Gas turbine rotor supporting mechanism and gas turbine with same

A gas turbine and rotor support technology, which is applied in the directions of machine/engine, engine lubrication, turbine/propulsion device lubrication, etc., can solve the problems of low axial bearing capacity of gas turbines, easy light-load skidding, etc., to eliminate light-load skid, Good structural stability and the effect of expanding the range of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

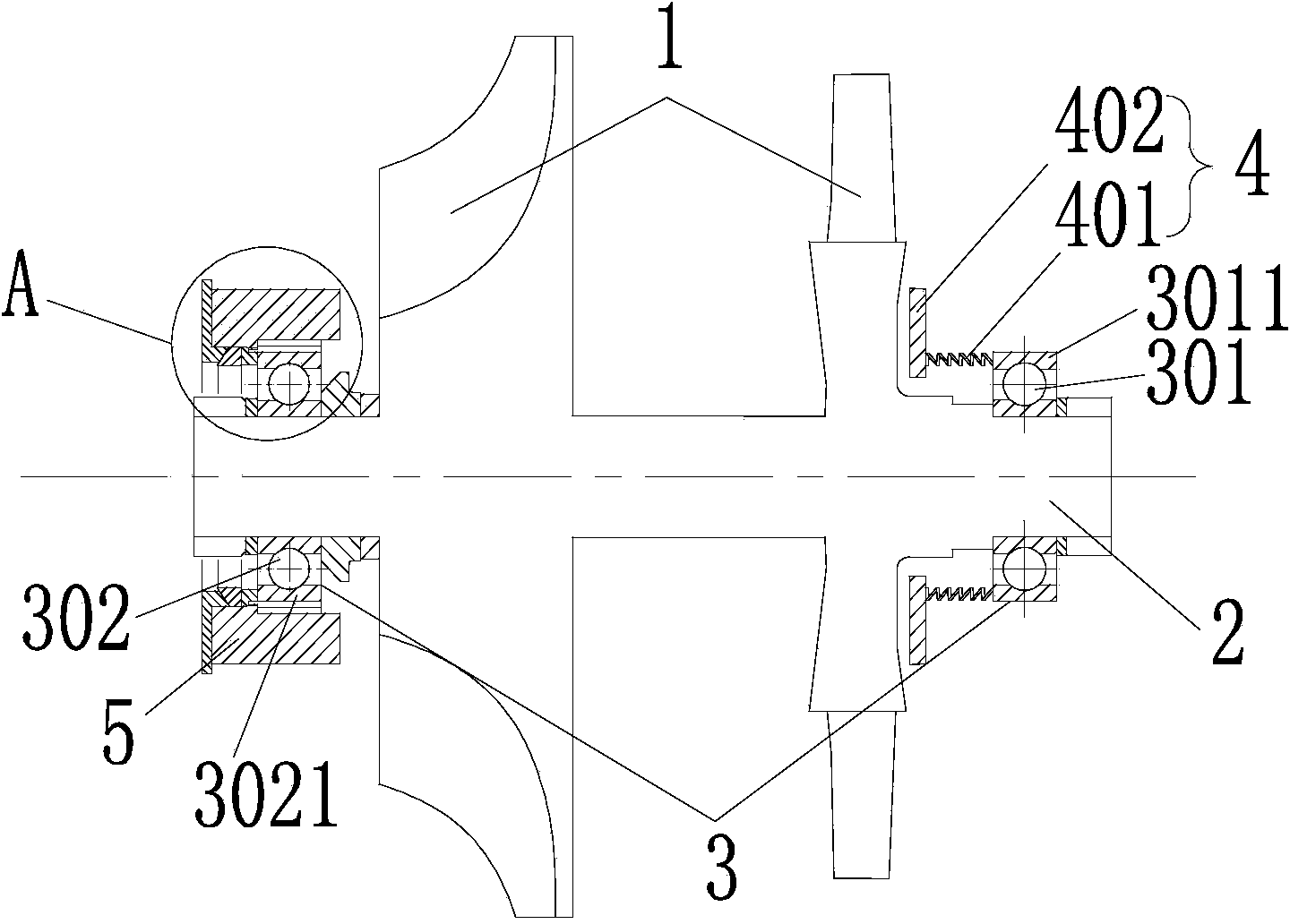

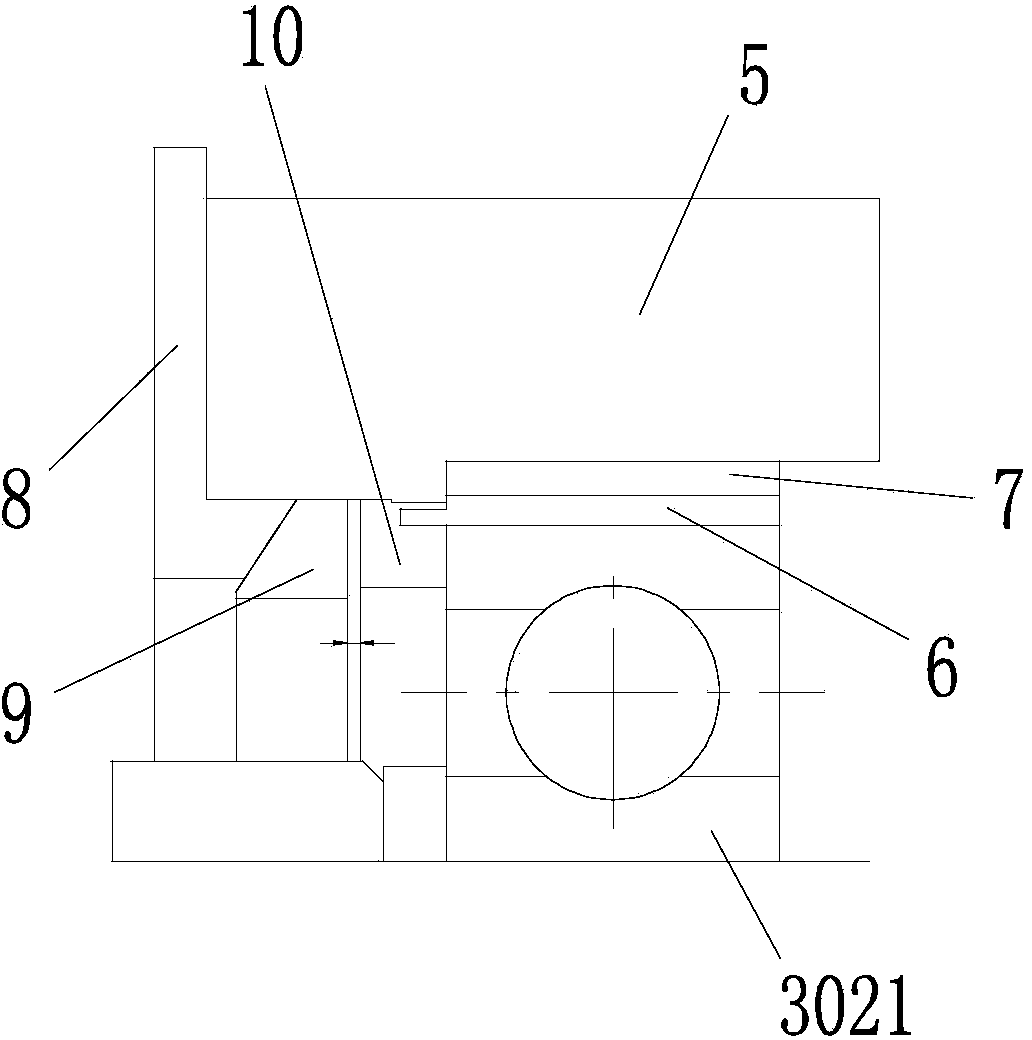

[0024] figure 1 It is a structural schematic diagram of a gas turbine rotor supporting mechanism in a preferred embodiment of the present invention; figure 2 yes figure 1 Schematic diagram of the partial enlarged structure of site A in the middle. Such as figure 1 and figure 2 As shown, the gas turbine rotor supporting mechanism of this embodiment includes ball bearings 3 arranged on both sides of the gas turbine rotor disk 1 for supporting the gas turbine rotor 2. The first ball bearing 301 and the second ball bearing 302 arranged on the rotor shaft on the second side of the rotor disc, the first ball bearing 301 includes a first outer ring 3011, and the first outer ring 3011 is provided with a direction to the gas turbine rotor 2 The elastic mechanism 4 that ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com