Vehicle-mounted electric hoist

A lift, electric technology, applied in the direction of lifting devices, etc., can solve the problem of time-consuming and labor-intensive jacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

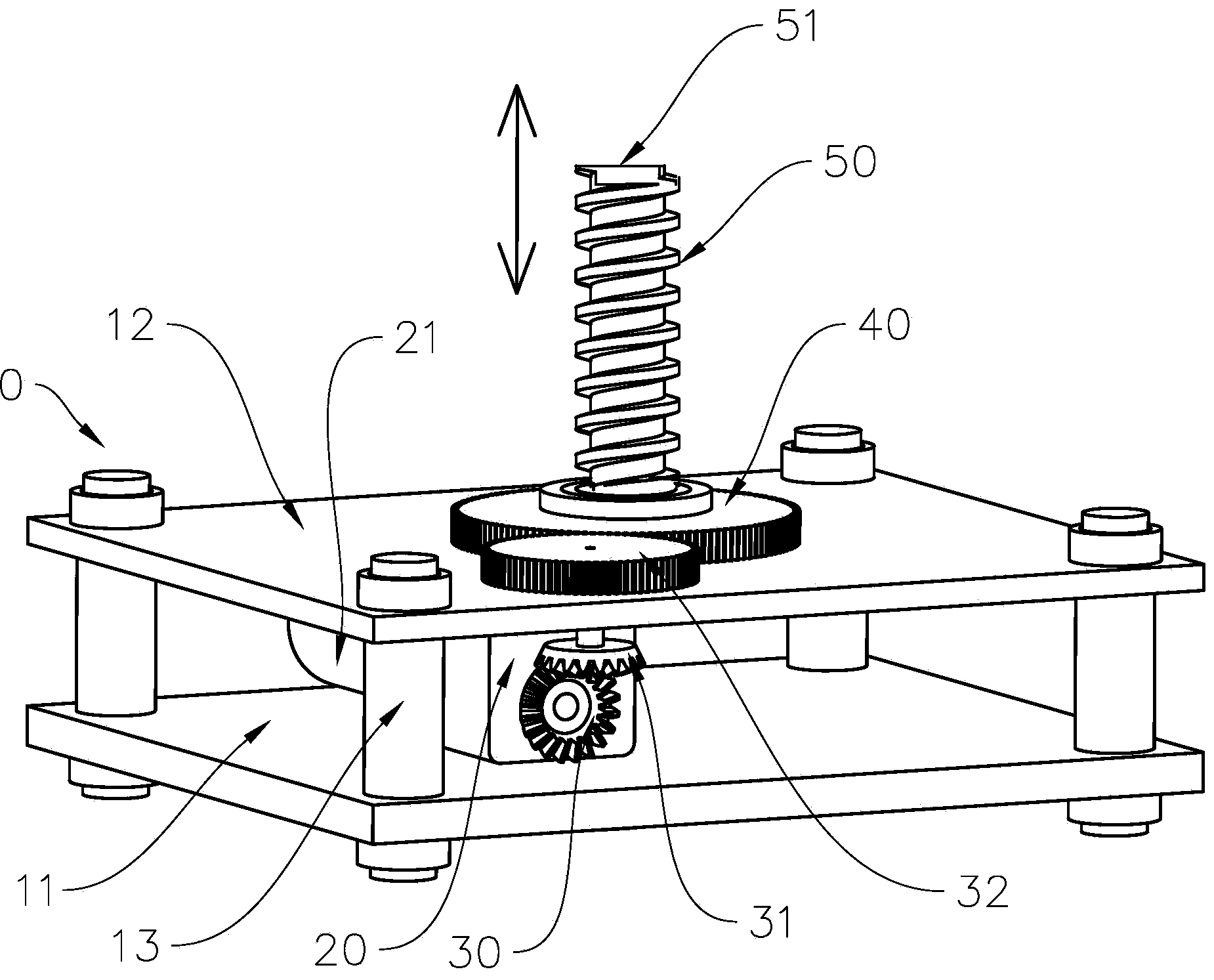

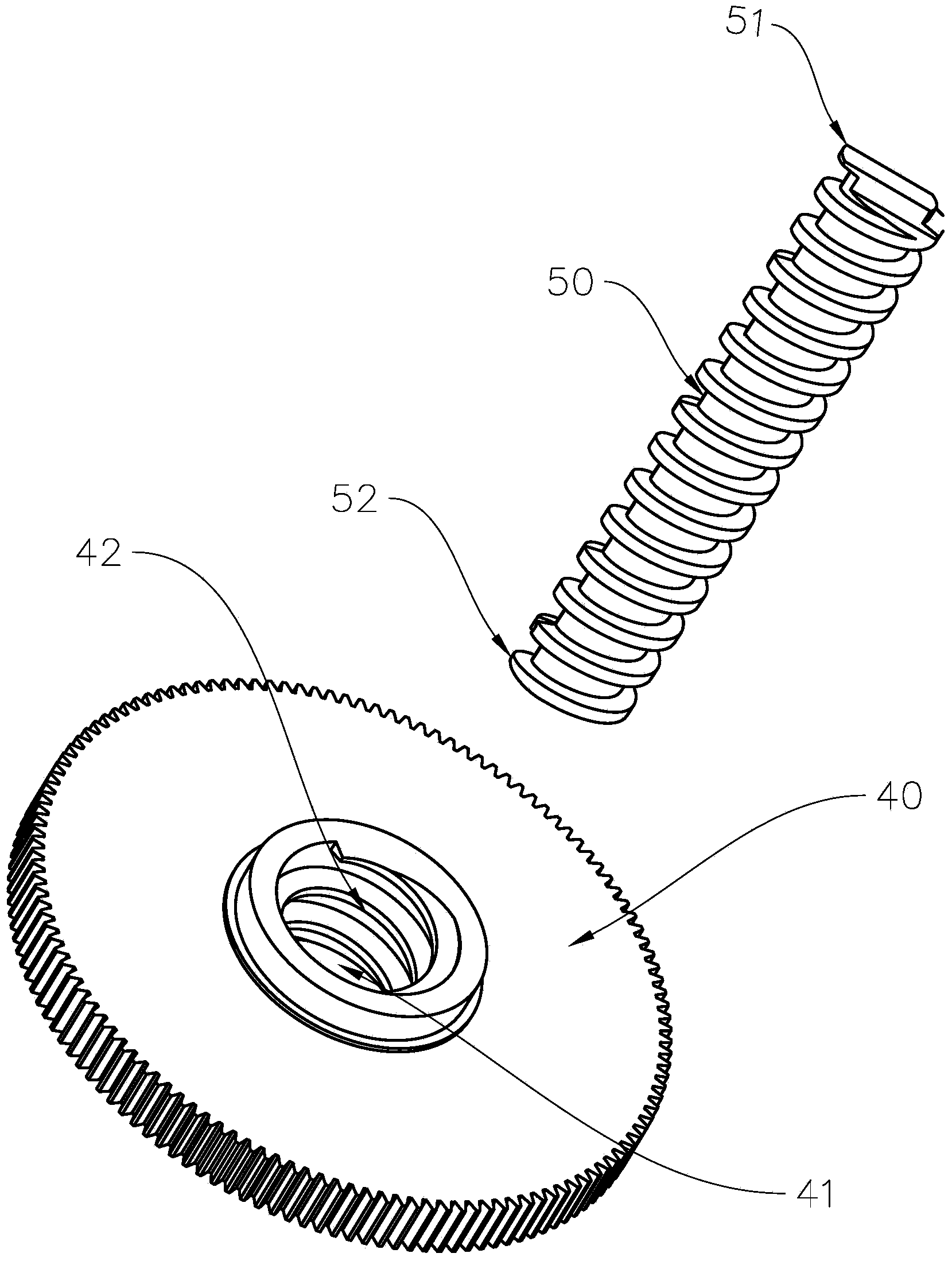

[0026] Such as figure 1 and figure 2 As shown, the vehicle-mounted electric elevator of the present embodiment includes a frame 10, and the frame 10 includes a first platform 11 and a second platform 12, and the first platform 11 and the second platform 12 are arranged in parallel, and the first platform 11 and the second platform 12 pass through the column The body 13 is connected, and the column body 13 can be a common mechanical connection part to fix the first platform 11 and the second platform 12 . Optionally, the frame 10 is made of high strength aluminum material.

[0027] A first motor 20 is arranged on the first platform 11, and the motor 20 can rotate in two directions. spinning speed. The rotating shaft on the first motor 20 drives the first bevel gear 30 to rotate, and the first bevel gear 30 meshes with the second bevel gear 31 , and when the first bevel gear 30 rotates, it drives the second bevel gear 31 to rotate.

[0028] A first driving wheel 32 is arran...

no. 2 example

[0034] This embodiment is another vehicle-mounted electric lift, and the same parts of the lift in this embodiment and the lift in the first embodiment will not be repeated here.

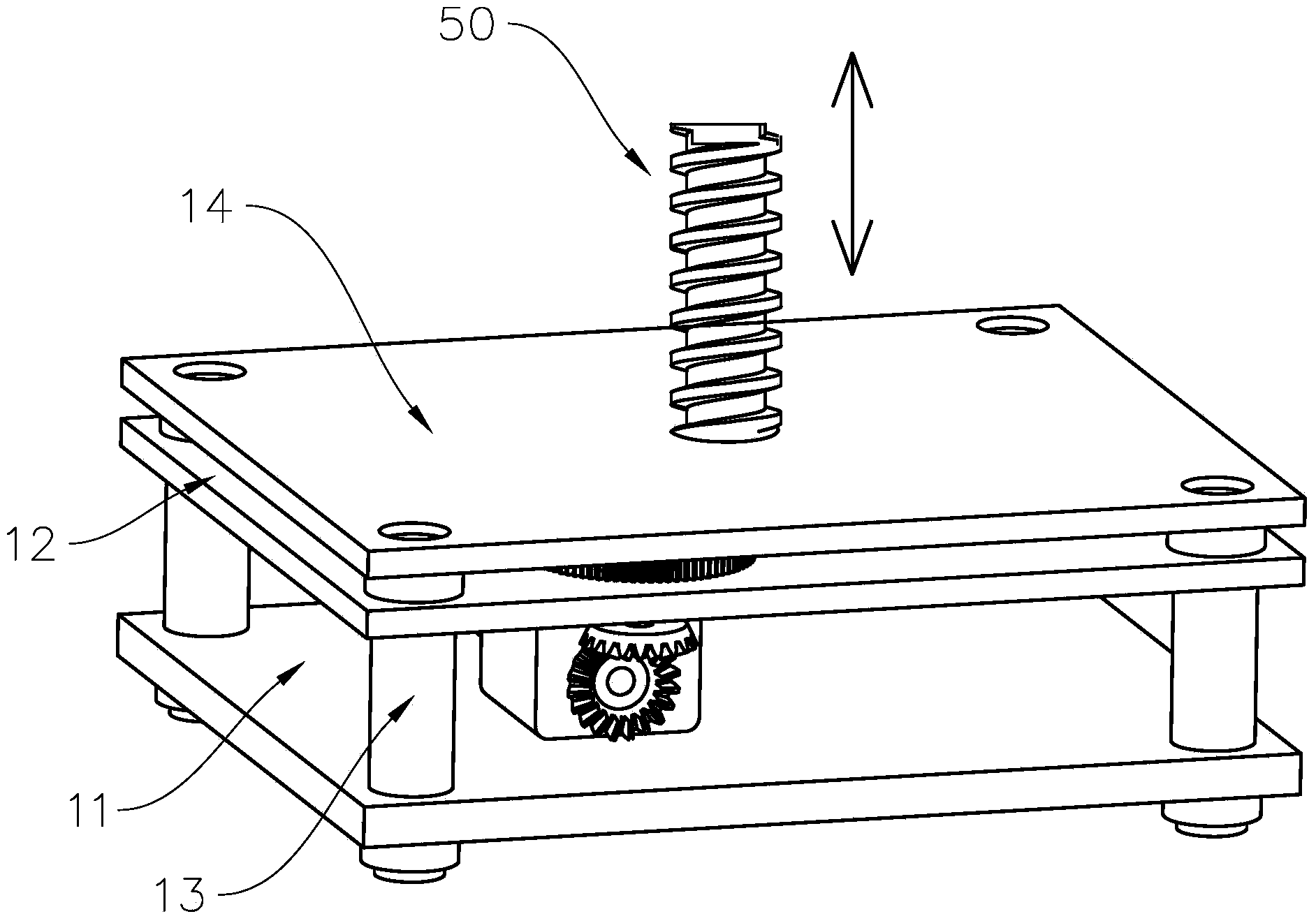

[0035] Such as Figure 4 and Figure 5 As shown, the vehicle-mounted electric lift in this embodiment has a frame 100, and the frame 100 includes a first platform 110 and a second platform 120, each platform can be connected by a column, and the second platform 120 is connected with a third platform 130. In addition, a fourth platform 140 is also provided on the frame 100, and three second driven wheels 400 are arranged on the fourth platform 140, and the second driven wheels 400 are supported on the fourth platform 140 through bearings, and the second driven wheels 400 can rotate to rotate. The center of the second driven wheel 400 is provided with a second opening, and the second opening is provided with internal threads along the axial direction. A second screw rod 500 is disposed through the ...

no. 3 example

[0040] For cars whose chassis height is less than 15 centimeters, such as Figure 6 As shown, on the basis of the second embodiment, this embodiment needs to be used in conjunction with an auxiliary mechanism. The auxiliary mechanism is a trapezoidal structure 600 , and the trapezoidal structure 600 includes an upper bottom surface 601 and a side surface 602 . When the car needs to change tires, the driver controls the car to run slowly, and moves a vehicle-mounted tire to the upper bottom surface 601 along the side 602. At this time, the height of the vehicle-mounted chassis from the ground increases. Through the vehicle-mounted electric lift of the first embodiment or the second embodiment, the vehicle-mounted chassis can be lifted, and such an embodiment significantly expands the application range of the vehicle-mounted electric lift of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com