Adjustable continuous injector

A syringe and injection volume technology, applied in veterinary instruments, medical science, etc., can solve the problems of unstable movement of the core rod, gap generation, inaccurate injection volume control, etc., and achieve long service life, reasonable structure, and control stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

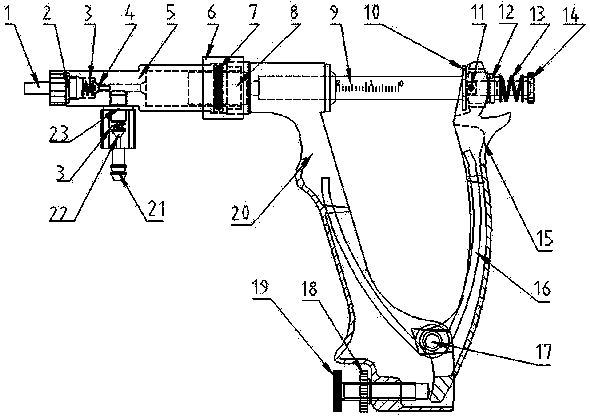

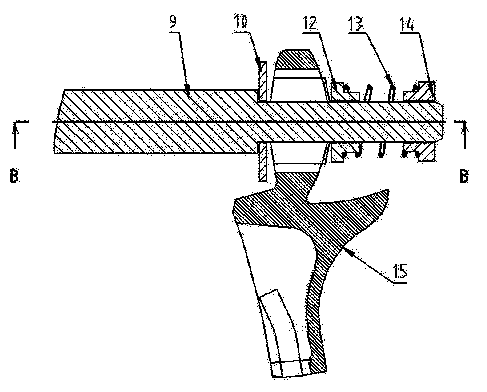

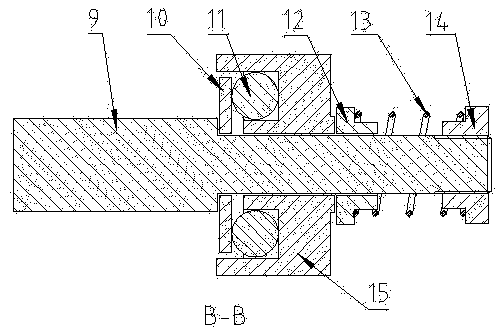

[0015] From figure 1 It can be seen from the figure that an adjustable continuous syringe includes a sleeve 5, a piston 8, a core rod 9, a fixed handle 20, a movable handle 15, an adjusting screw 19, and the like. The piston 8 is installed on the front end of the core rod 9, driven by the core rod 9 to move in the sleeve 5, the front end of the sleeve 5 is provided with a needle seat 1, and a gasket 2, a spring 3, Check valve 4. The cavity of the sleeve 5 is also connected to a connector 21 through a connecting nut 23, and a one-way suction valve 22 and a spring 3 are housed in the connector 21 for connecting an infusion hose or an infusion bottle. The above composition structure is basically the same as that of the prior art and will not be described in detail.

[0016] The rear part of the sleeve 5 of the present invention is connected and fixed to the handle 20 through the connecting sleeve 6 and the sealing ring 7 . The piston 8 cooperates with the sealing ring 7 for se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com