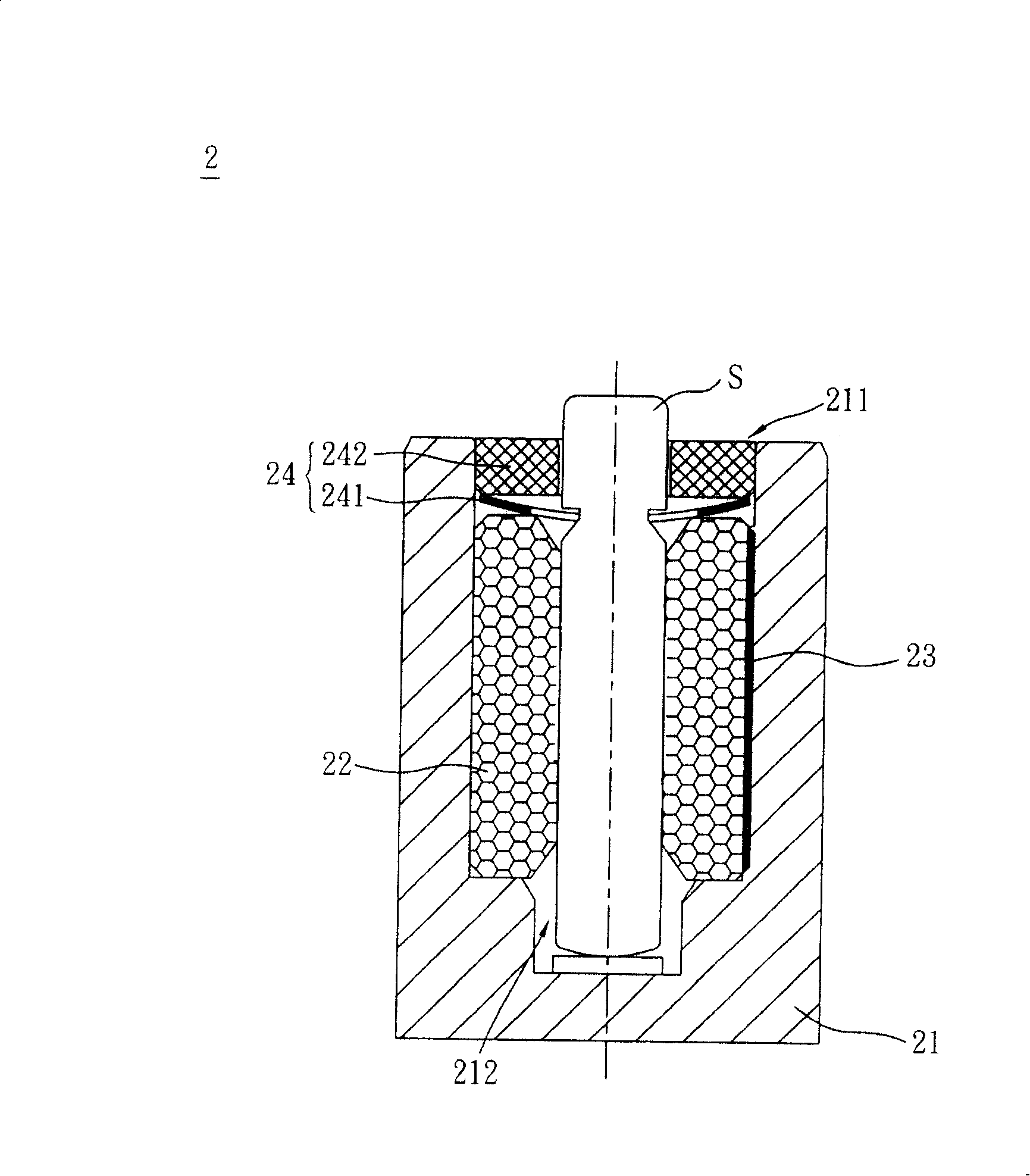

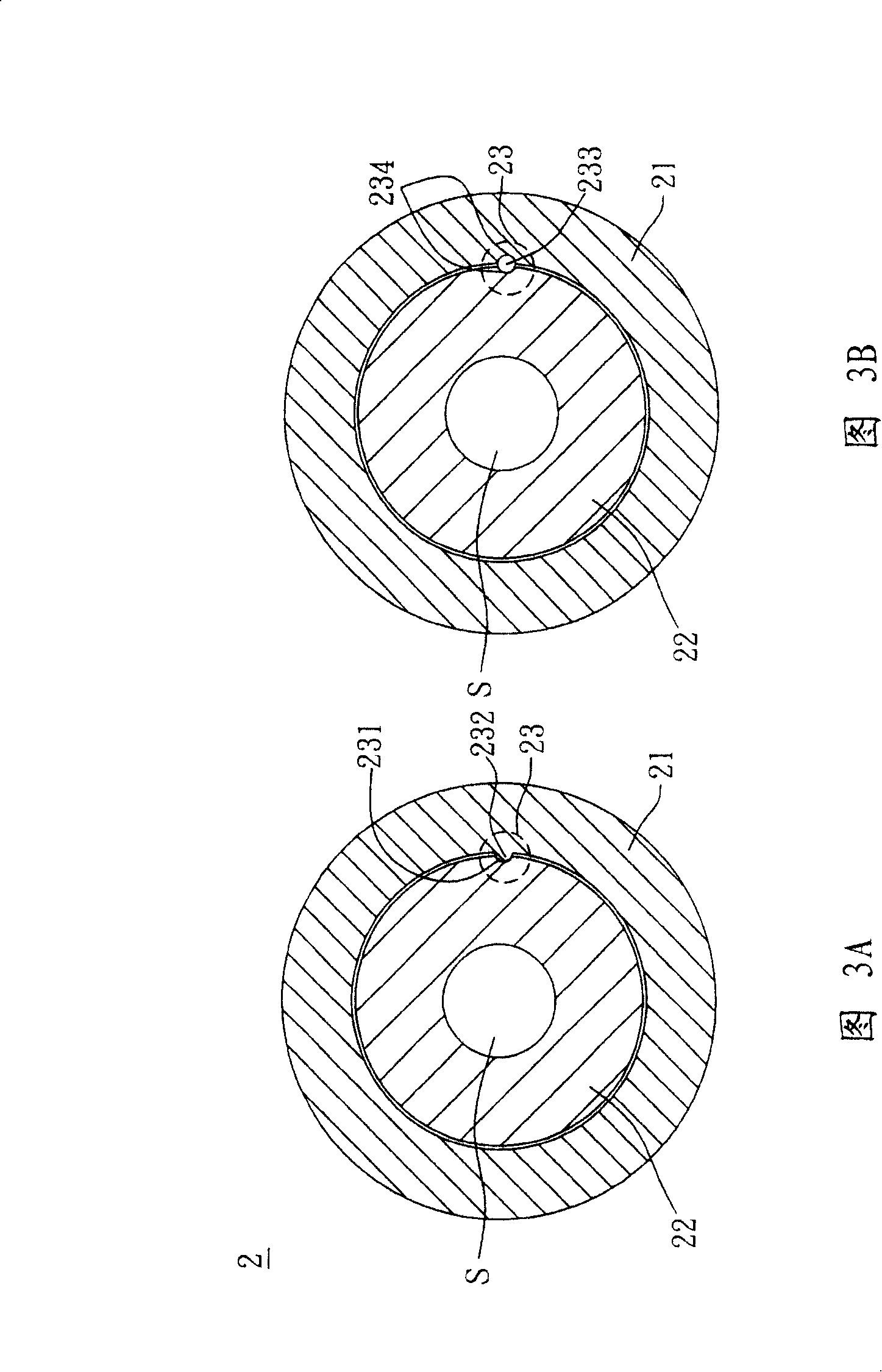

[0036] Please refer to figure 2 , a bearing support structure 2 in a preferred embodiment of the present invention includes a bushing 21 and a bearing 22 , and the bearing support structure 2 supports a rotating shaft S. Wherein, the bushing 21 has an opening 211 and an accommodating space 212 , the bearing 22 is disposed in the accommodating space 212 of the bushing 21 , the rotating shaft S passes through the bearing 22 , and the bearing 22 supports at least part of the rotating shaft S. The bearing support structure 2 also includes at least one first limiting component 23, such as a circumferential limiting component, which is arranged at the connection between the bearing 22 and the bushing 21, so as to prevent the relative rotation of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com