Metal part grinding machine

A technology for grinding machines and metal parts, applied in metal processing equipment, grinding machines, portable grinding beds, etc., can solve the problems of endangering the health of workers and the impact of the surrounding environment, so as to improve safety and hygiene performance, ensure health, and prevent environmental damage. effect of turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

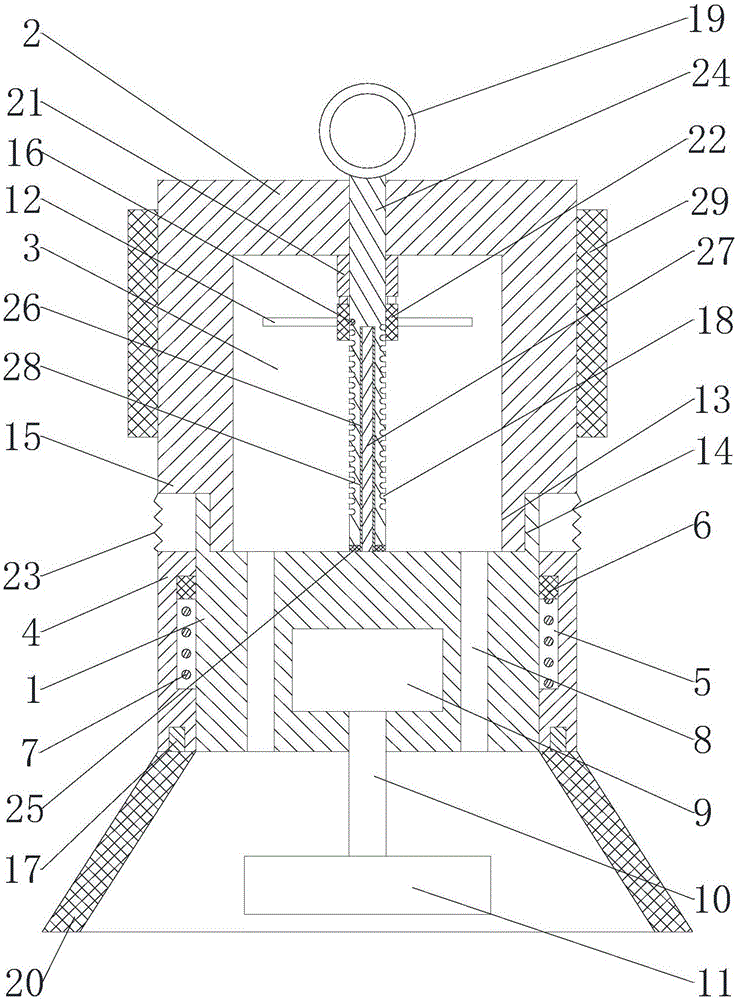

[0035] Such as figure 1 As shown, a metal grinding machine includes a fixed body 1, a connecting cylinder 4 and a collecting cylinder 2 with a collecting cavity 3;

[0036] A driving motor 9 is installed in the fixed body 1, the output end of the driving motor 9 is connected with a rotating shaft 10, the lower end of the rotating shaft 10 passes through the lower end surface of the fixed body 1, and a grinding wheel 11 is connected at this end;

[0037] The connecting cylinder 4 is sleeved on the outer surface of the fixed body 1, and the bottom end of the connecting cylinder 4 is provided with a protective cover 20 surrounding the grinding wheel 11;

[0038] The collection tube 2 is connected to the upper end of the fixed body 1, and the fixed body 1 is provided with a channel 8 that runs through its upper and lower end surfaces and communicates with the collection chamber 3;

[0039]A support cylinder 21 located in the collection cavity 3 is installed on the top of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com