Patents

Literature

31results about How to "Does not affect axial movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

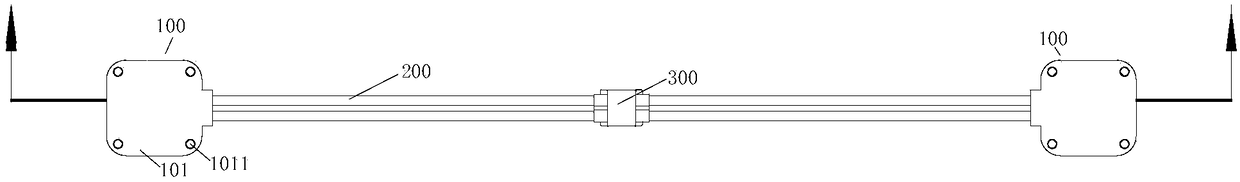

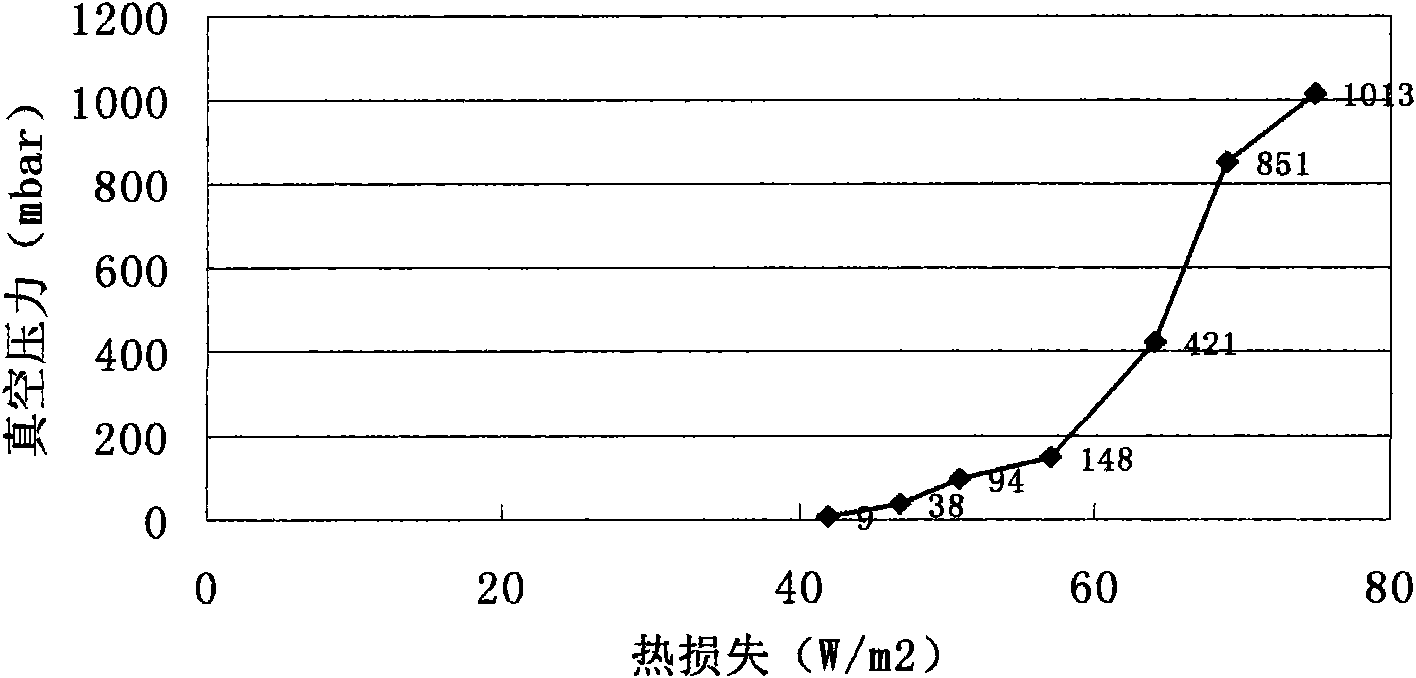

Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

InactiveCN101666419AReduce processImprove insulation effectPipe supportsThermal insulationRolling resistanceEngineering

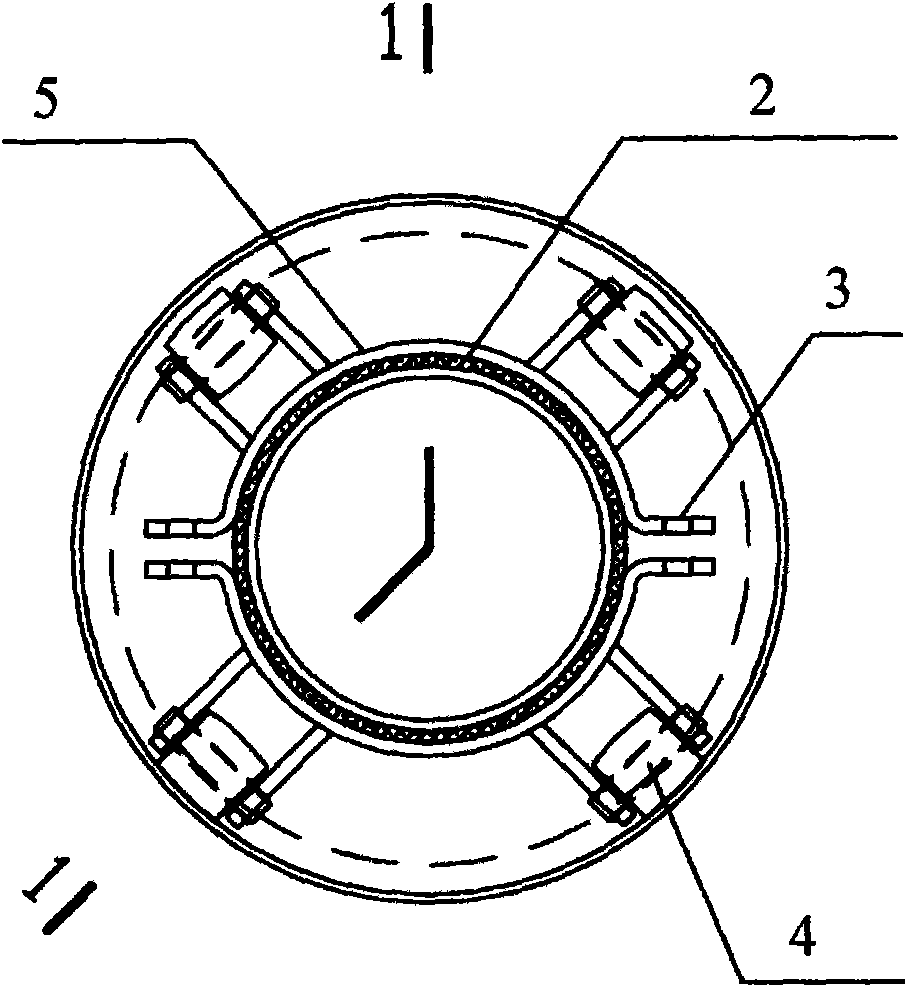

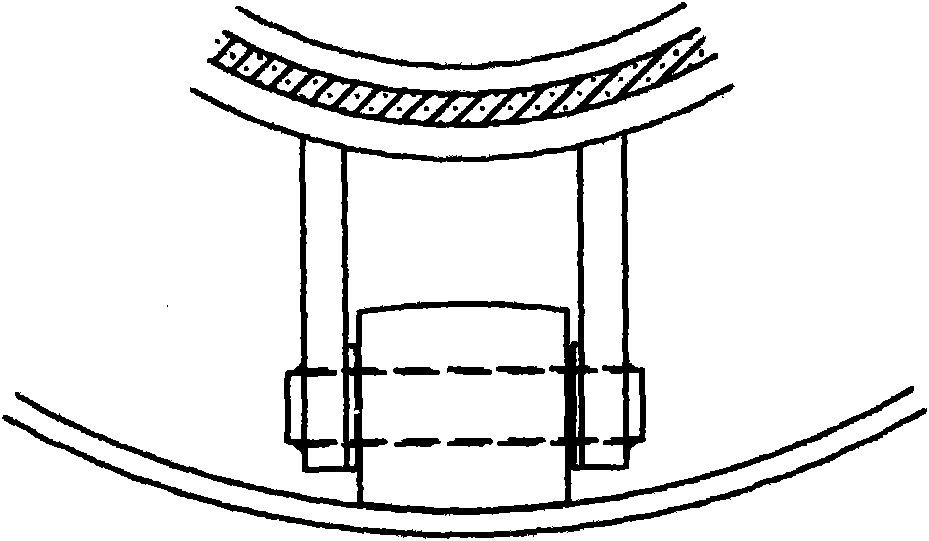

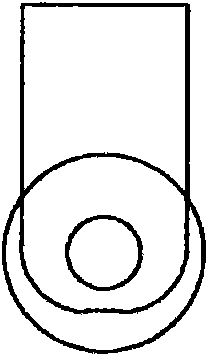

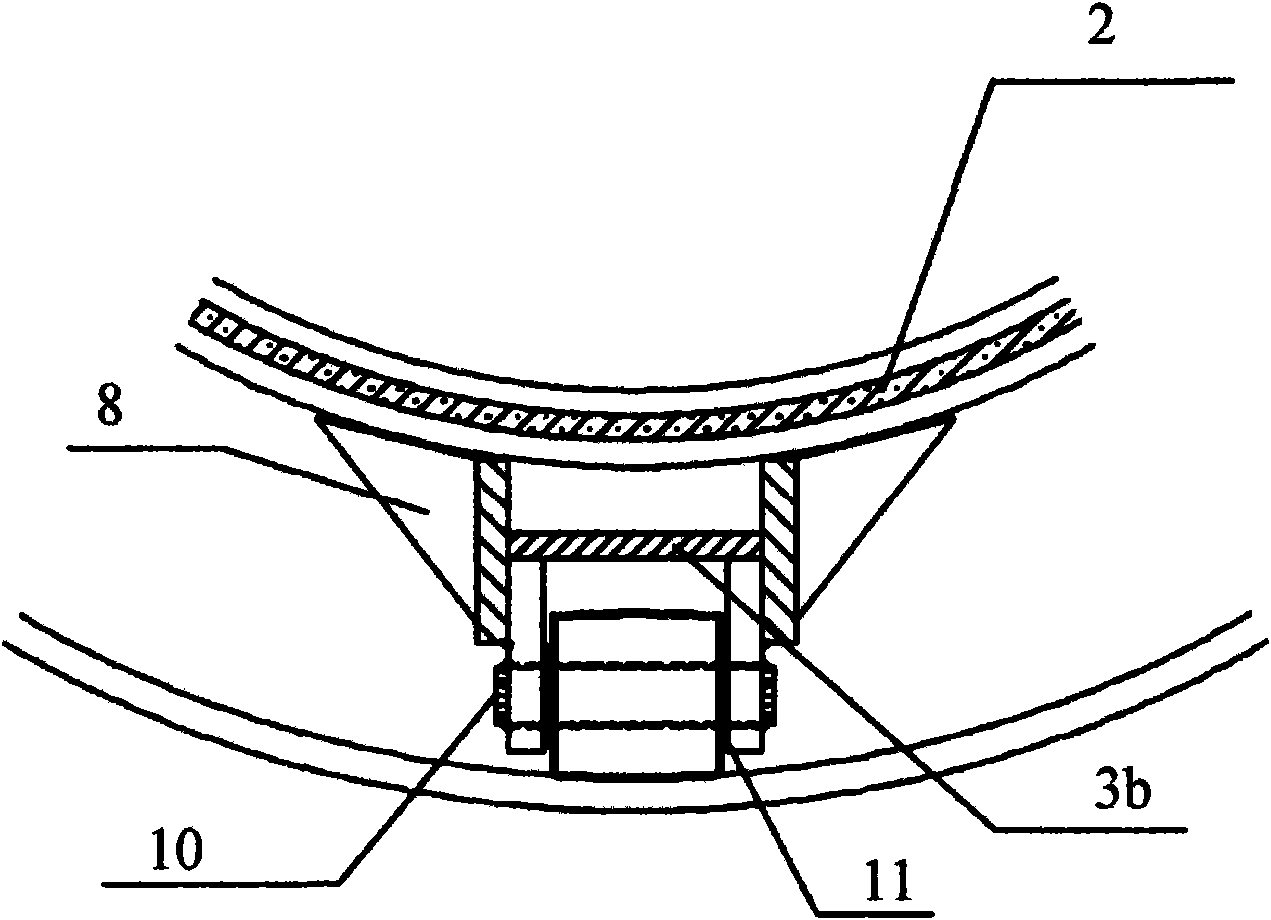

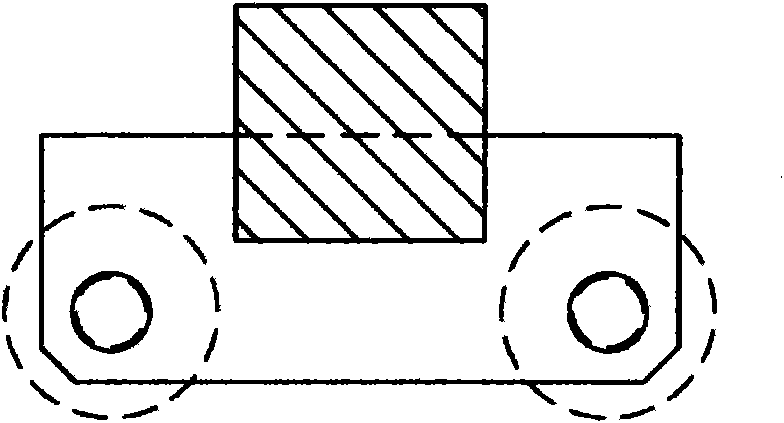

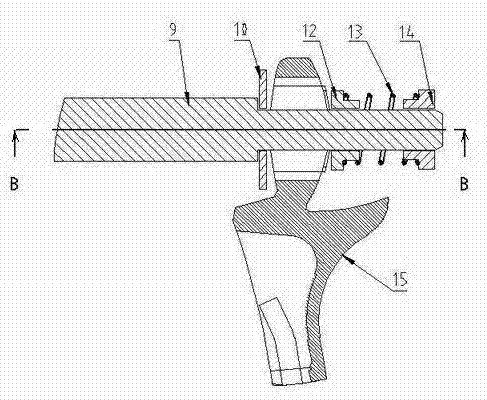

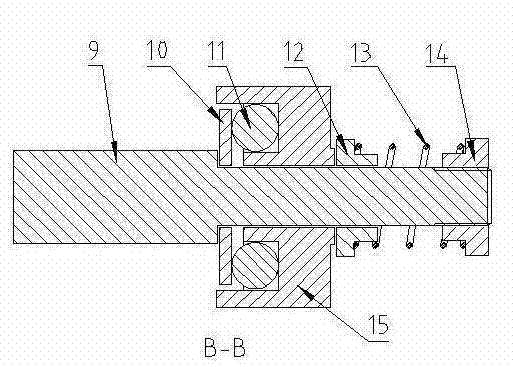

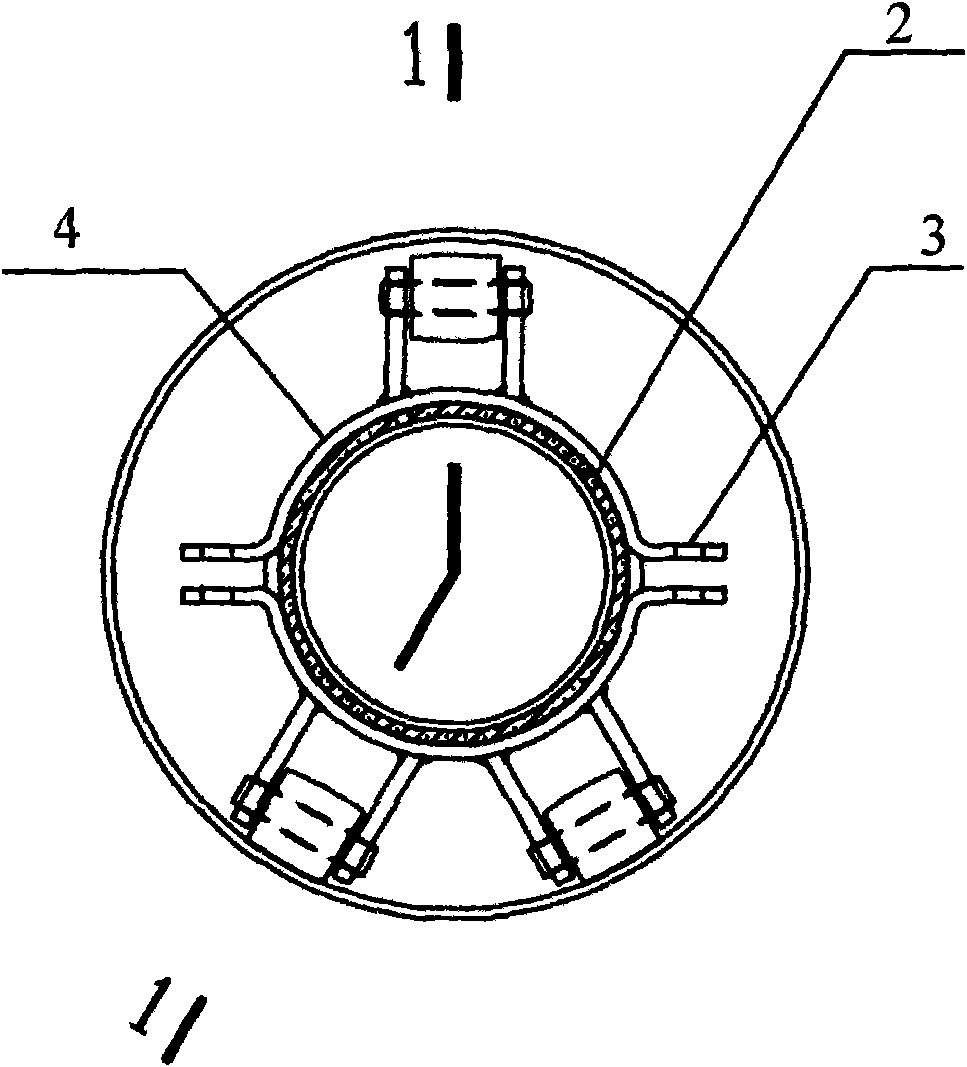

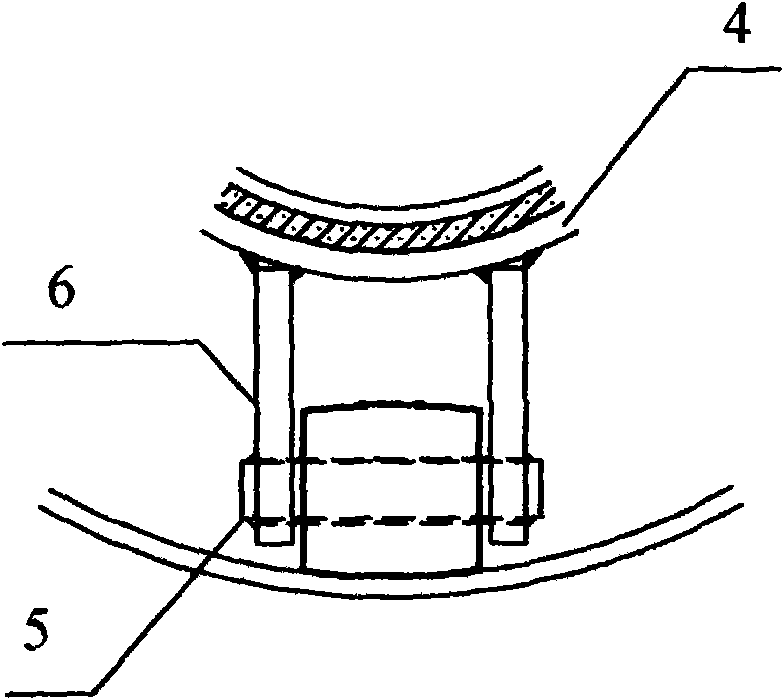

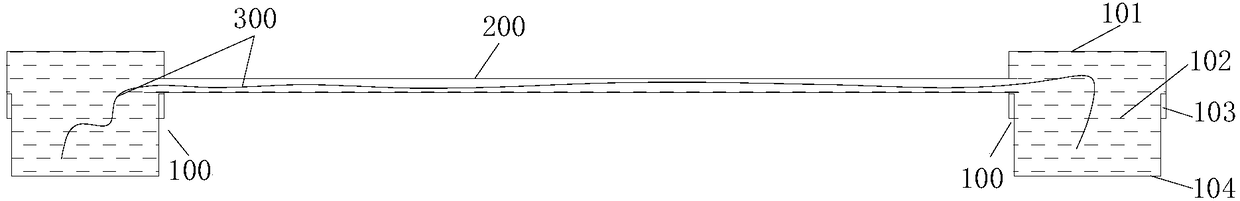

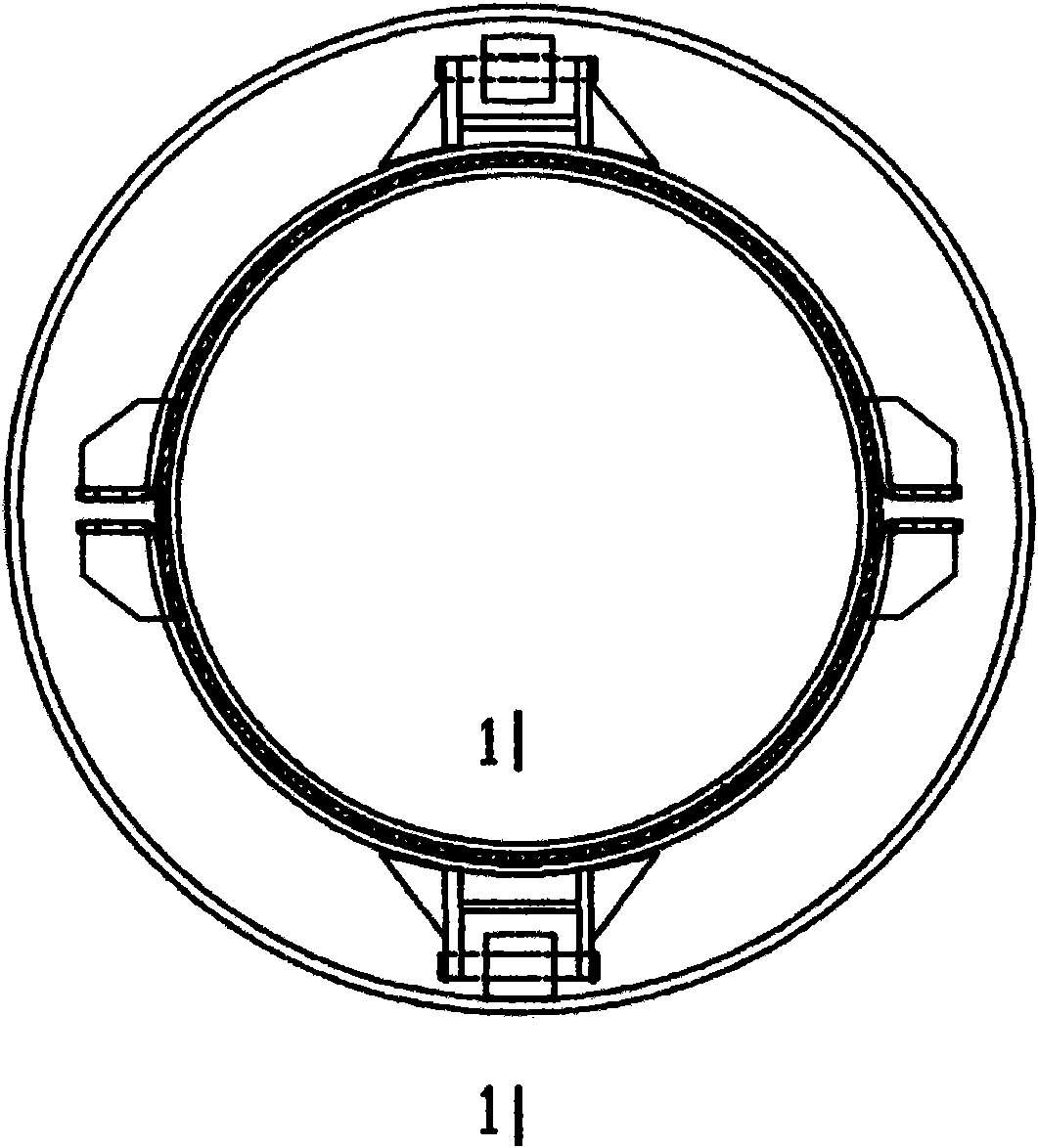

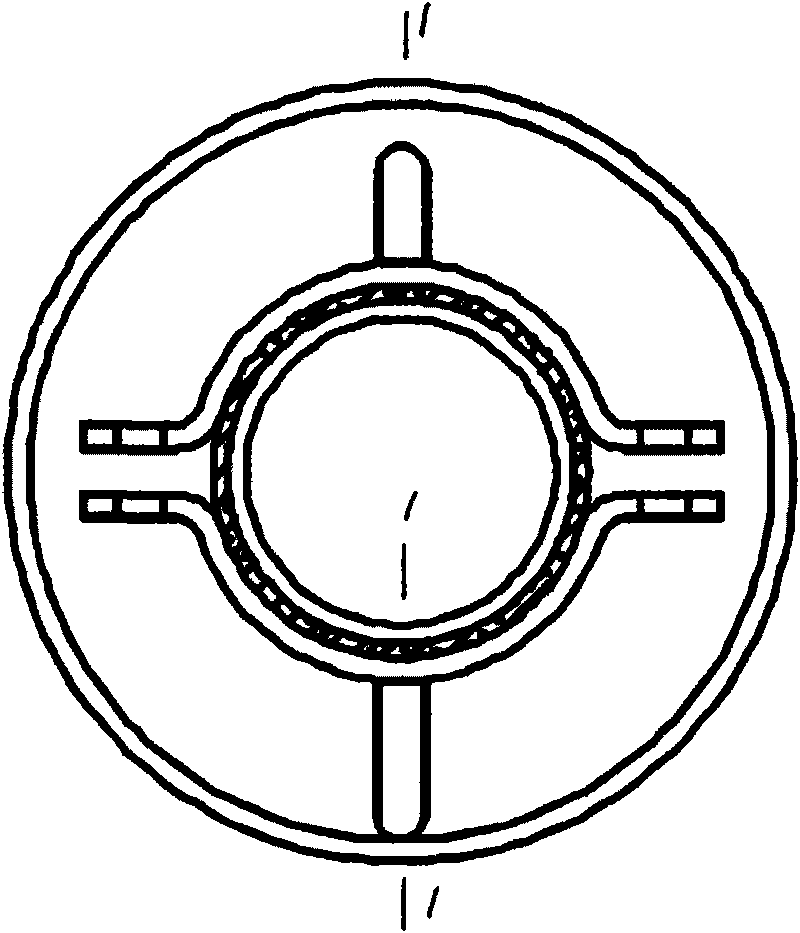

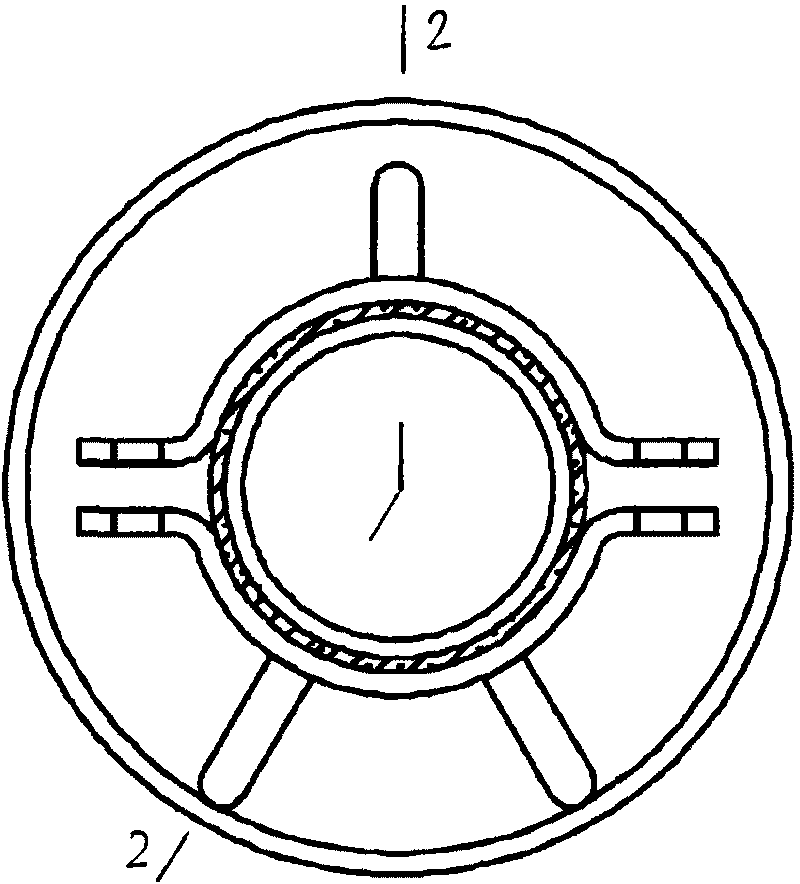

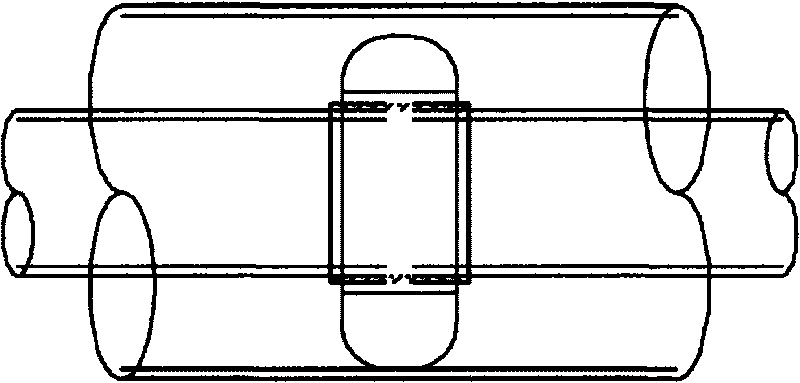

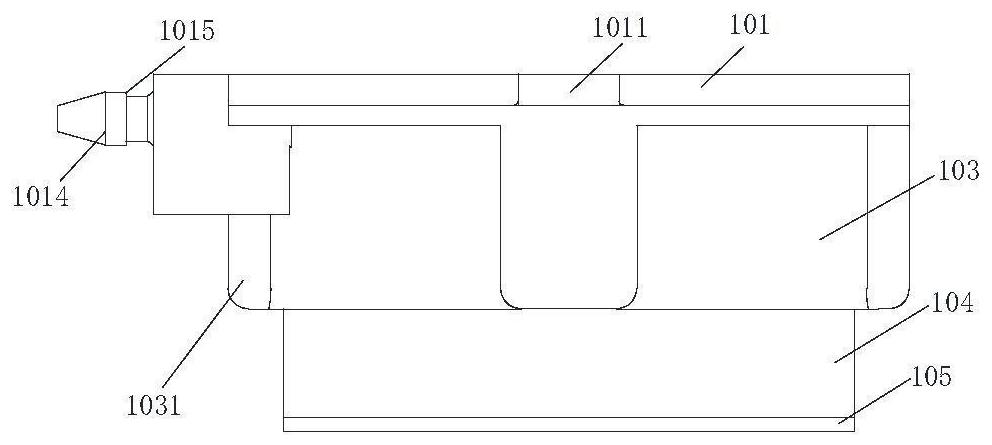

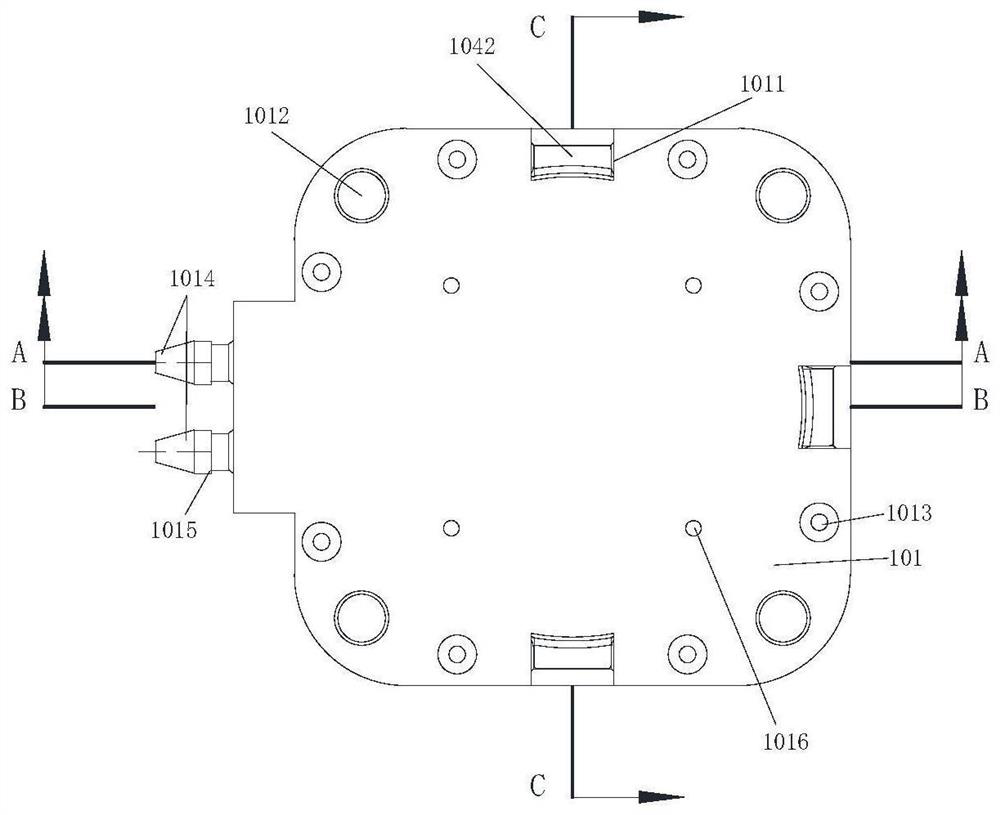

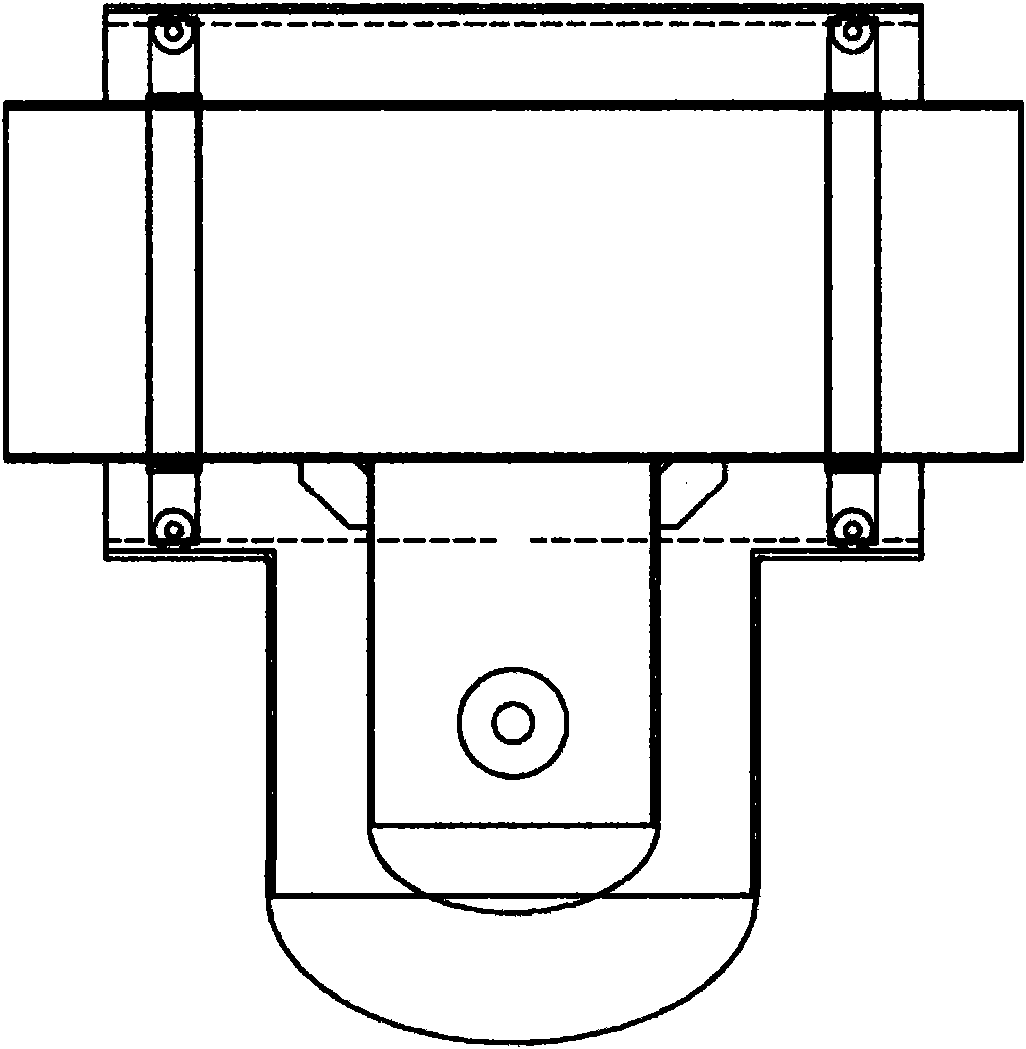

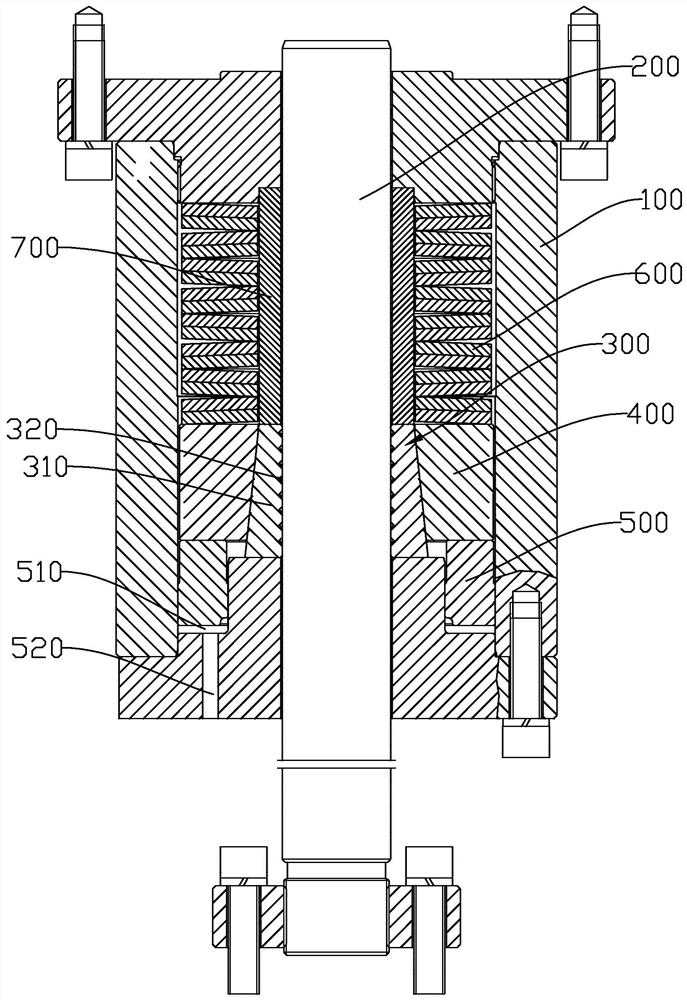

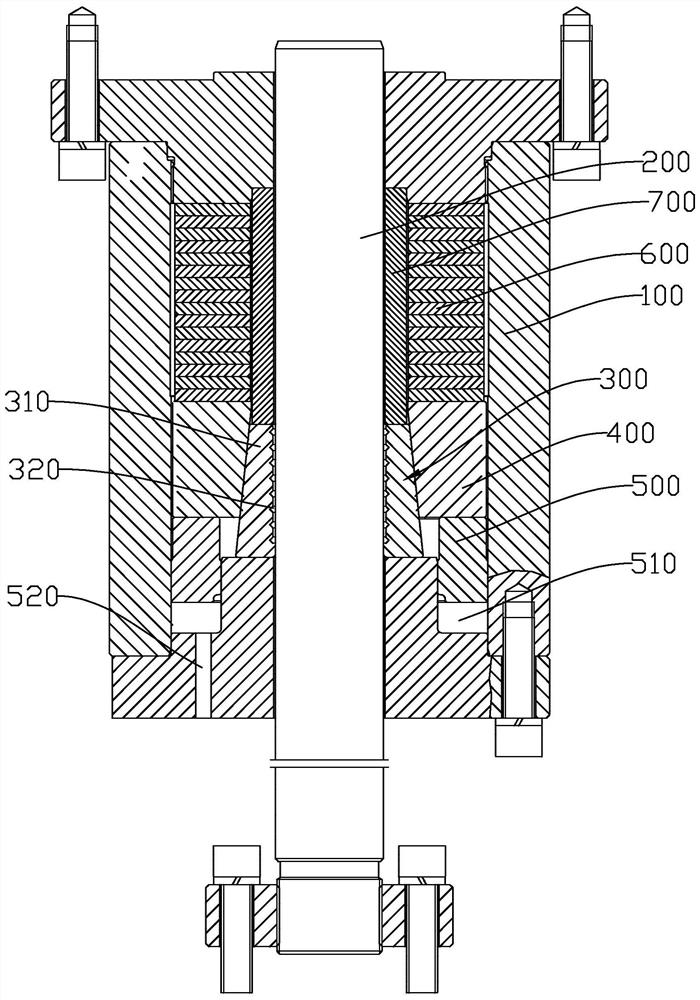

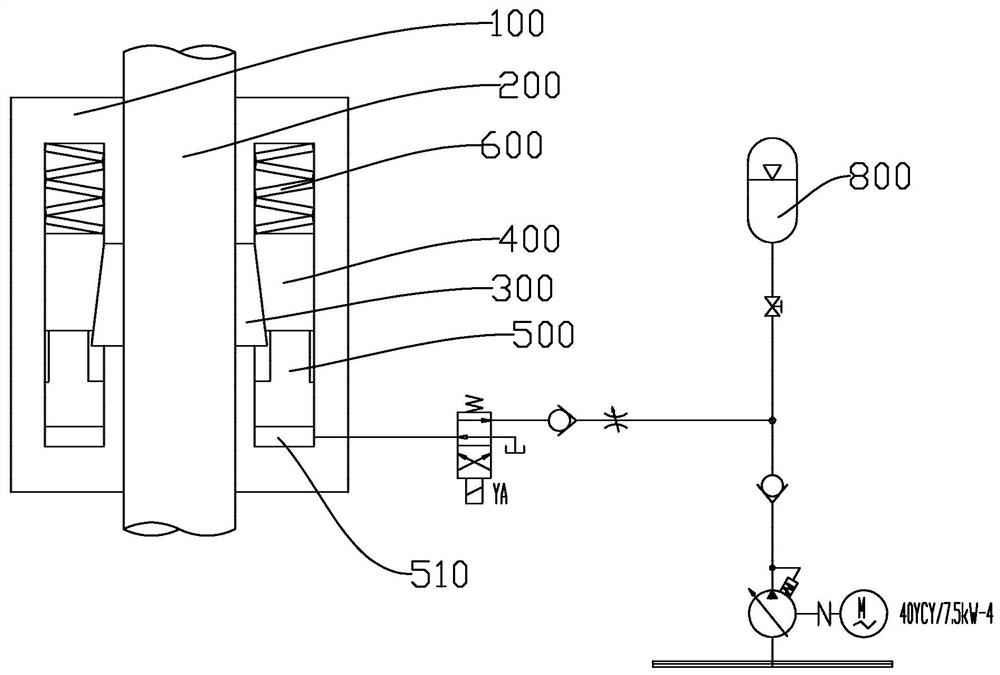

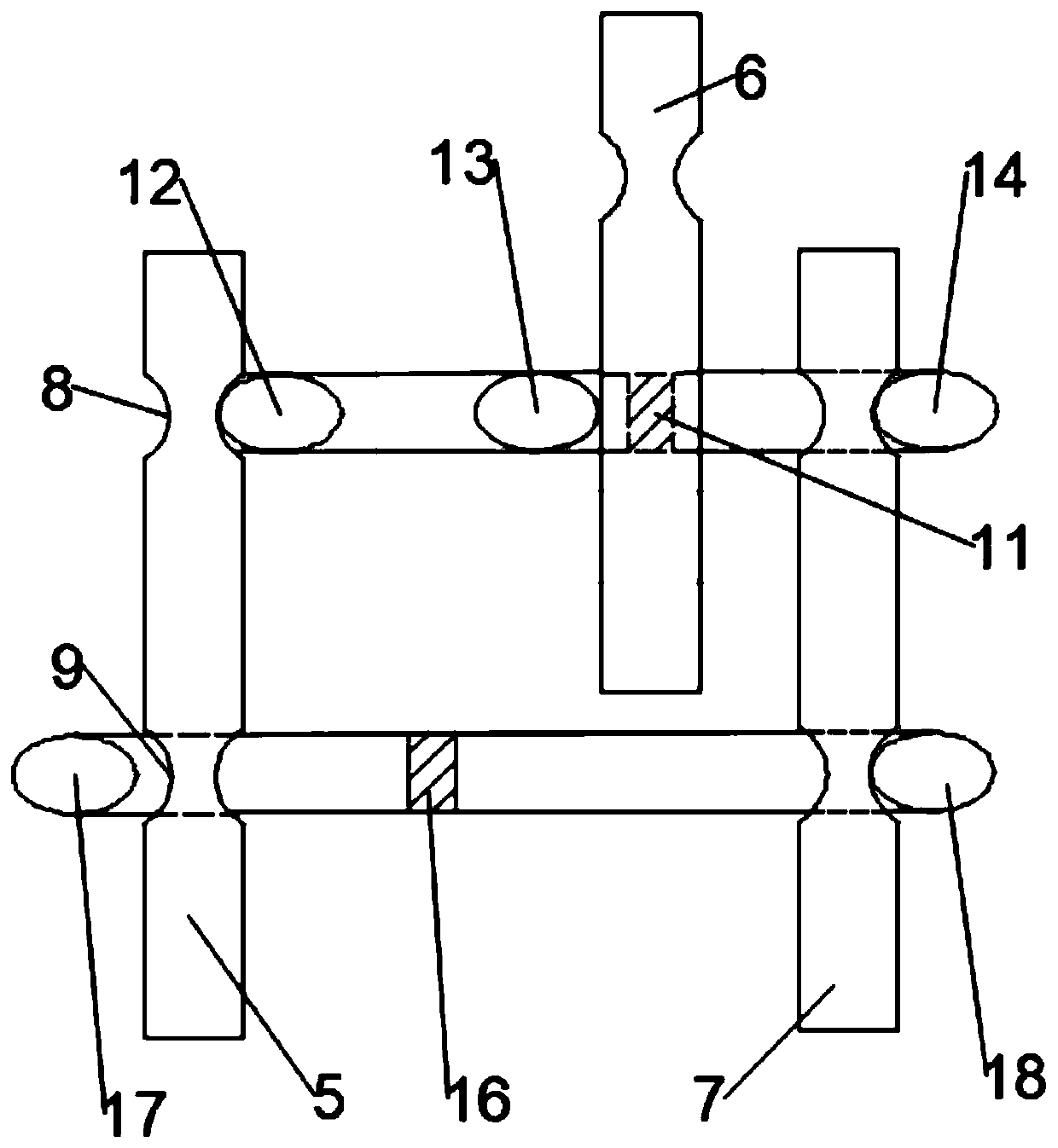

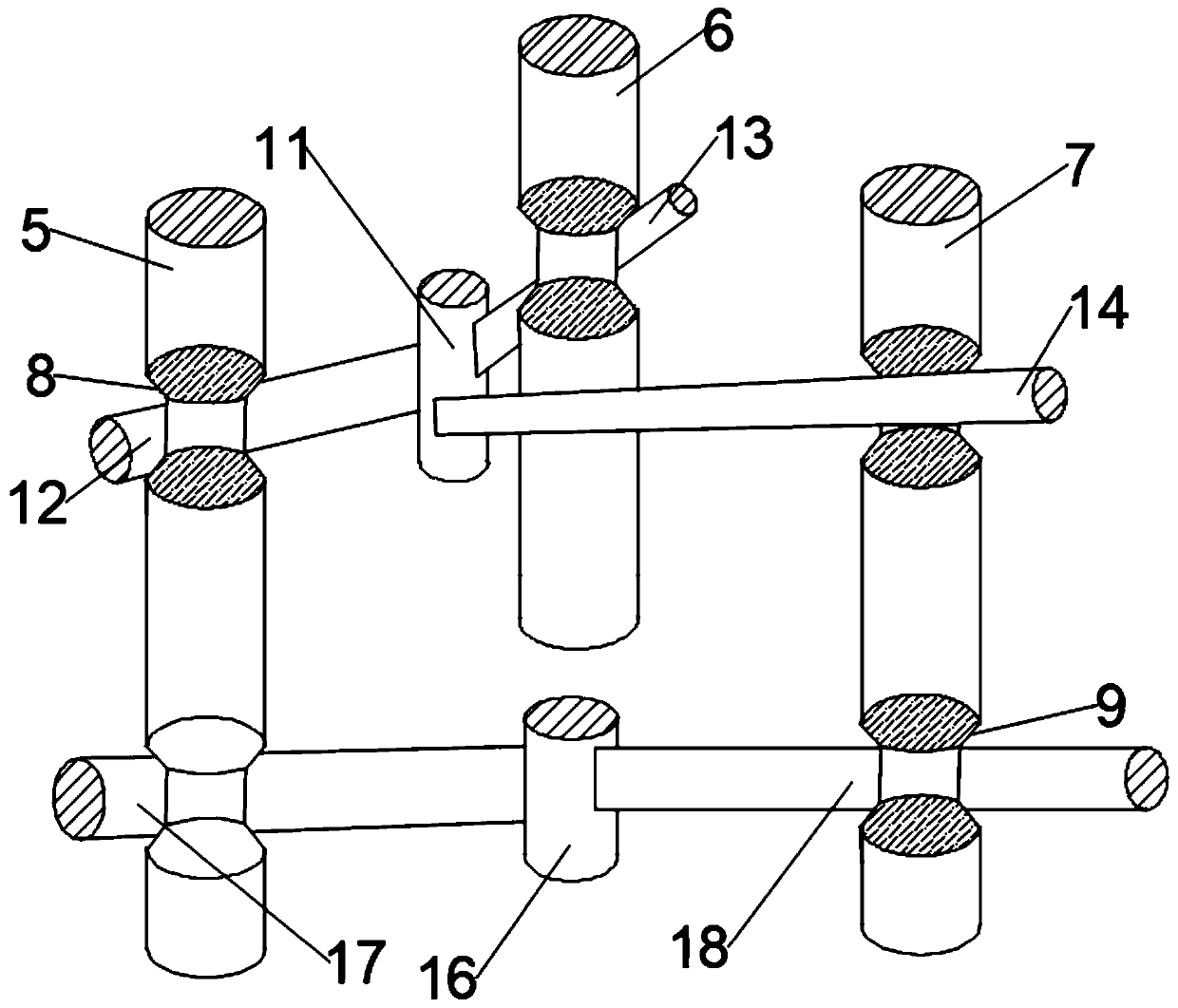

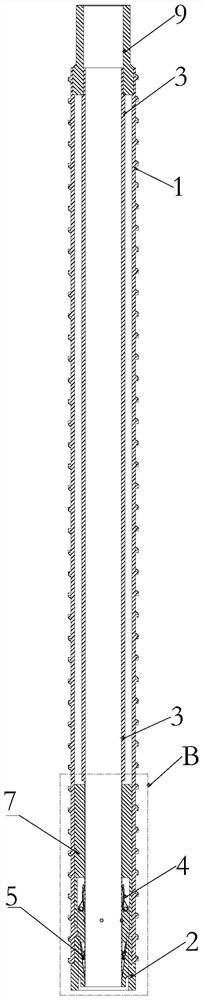

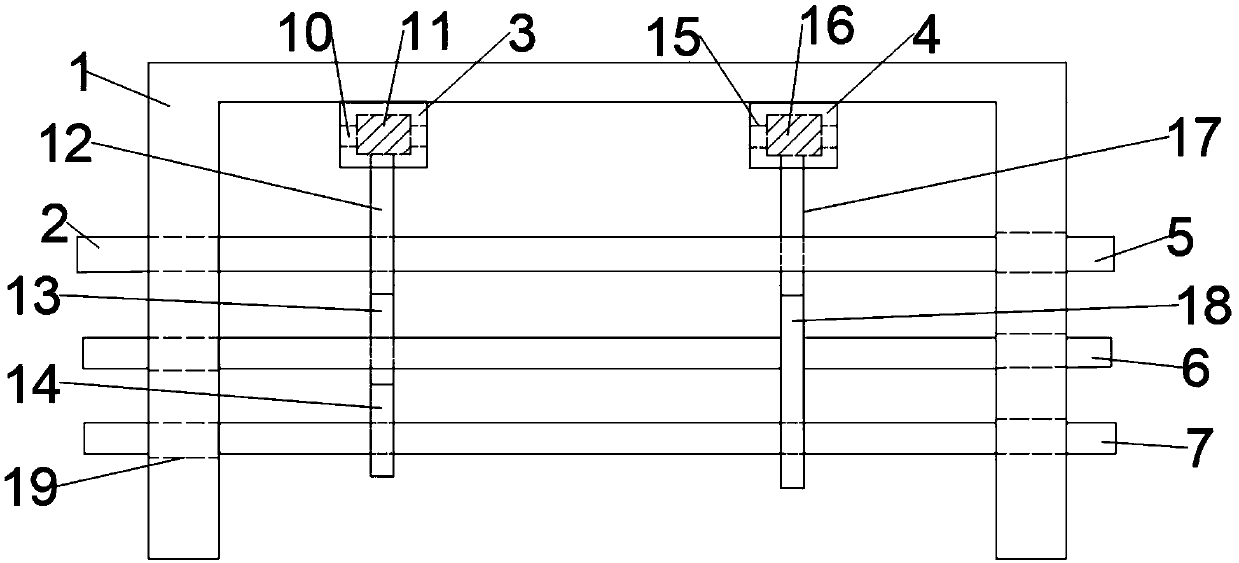

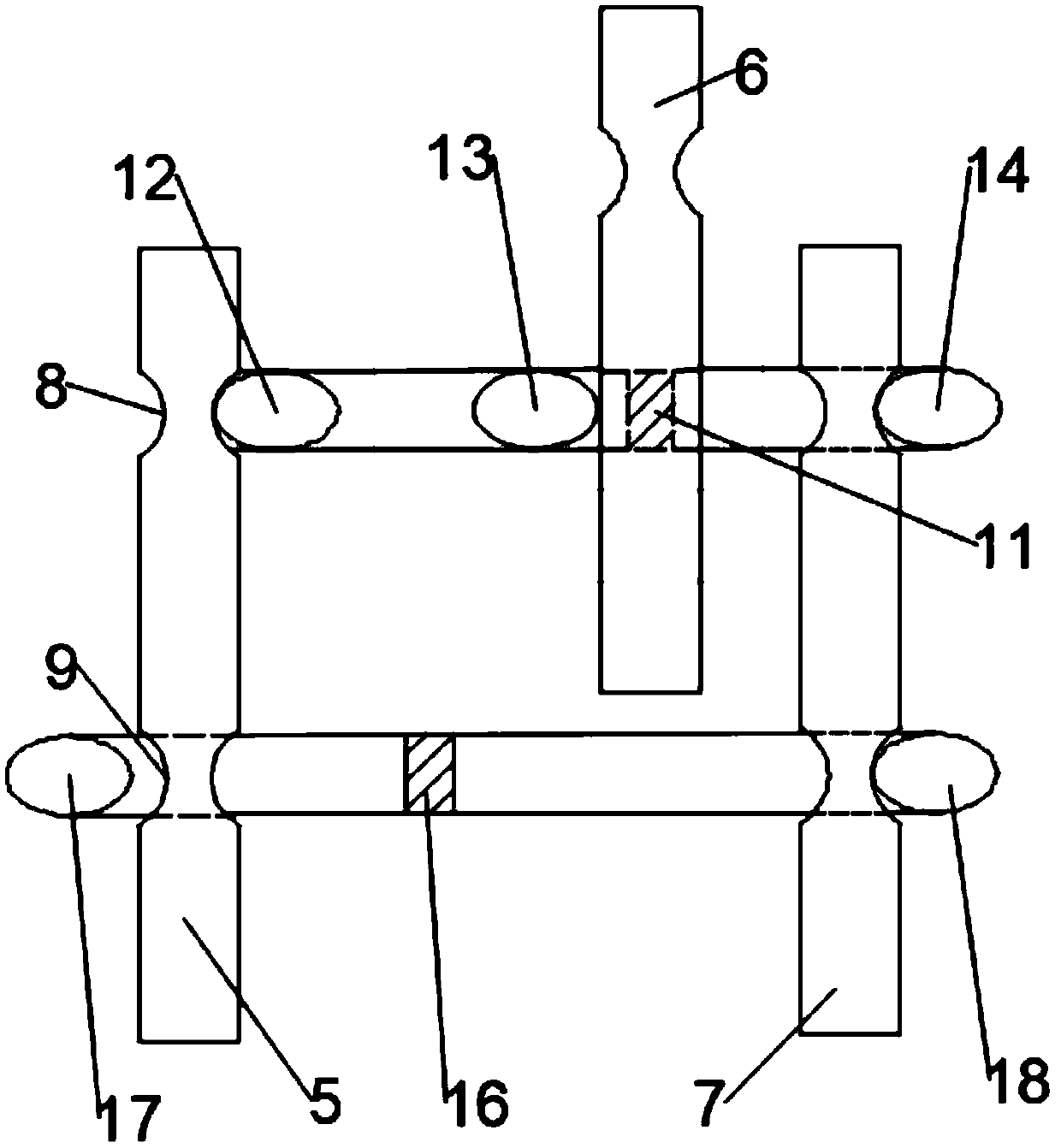

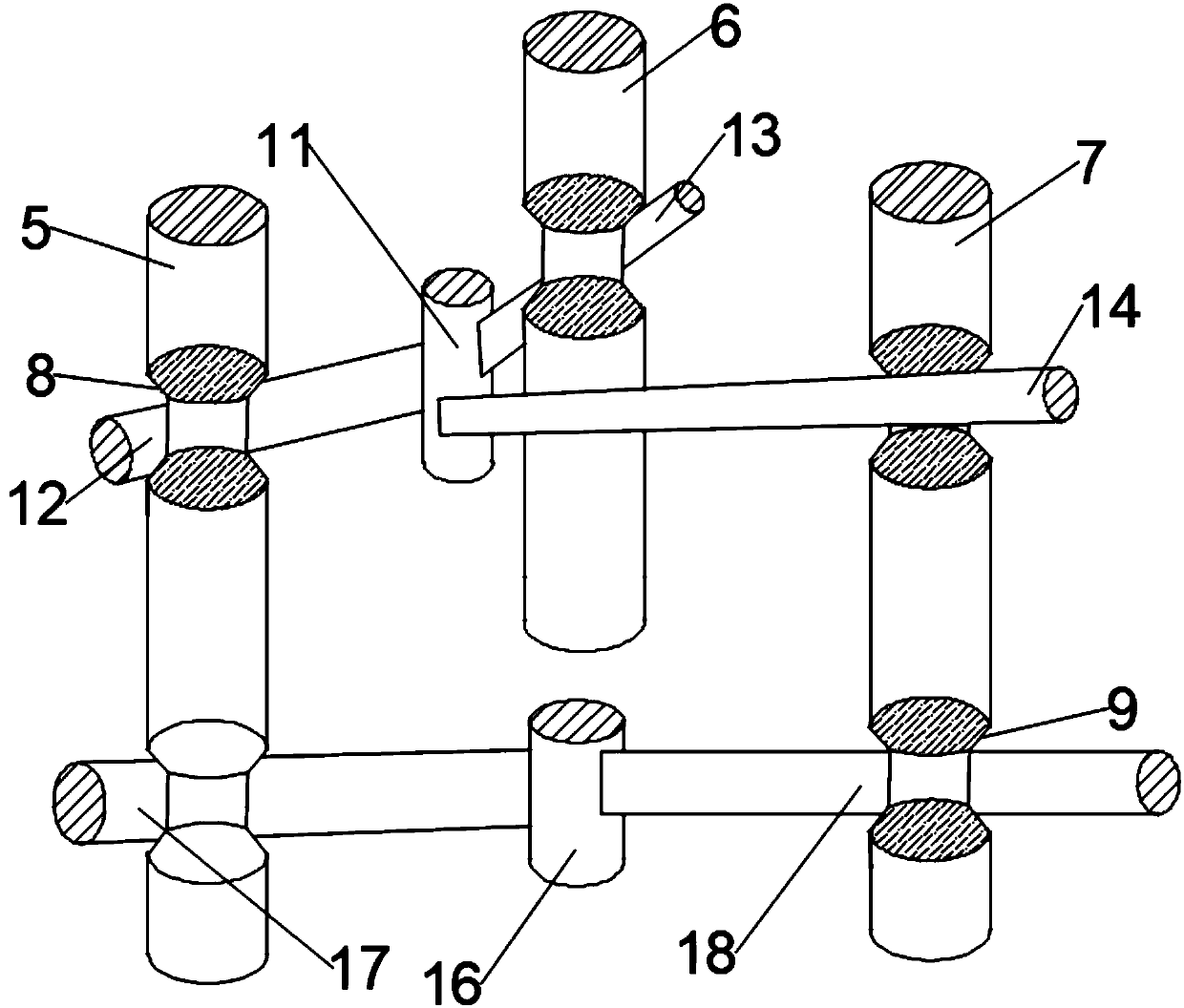

The invention relates to a steel-sleeve steel steam insulation pipe and a rolling supporting mechanism thereof, wherein the nominal diameter of an inner sleeve steel pipe of the steel-sleeve steel steam insulation pipe is DN 250-DN 500. The rolling supporting mechanism comprises an upper steel hoop, a lower steel hoop, two upper idler wheels and two lower idler wheels, wherein the upper idler wheels and the lower idler wheels are respectively arranged on the upper steel hoop and on the lower steel hoop and distributed symmetrically; the end parts of the upper steel hoop and the lower steel hoop are clamped tightly by bolts; and when the axes of the inner sleeve steel pipe and an outer sleeve steel pipe are overlapped, the two lower idler wheels and the inner wall of the outer sleeve steelpipe are contacted in a rolling friction way, and fit-up gaps are left between the upper idler wheels and the inner wall of the outer sleeve steel pipe. The steel-sleeve steel steam insulation pipe comprises the inner sleeve steel pipe, the outer inner sleeve steel pipe, the rolling supporting mechanism, insulation material and heat-preservation material, wherein the external diameter of the heat-preservation layer is smaller than the internal diameter of the outer sleeve steel pipe and an air layer is formed between the heat-preservation layer and the sleeve steel pipe. The rolling supportingmechanism has small friction force, therefore, the stress of the rolling supporting mechanism and the inner sleeve steel pipe is reduced.

Owner:刘毅 +1

Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

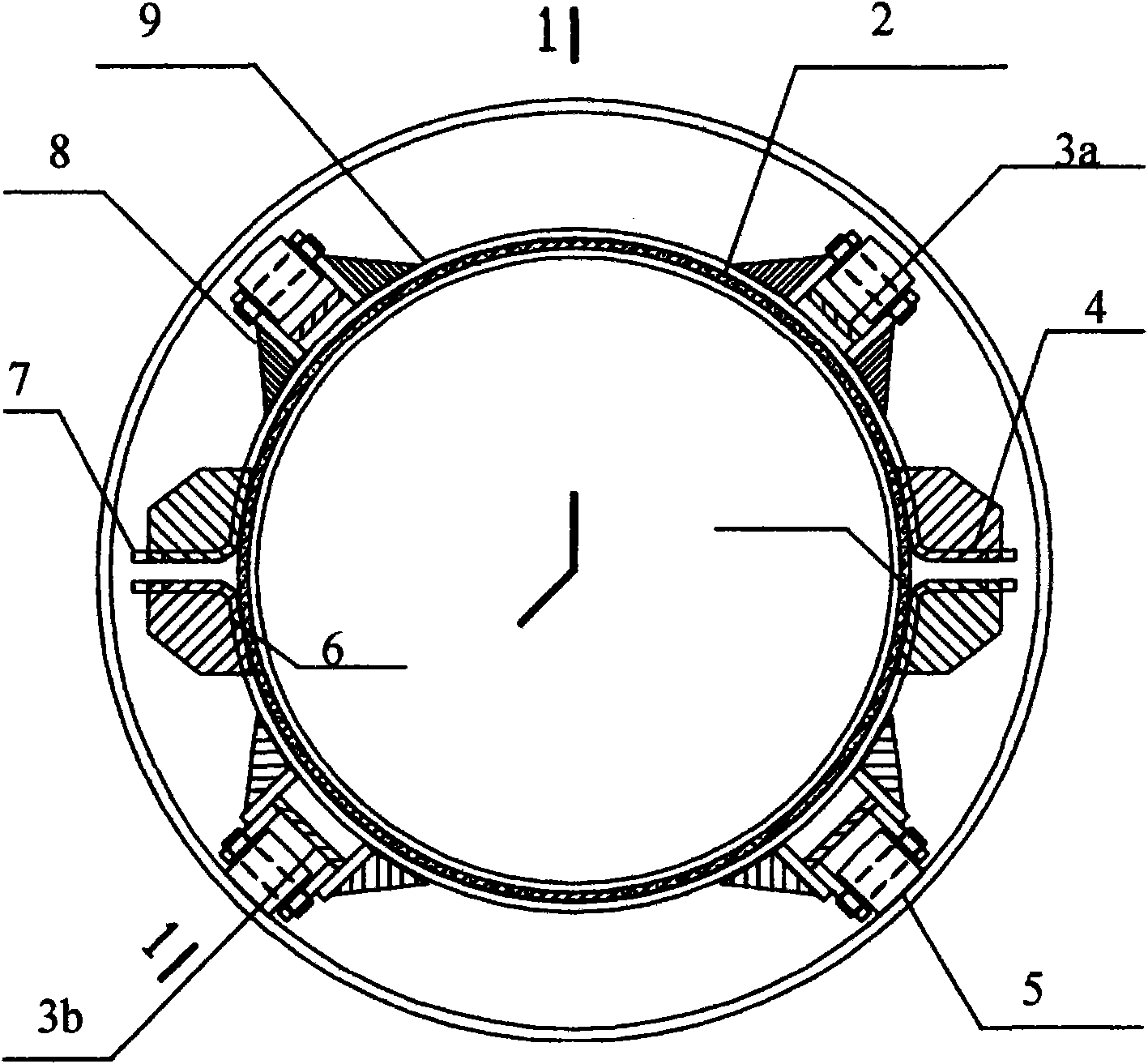

The invention relates to a steel-sleeve steel steam insulation pipe and a rolling supporting mechanism thereof, wherein the nominal diameter of an inner sleeve steel pipe of the steel-sleeve steam insulation pipe is DN 600-DN 700. The rolling supporting mechanism comprises an upper steel hoop, a lower steel hoop, two upper idler wheels arranged on the upper steel hoop and distributed symmetrically, and four lower idler wheels arranged on the lower steel hoop and distributed symmetrically, wherein the four lower idler wheels are evenly divided into two groups; the end parts of the upper steel hoop and the lower steel hoop are connected by bolts; and when the axes of the inner sleeve steel pipe and an outer sleeve steel pipe are overlapped, the four lower idler wheels and the inner wall of the outer sleeve steel pipe are contacted in a rolling friction way, and gaps are left between the two upper idler wheels and the inner wall of the outer sleeve steel pipe. The steel-sleeve steel steaminsulation pipe comprises the rolling supporting mechanism and also comprises insulation material positioned between the rolling supporting mechanism and the inner sleeve steel pipe, heat-preservation material with the external diameter smaller than the internal diameter of the outer sleeve steel pipe, an air evaporation valve arranged on the outer sleeve steel pipe, and erosion resistant coatingsleeved outside the outer sleeve steel pipe. The rolling supporting mechanism has small friction force, therefore, the stress of the rolling supporting mechanism and the inner sleeve steel pipe is reduced.

Owner:刘毅 +1

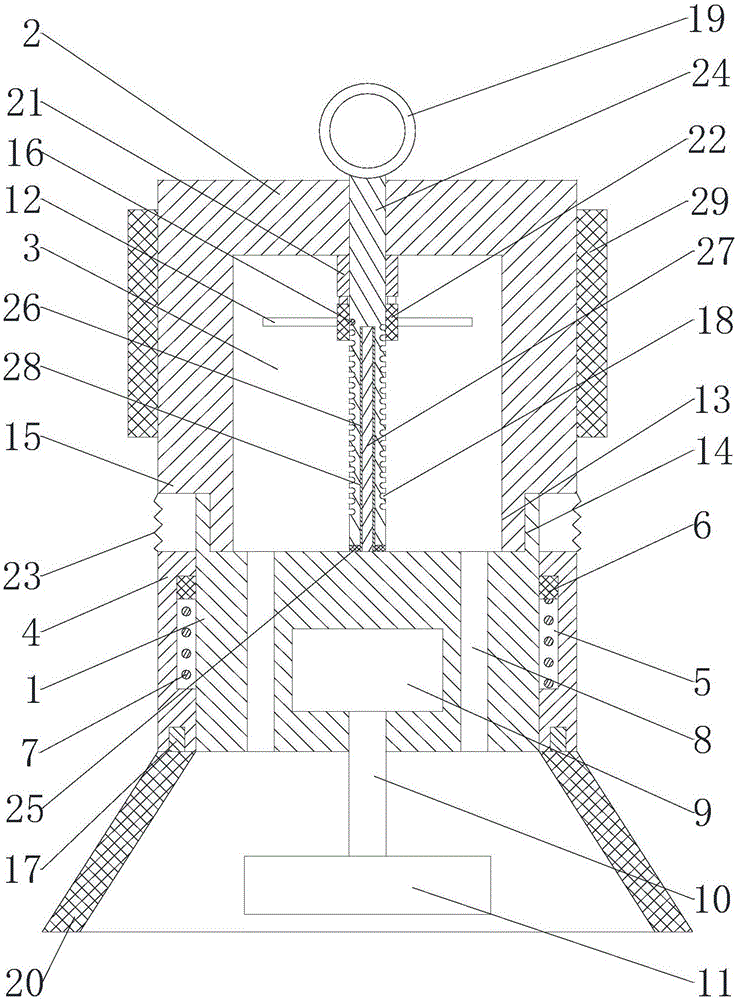

Metal part grinding machine

InactiveCN106425780AAvoid flying aroundKeep healthyPortable grinding machinesGrinding/polishing safety devicesDrive motorPulp and paper industry

The invention discloses a metal part grinding machine. The metal part grinding machine comprises a fixing body, a connecting cylinder and a collecting cylinder, wherein the collecting cylinder comprises a collecting chamber; a driving motor is mounted inside the fixing body; an output end of the driving motor is connected with a rotating shaft; the lower end of the rotating shaft is connected with a grinding wheel; the connecting cylinder sleeves the outer surface of the fixing body; a protective cover is arranged at the bottom end of the connecting cylinder; a supporting cylinder is mounted at the top of the inner wall of the collecting cylinder; a movable cylinder is rotationally arranged at the lower end of the supporting cylinder; a guide column is vertically arranged at the upper end face of the fixing body; a positioning protruding bar is arranged on the sidewall of the guide column; an adjusting rod is also vertically arranged inside the collecting chamber; the inner wall surface of the adjusting rod is provided with a positioning groove; the outer wall surface of the adjusting rod is provided with a helical groove; the inner wall of the movable cylinder protrudes outwards to form a transmission column. By coordination between the adjusting rod and the movable cylinder, the metal part grinding machine disclosed by the invention is capable of realizing forward rotation or reverse rotation of a plurality of blades so as to realize collection and emission of iron scraps and dust.

Owner:重庆新缔欧机械制造有限公司

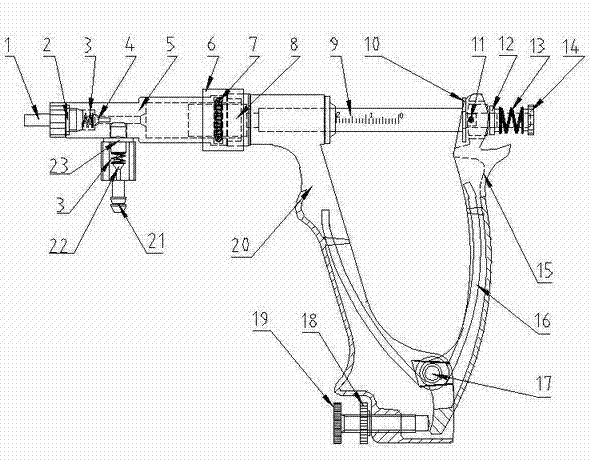

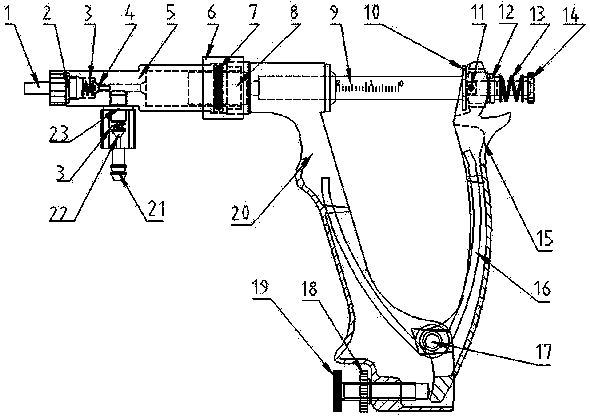

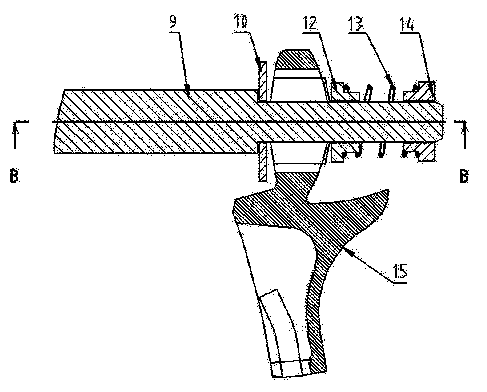

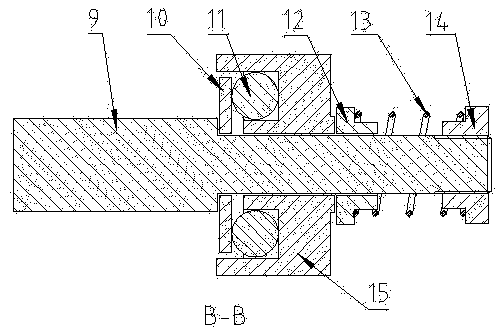

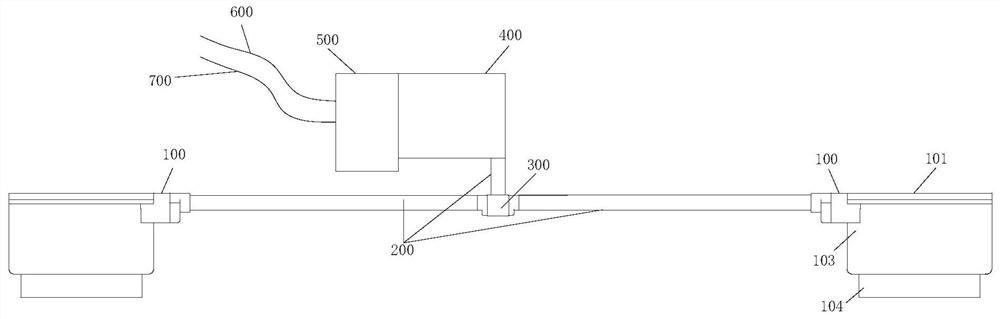

Adjustable continuous injector

The invention relates to an adjustable continuous injector. The injector comprises a sleeve, a piston, a core rod, a fixed handle, a movable handle and an adjusting screw rod, wherein the rear part of the sleeve is connected with the fixed handle; a screw hole is formed at the bottom of the fixed handle; the adjusting screw rod passes through the screw hole and is contacted with the lower lateral face of the movable handle; the adjusting screw rod pushes the movable handle to rotate with a pin roll, and the core rod is driven to displace, so that adjustment of injection amount is realized; a slotted hole is formed in the middle of the upper end of the movable handle along the axial direction of the core rod; the movable handle is sleeved on the core rod; a core rod catch, a gasket and a spring are sleeved on the core rod close to protruded cambered surfaces of the front and rear parts of the movable handle; and when the movable handle drives the core rod to move front and back, the movable handle can freely and slightly float up and down relative to the core rod, the core rod is prevented from generating friction, and axial movement of the core rod is not influenced. The adjustable continuous injector has the advantages of reasonable structure, accurate quantitation, convenience in adjustment, reliability in operation, good stability of injection quantity control and long service life.

Owner:王喜增

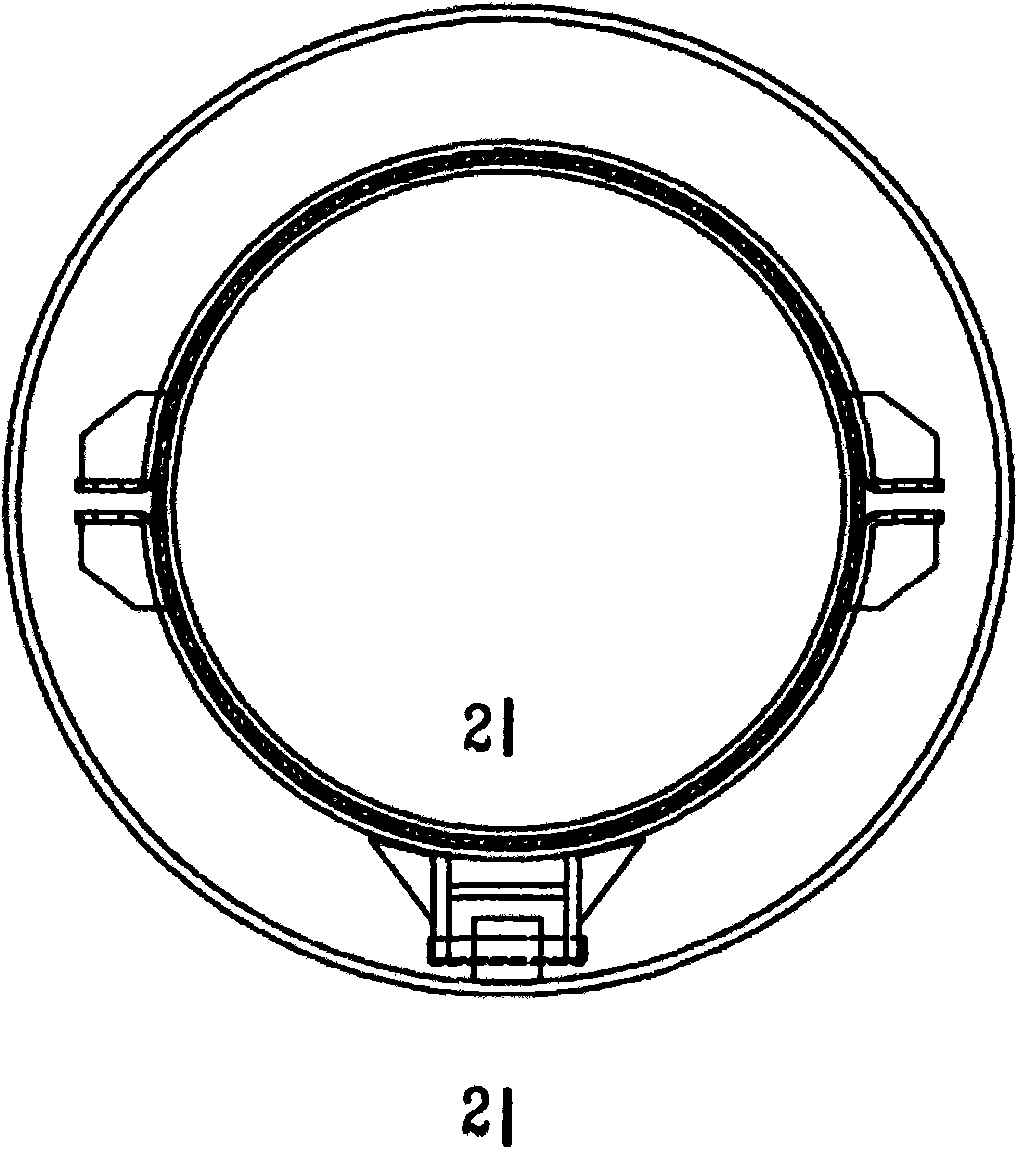

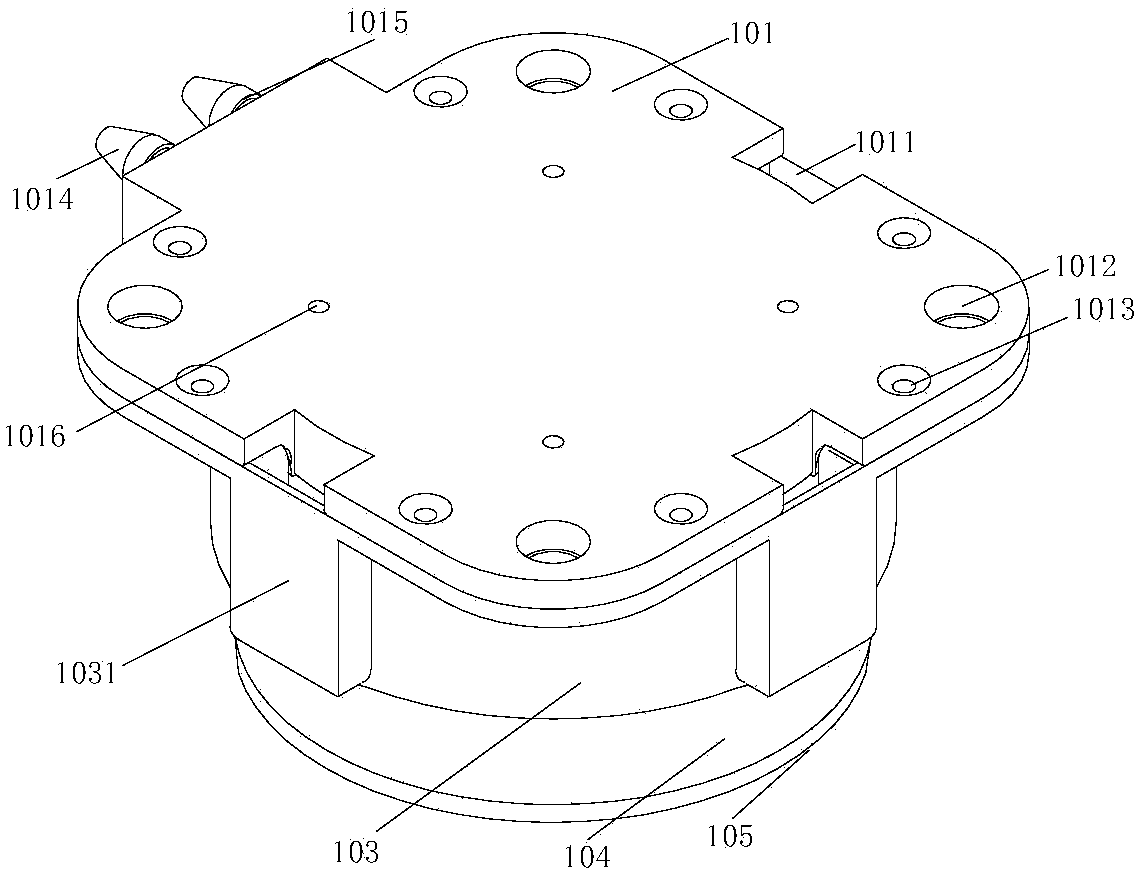

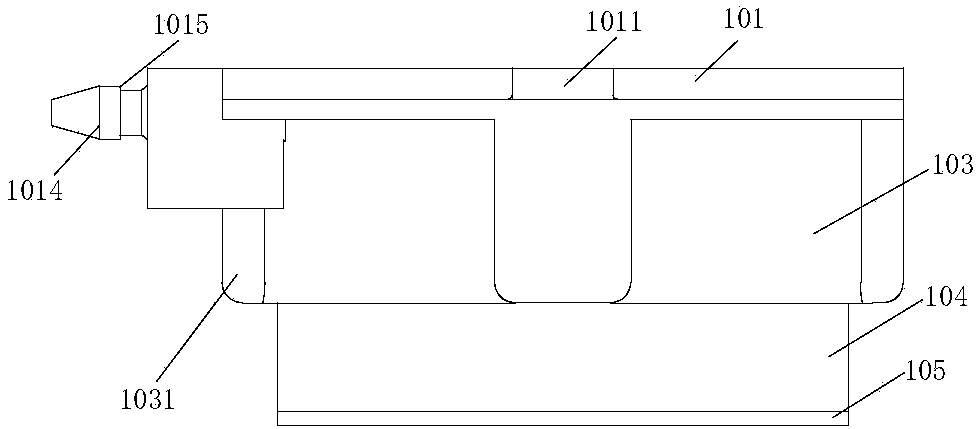

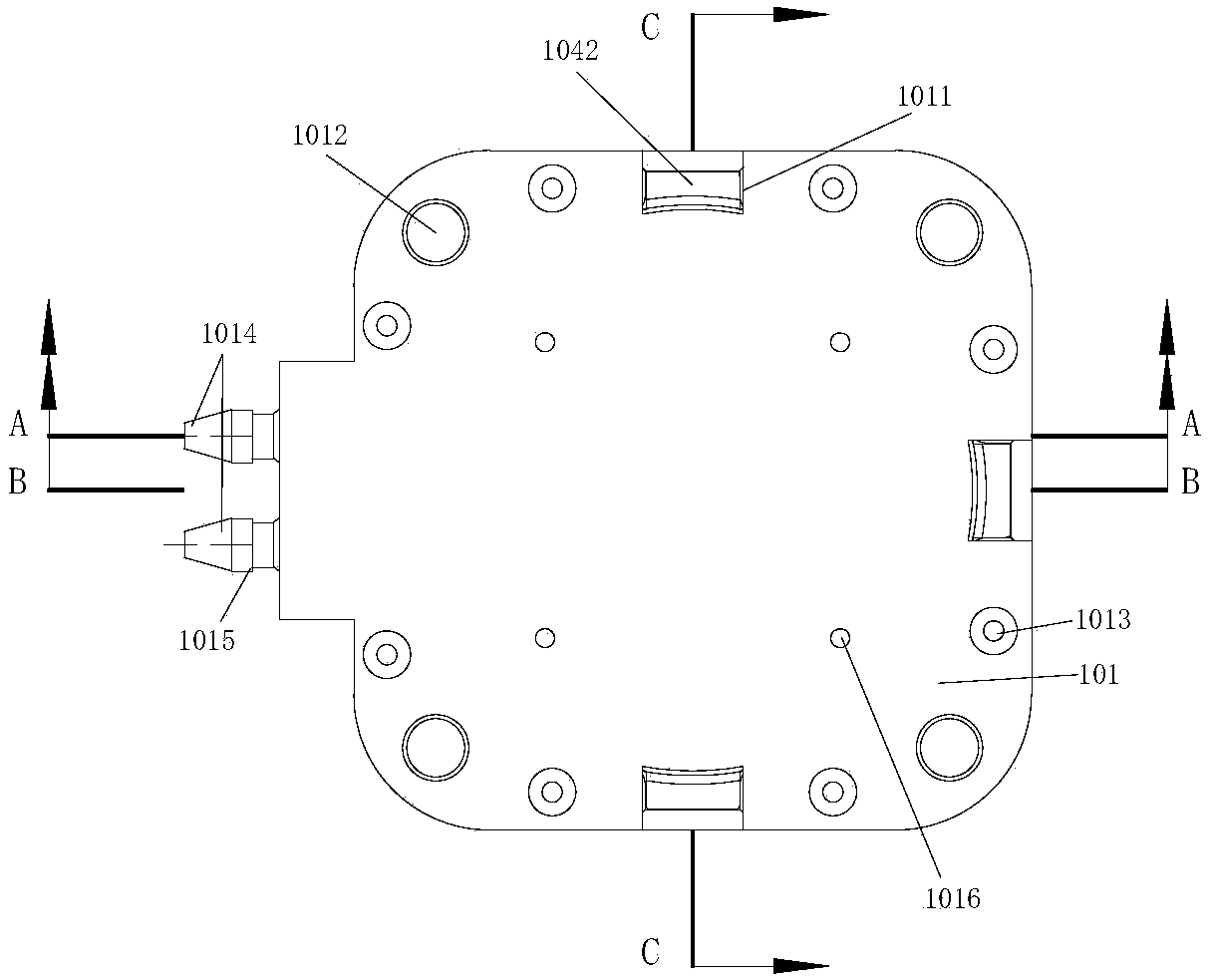

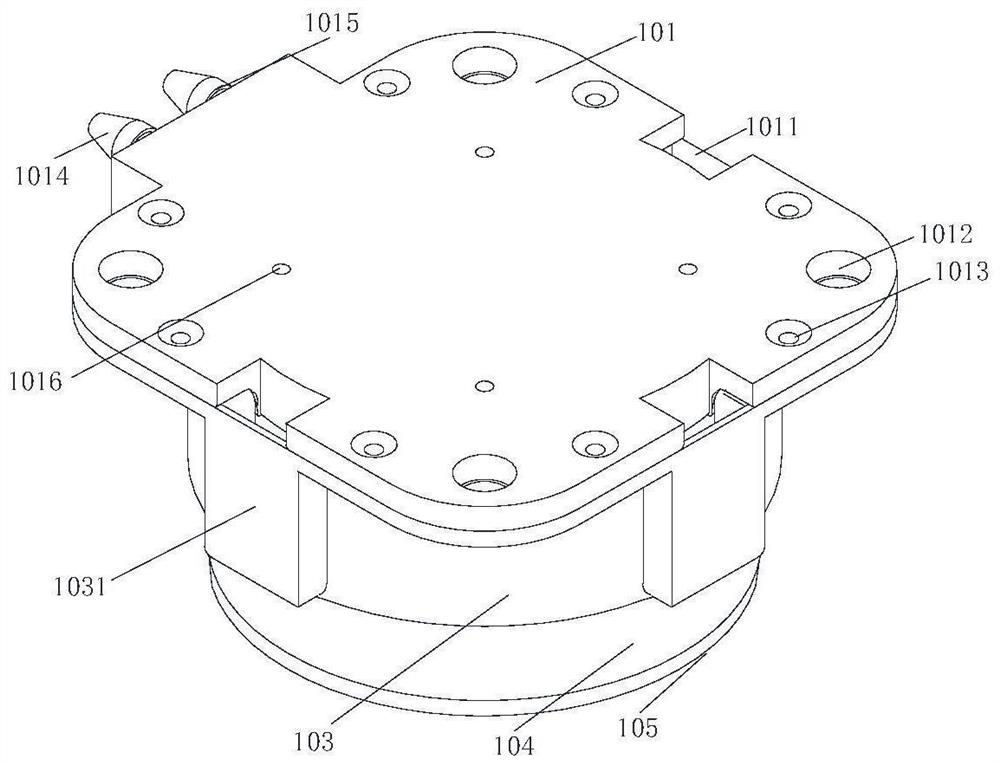

Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

InactiveCN101666418AReduce processImprove insulation effectPipe supportsThermal insulationSteel tubeEngineering

The invention relates to a steel-sleeve steel steam insulation pipe and a rolling supporting mechanism thereof, wherein the nominal diameter of an inner sleeve steel pipe of the steel-sleeve steel steam insulation pipe is DN 150-DN 200. The rolling supporting mechanism comprises an upper steel hoop, a lower steel hoop, one upper idler wheel arranged at the right center of the upper steel hoop, andtwo lower idler wheels arranged on the lower steel hoop and distributed symmetrically, wherein the end parts of the upper steel hoop and the lower steel hoop are clamped tightly by bolts; and when the axes of the inner sleeve steel pipe and an outer sleeve steel pipe are overlapped, the two lower idler wheels and the inner wall of the outer sleeve steel pipe are contacted in a rolling friction way, and a fit-up gap is left between the upper idler wheel and the inner wall of the outer sleeve steel pipe. The steel-sleeve steel steam insulation pipe comprises the inner sleeve steel pipe and theouter inner sleeve steel pipe, and also comprises the rolling supporting mechanism, insulation material, heat-preservation material, an air evaporation valve and erosion resistant coating. The rollingsupporting mechanism has small friction force, therefore, the stress of the rolling supporting mechanism and the inner sleeve steel pipe is reduced.

Owner:刘毅 +1

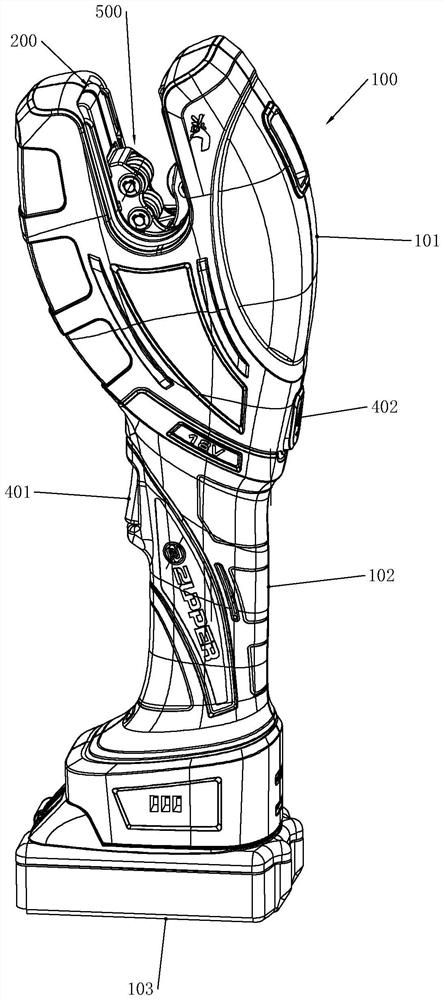

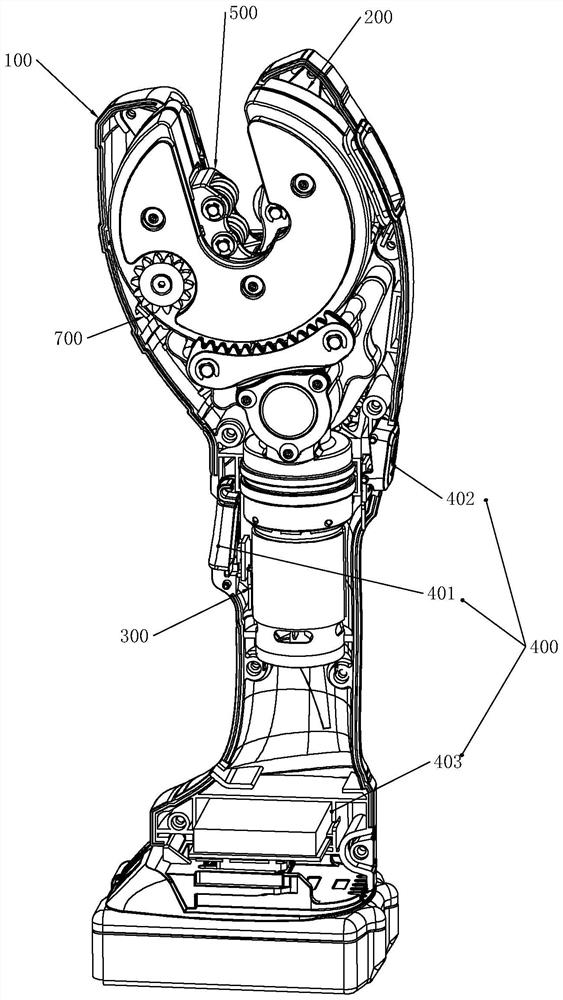

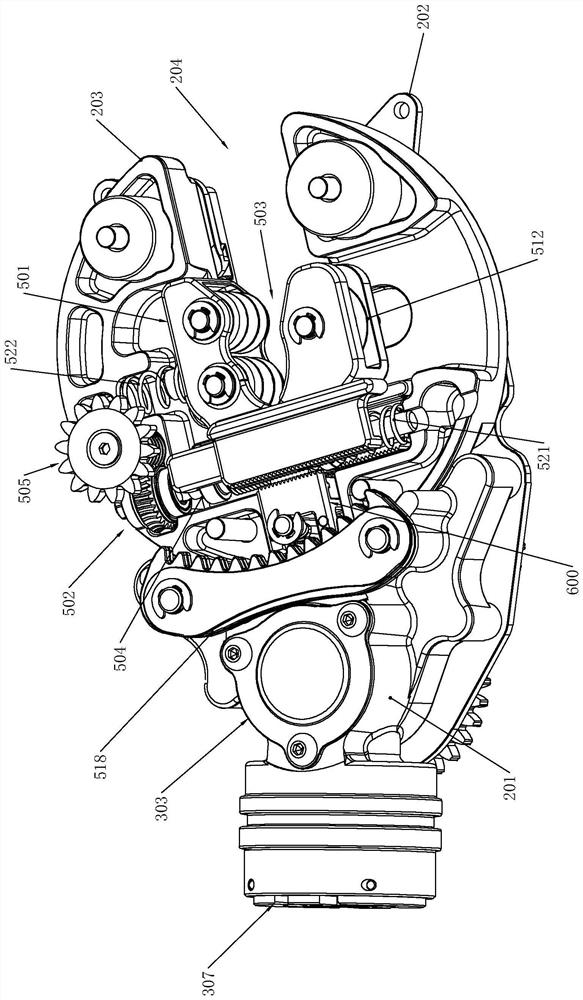

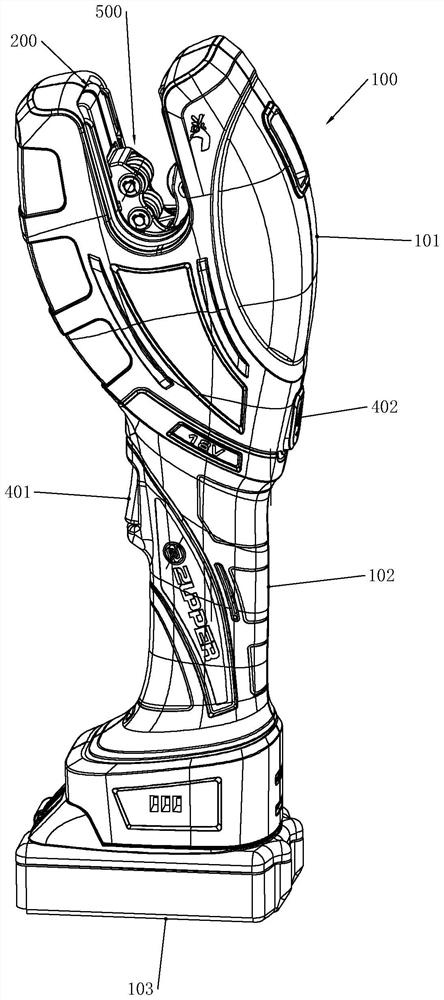

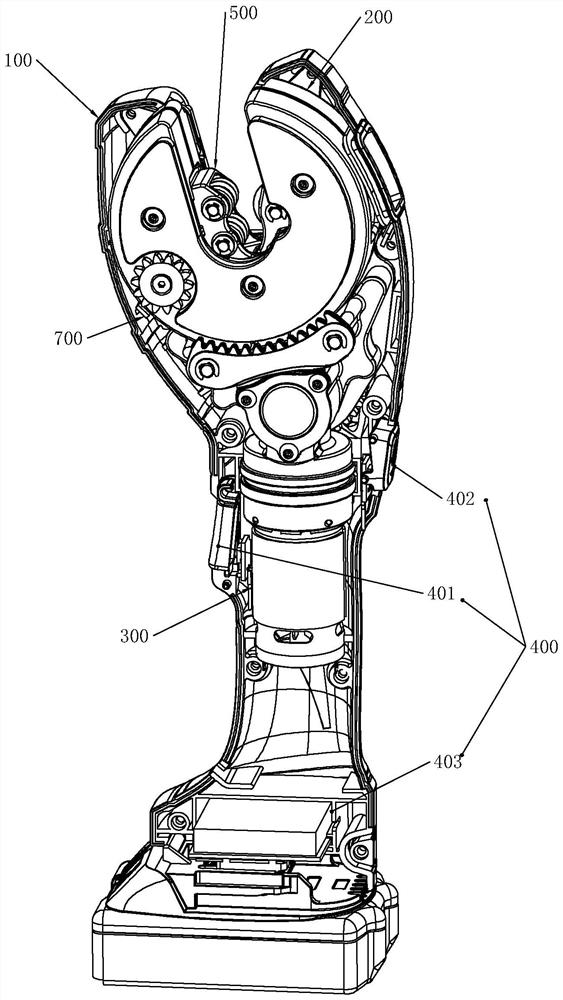

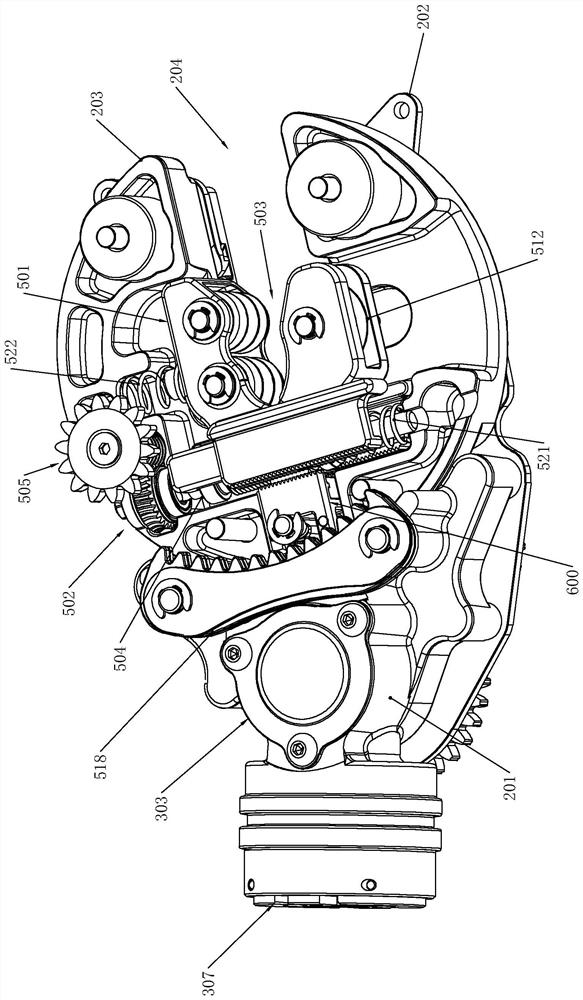

Handheld electric cutting tool

The invention relates to the technical field of electric tools, in particular to a handheld electric cutting tool which is used for cutting a pipe and comprises a shell, a handle and a handle. The cutter feeding device is rotatably mounted in the shell; a clamping position is arranged in the cutter feeding device, and a cutting knife is arranged on the peripheral side of the clamping position; when the feeding device rotates, the cutting knife executes a cutting action; and the driving device is used for providing power for the execution device. The driving device is used for driving the cutter feeding device to work, cutter feeding is achieved, cutting force is generated, pipes are cut, and the problems that in the prior art, due to the fact that the elastic force of an elastic piece is limited, the cutting force is small, high-hardness and thick pipes cannot be cut, and use is inconvenient are solved.

Owner:TAIZHOU JULI TOOLS

Cleaning spraying head assembly and self-cleaning bathtub

The invention discloses a cleaning spraying head assembly and a self-cleaning bathtub. The cleaning spraying head assembly comprises a support, a spraying head and a rotating driving assembly, whereinthe support is provided with a water inlet channel, and the spraying head is installed on the support and communicates with the water inlet channel. The cleaning spraying head assembly is characterized in that a first spraying hole and a second spraying hole are formed in the water outlet end of the spraying head, and the rotating driving assembly is connected with and drives the spraying head torotate within a certain angle range so as to output a double-layer sector-shaped cleaning water curtain. The cleaning spraying head assembly and the self-cleaning bathtub are small in assembly number, simple in structure, large in cleaning area and good in cleaning effect.

Owner:JOMOO KITCHEN & BATHROOM

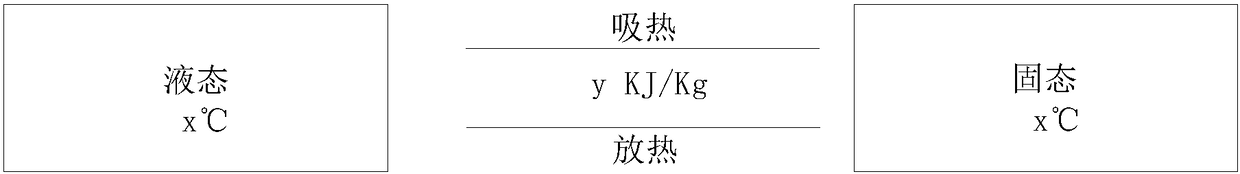

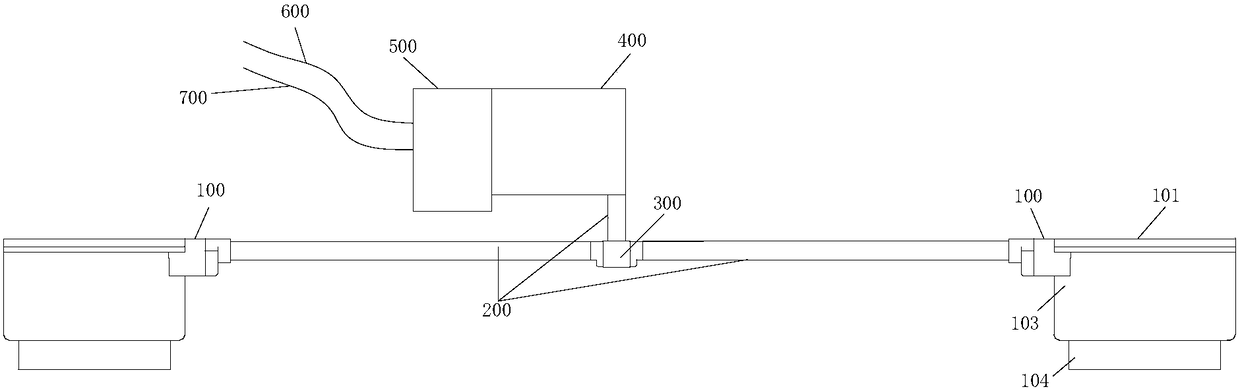

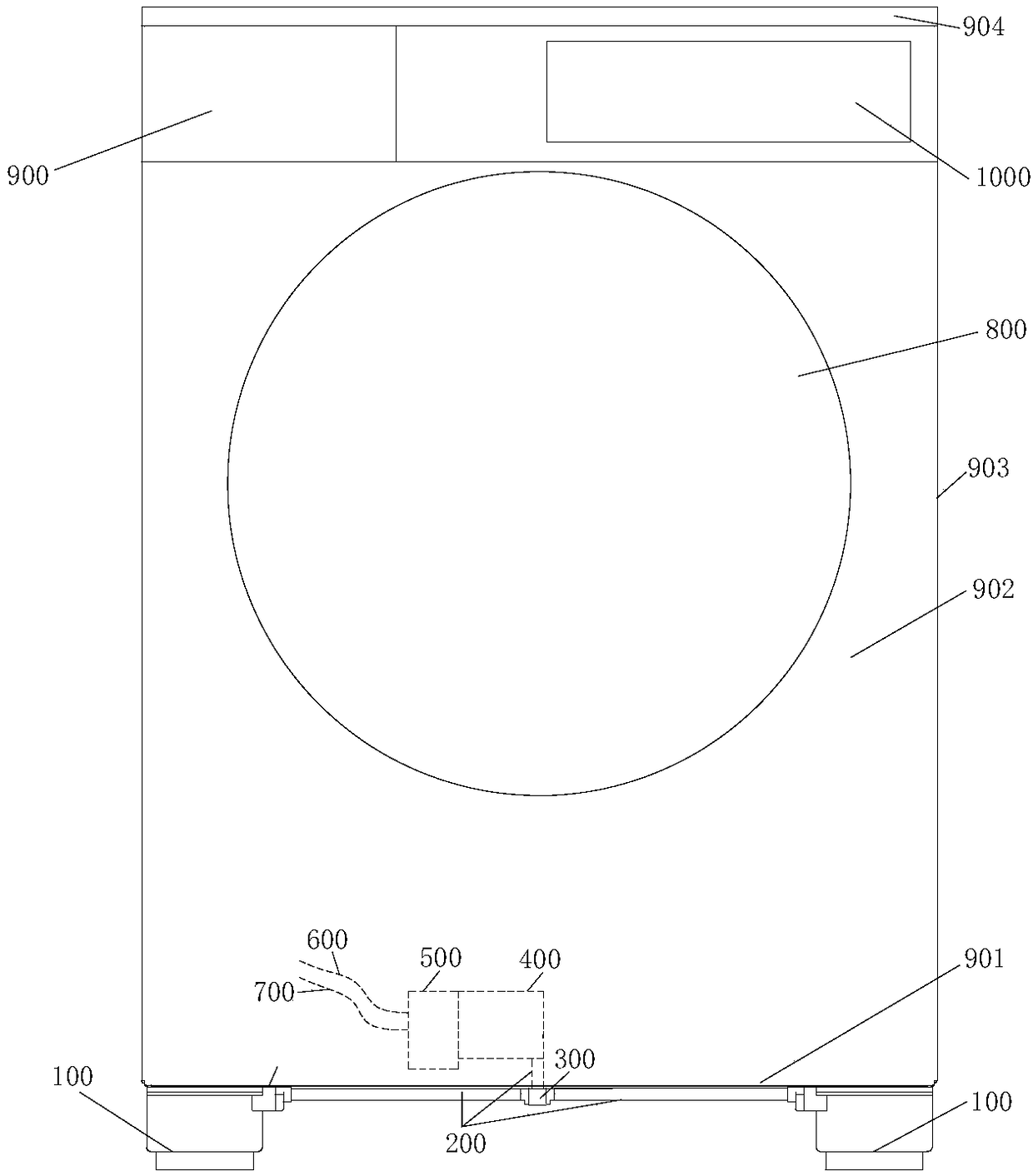

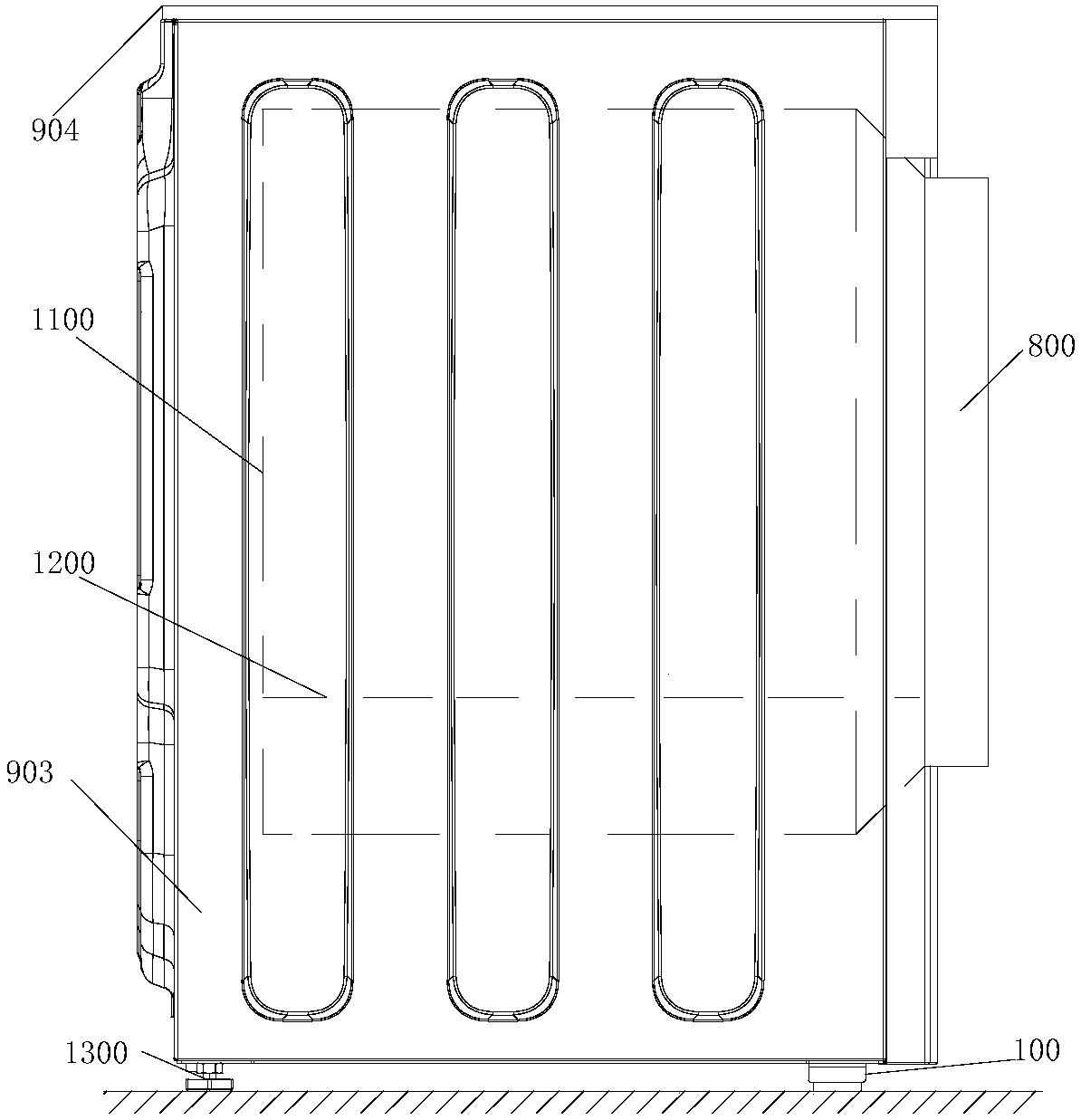

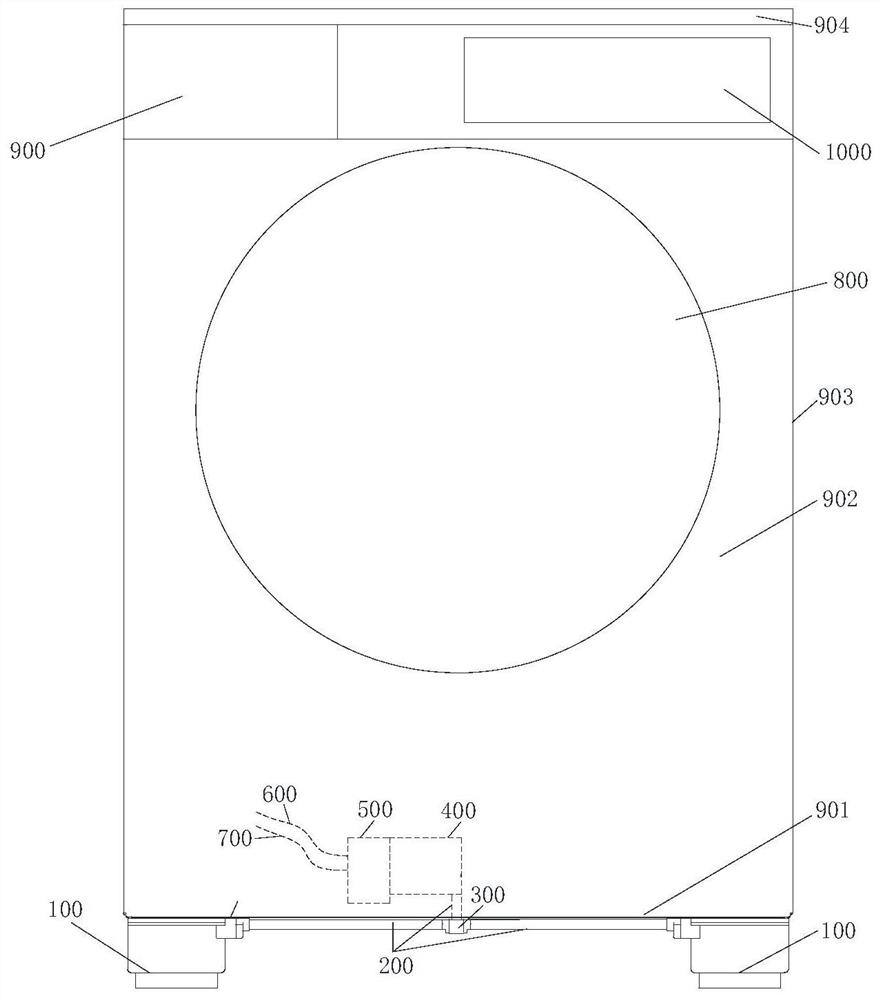

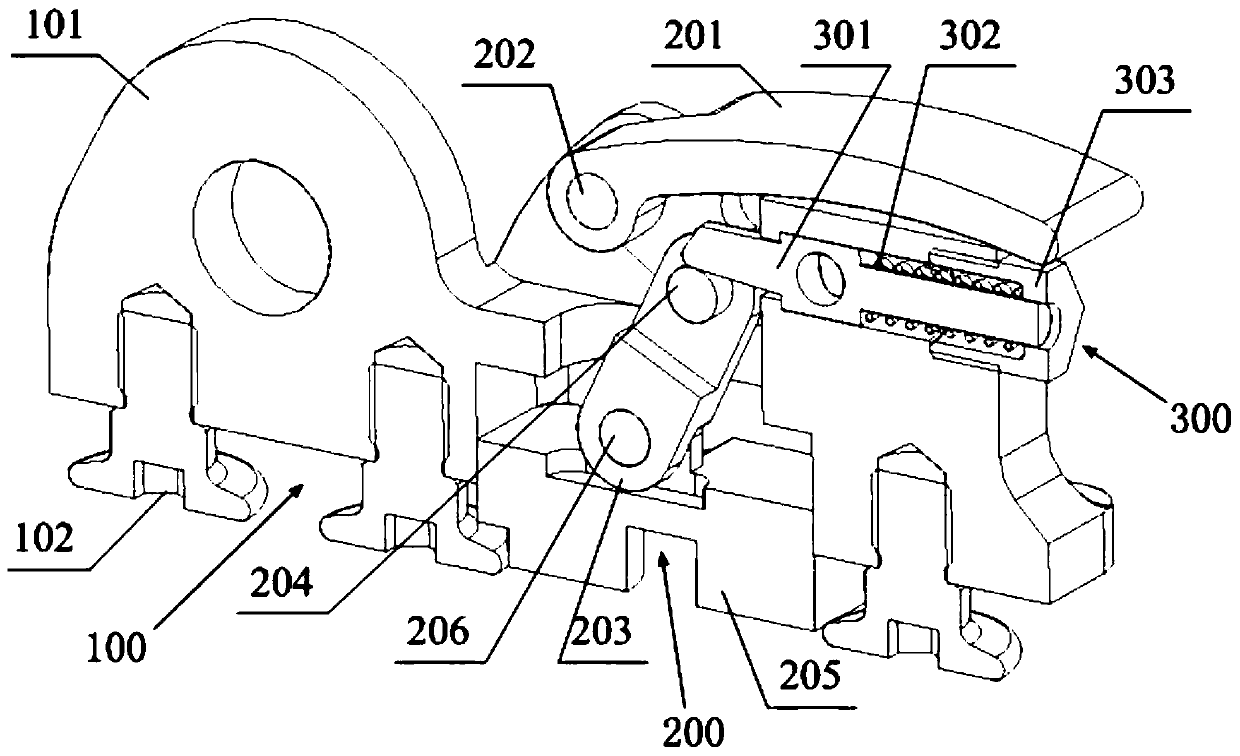

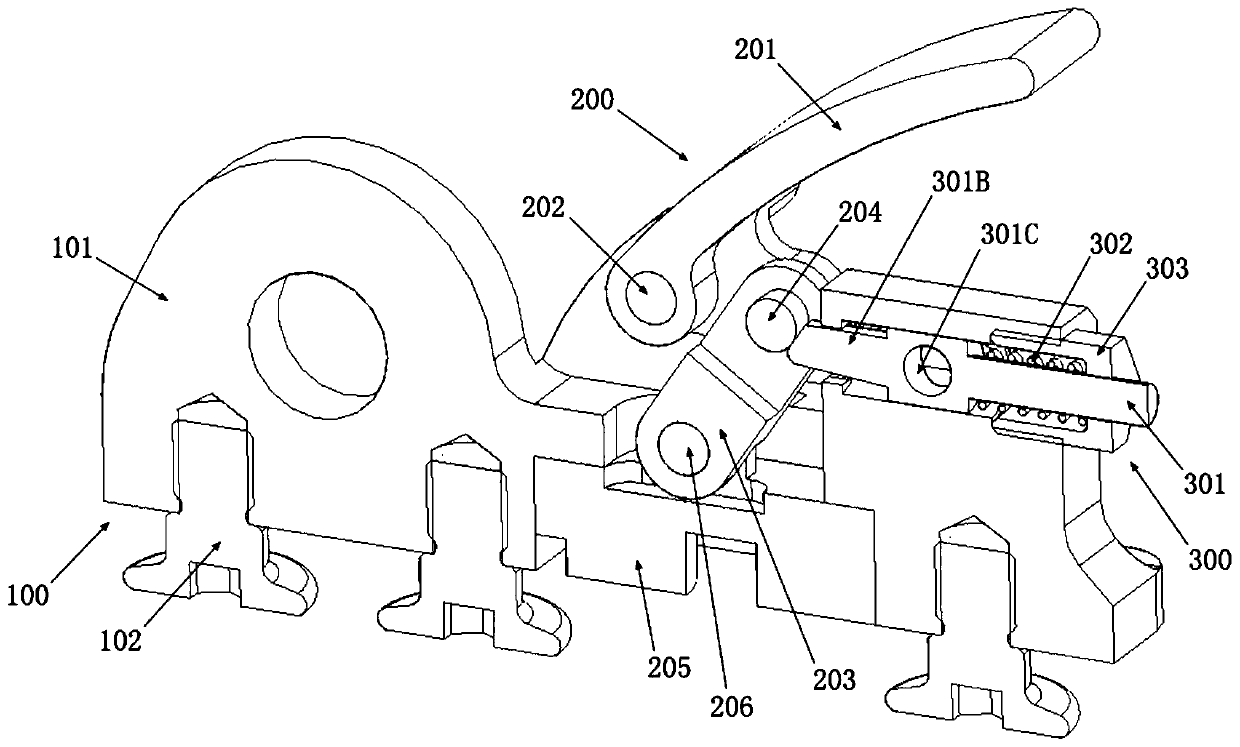

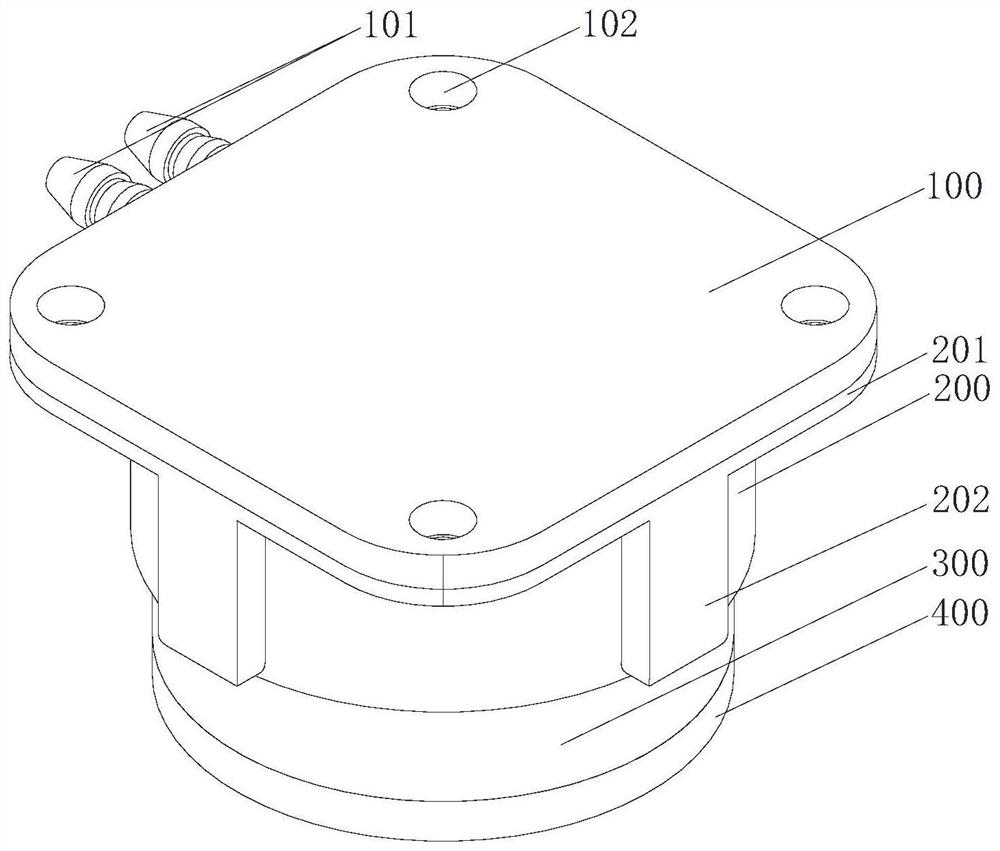

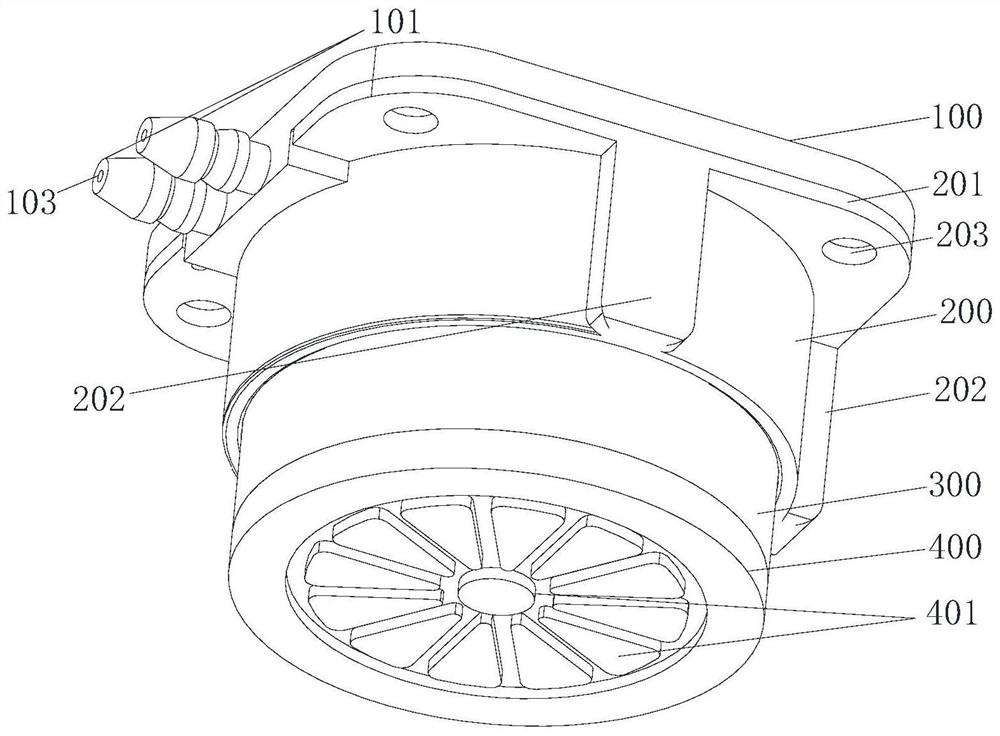

Leveling device, washing machine with leveling device and control method of washing machine with leveling device

ActiveCN108662358ARealize automatic levelingNot shakingMachine framesOther washing machinesPhase-change materialMechanical engineering

The invention provides a leveling device, a washing machine with the leveling device and a control method of the washing machine with the leveling device. The leveling device is used for supporting and leveling of a household appliance and comprises adjusting bottom feet; the adjusting bottom feet comprise fixed parts, movable adjusting parts and phase-change material media, wherein the fixed parts are arranged at the bottom of the household appliance, the movable adjusting parts sleeve the fixed parts and can move axially relative to the fixed parts, containing cavities are formed between themovable adjusting parts and the fixed parts, and the phase-change material media are arranged in the containing cavities; at least two adjusting bottom feet communicate with each other through a communicating device, wherein at least one adjusting bottom foot and / or the communicating devices are provided with heating devices correspondingly; the heating devices are used for heating the phase-change material media, the phase-change material media are converted into liquid, and the liquid flows among the adjusting bottom feet and drives the movable adjusting parts to move axially so as to carryout leveling under the action of pressure; and when the heating devices stop heating, the phase-change material media are converted into solid, and the rigid support in a leveling state is kept.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

Rotary button lock

PendingCN111946152APrevent fallingGood aerodynamic shapeBuilding locksStructural engineeringAirplane

The invention discloses a rotary button lock. The rotary button lock comprises a lock bracket, a driving piece, a swing arm, a sliding block, a support and a pressing head, wherein the driving piece,the swing arm, the sliding block, the support and the pressing head are arranged on the lock bracket, a driving insertion hole is formed in one side of the lock bracket, a sliding groove is formed inthe other side of the lock bracket, the driving piece is sleeved with the driving insertion hole, the sliding block is installed in the sliding groove, one end of the swing arm is connected with the driving piece, the other one end of the swing arm is connected with one end of the sliding block, the support is in a bent shape, one end of the support is hinged to the lock bracket, guide grooves areformed in the middle of the support, the other end of the support is connected with the pressing head, a shifting pin is arranged at the other end of the sliding block, the end part of the shifting pin extends into the guide groove, the driving piece comprises a shaft shell and an ejector rod, the shaft shell is sleeved with the driving insertion hole, a through groove is formed in the shaft shell, and a limiting clamping block is arranged on the ejector rod. The rotary button lock is simple in structure, small in size, light in weight, convenient to install and rapid and reliable in unlocking and locking operation, no protruding structure exists on the surface of a covering cap after installation, and the better aerodynamic configuration of an aircraft is guaranteed.

Owner:东方蓝天钛金科技有限公司

Rotary waterproof button lock

PendingCN111980497AGood aerodynamic shapeAchieve unlockAircraft accessoriesBuilding locksAirplaneStructural engineering

The invention discloses a rotary waterproof button lock. The rotary waterproof button lock comprises a lock seat, a driving assembly, a swing arm, a sliding block, a support and a pressing head, wherein the driving assembly comprises a shaft shell and an ejector rod; the shaft shell is sleeved with a driving insertion hole; a through groove is formed in the shaft shell; a pin shaft is arranged onthe ejector rod and extends into the through groove; a spring is arranged in the portion, below the pin shaft, of the ejector rod; a locking groove matched with the end of the pin shaft is formed in the lock seat; the sliding block is installed in a sliding groove; the swing arm is connected with the shaft shell and hinged to the sliding block through a connecting rod; the support is bent; one endof the support is hinged to the lock seat, a guide groove is formed in the middle of the support, and the other end of the support is connected with the pressing head; a shifting pin is arranged on the sliding block and extends into the guide groove; and a sliding supporting face used for guiding the sliding block is arranged in the lock seat. The rotary waterproof button lock is simple in structure, small in size, low in weight and convenient to install, unlocking and locking operation is rapid and reliable, no protruding structure exists on the surface of an opening cover after installation, and the good aerodynamic configuration of an airplane is guaranteed.

Owner:东方蓝天钛金科技有限公司

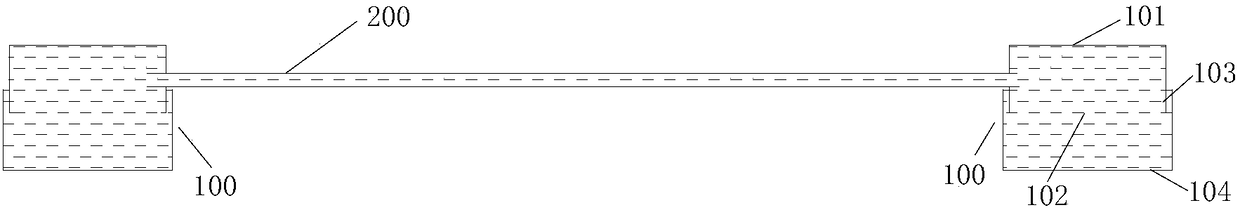

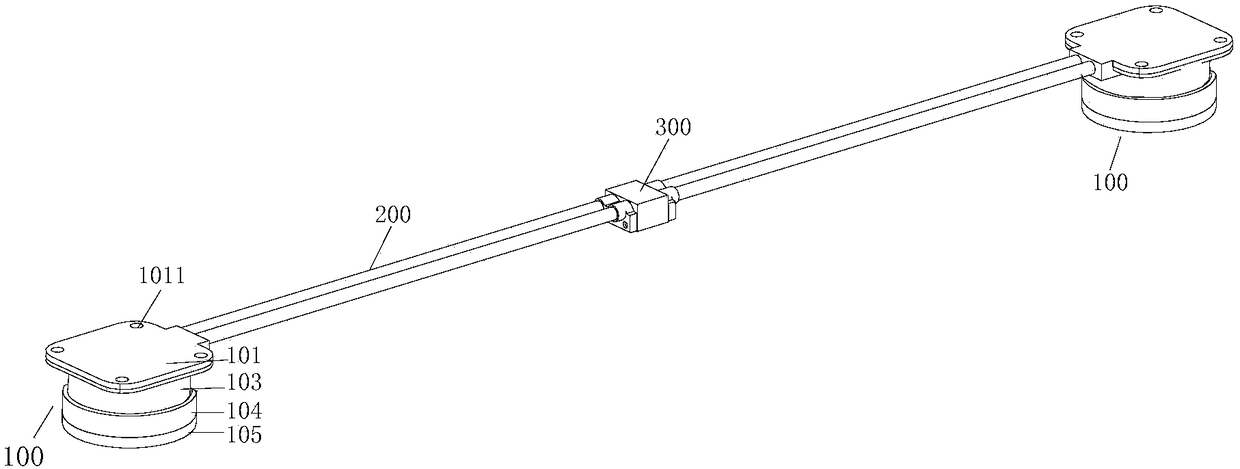

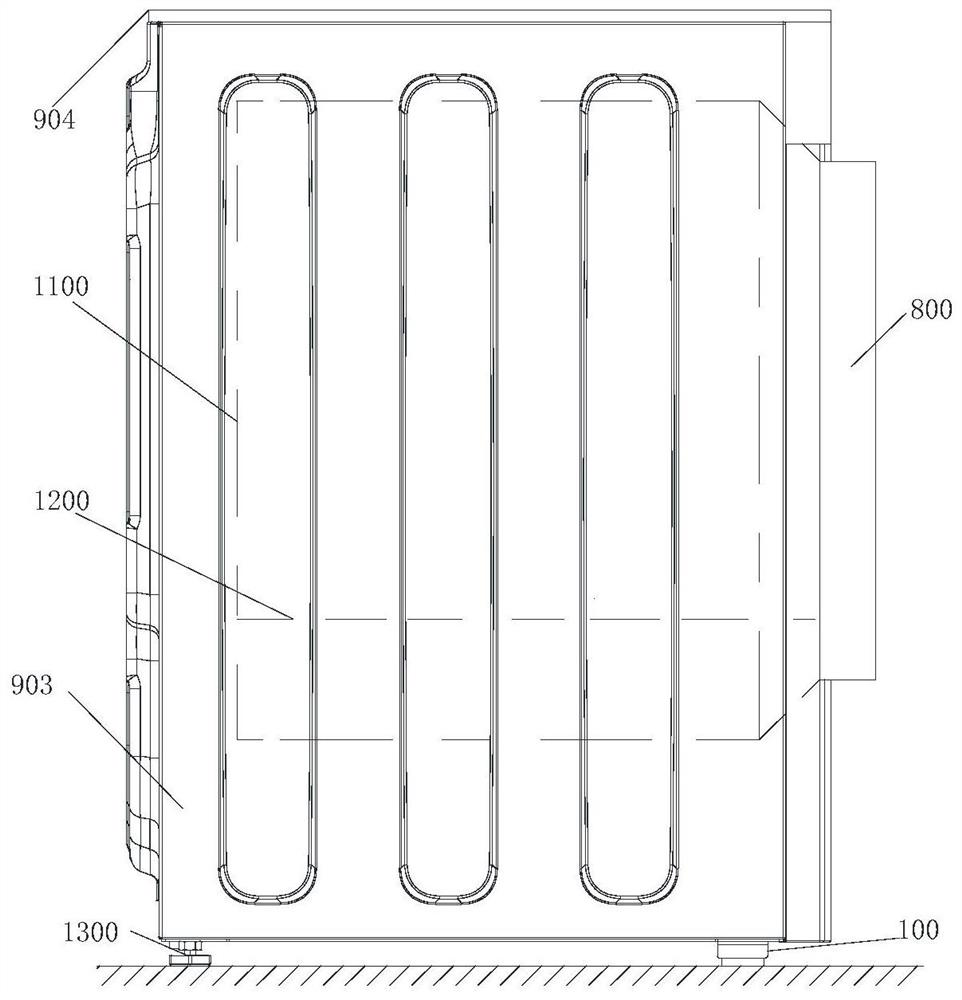

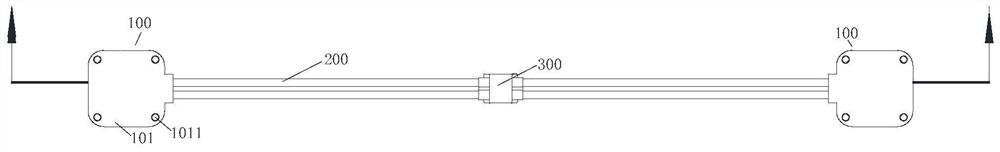

Hydraulic lifting bottom legs, washing machine with bottom legs and control method of washing machine

ActiveCN108660698AWon't overflowAvoid settingOther washing machinesControl devices for washing apparatusEngineeringWater level

The invention provides hydraulic lifting bottom legs, a washing machine with the bottom legs and a control method of the washing machine. The hydraulic lifting bottom legs include hydraulic bottom legbodies, a communicating device and a liquid storage device. The hydraulic bottom leg bodies include a fixing part and a movable adjusting part, wherein the fixing part is installed on the bottom of ahousehold appliance, and the movable adjusting part sleeves the fixing part and can relatively move in the axial direction. A containing cavity for containing a hydraulic medium is formed between thefixing part and the movable adjusting part; at least two hydraulic bottom leg bodies and the liquid storage device are communicated with each other through the communicating device. Along with the changes of pressure, the hydraulic medium flows among the hydraulic bottom leg bodies and drive the movable adjusting part to move axially under the action of pressure for levelling. The hydraulic medium is injected into / sucked out of the hydraulic bottom leg bodies through the liquid storage device, and lifting adjustment of the hydraulic bottom legs is controlled. The hydraulic lifting bottom legs are particularly applicable to a roller washing machine, the supporting height of the hydraulic bottom leg bodies is increased by means of the liquid storage device in order to lift an opening of adoor body, and therefore the water level is lower than the opening of the door body so that the door body can be opened for adding clothes during running of the washing machine.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

Leveling device of household appliance and washing machine with same

ActiveCN108662359AImprove support stabilityLarge horizontal sizeMachine framesNon-rotating vibration suppressionHome applianceSupport surface

The invention provides a leveling device of a household appliance and a washing machine with the same. The leveling device comprises hydraulic bottom legs; each hydraulic bottom leg comprises a fixingpart, a movable adjusting part and a containing cavity; and for each hydraulic bottom leg, the movable adjusting part sleeves the outer side of the fixing part and can move axially relative to the fixing part, the containing cavity for containing a hydraulic medium is formed between the fixing part and the movable adjusting part, and along with the change of the pressure, the hydraulic medium drives the movable adjusting part to axially move along the exterior of a protective sleeve to carry out leveling. According to the leveling device, when the hydraulic bottom legs are fixed on a bottom plate of the household appliance, the movable adjusting part capable of moving up and down sleeves the outer side of the fixing part so that the transverse size of the movable adjusting part can be increased, the contact area between the movable adjusting part and a supporting surface is effectively increased, and the supporting stability of the leveling device on the household appliance is improved.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +2

Adjustable continuous injector

The invention relates to an adjustable continuous injector. The injector comprises a sleeve, a piston, a core rod, a fixed handle, a movable handle and an adjusting screw rod, wherein the rear part of the sleeve is connected with the fixed handle; a screw hole is formed at the bottom of the fixed handle; the adjusting screw rod passes through the screw hole and is contacted with the lower lateral face of the movable handle; the adjusting screw rod pushes the movable handle to rotate with a pin roll, and the core rod is driven to displace, so that adjustment of injection amount is realized; a slotted hole is formed in the middle of the upper end of the movable handle along the axial direction of the core rod; the movable handle is sleeved on the core rod; a core rod catch, a gasket and a spring are sleeved on the core rod close to protruded cambered surfaces of the front and rear parts of the movable handle; and when the movable handle drives the core rod to move front and back, the movable handle can freely and slightly float up and down relative to the core rod, the core rod is prevented from generating friction, and axial movement of the core rod is not influenced. The adjustable continuous injector has the advantages of reasonable structure, accurate quantitation, convenience in adjustment, reliability in operation, good stability of injection quantity control and long service life.

Owner:王喜增

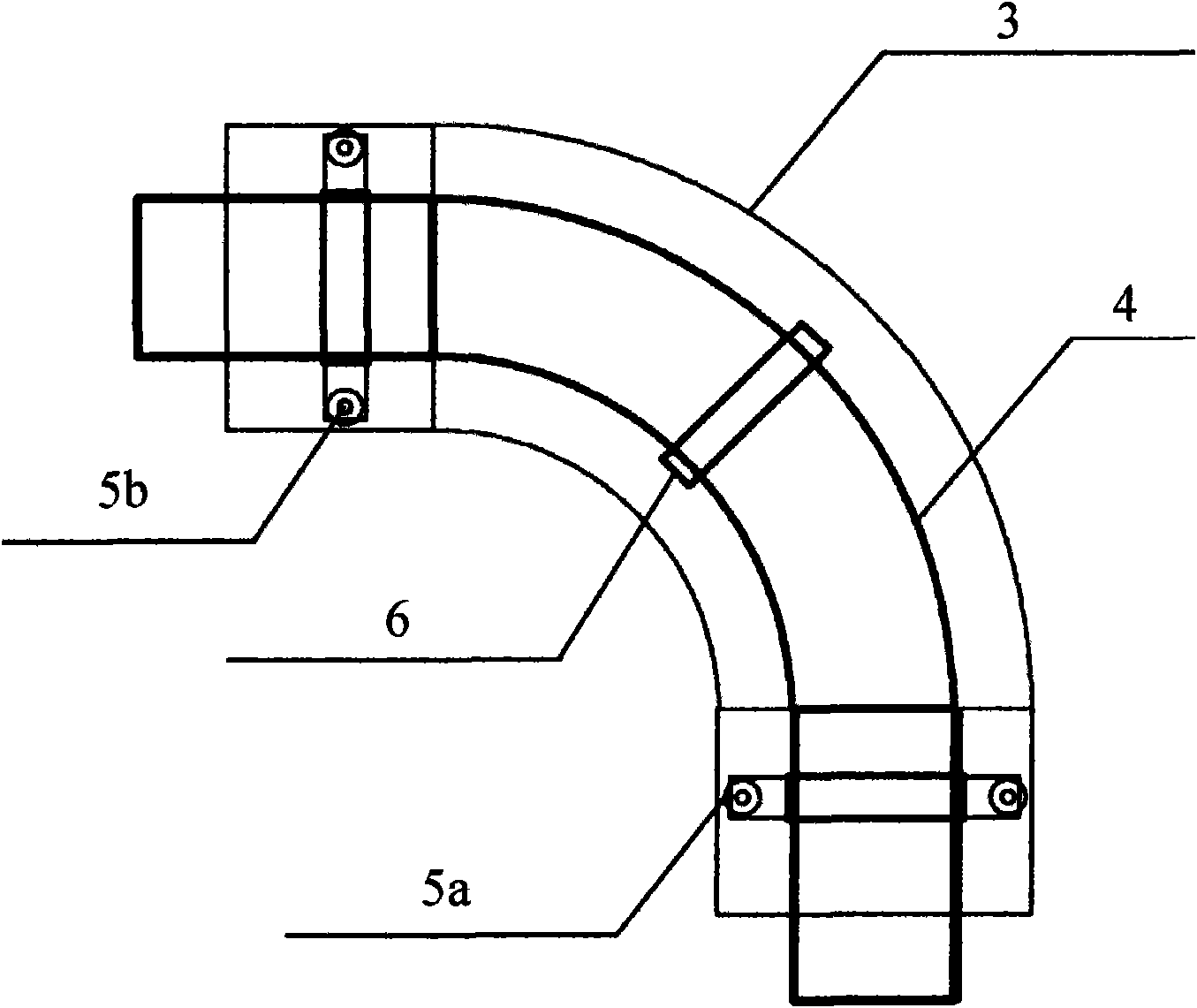

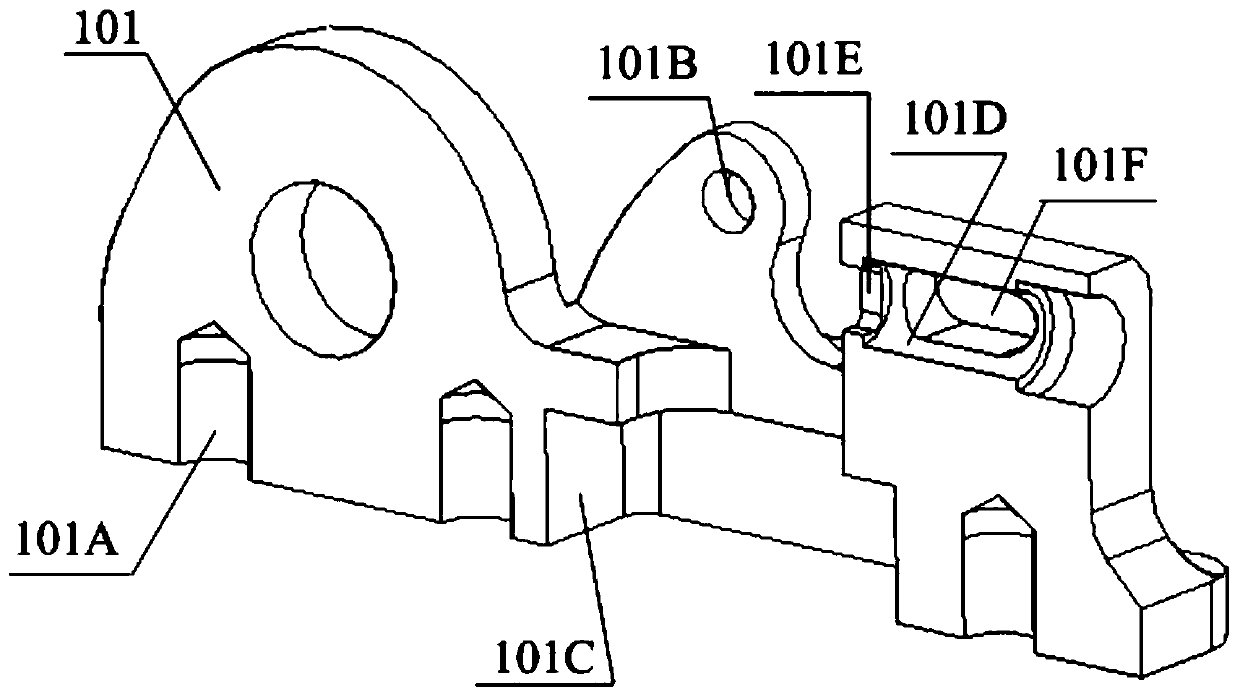

Steel-sleeve steel steam insulation pipe elbow and rolling supporting mechanisms at end part and middle part thereof

InactiveCN101666420AMechanical Analysis ConciseReduce stressPipe supportsThermal insulationClassical mechanicsIdler-wheel

The invention relates to a steel-sleeve steel steam insulation pipe elbow and rolling supporting mechanisms at the end part and the middle part thereof. The rolling supporting mechanism at the end part comprises an upper steel hoop, a lower steel hoop, one upper idler wheel and one lower idler wheel, wherein the lower idler wheel and the inner wall of an outer sleeve steel are contacted in a rolling friction way, and an upper idler wheel vertical plate and a lower idler wheel vertical plate are in a clearance fit with the upper idler wheel and the lower idler wheel. The rolling supporting mechanism at the middle part comprises an upper steel hoop, a lower steel hoop and one lower idler wheel arranged at the right center of the lower steel hoop, wherein the lower idler wheel and the inner wall of an outer sleeve steel are contacted in a rolling friction way, and a lower idler wheel vertical plate is in a clearance fit with the lower idler wheel. The steel-sleeve steel steam insulation pipe elbow comprises an outer sleeve steel pipe, an inner sleeve steel pipe, two rolling supporting mechanisms at the end part, the rolling supporting mechanism at the middle part, insulation material,and erosion resistant coating. Gaps exist between the lower idler wheels and the lower idler wheels of the rolling supporting mechanisms respectively at the end part and the middle part, thereby solving the problem of side displacement of the inner sleeve steel pipe, which is caused by the right angle.

Owner:刘毅 +1

Novel dust sealing external pressure type expansion joint

InactiveCN105526454ASimple structureEasy to manufacturePipeline expansion-compensationEngineeringExpansion joint

The invention discloses a novel dust sealing external pressure type expansion joint which comprises a long joint tube, a bolt, a filler, a gland, joints, a corrugated tube, an outer shell, an internal protective tube and a nipple. The internal protective tube is embedded into the nipple, and the nipple is connected with the right end of the shell in a sealed way by a flange. Two ends of the corrugated tube are respectively fixedly connected with the joints, and the long joint tube is inserted into a hole of the corrugated tube and is fixedly connected with a joint inner hole at the right end to form an axial compensation structure. The shell covers the axial compensation structure and is connected with the joint at the left end in a sealed way. According to the expansion joint provided in the invention, an axial dust sealing structure is arranged outside the outer end face of the joint at the left end, the gland in the structure is connected with the joint by the bolt, and a sealing ring embedded into an inner hole groove of the gland plugs a clearance between the dynamic compensation structure and the static joint. The novel dust sealing external pressure type expansion joint is simple in structure and easy to produce, can prevent dust, cannot affect the axial movement of the compensation structure, and is convenient to maintain.

Owner:JIANGYAN CITY YICEN MACHINERY PARTS FACTORY

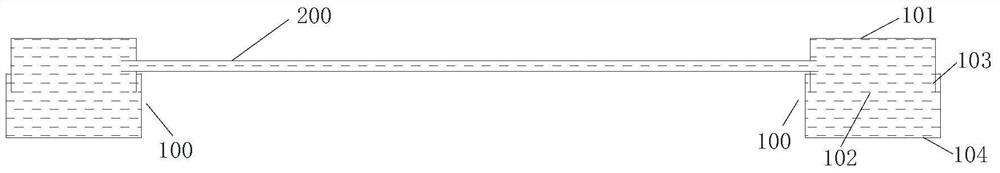

Steel sheathed steel steam heat preserving pipeline and lateral displacement sliding support mechanism thereof

InactiveCN101701659ASimple processLow costThermal insulationPipe protection by thermal insulationEngineeringLateral displacement

The invention relates to a steel sheathed steel steam heat preserving pipeline with the nominal diameter of an inner sheathed steel pipe below DN125 and a sliding support mechanism thereof. The mechanism comprises an upper steel hoop, a lower steel hoop, an upper sliding support plate and two lower sliding support plates, wherein the upper sliding support plate is positioned in the center of the upper steel hoop, and the two lower sliding support plates are symmetrically distributed on the lower steel hoop; when the inner sheathed steel pipe is displaced along an axis in an outer sheathed steel pipe, the lower sliding support plates are in contact with the inner wall of an outer steel sheath in a sliding friction way, and an assembly clearance is arranged between the upper sliding support plate and the inner wall of the outer steel sheath. The steel sheathed steel steam heat preserving pipeline comprises the inner sheathed steel pipe, the outer sheathed steel pipe, the sliding support mechanism, heat insulating materials, heat preserving material and a corrosion preventing layer, wherein the corrosion preventing layer is sleeved outside the outer sheathed steel pipe. The invention is just provided with the three sliding support plates and has quite simple process and low cost.

Owner:刘毅 +1

A hydraulic lifting foot, a washing machine with the foot and a control method thereof

ActiveCN108660698BAvoid settingPlay a limiting roleOther washing machinesControl devices for washing apparatusLaundry washing machineControl engineering

The invention provides a hydraulic lift foot, a washing machine with the foot and a control method thereof. The hydraulic lift foot includes a hydraulic foot, a communication device, and a liquid storage device. The hydraulic foot includes: a fixing part installed on a household appliance the bottom of the bottom; the movable adjustment part is sheathed with the fixed part and can move axially relative to it; there is an accommodation chamber for accommodating the hydraulic medium between the fixed part and the movable adjustment part; at least two hydraulic feet, storage The hydraulic devices communicate with each other through the communication device: as the pressure changes, the hydraulic medium circulates between the hydraulic feet and drives the movable adjustment part to move axially for leveling under the pressure; it is injected into the hydraulic feet through the liquid storage device / Suck out the hydraulic medium and control the lifting adjustment of the hydraulic feet. The hydraulic lifting feet of the present invention are especially suitable for drum washing machines. The liquid storage device raises the support height of the hydraulic feet to raise the door opening so that the water level is lower than the door opening, so that the door can be opened midway by adding clothes.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

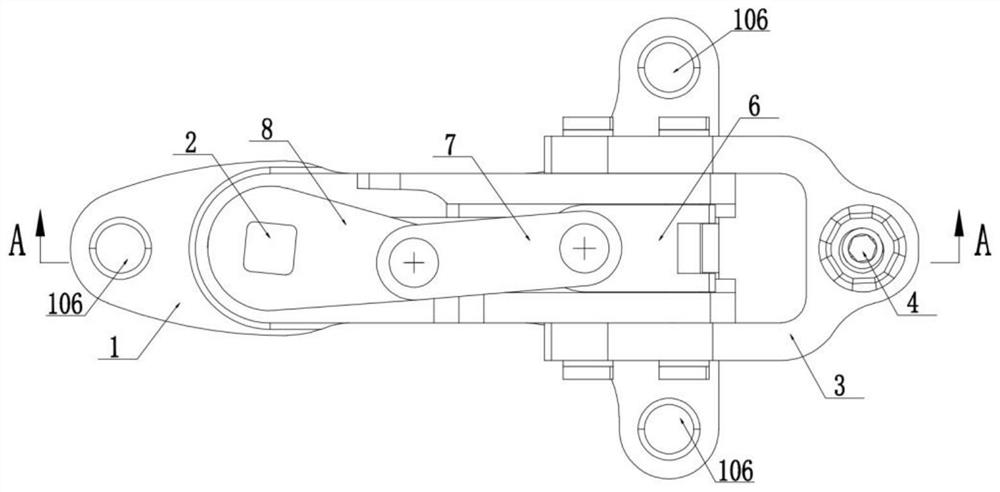

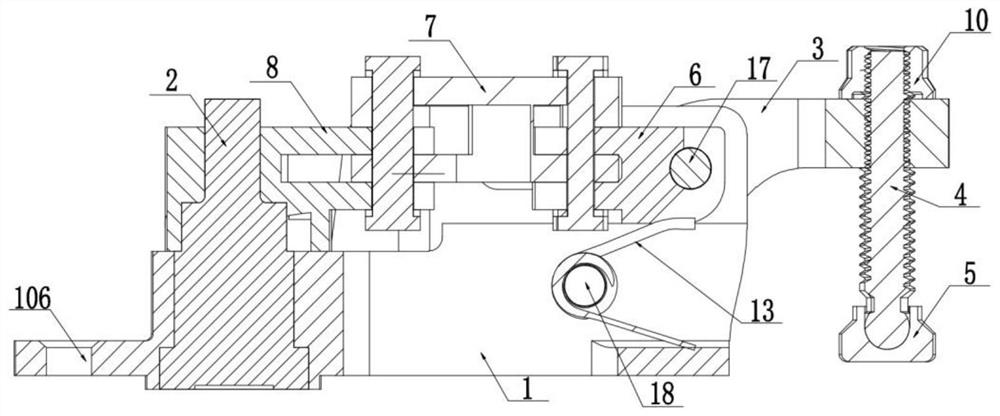

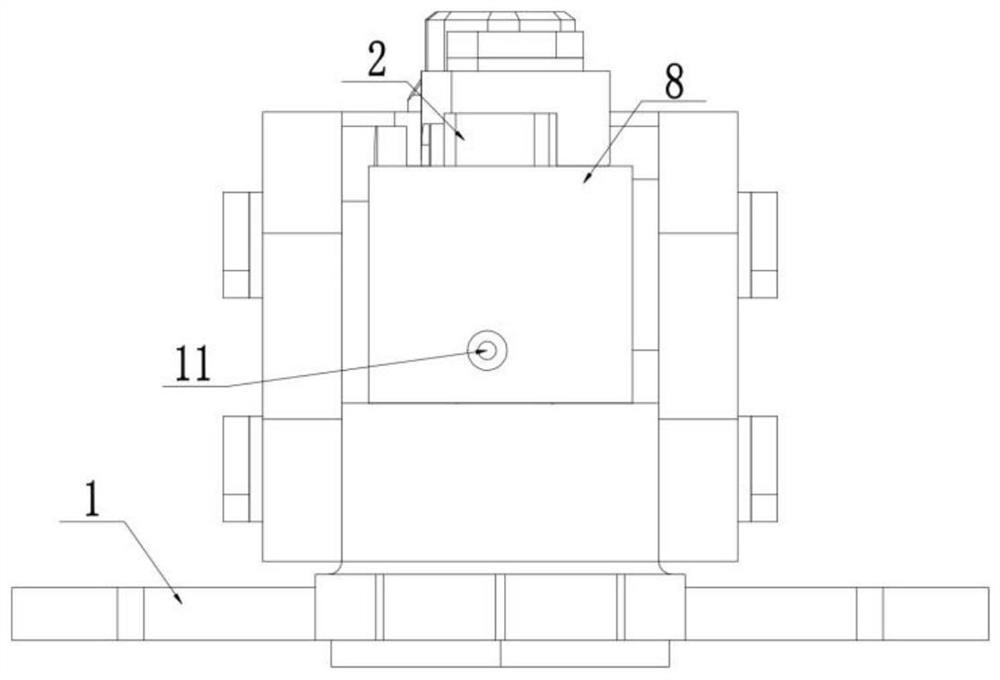

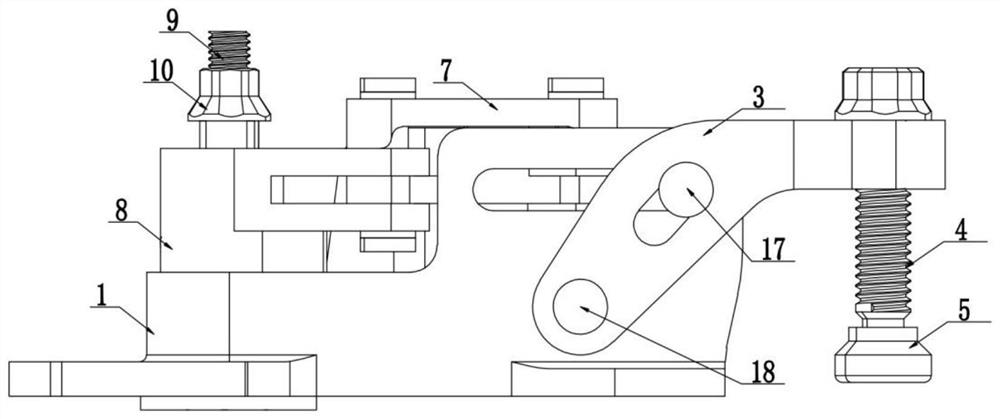

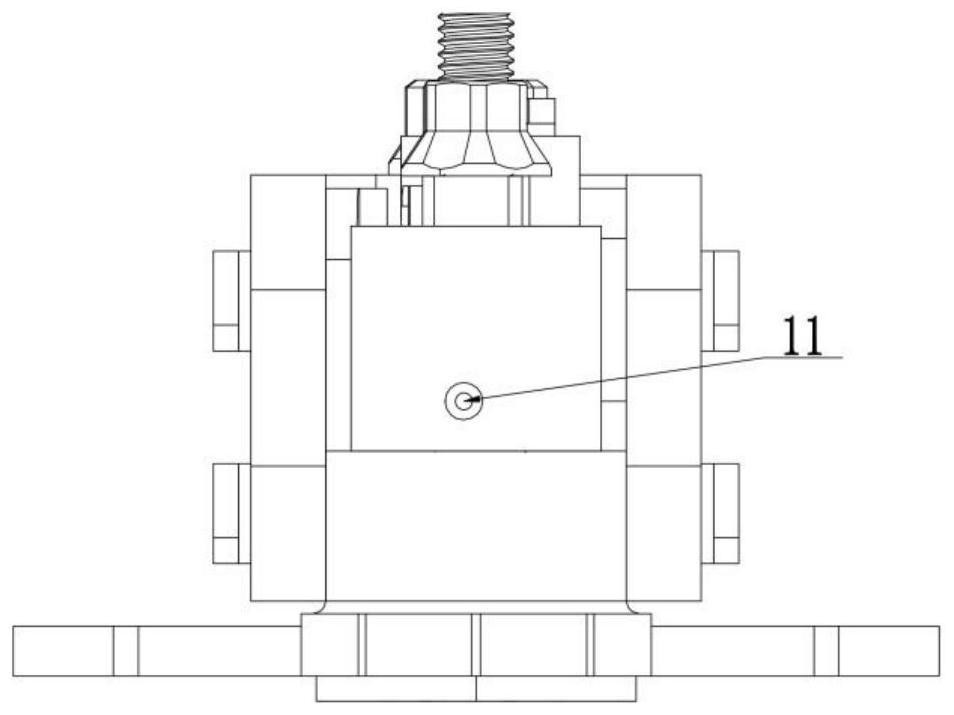

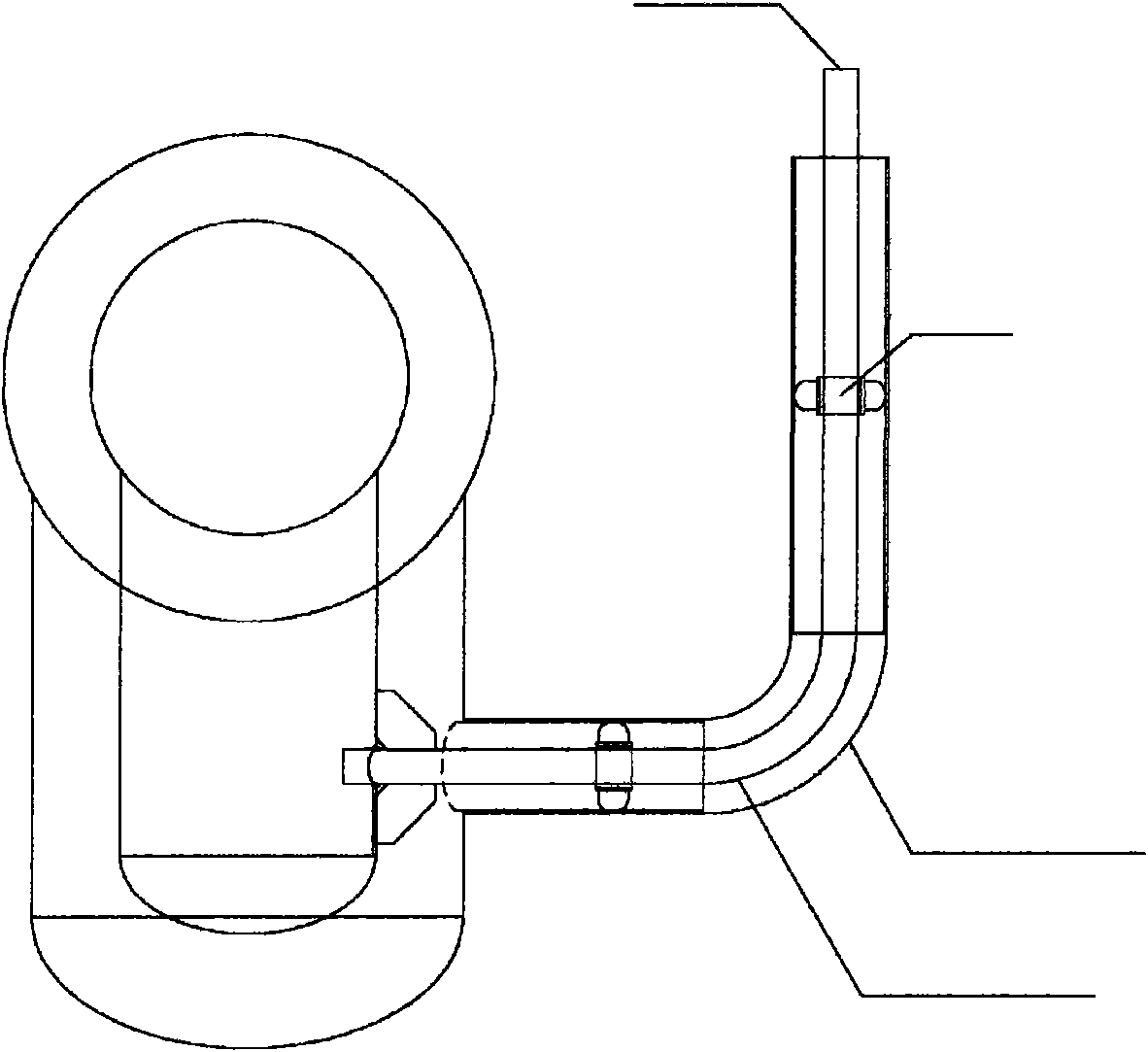

Aero seat foot lock device

The invention discloses an aero seat foot lock device which solves the technical problems that in the prior art, switching of an aero seat foot lock between a fixed state and a moving state is troublesome and time-consuming, and operation is tedious after switching. The device comprises a foundation lock structure mounted between an aero seat and an aircraft guide rail, the ground foot lock structure comprises a ground foot lock body installed on the aero seat and a fixed support installed on the ground foot lock body and matched with an airplane guide rail. Wherein the rocker sliding block mechanism is matched with the airplane guide rail and used for adjusting and switching the fixed state or the moving state of the foundation lock structure relative to the airplane guide rail, and the self-locking mechanism is used for maintaining the rocker sliding block mechanism in the current state. The aircraft seat self-locking device can conveniently switch the state of the aircraft seat relative to the aircraft guide rail, the self-locking function can greatly improve the operation safety, the applicability is high, and the aircraft seat self-locking device is suitable for being widely applied and popularized in the technical field.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

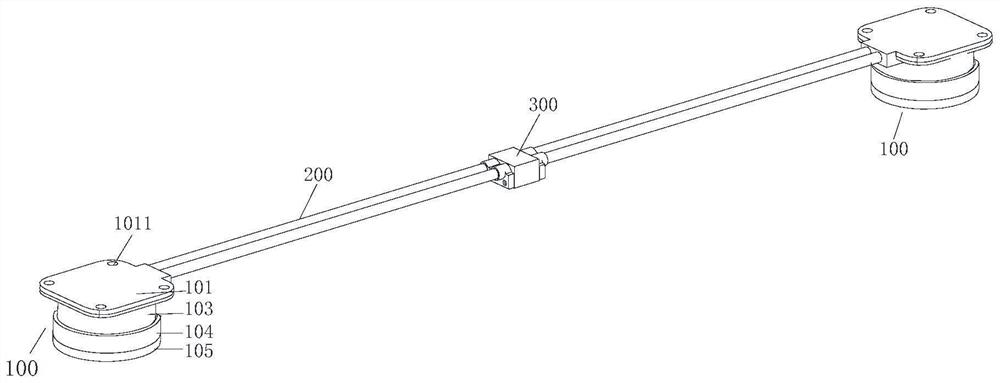

A foot for household appliances and household appliances

ActiveCN108278452BRealize automatic levelingSelf-leveling is simple and reliableMachine framesSpringsPhysical medicine and rehabilitationLiquid medium

The invention provides a foot for a household appliance and a household appliance. The foot for a household appliance includes: a hydraulic plate; a sheath fixedly connected to the hydraulic plate; Move; a housing chamber is formed between the hydraulic plate, the sheath and the adjustment feet; the flexible housing, which contains the liquid medium inside, is arranged in the housing chamber; under the action of pressure, the flexible housing stretches to drive the adjustment The feet move axially in the sheath for leveling. The sheath and / or the adjustment foot are provided with a guide limit mechanism for limiting the circumferential rotation of the adjustment foot relative to the sheath, and the hydraulic plate is set corresponding to the guide limit mechanism avoidance department. In the present invention, an avoidance part is provided on the hydraulic plate corresponding to the guiding and limiting mechanism. While satisfying the setting of the guiding and limiting mechanism, the axial movement of the adjusting foot is not affected, and the overall height of the feet of household appliances can be reduced, and the shock-absorbing stability thereof can be improved. sex.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

Bottom foot for household electrical appliance and household electrical appliance

ActiveCN108626528ARealize automatic levelingImprove buffering effectMachine framesVibration dampersHome applianceEngineering

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +2

A foot for household appliances and household appliances

ActiveCN108626528BRealize automatic levelingImprove buffering effectMachine framesSpringsPhysical medicine and rehabilitationHome appliance

The invention provides a foot for a household appliance and a household appliance. The foot for a household appliance includes: a hydraulic plate; a sheath fixedly connected to the hydraulic plate; Move; the hydraulic plate, the sheath and the adjustment foot form an accommodation chamber; the hydraulic medium is arranged in the accommodation chamber, and as the pressure changes, the hydraulic medium compresses / expands to drive the adjustment foot in the sheath The internal axial movement is used for leveling; the communication device connects at least two household appliances with feet to realize the circulation of the hydraulic medium between the household appliances; the communication device is provided with a throttling structure for slowing down the flow rate of the hydraulic medium . In the present invention, a throttling structure is arranged in the connecting device to prevent the hydraulic medium from rapidly flowing between the feet of the household appliances, so that the adjustment process is more stable; in addition, the throttling structure can Makes for good buffering.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +2

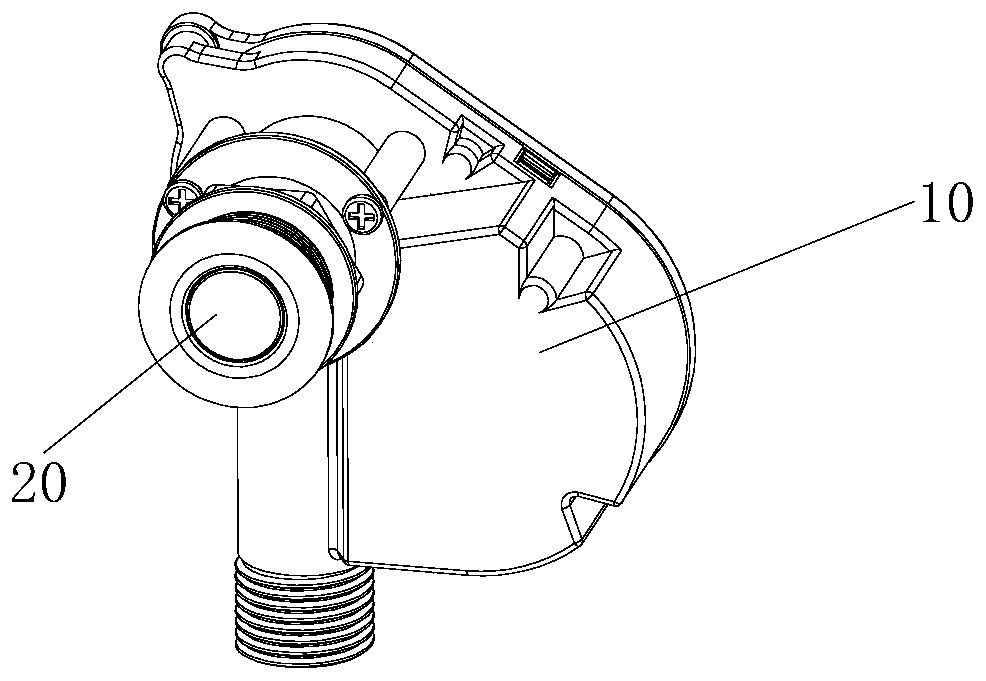

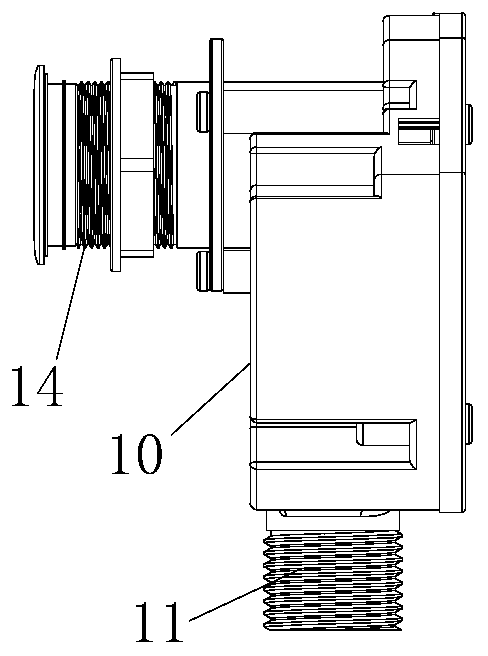

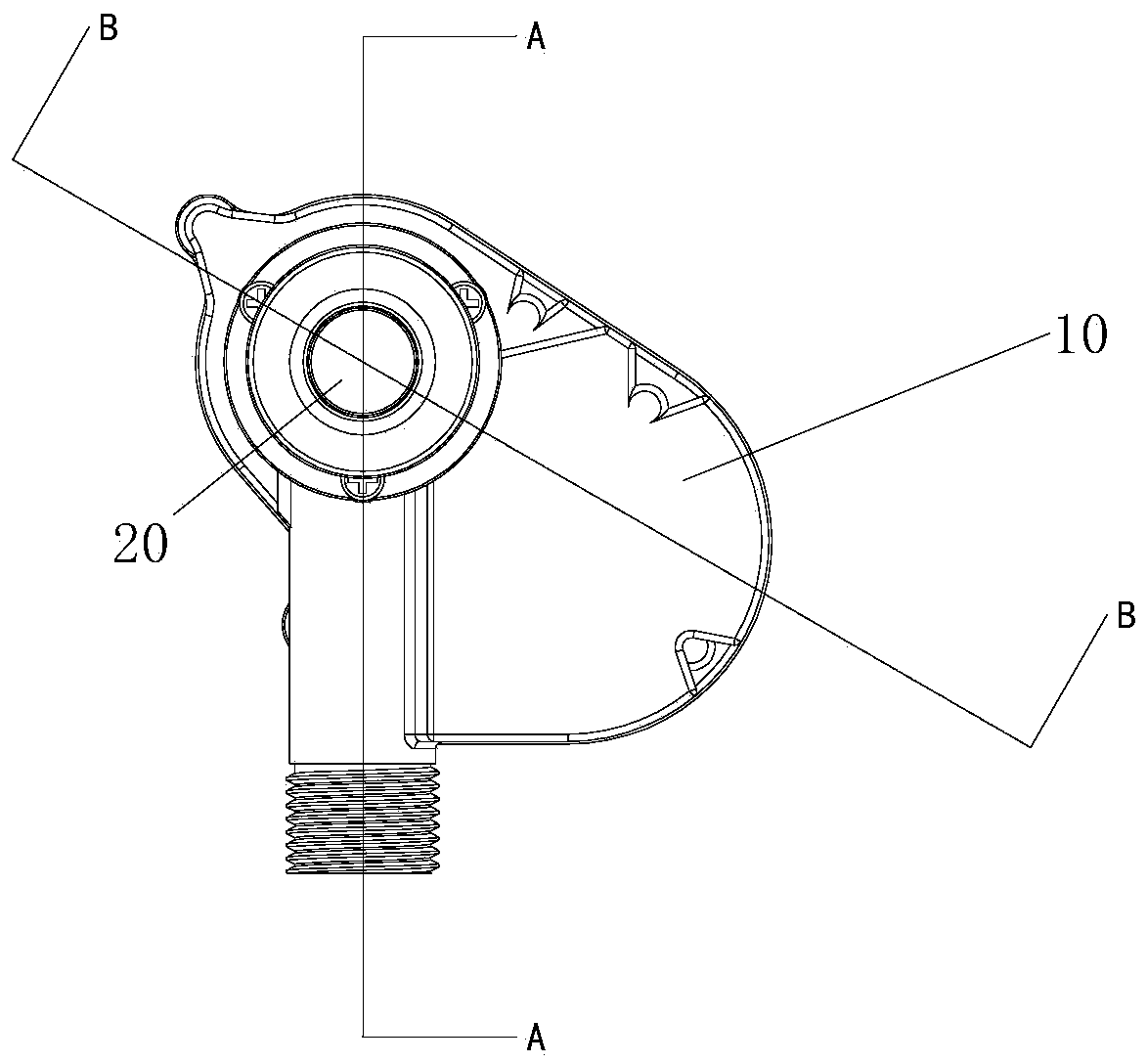

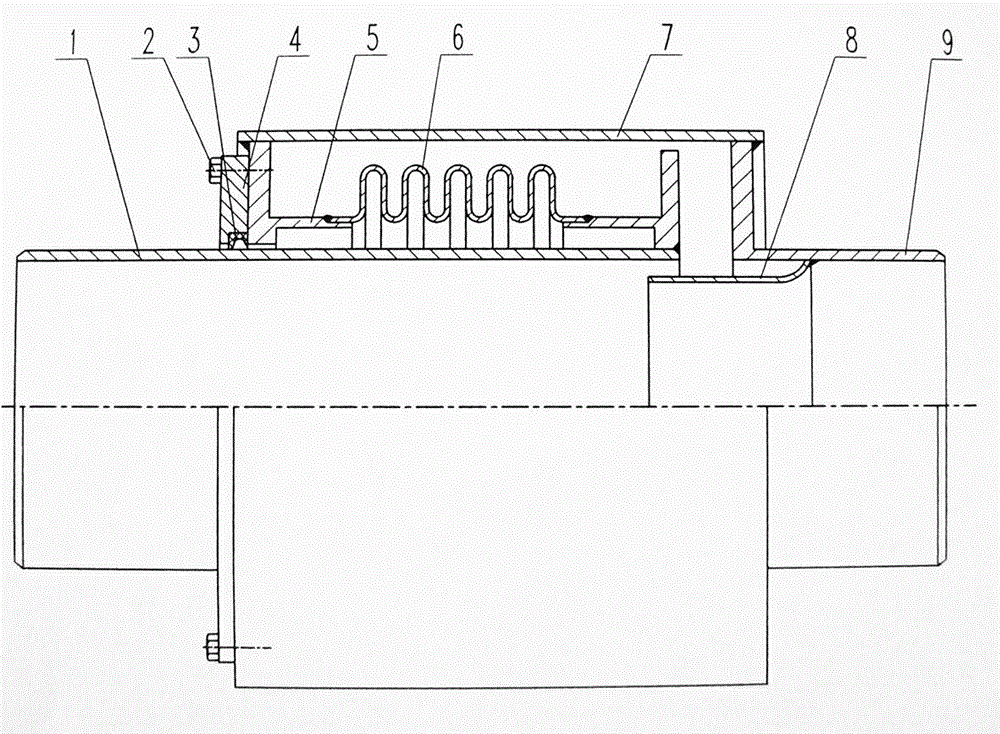

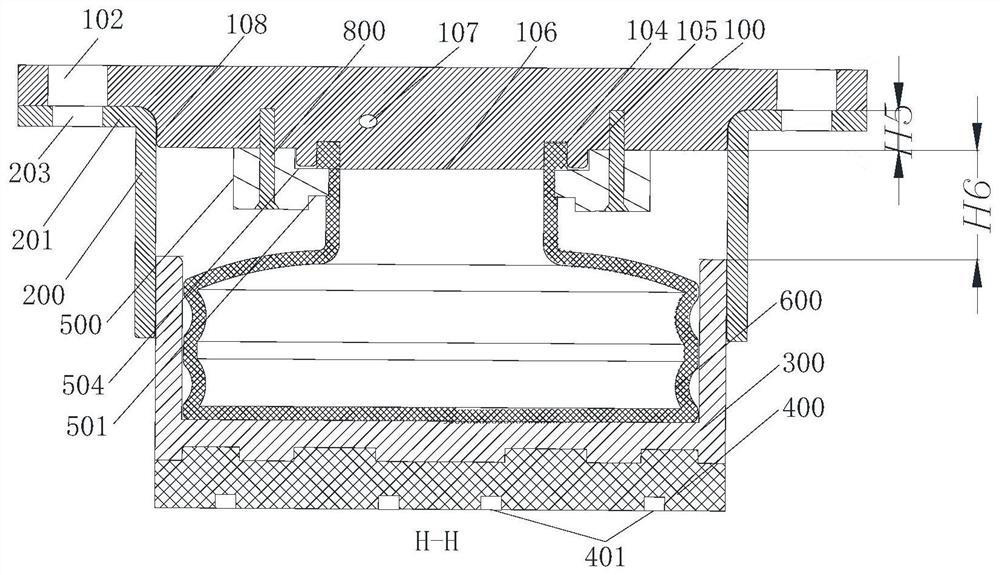

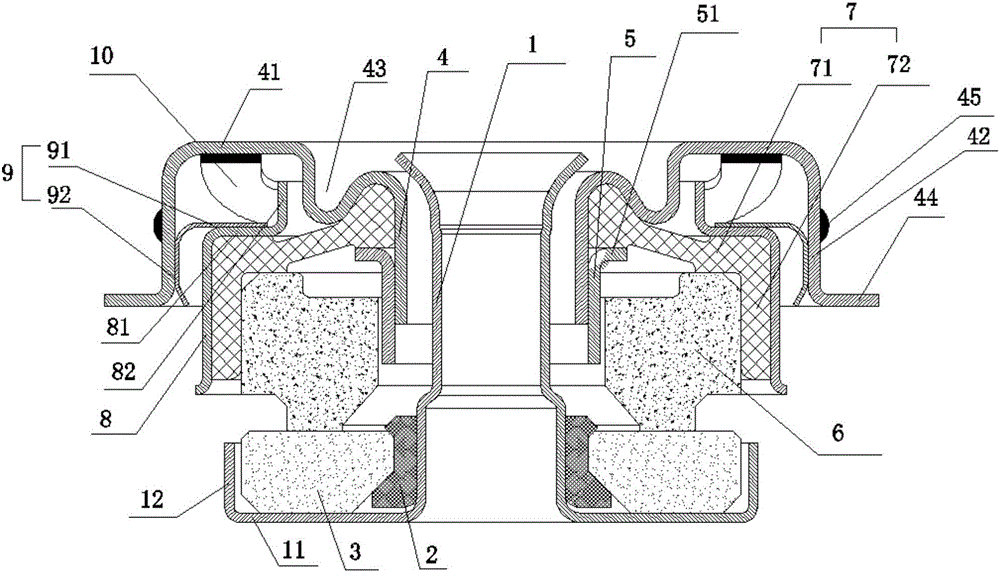

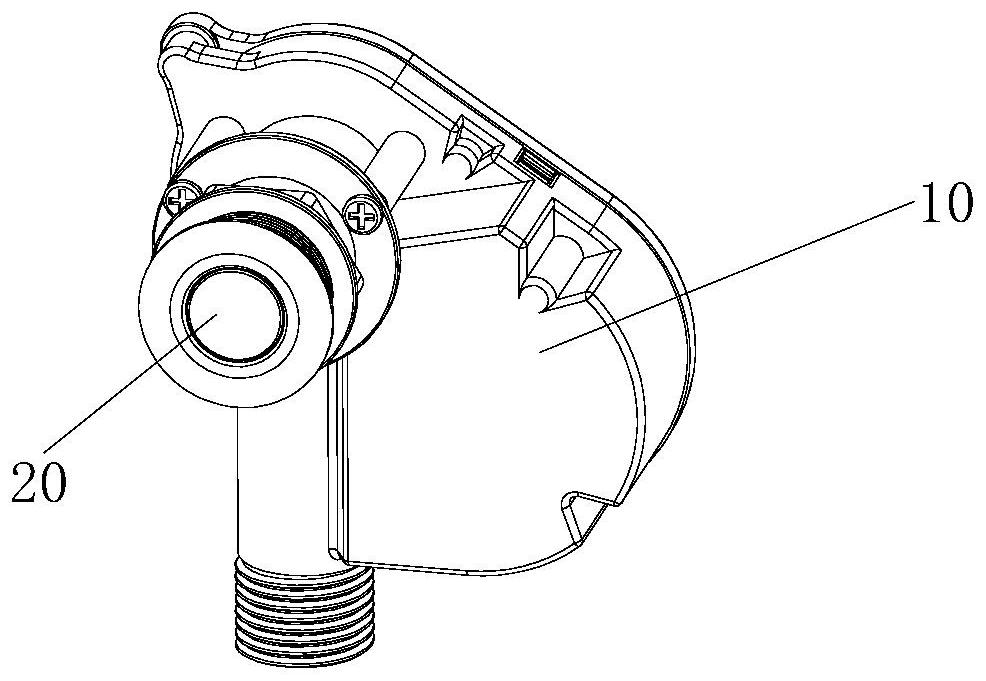

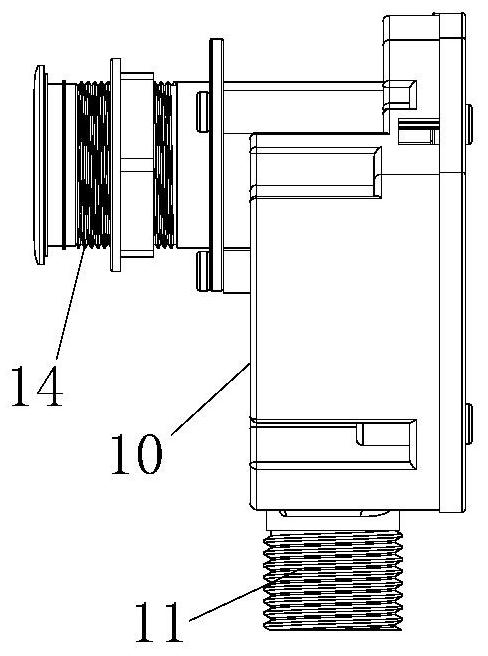

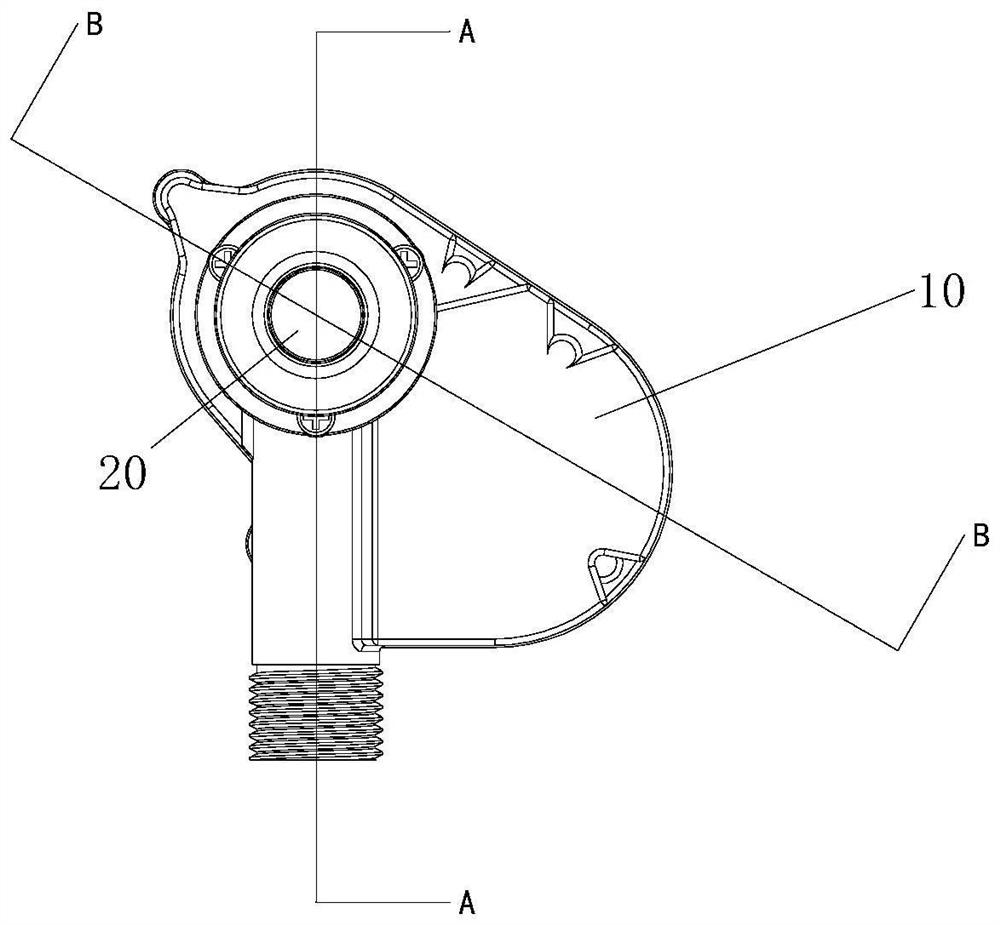

Noise reduction type water seal for automobile water pump

InactiveCN106523440AReduce or eliminate vibrationDoes not affect axial movementPump componentsPumpsEngineeringNoise reduction

The invention provides a noise reduction type water seal for an automobile water pump. The water seal comprises a movable ring assembly and a static ring assembly; a first outer side ring extending outwards in the radial direction of a shaft sleeve is arranged at one end of the shaft sleeve, an installation base is arranged at the end, away from the first outer side ring, of the shaft sleeve in a sleeving mode, a second outer side ring extending outwards in the radial direction of the installation base is arranged at the end, away from the first outer side ring, of the installation base, and a first annular ring extending towards the first outer side ring is arranged on the outer edge of the second outer side ring; a moving ring is arranged on the outer side of the shaft sleeve in a sleeving mode; an inner sleeve is arranged on the outer side of the installation base in a sleeving mode; a static ring is arranged on the outer side of the inner sleeve in a sleeving mode and abuts against the moving ring; an outer sleeve is arranged on the outer side of the static ring in a sleeving mode; a corrugated rubber pipe is arranged in the gap among the installation base, the inner sleeve, the static ring, the outer sleeve and an inner side ring; and an elastic noise-reducing ring is arranged in the gap between the outer sleeve and the installation base. According to the water seal, the metal elastic noise-reducing ring is additionally arranged in the gap between the outer sleeve and the installation base to reduce or eliminate vibration, and therefore noise can be avoided or lowered to be lower than the human ear hearing range.

Owner:嘉科(安徽)密封技术有限公司

Drainage device of steel-sleeve steel steam insulation pipe

InactiveCN101666426AGuaranteed StrengthAvoid diggingPipeline systemsArchitectural engineeringEngineering

The invention relates to a drainage device of a steel-sleeve steel steam insulation pipe, which comprises a section of inner sleeve steel pipe, a section of outer sleeve steel pipe, insulation material, a supporting mechanism, a header tank inner sleeve, an outlet entrance, a header tank outer sleeve, insulation material, a discharge opening arranged at the bottom of the header tank inner sleeve,another discharge opening arranged at the matched header tank outer sleeve, and erosion resistant coating sleeved outside the outer sleeve steel pipe and at the outer part and at the bottom of the header tank outer sleeve, wherein water in the discharge openings is discharged in a discharge well by an external pipe. The invention avoids digging a hole at the lower side of the inner sleeve steel pipe, simplifies the welding technology and also ensures the strength of the inner sleeve steel pipe.

Owner:刘毅 +1

Anti-idling device of handheld electric cutting tool

PendingCN114433931AEliminate power wasteGuaranteed service lifeFeeding apparatusTube shearing machinesPower toolAutomotive engineering

The invention relates to the technical field of electric tools, in particular to an anti-idling device of a handheld electric cutting tool, which comprises a cutting seat, a roller seat and a cutter seat are mounted in the cutting seat, a roller is mounted on the roller seat, and a cutter is mounted on the cutter seat; a clamping position is formed between the roller and the cutting knife; the guide rod is movably mounted in the cutting seat, and the roller seat or the tool apron is connected to the guide rod; the sensor is mounted outside the cutting seat and is used for sensing the guide rod; and when the pipe enters the clamping position, the roller seat or the tool apron is opened to move, so that the end part of the guide rod is far away from the sensor. When the pipe enters the clamping position, the roller seat is opened to move, so that the end part of the guide rod is far away from the sensor, and therefore, the equipment can work normally, and the problems of equipment damage, electric quantity waste and influence on the service life caused by idling in the prior art are solved.

Owner:TAIZHOU JULI TOOLS

A leveling device for household appliances and a washing machine with the same

ActiveCN108662359BAvoid settingPlay a limiting roleMachine framesNon-rotating vibration suppressionLaundry washing machineControl engineering

The invention provides a leveling device for household appliances and a washing machine with the leveling device. The leveling device includes a hydraulic foot, and the hydraulic foot includes: a fixed part; a movable adjustment part, which is sleeved outside the fixed part and can be relative to its axial movement; there is an accommodating chamber for containing hydraulic medium between the fixed part and the movable regulating part; as the pressure changes, the hydraulic medium drives the movable regulating part to move axially along the outer sheath Leveling. In the leveling device of the present invention, when the hydraulic foot is fixed on the bottom plate of the household appliance, the movable adjustment part that can move up and down is sleeved outside the fixed part, so that the lateral size of the movable adjustment part can be increased, and the activity can be effectively increased. The contact area between the adjustment part and the support surface improves the support stability of the leveling device for the household appliances.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +2

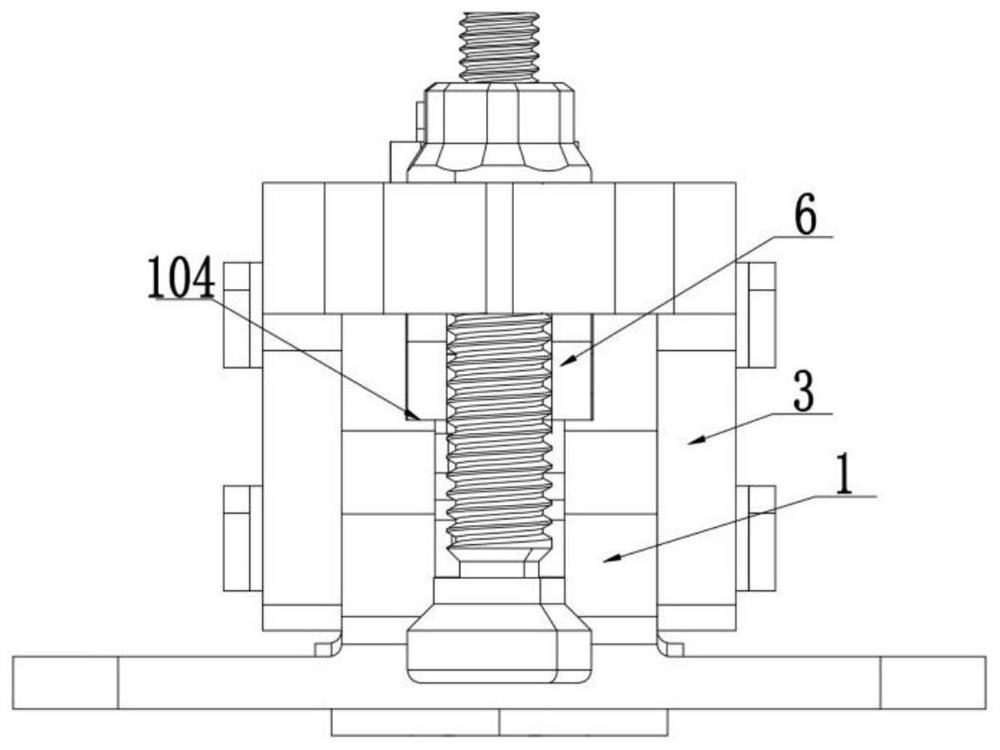

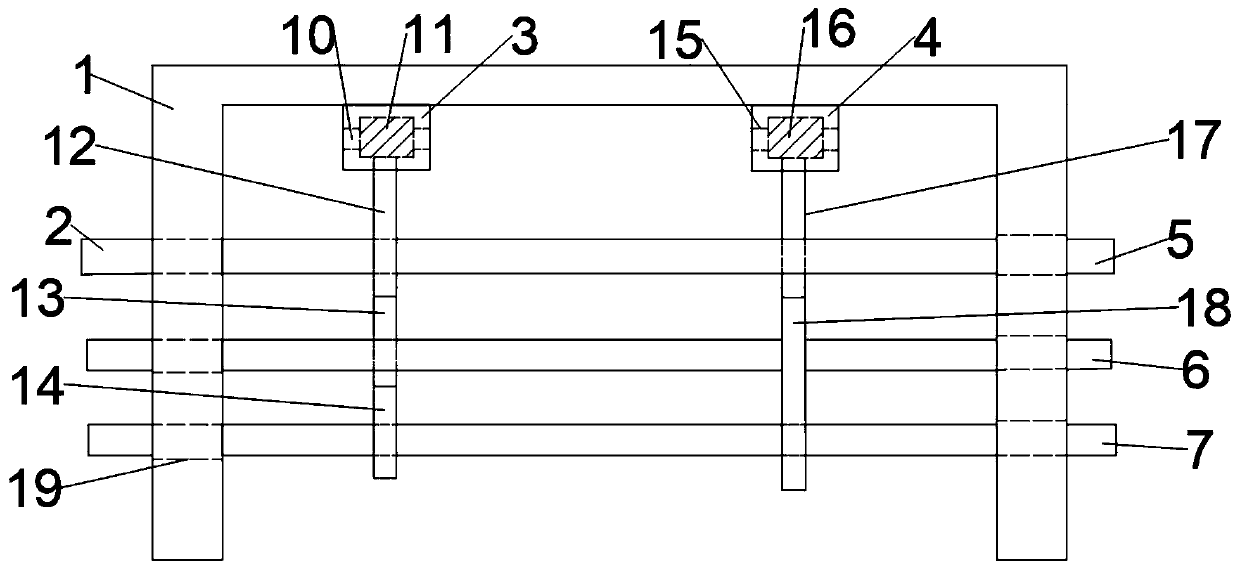

Stepless latching mechanism for press slider

PendingCN113103654ARealize stepless self-lockingDoes not affect axial movementPress ramStructural engineeringMechanical engineering

The invention discloses a stepless latching mechanism for a press slider and belongs to the field of press slider locking devices. The stepless latching mechanism can lock any portion of a latching rod to achieve stepless self-locking of the press slider. The stepless latching mechanism for the press slider comprises a shell, wherein the latching rod used for being connected with the press slider is arranged in the shell, at least two clamping blocks are arranged on the periphery of the latching rod at intervals, wedge blocks located on the outer sides of the at least two clamping blocks and extrusion pieces controlling the corresponding wedge blocks to move in an axial direction of the latching rod are arranged in the shell, and the wedge blocks control the at least two clamping blocks to clamp or loosen the latching rod when sliding in the axial direction of the latching rod. For the stepless latching mechanism, the wedge blocks are controlled to ascend and descend by controlling ascending and descending of the extrusion pieces, and stepless self-locking of the press slider is achieved.

Owner:HUZHOU MACHINE TOOL WORKS

A gear interlocking device for automobile transmission

The invention discloses a gear interlocking device for an automobile transmission. The gear interlocking device comprises an installing seat. Shifting fork shafts are installed on the side face of theinstalling seat, a first shaft seat and a second shaft seat are fixedly installed on the bottom face of the installing seat, the shifting fork shafts comprise the first shifting fork shaft, the second shifting fork shaft and the third shifting fork shaft, and first grooves are formed in the outer sides of the left ends of the first shifting fork shaft, the second shifting fork shaft and the thirdshifting fork shaft correspondingly; second grooves are formed in the outer sides of the right ends of the first shifting fork shaft and the third shifting fork shaft correspondingly, the first shaftseat is provided with a left shaft sleeve through a left fixing shaft, and a first clamping rod, a second clamping rod and a third clamping rod are fixedly installed on the outer side of the left shaft sleeve; and the second shaft seat is provided with a right shaft sleeve through a right fixing shaft, and a first limiting rod and a third limiting rod are installed on the outer side of the rightshaft sleeve. According to the gear interlocking device, the structure is simple, less space is occupied, the structure is compact, the service life of the interlocking device is long, and an automobile can travel more stably; and the axial movement of the shifting fork shafts is stable, the interlocking effect of the interlocking device is good, the machining requirement is low, and the cost is low.

Owner:LIXIN COUNTY YURUO INFORMATION TECH CO LTD

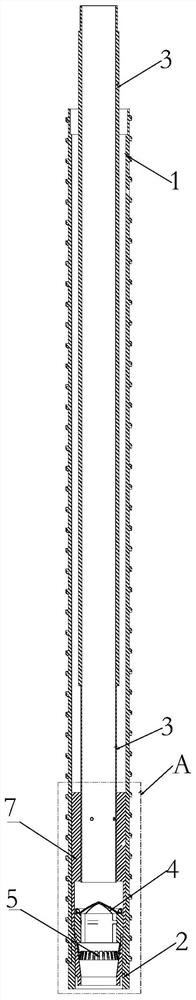

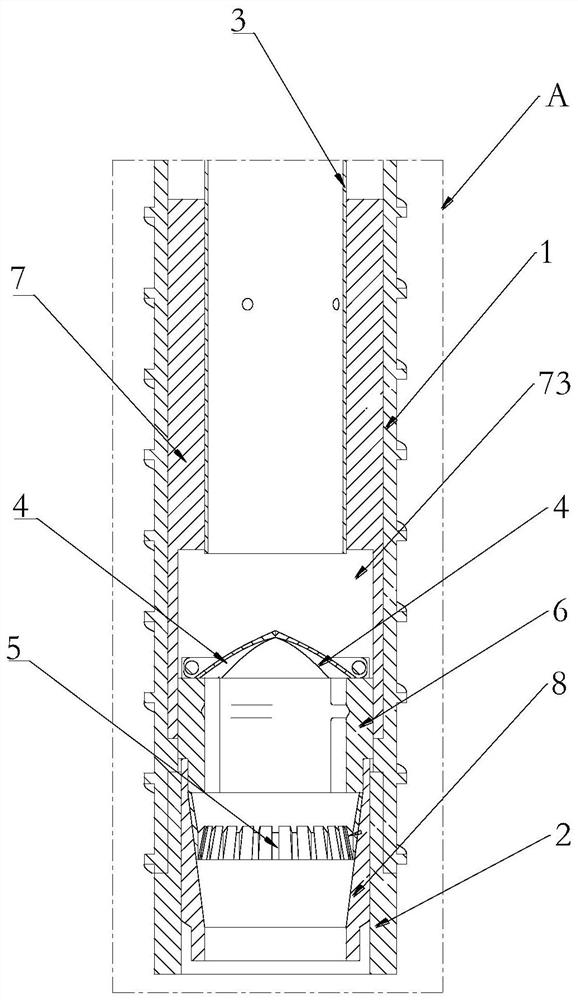

A drill pipe for deep sampling of lunar soil with sample locking function

ActiveCN111911088BQuick extractionEasy extractionDrilling rodsDrilling casingsSoil scienceLunar soil

The invention relates to a lunar soil deep sampling drill pipe with a sample locking function, comprising a drill pipe body, a sample locking structure and an internal coring tube, the sample locking structure is provided with a sample blocking mechanism; the internal coring tube and The sample locking structures are respectively sleeved in the drill pipe body and can move axially relative to the drill pipe body. A pin is provided on the outer wall of one end of the inner core tube, and a pin is provided on the inner wall of the sample locking structure. Limiting chute, one end of the inner core tube is sleeved in the sample locking structure, and the pin is slidably arranged in the limit chute; the inner core tube is locked relative to the sample The axial movement of the structure makes the sample blocking mechanism change from being stretched by the inner core tube to a closed state. The lunar soil deep sampling drill pipe of the present invention adopts a double-layer drill pipe structure, and the external threaded drill pipe can effectively improve the drilling efficiency. The inner core pipe adopts a polished rod with a sample locking structure, which can extract samples more quickly .

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

Gear interlocking device for automobile transmission

ActiveCN107763210ANot easy to damageSolution to short lifeGearing controlEngineeringMechanical engineering

The invention discloses a gear interlocking device for an automobile transmission. The gear interlocking device comprises an installing seat. Shifting fork shafts are installed on the side face of theinstalling seat, a first shaft seat and a second shaft seat are fixedly installed on the bottom face of the installing seat, the shifting fork shafts comprise the first shifting fork shaft, the second shifting fork shaft and the third shifting fork shaft, and first grooves are formed in the outer sides of the left ends of the first shifting fork shaft, the second shifting fork shaft and the thirdshifting fork shaft correspondingly; second grooves are formed in the outer sides of the right ends of the first shifting fork shaft and the third shifting fork shaft correspondingly, the first shaftseat is provided with a left shaft sleeve through a left fixing shaft, and a first clamping rod, a second clamping rod and a third clamping rod are fixedly installed on the outer side of the left shaft sleeve; and the second shaft seat is provided with a right shaft sleeve through a right fixing shaft, and a first limiting rod and a third limiting rod are installed on the outer side of the rightshaft sleeve. According to the gear interlocking device, the structure is simple, less space is occupied, the structure is compact, the service life of the interlocking device is long, and an automobile can travel more stably; and the axial movement of the shifting fork shafts is stable, the interlocking effect of the interlocking device is good, the machining requirement is low, and the cost is low.

Owner:LIXIN COUNTY YURUO INFORMATION TECH CO LTD

A cleaning nozzle assembly and a self-cleaning bathtub

ActiveCN110420765BIncrease the cleaning areaGood effectBathsDouchesEnvironmental engineeringMechanical engineering

A cleaning nozzle assembly and a self-cleaning bathtub, including a bracket, a nozzle and a rotating drive assembly; the bracket is provided with a water inlet channel; There are a first spray hole and a second spray hole, and the rotary drive assembly is connected to drive the spray head to rotate within a certain angle range to output a double-layer fan-shaped cleaning water curtain. The invention has few components, simple structure, large cleaning area and good cleaning effect.

Owner:JOMOO KITCHEN & BATHROOM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com