Steel-sleeve steel steam insulation pipe elbow and rolling supporting mechanisms at end part and middle part thereof

A technology of thermal insulation pipeline and rolling support, applied in pipeline support, pipeline protection through thermal insulation, thermal insulation, etc., can solve the problems of large deformation of inner sleeve steel pipe, left and right drift, etc., to save welding, reduce the number of welding peaks, and reduce leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

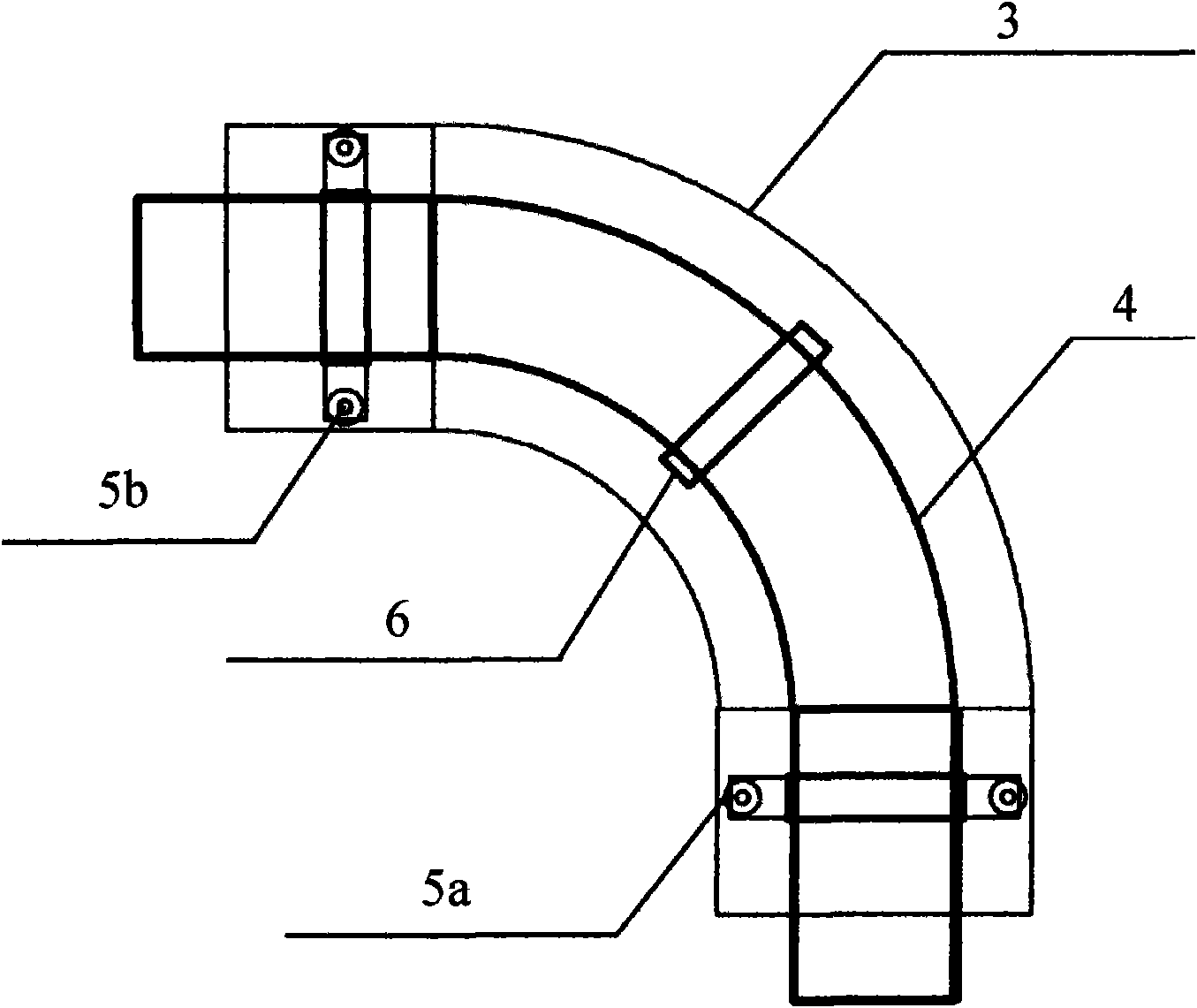

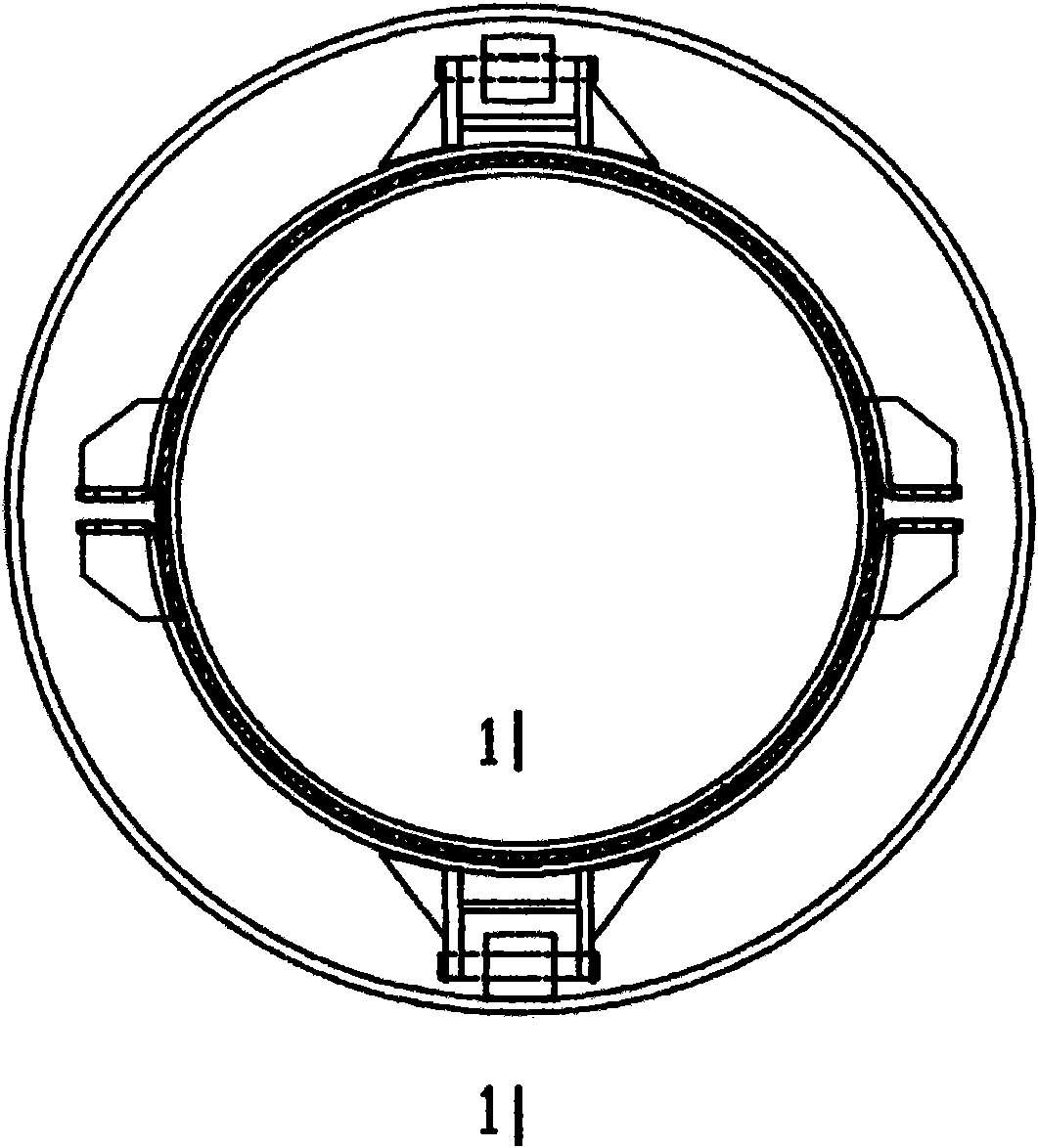

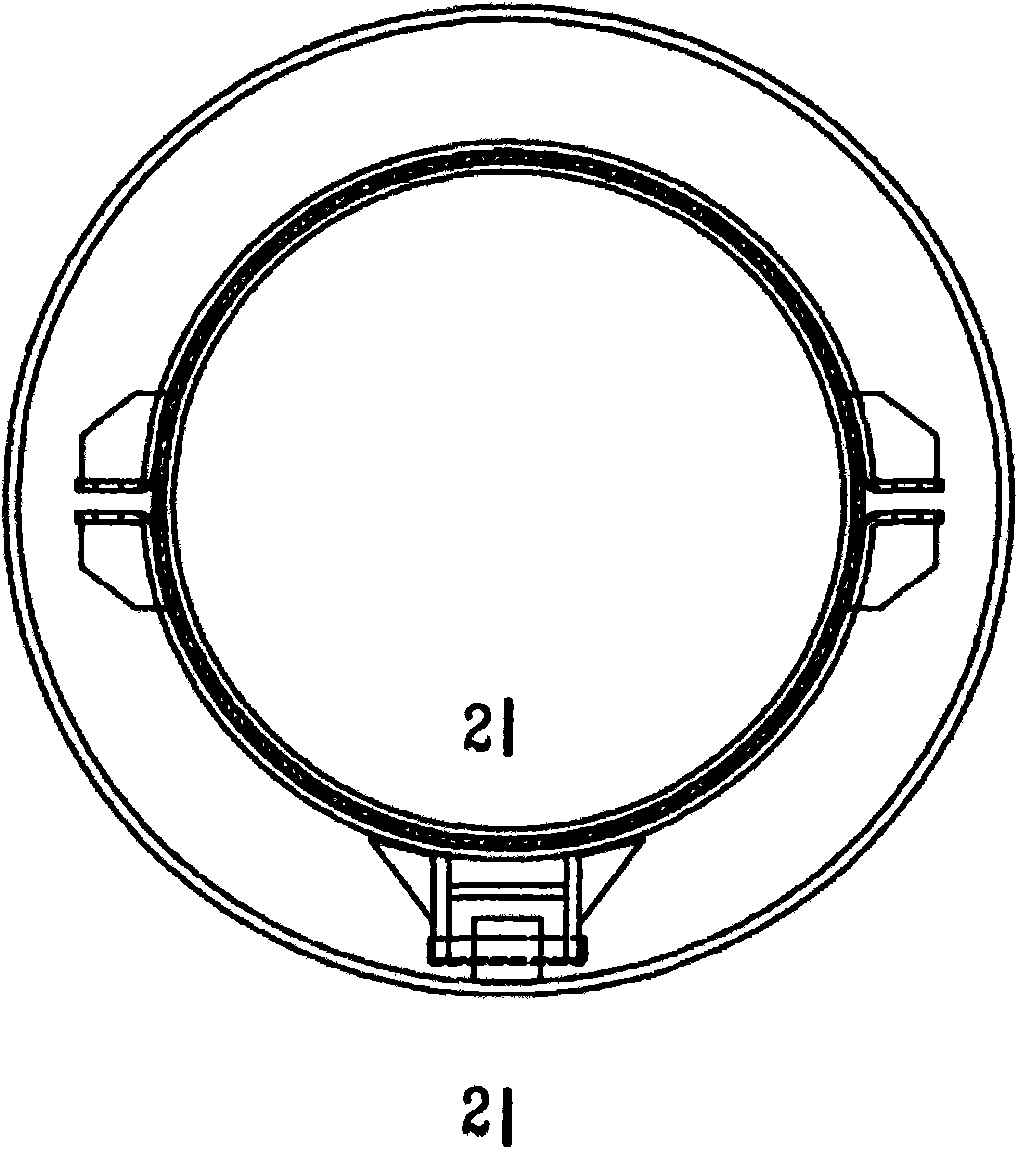

[0021] control Figure 1-4 , to illustrate the specific technical solutions of the present invention. In this embodiment, the steel-sheathed steel steam insulation pipe elbow includes:

[0022] Outer steel pipe (Q235B) with a diameter of 529 mm and an arc of 90 degrees; an inner steel pipe (Q235B) with a diameter of 273 mm coaxial with the outer steel pipe; a straight pipe extending outside the arc sections at both ends of the inner steel pipe , the straight pipe and the arc section are integrated; it also includes: two end rolling support mechanisms respectively located on the straight pipes at both ends of the inner sleeve steel pipe; the middle rolling support mechanism located in the middle of the inner sleeve steel pipe arc section; The thermal insulation material placed between the rolling support mechanism and the inner steel pipe; the thermal insulation material that is placed outside the inner steel pipe and between the rolling support mechanisms of the steel-steel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com