Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

A technology of rolling support and thermal insulation pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

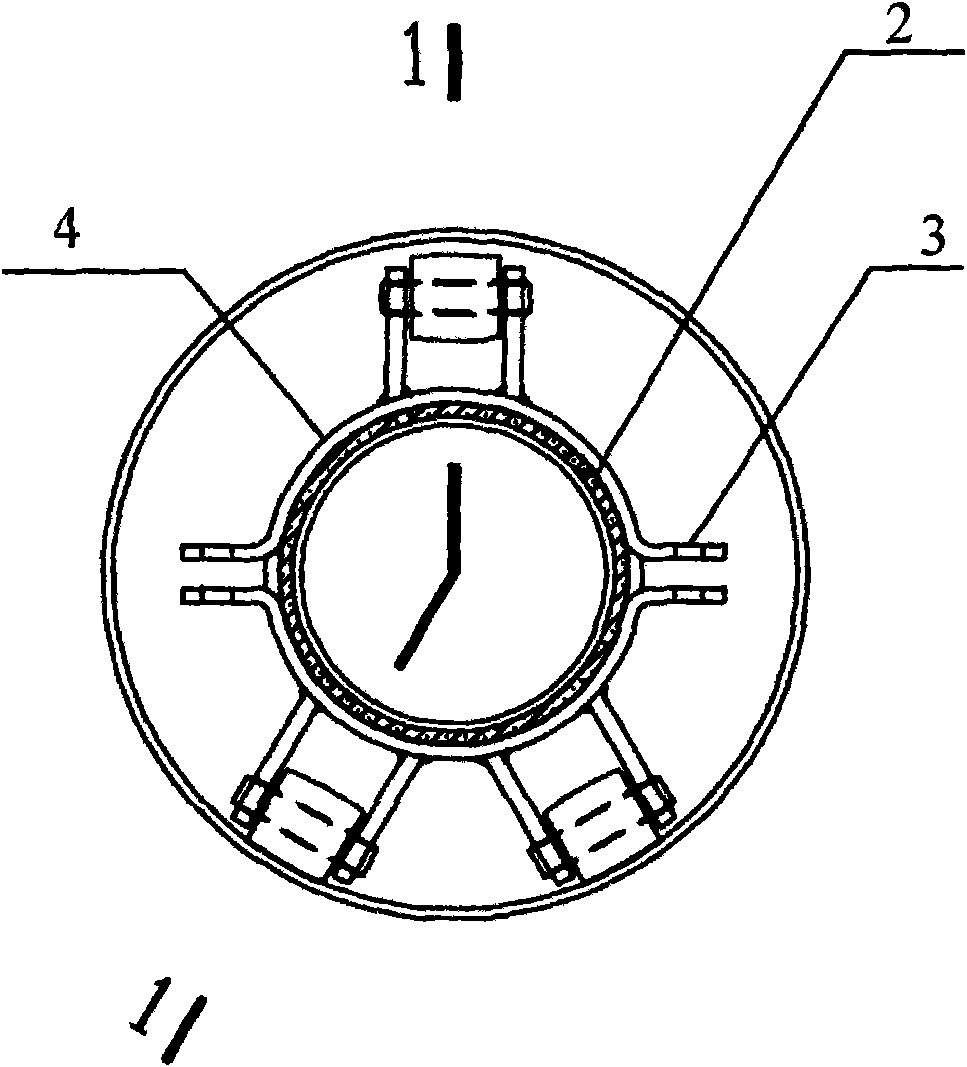

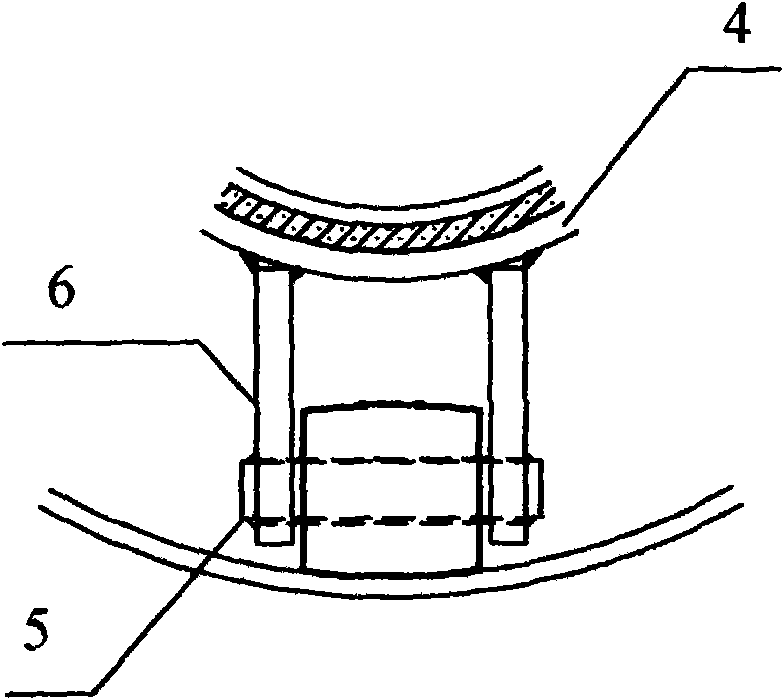

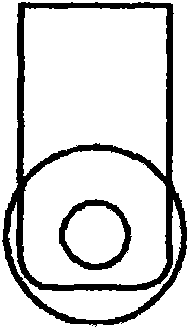

[0021] control Figure 1-4 , to illustrate the specific technical solutions of the present invention. In this embodiment, the steel jacketed steel steam insulation pipeline includes: an inner sleeve steel pipe with a diameter of 219 mm; The thickness of the material is 9 mm (high-strength heat-resistant asbestos rubber); the rolling support mechanism located between the outer heat insulation material and the outer steel pipe; The insulation material is ultra-fine glass wool tube shell, which is wrapped with double-layer staggered seams. The outer diameter of the insulation layer is smaller than the inner diameter of the jacket steel pipe, and an air layer is formed between the two; Air valve, through the exhaust valve, the air layer can be converted into a vacuum layer; the anti-corrosion layer (3PE) is set on the outer steel pipe. The rolling support mechanism includes:

[0022] The upper steel hoop and the lower steel hoop bent into the outer circle of the inner sleeve st...

Embodiment 2

[0026] In this embodiment, the steel jacketed steel steam insulation pipeline includes: an inner sleeve steel pipe with a diameter of 108 mm; The thickness of the thermal material is 6 mm (high-strength heat-resistant asbestos rubber); the rolling support mechanism located between the outer heat insulation material and the outer steel pipe; Insulation material, the insulation material is an ultra-fine glass wool tube shell, which is wrapped with double-layer staggered seams. The outer diameter of the insulation layer is smaller than the inner diameter of the jacket steel pipe, and an air layer is formed between the two; it is located on the jacket steel pipe and communicated with the air layer Exhaust valve, through the exhaust valve, the air layer can be converted into a vacuum layer; the anti-corrosion layer (3PE) is set outside the jacket steel pipe. The rolling support mechanism includes:

[0027] The upper steel hoop and the lower steel hoop bent into the outer circle of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com