Gear interlocking device for automobile transmission

A technology of automobile transmission and interlocking device, which is used in transmission control, components with teeth, belt/chain/gear, etc., can solve the problem of damage to the internal gear of the transmission, the length of the spring should not be too long, the interlocking device is not sensitive, etc. problems, to achieve the effect of less space, long life of the interlocking device, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

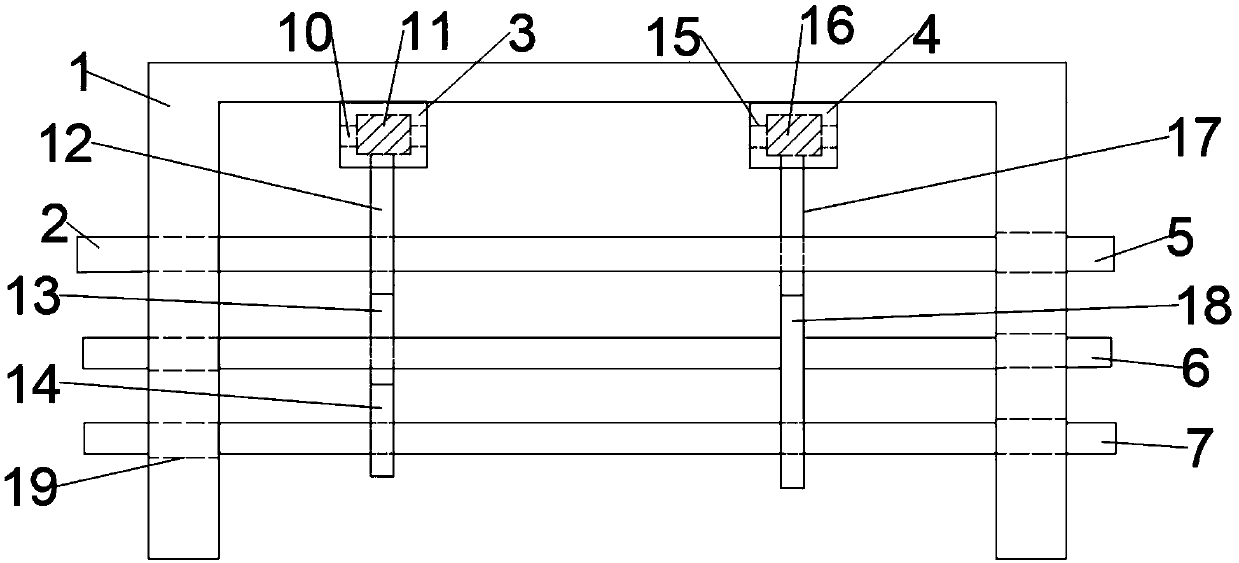

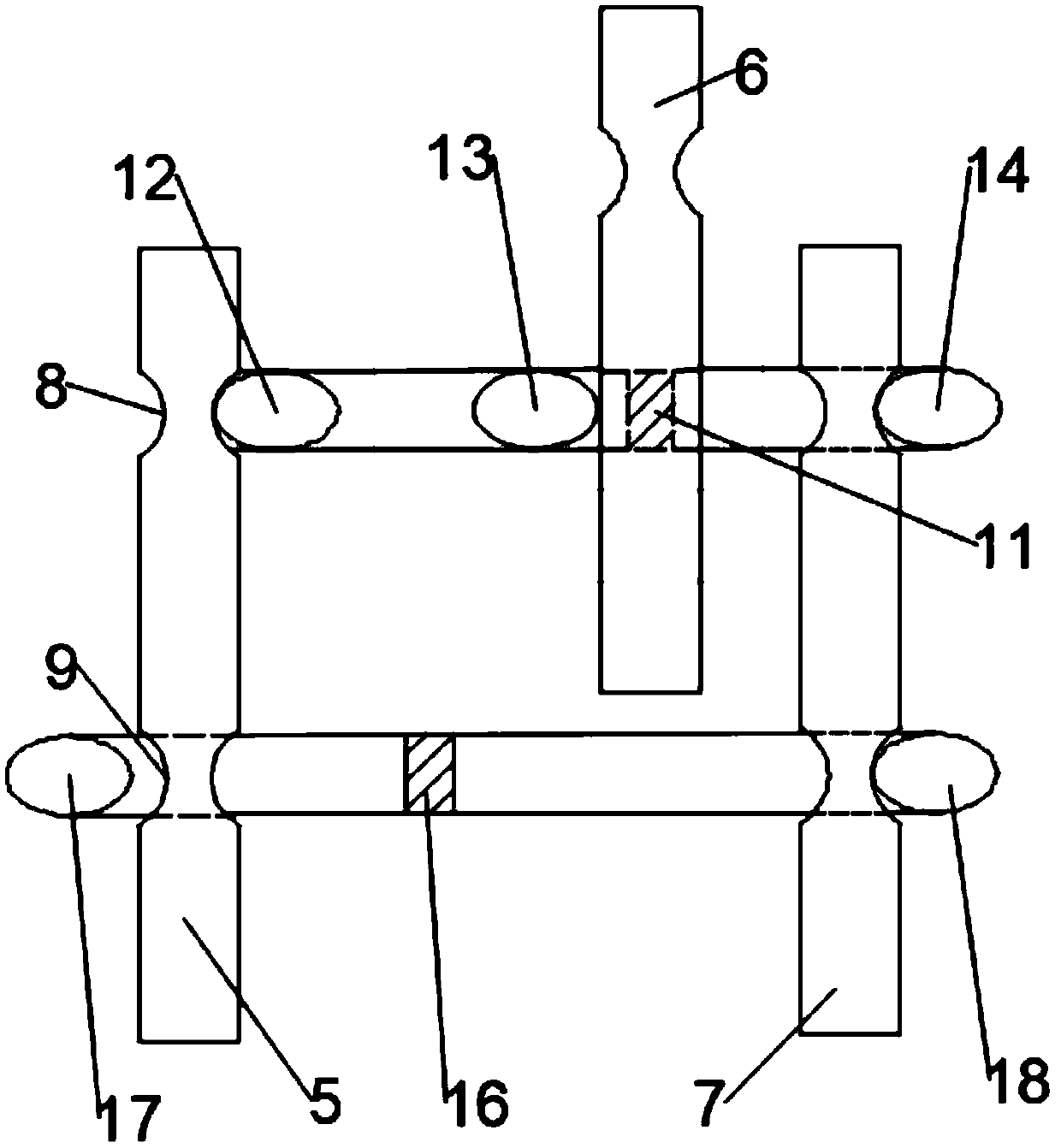

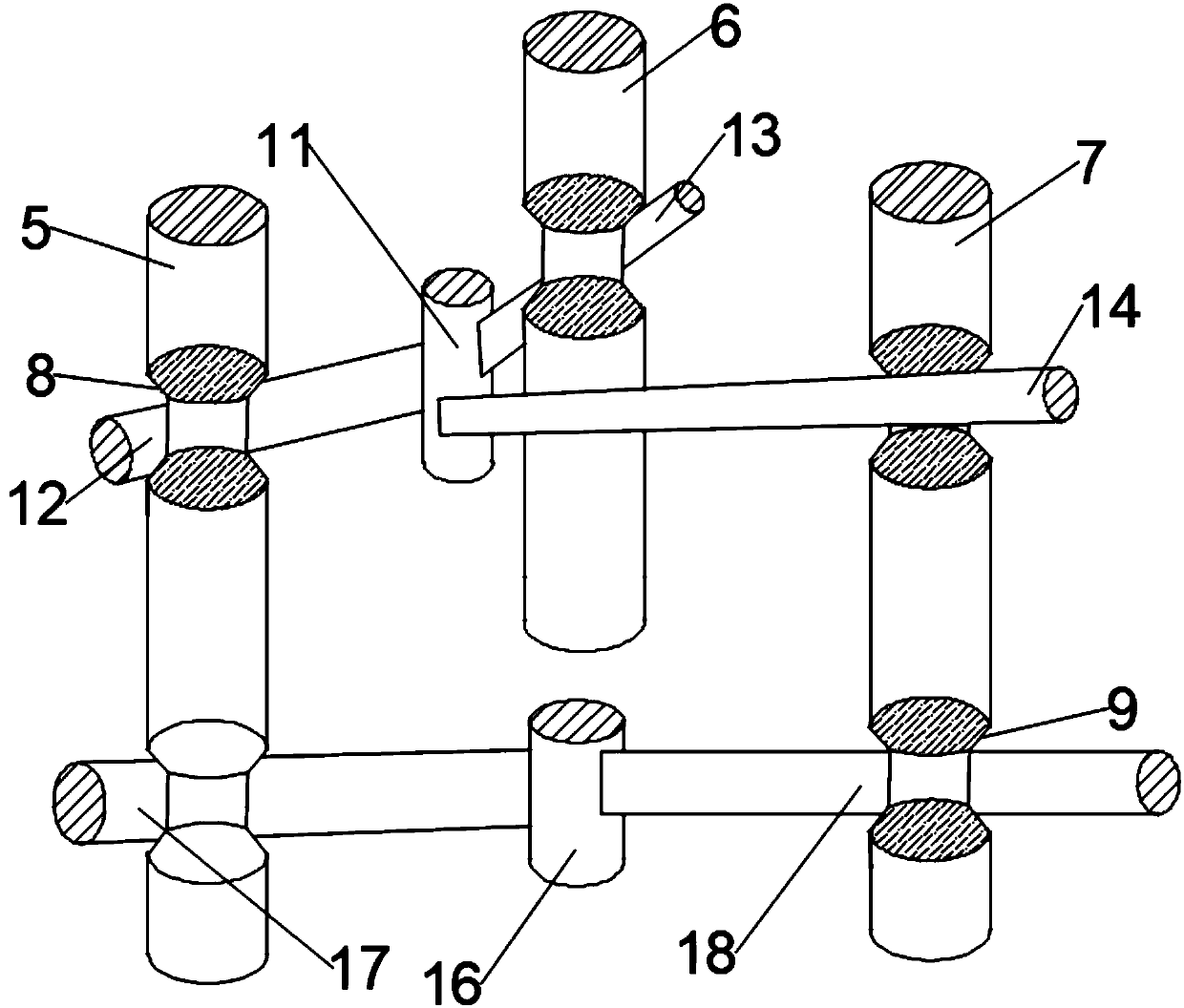

[0026] Such as figure 1 As shown, the present invention provides a gear interlocking device for an automobile transmission, including a mounting base 1, which is fixedly installed in the mounting frame at the bottom of the automobile, and a shift fork shaft 2 is installed on the side of the mounting base 1, The shift fork shaft 2 is also called the gear shift shaft. A shift fork is installed on the outside of the shift fork shaft 2. The shift fork shaft 2 moves axially so that the shift fork is connected to a certain gear so that the car can shift gears. The section of the end of the mounting seat 1 The shape is U-shaped, and the U-shaped mounting seat 1 saves space, and is more convenient to install the shift fork shaft 2. The side of the mounting seat 1 is provided with a mounting hole 19, and the shift fork shaft 2 is inserted in the mounting hole 9. The shift fork shaft 2 slides left and right in the installation hole 19, and the installation hole 19 restricts the shift fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com