Expansion pole

A telescopic rod and rod body technology is applied in the field of column-type clothes dryers, which can solve the problems of high production cost, complicated process, easy loosening and the like, and achieve the effects of convenient processing, reliable connection and guaranteed strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

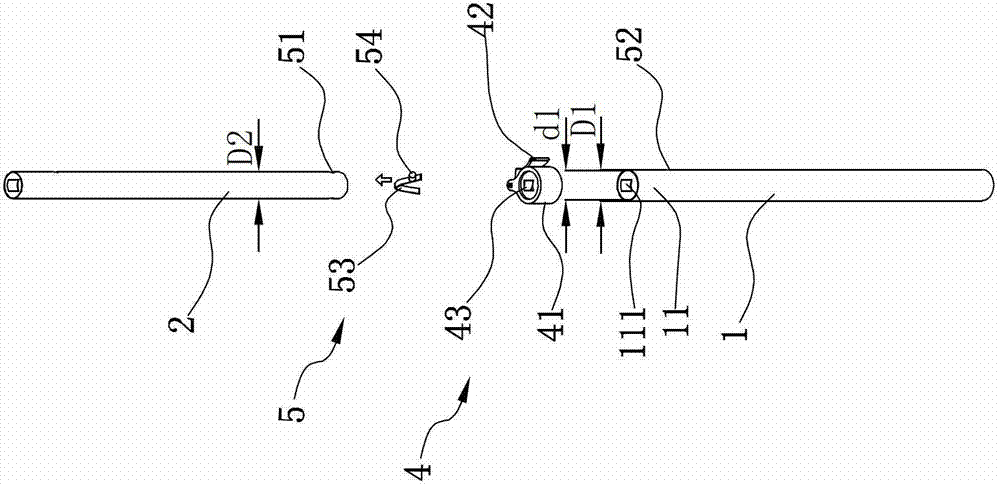

[0038] Such as Figure 1A , 1B , 1C, the first rod body 1 is preferably a round tube made of metal material, its outer diameter is D1 and the inner diameter is d1, the outer diameter of the second rod body 2 is D2, and the outer diameter D2 of the second rod body is smaller than the first rod body. An inner diameter d1 of the rod body 1 . The lower end of the second rod body 2 extends into the first rod body 1, and the second rod body 2 can extend upwards and retract downwards into the first rod body. That is to say, the second rod body 2 can perform a relative linear displacement relative to the first rod body 1 so as to be elongated to obtain a longer rod body.

[0039] A locking device 4, comprising: a sleeve 41, a pull lever 42 and a lock block 43, the pull lever 42 is arranged along the peripheral surface of the sleeve 41, and one end of the pull lever 42 is hinged on the peripheral surface of the sleeve 41, The connection between the trigger lever 42 and the sleeve 41 ...

no. 2 example

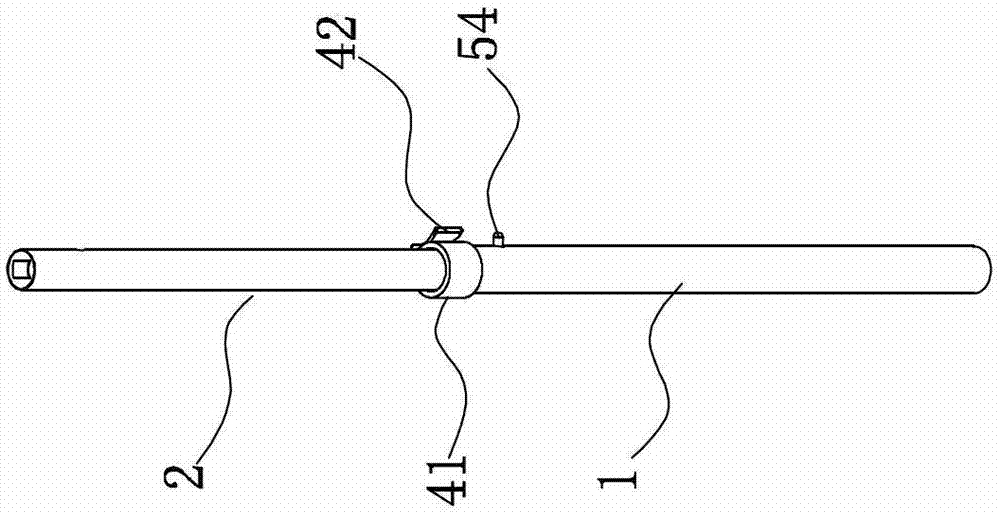

[0043] Such as figure 2 As shown, the first rod body 1 is preferably a round tube made of metal material, its outer diameter is D1 and its inner diameter is d1, the outer diameter of the second rod body 2 is D2, and the outer diameter D2 of the second rod body is smaller than that of the first rod body 1 inner diameter d1. The lower end of the second rod body 2 extends into the first rod body 1, and the second rod body 2 can extend upwards and retract downwards into the first rod body. That is to say, the second rod body 2 can perform a relative linear displacement relative to the first rod body 1 so as to be elongated to obtain a longer rod body.

[0044] The telescopic rod has a locking device 4, which includes a socket 41', a tightening hoop 411 located on the upper part of the socket 41', and a tightening nut 42' set outside the tightening hoop 411. The receiving sleeve 41' of the locking device 4 is fixed on the end 11 of the first rod body 1 protruding from the second...

no. 3 example

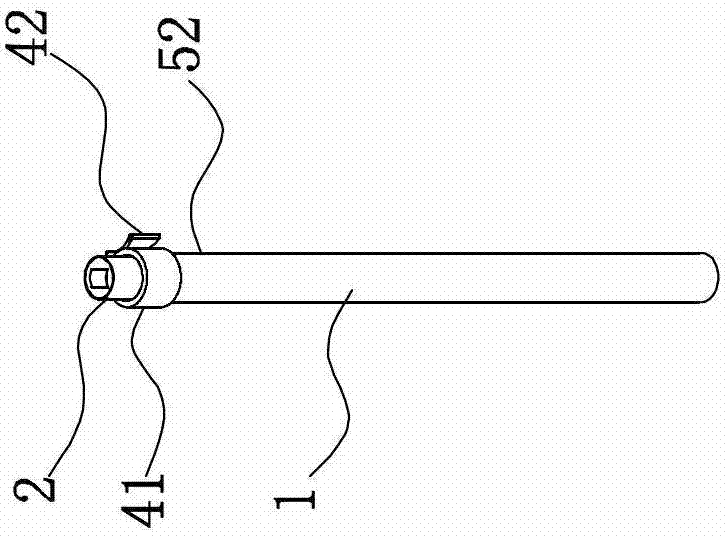

[0048] Such as Figure 3A , 3B As shown, the difference from the first embodiment is that the sides of the first rod body 1 and the second rod body 2 are respectively provided with shafts along the axis of the first rod body 1 and the second rod body 2 for guiding when the two are mutually telescopic. Extending guide grooves 12, 21. After the mutual expansion and contraction between the first rod body 1 and the second rod body 2 is completed, the direction of the peripheral surface is always kept so as not to rotate with each other.

[0049] Such as Figure 3C As shown, the difference from the second embodiment is that the side surfaces of the first rod body 1 and the second rod body 2 are respectively provided with guide rails along the first rod body 1 and the second rod body 2 for mutual expansion and contraction between the two. Axially extending guide grooves 12, 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com