Mini electric carrier

A technology of electric pallet trucks and miniatures, applied in the direction of lifting devices, etc., can solve the problems of increasing the volume and weight of electric pallet trucks, inability to enter and exit narrow and small aisles, shortening the effective use length of forks, etc., to achieve light weight, less Effect of small weight, volume and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

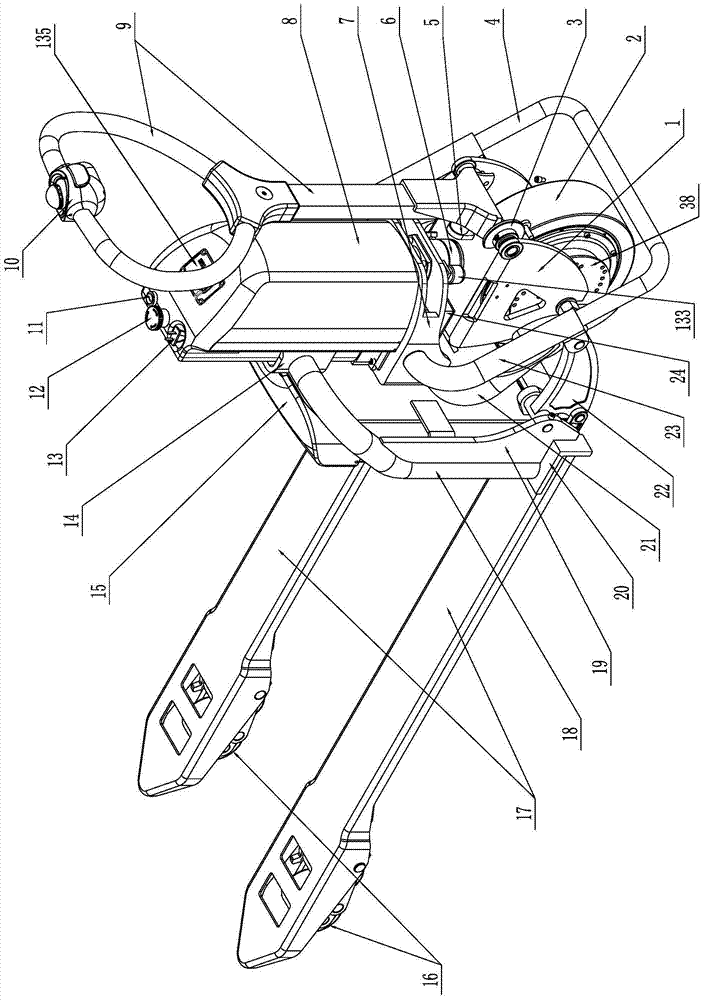

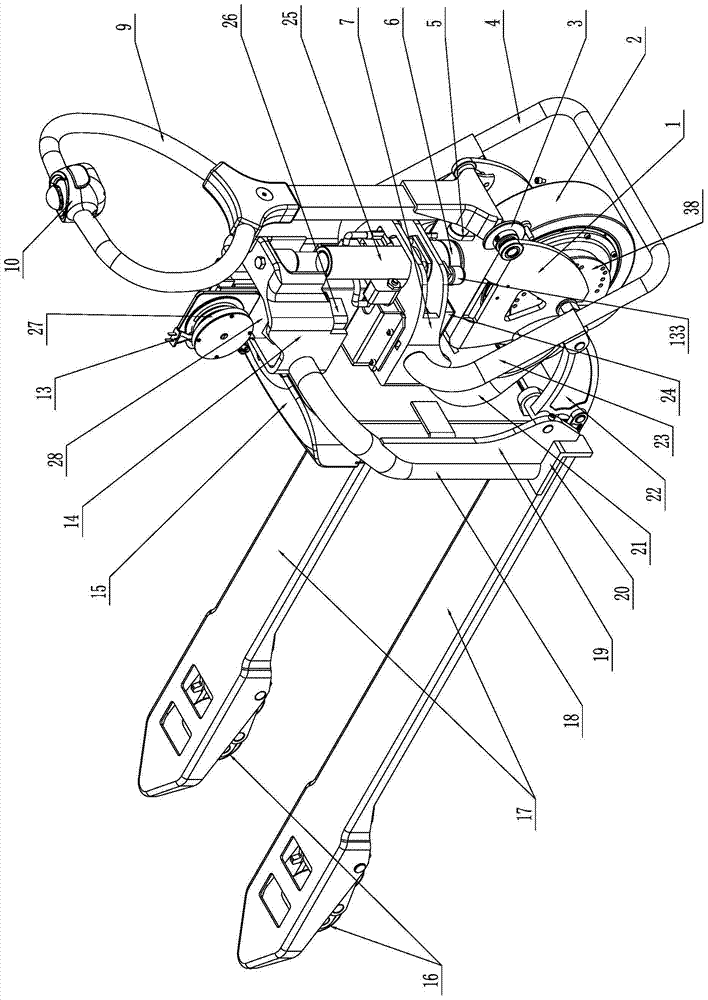

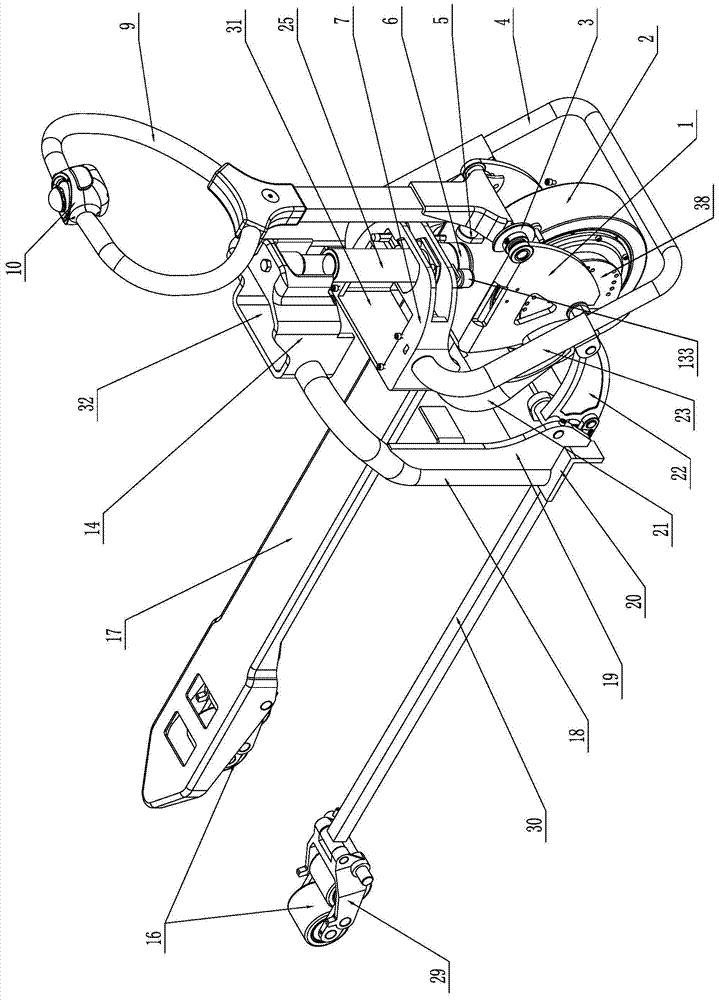

[0032] Below in conjunction with accompanying drawing and specific embodiment, the miniature electric pallet truck of the present invention will be further described:

[0033] like Figure 1 to Figure 16As shown, in this specific embodiment, the mini electric pallet truck of the present invention comprises support seat board 7, wheel frame 1, drive wheel 2, handle 9, lifting frame, top plate 14, battery case 15 that storage battery is housed, two Pallet fork 17, main controller 26, oil cylinder 25 and the hydraulic pump station system that controls the lifting of oil cylinder 25, the wheel frame 1 is connected with the support seat plate 7 through the slewing bearing 6, the driving wheel 2 is installed on the wheel frame 1, the handle 9 is connected with the wheel The frame 1 is hinged, the wheel frame 1 is provided with a handle limit block 5, a gas spring 33 is provided between the handle 9 and the wheel frame 1, a handle controller 10 is provided on the handle 9, and each f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com