Drainage device of steel-sleeve steel steam insulation pipe

A technology for thermal insulation pipelines and steel sleeves, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc. It can solve problems such as pipeline corrosion and accumulation, and achieve the advantages of improving strength, simplifying welding process, and improving thermal insulation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

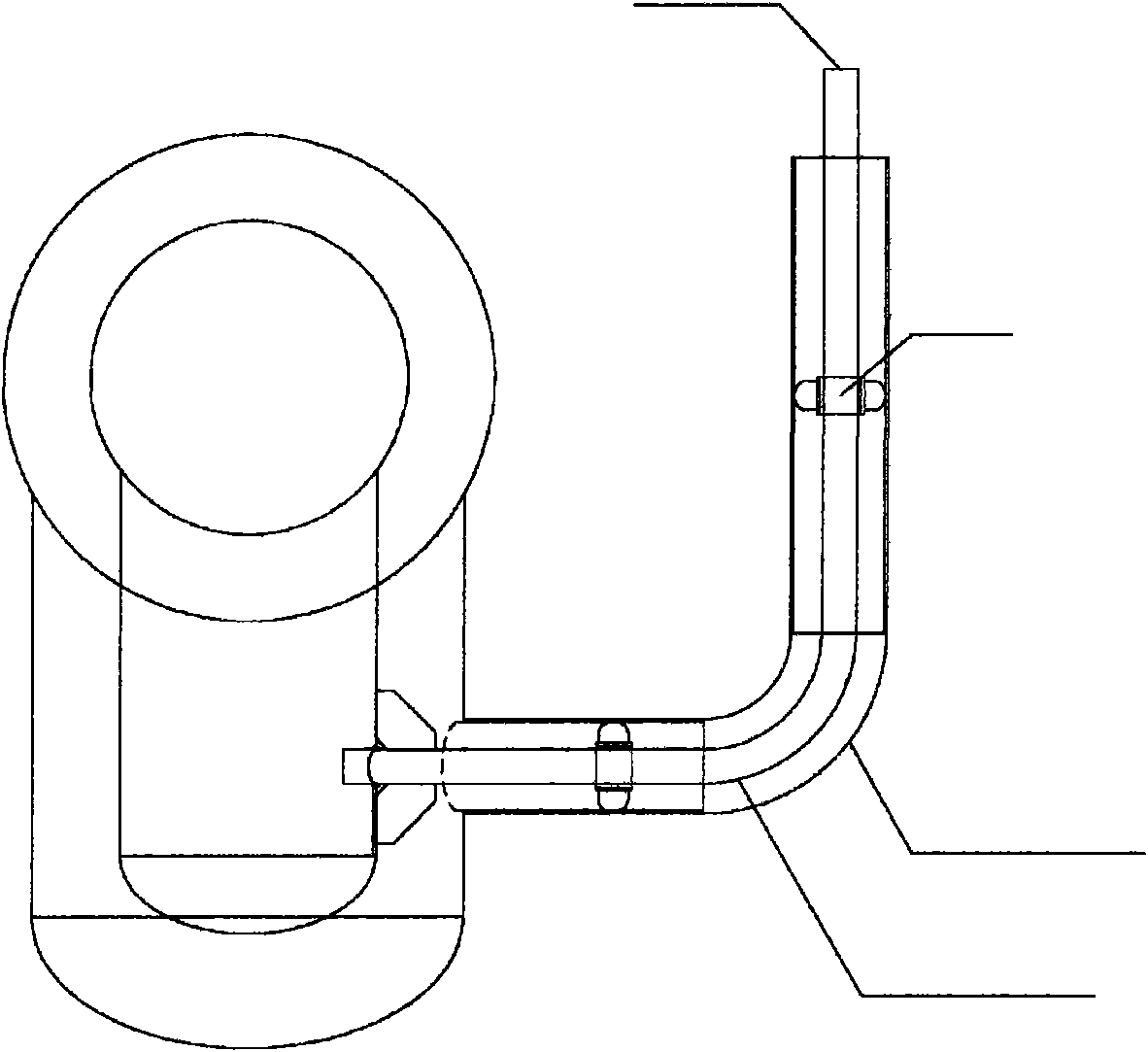

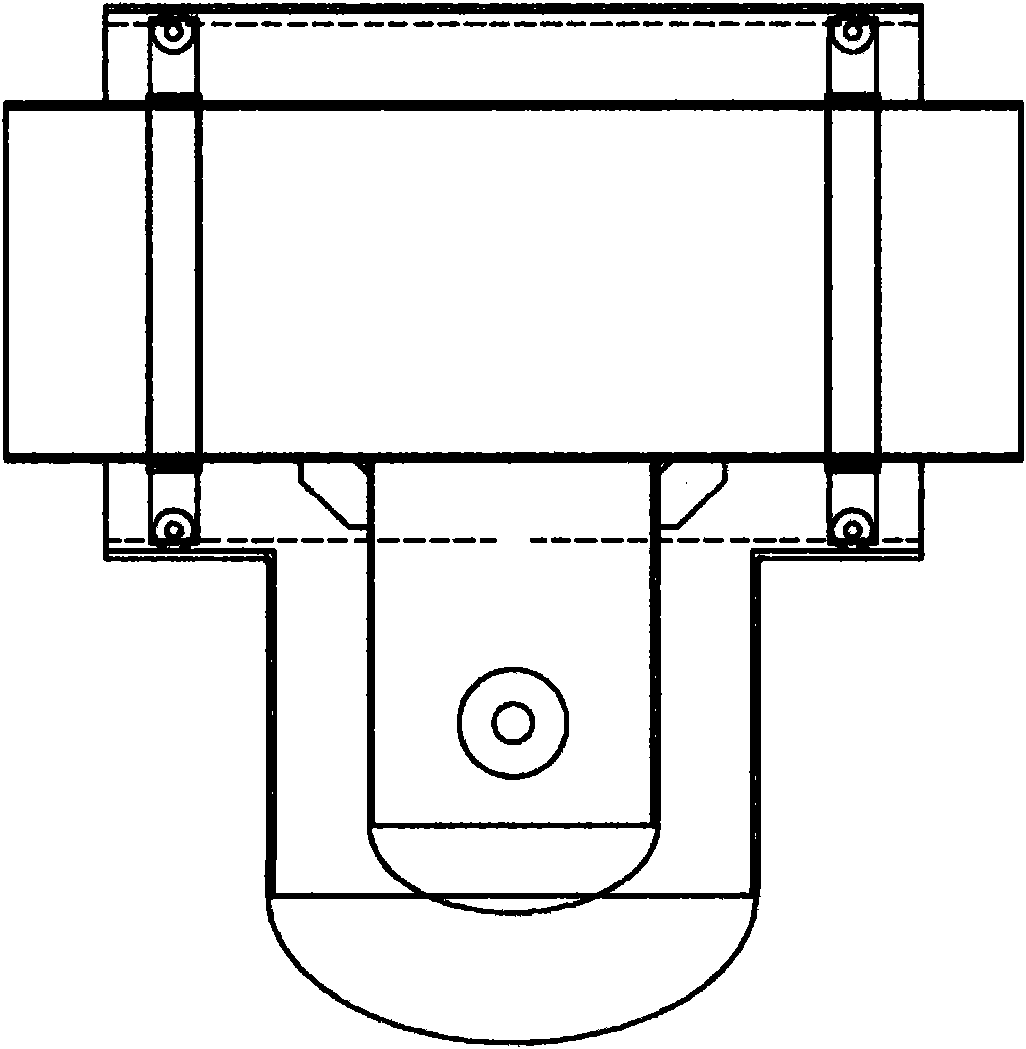

[0018] control Figure 1-2 , to illustrate the specific technical solutions of the present invention. In this embodiment, the steel jacketed steel steam insulation pipeline drainage device includes:

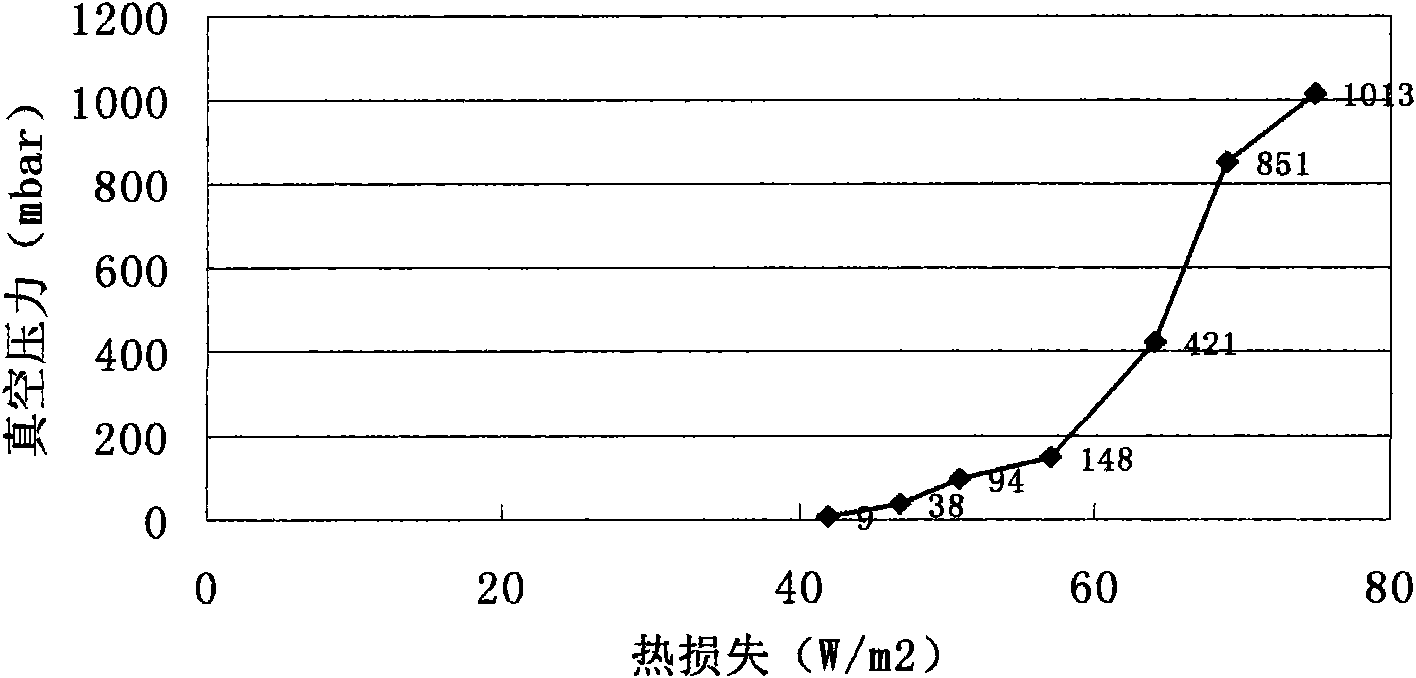

[0019] A piece of inner steel pipe (Q235B) with a diameter of 273mm; a piece of outer steel pipe (Q235B) with a diameter of 529mm matched with the inner steel pipe; the insulation material and supporting mechanism between the inner steel pipe and the outer steel pipe; The inner sleeve of the water collection tank in the middle of the steel pipe and directly below it vertically, the upper part of the inner sleeve of the water collection tank is connected with the inner steel pipe through the drain hole at the lower part of the inner steel pipe, the diameter of the drain hole is 8 mm, and the interval is 25 mm, and It is connected with the inner sleeve steel pipe by welding; the jacket of the water collection tank matched with the inner sleeve of the water collection tank; the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com