Steel sheathed steel steam heat preserving pipeline and lateral displacement sliding support mechanism thereof

A technology for sliding support and thermal insulation pipelines, which is applied in the direction of thermal insulation protection of pipelines, thermal insulation, pipeline protection, etc. It can solve problems such as large thermal deformation, heat flow leakage, and insulation layer damage, and achieve good air permeability and the number of welds Reduce and save the effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

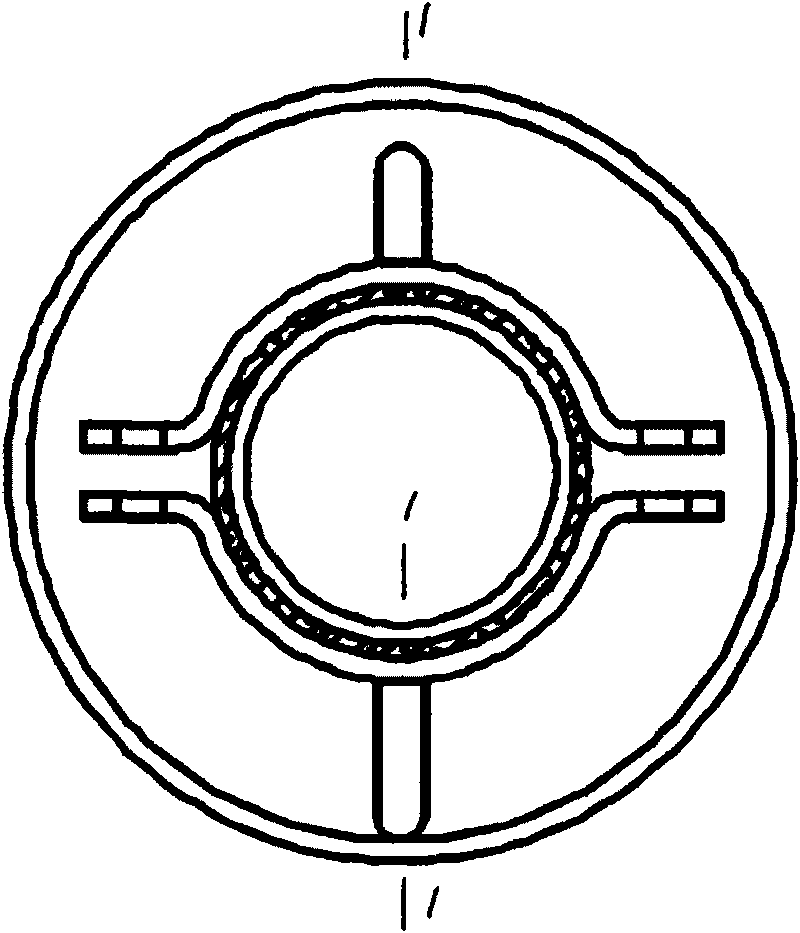

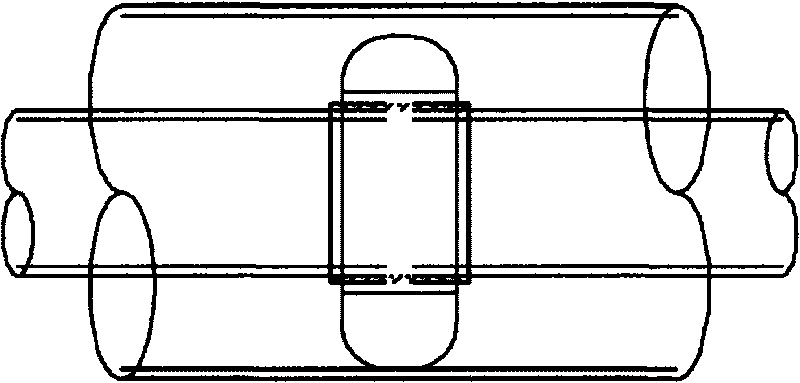

[0019] control figure 1 , image 3 , to illustrate the specific technical solutions of the present invention. In this embodiment, the steel jacketed steel steam insulation pipeline includes: an inner sleeve steel pipe with a diameter of 133 mm; The thickness of the thermal material is 3 mm (high-strength and temperature-resistant asbestos rubber); the rolling support mechanism located between the outer heat insulation material and the outer steel pipe; Insulation material, the insulation material is an ultra-fine glass wool tube shell, which is wrapped with double-layer staggered seams. The outer diameter of the insulation layer is smaller than the inner diameter of the jacket steel pipe, and an air layer is formed between the two; it is located on the jacket steel pipe and communicated with the air layer Exhaust valve, through the exhaust valve, the air layer can be converted into a vacuum layer; the anti-corrosion layer (3PE) is set outside the jacket steel pipe.

[0020]...

Embodiment 2

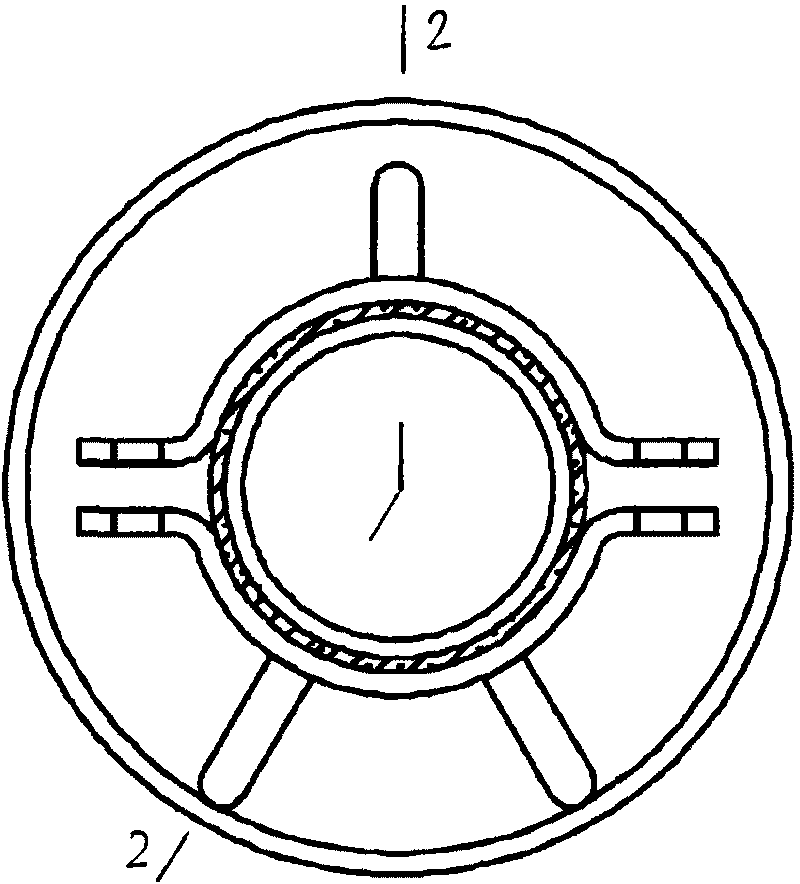

[0022] control figure 2 , image 3 , to illustrate the specific technical solutions of the present invention. In this embodiment, the steel jacketed steel steam insulation pipeline includes: an inner sleeve steel pipe with a diameter of 57 mm; The thickness of the thermal material is 3 mm (high-strength and temperature-resistant asbestos rubber); the rolling support mechanism located between the outer heat insulation material and the outer jacket steel pipe; Insulation material, the insulation material is an ultra-fine glass wool tube shell, (adopt double-layer staggered seam wrapping, the outer diameter of the insulation layer is smaller than the inner diameter of the jacket steel pipe, and an air layer is formed between the two; it is located on the jacket steel pipe and communicated with the air layer The exhaust valve, through the exhaust valve, can convert the air layer into a vacuum layer; the anti-corrosion layer (3PE) is set outside the jacket steel pipe.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com