Rotary button lock

A rotary, push-button technology, applied in the field of aircraft flap locks, can solve the problems of inability to meet the use requirements of military products, large operating space and opening size, and unchanged operation, and achieve fast, reliable, and good aerodynamic unlocking and locking operations. Appearance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

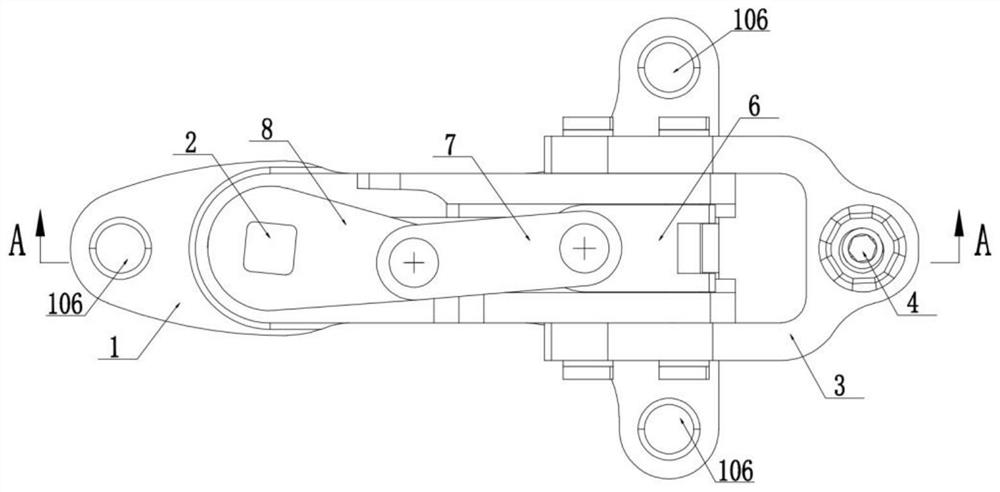

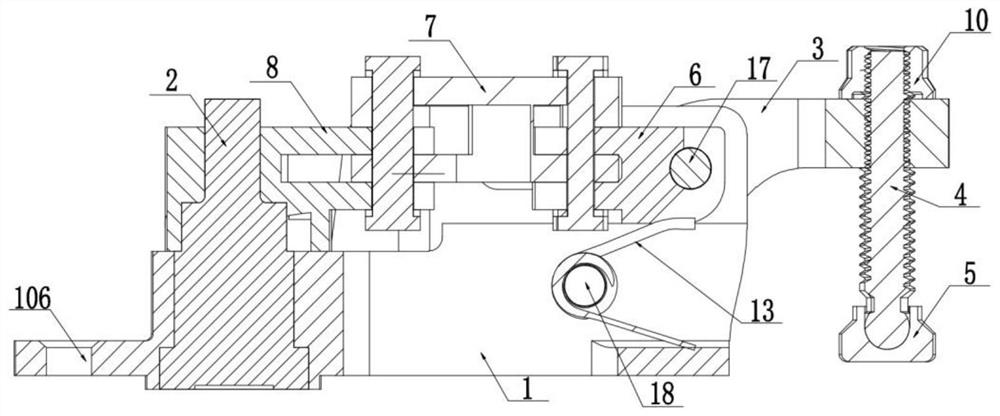

[0057] Example 1, such as Figure 1-Figure 7 As shown, a rotary button lock includes a lock base 1, a driver 2 disposed on the lock base 1, a swing arm 8, a slider 6, a support 3 and a pressure head, and one side of the lock base is provided with a drive The other side of the socket 101 is provided with a chute 102, the driver is set in the drive socket, the slider is installed in the chute, one end of the swing arm is connected to the driver, The other end is hinged with one end of the slider through the connecting rod 7, the support 3 is bent, one end of the support is hinged with the lock seat, the middle part is provided with a guide groove 301, and the other end is connected with the lock seat. The pressure head is connected, and the other end of the slider is provided with a pin 17, and the end of the pin extends into the guide groove.

[0058] The lock seat is provided with a long through hole 107 for the movement of the pin, and the pin passes through the long through...

Embodiment 2

[0067] Example 2, such as Figure 8-Figure 11 As shown, on the basis of Embodiment 1, the driving member 2 includes a shaft housing 201 and a push rod 202 inserted in the shaft housing, the shaft housing is sleeved in the driving socket, and the shaft A through groove 203 is provided on the shell, and a limit block 15 is arranged on the push rod, and the limit block extends into the through groove, and a return spring is arranged on the push rod below the limit block 12. The swing arm is connected to the axle housing. The return spring is sleeved on the push rod between the head of the push rod and the limit block. The function of the return spring is that when the wrench needs to be matched with the slot on the shaft shell, the compressed return spring will push up the push rod so that the shaft shell exposes the slot matched with the wrench. If the wrench is an outer hexagon, the slot will The hole is an inner hexagonal hole. After the wrench is adjusted, the return spring...

Embodiment 3

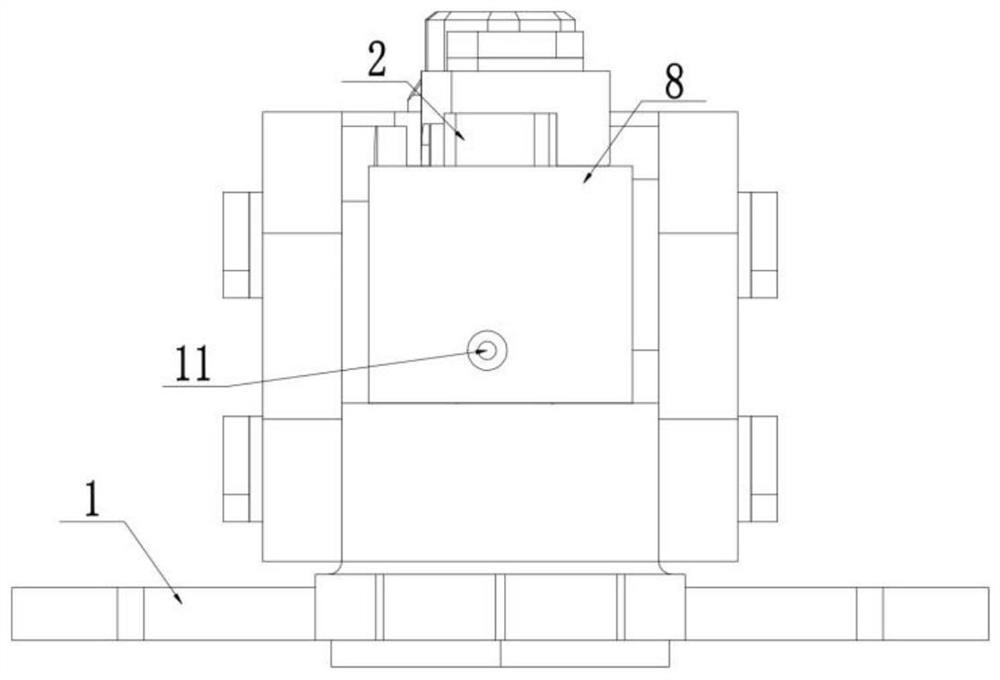

[0068] Example 3, such as Figure 12-Figure 26 As shown, on the basis of Embodiment 2, a locking mechanism is also included, and the locking mechanism includes a locking ball 9 and a locking spring 19. The locking groove 204 is used, the lock seat is provided with a locking positioning hole 103, and the locking ball and locking spring are installed in the locking positioning hole. When the driving part is an integral part, the locking groove is on the outer surface of the driving part; when the driving part includes a shaft housing and a push rod, the locking groove is on the outer surface of the shaft housing. The locking ball is stuck in the locking groove under the action of the locking spring, which can realize the complete locking of the button lock, and the locking of the button lock is more stable. When unlocking, when the rotational force reaches a certain value, the driving part can be unlocked from the locking ball and rotate with the swing arm, thereby improving th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com