Structure-optimized long-life tapered roller bearings

A tapered roller bearing, long-life technology, used in rolling contact bearings, rotating bearings, bearings and other directions, can solve the problems of accelerated bearing fatigue damage, large rib rupture, bearing failure, etc., to solve the problem of bearing damage, The effect of improving the strength of the rib and preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

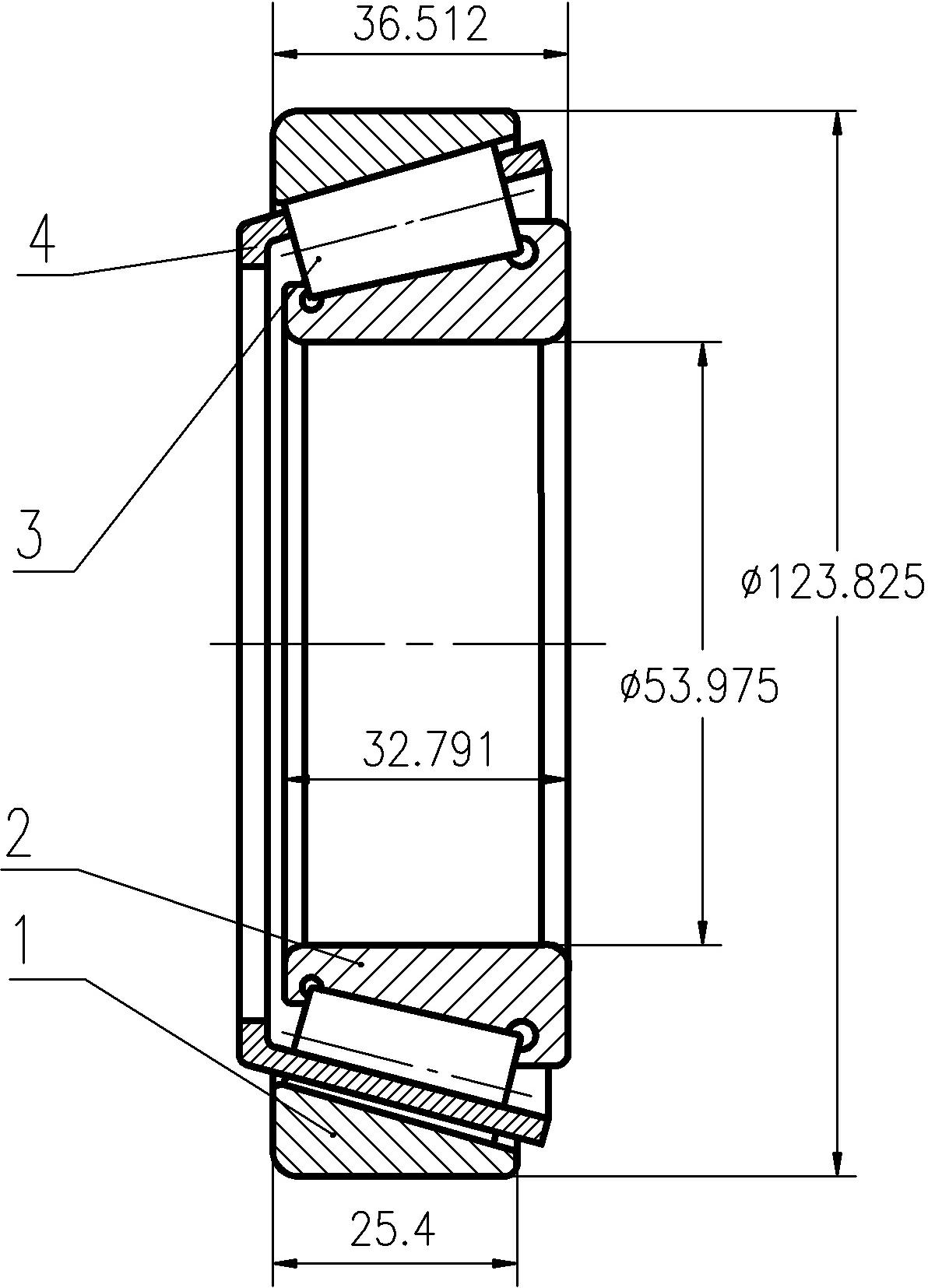

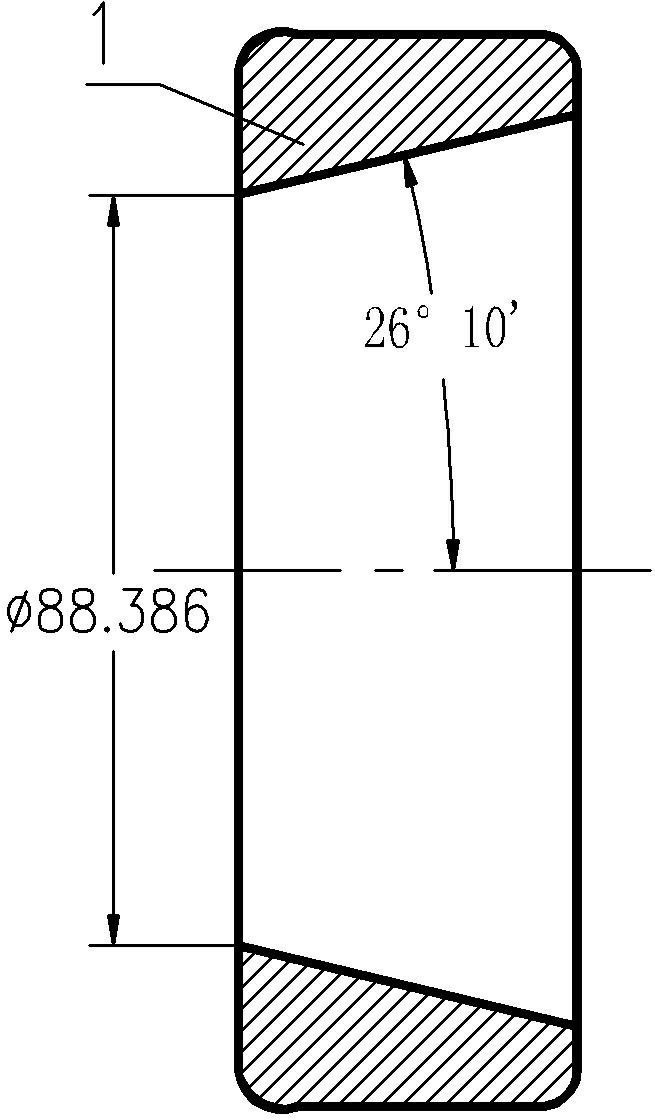

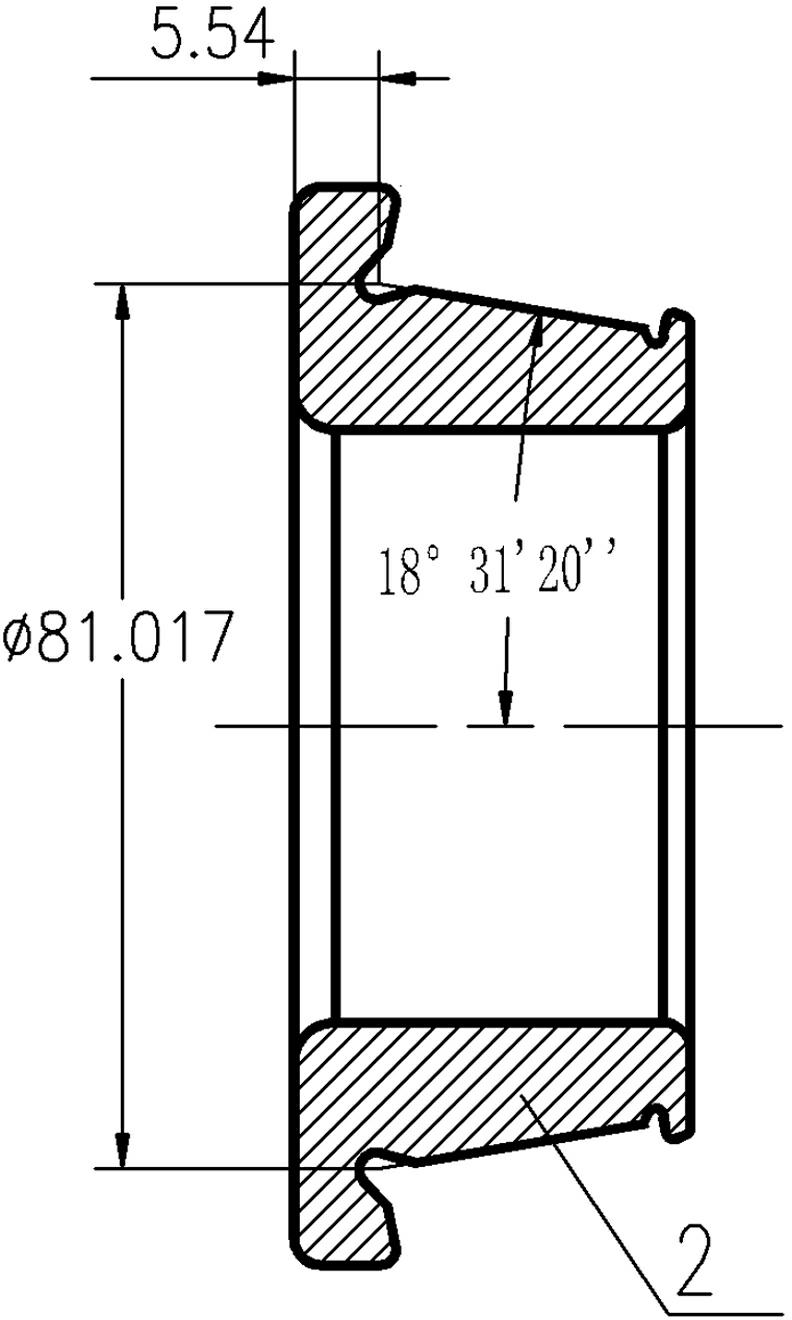

[0032] Such as Figure 1-Figure 4 Shown is a schematic diagram of a conventional tapered roller bearing of the prior art.

[0033] Such as Figure 5-Figure 6 Shown is a schematic diagram of an embodiment of the structure-optimized long-life tapered roller bearing provided by the present invention, which includes an outer ring 1, an inner ring 2, and is sandwiched between the outer ring 1 and the inner ring 2 to play a supporting role and realize relative rotation A plurality of rollers 3 and a cage 4 that separates and guides the movement of the rollers.

[0034] Compared with the corresponding parts of the prior art, the present invention has the following improvements:

[0035] 1. The raceway busbars of the inner ring 2, the raceway busbars of the outer ring 1 and the roller 3 busbars are in the shape of logarithmic curve convexities that match each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com