Hydraulic lifting bottom legs, washing machine with bottom legs and control method of washing machine

A technology of hydraulic lifting and washing machine, applied in the control device of washing machine, other washing machines, cleaning methods and utensils, etc., can solve the problems of strong, inconvenient user operation, loud noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

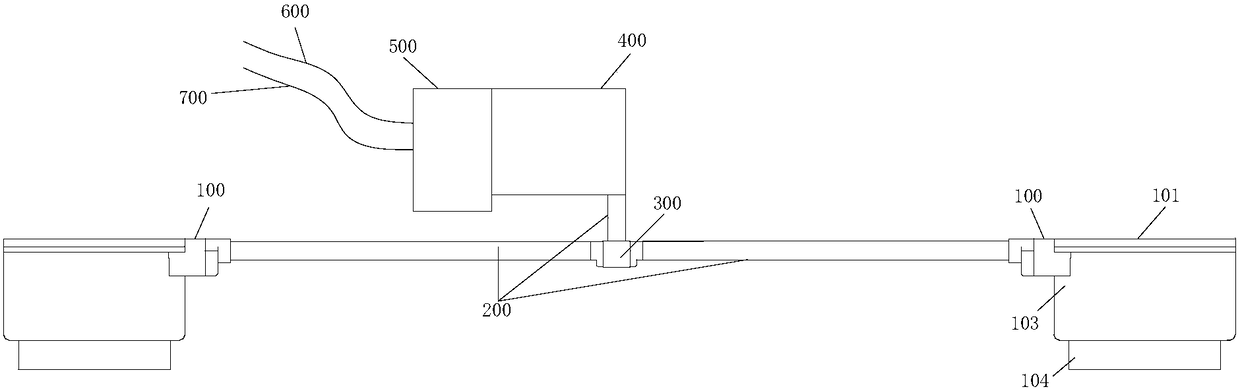

[0037] like figure 1 As shown, a hydraulic lifting foot of this embodiment is used for supporting and leveling household appliances, and includes a hydraulic foot 100, a communication device and a liquid storage device. The hydraulic foot 100 includes:

[0038] The fixing part is installed on the bottom of the household appliance;

[0039] The movable adjustment part is sleeved with the fixed part and can move axially relative to it;

[0040] There is an accommodating chamber for accommodating hydraulic medium between the fixed part and the movable regulating part;

[0041] At least two hydraulic feet 100 and the liquid storage device communicate with each other through the communication device: as the pressure changes, the hydraulic medium circulates between the hydraulic feet 100 and drives the movable adjustment part to move axially for leveling under the action of pressure; The hydraulic medium is injected / suctioned into the hydraulic foot through the liquid storage devi...

Embodiment 2

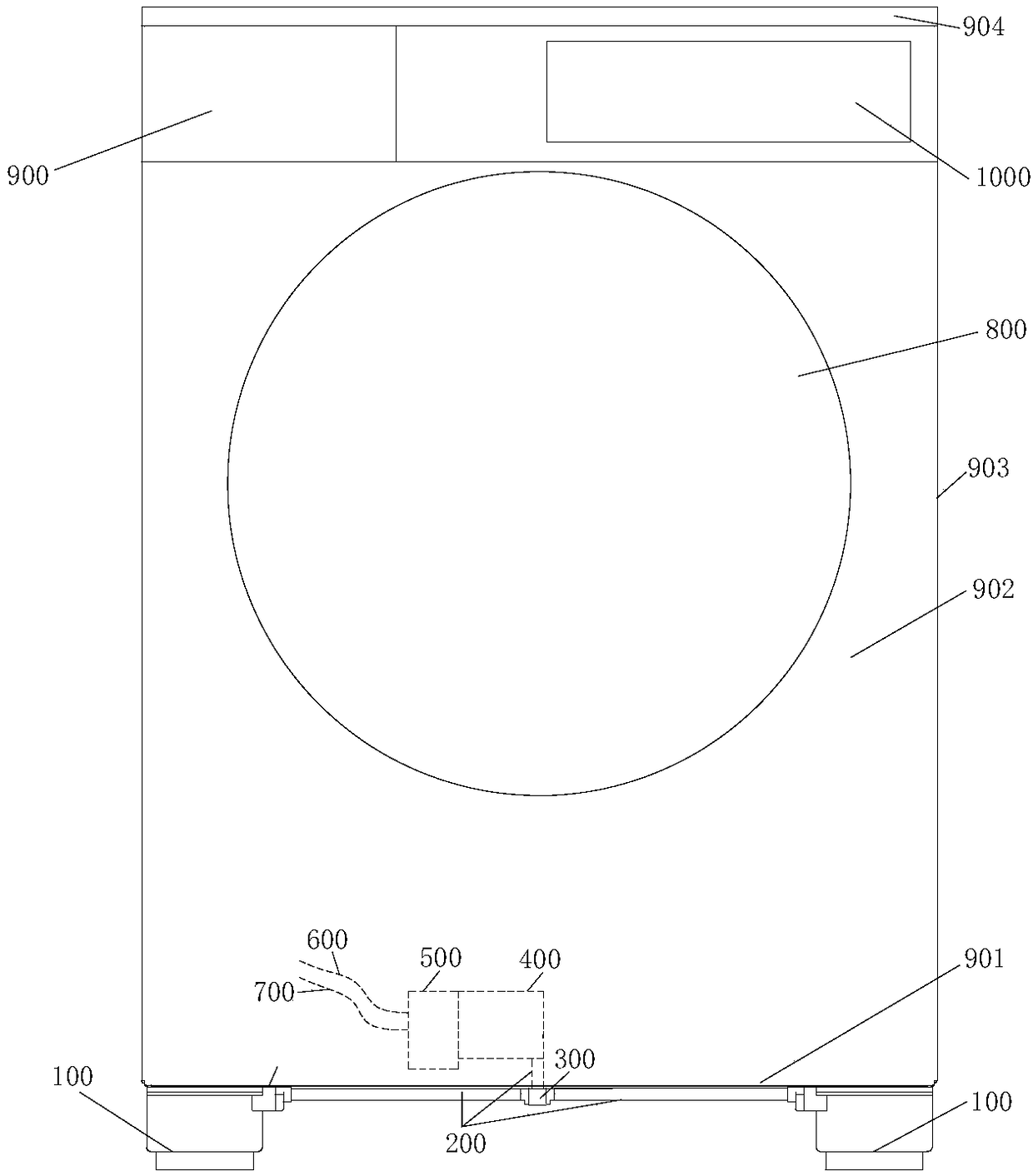

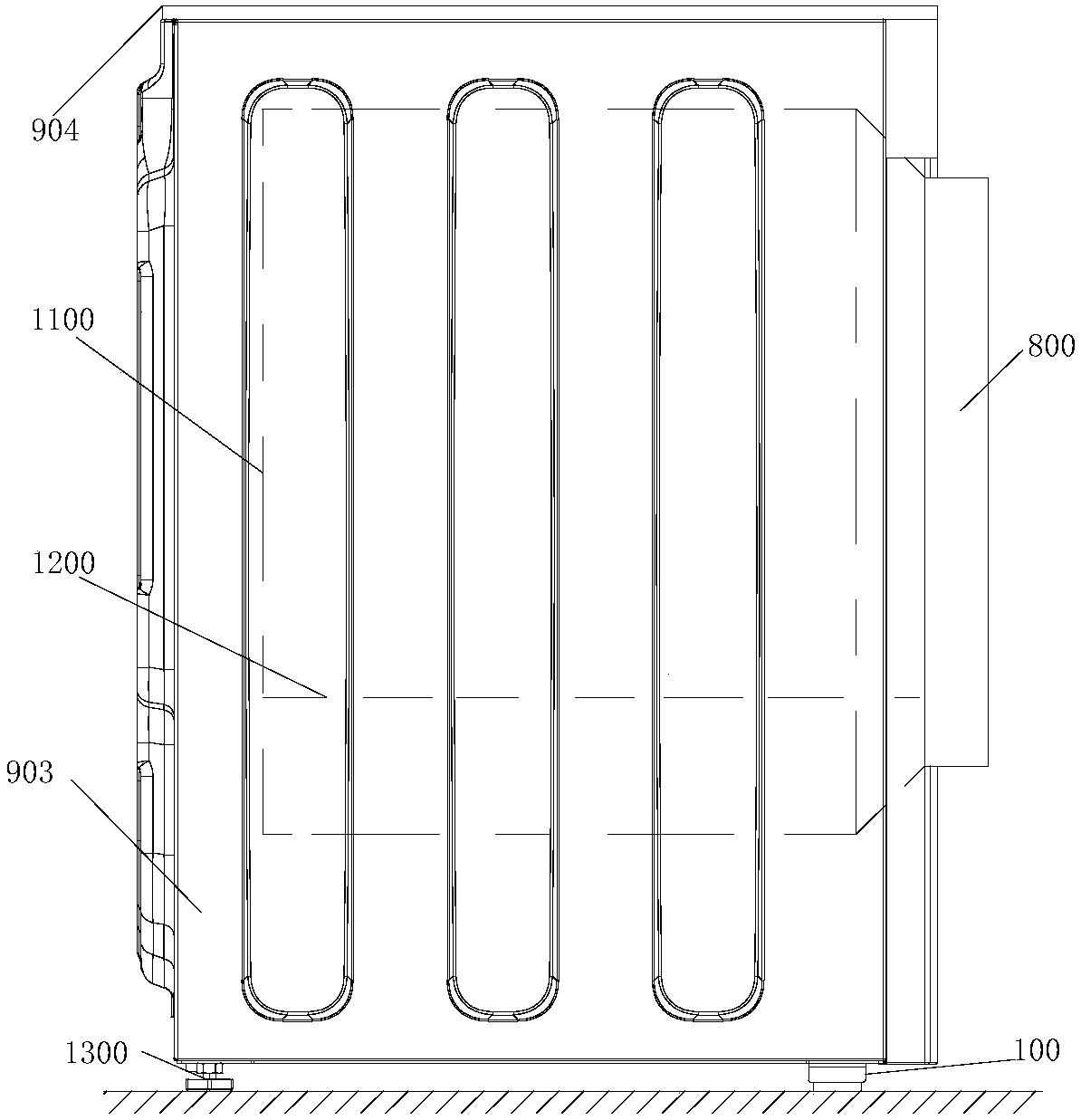

[0070] like Figure 1-Figure 4 As shown, in this embodiment, a washing machine with hydraulic lifting feet as described in Embodiment 1, the washing machine is a drum washing machine, including a housing and an openable / closable door 800 installed on the housing. The housing described above includes a front panel 902 and a bottom plate 901. A door opening is set on the front panel 902. The door body 800 is installed on the front panel 902 to close / open the door body opening. The hydraulic lifting feet are installed on the bottom plate. 901 and along a side intersecting with the front panel 902.

[0071] Further, the washing machine in this embodiment includes a controller 1000, the motor 500 of the liquid storage device is electrically connected to the controller 1000, and the controller 1000 controls the filling of the hydraulic medium into the hydraulic foot 100 by controlling the operation of the motor 500 Inside.

[0072] The motor 500 in this embodiment is connected to ...

Embodiment 3

[0084]This embodiment provides a control method for the washing machine as described in Embodiment 2. When the washing machine detects that the user needs to add clothes halfway and opens the door, if the water level is higher than the opening of the door, the liquid storage device is controlled to flow into the hydraulic foot. The hydraulic medium is injected to raise the support height of the hydraulic feet, and one side of the door body of the washing machine rises with the hydraulic feet, and the door is allowed to open when it is judged that the water level is lower than the opening of the door body.

[0085] Furthermore, when the washing machine detects that the user has finished adding clothes midway, the door closes, the motor controlling the liquid storage device is powered off, the hydraulic medium in the hydraulic feet gradually flows back into the liquid storage cylinder under the gravity of the washing machine, and the hydraulic pressure The automatic leveling of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com