Cylindrical roller bearing with high axial bearing capacity

A technology of cylindrical roller bearings and bearing capacity, which is applied in the field of rolling bearings, and can solve problems affecting the driving safety of vehicles, cracking of inner ring ribs of bearings, and damage of related parts, so as to eliminate large stress, prevent cracking, and improve elastic fluid The effect of dynamic lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

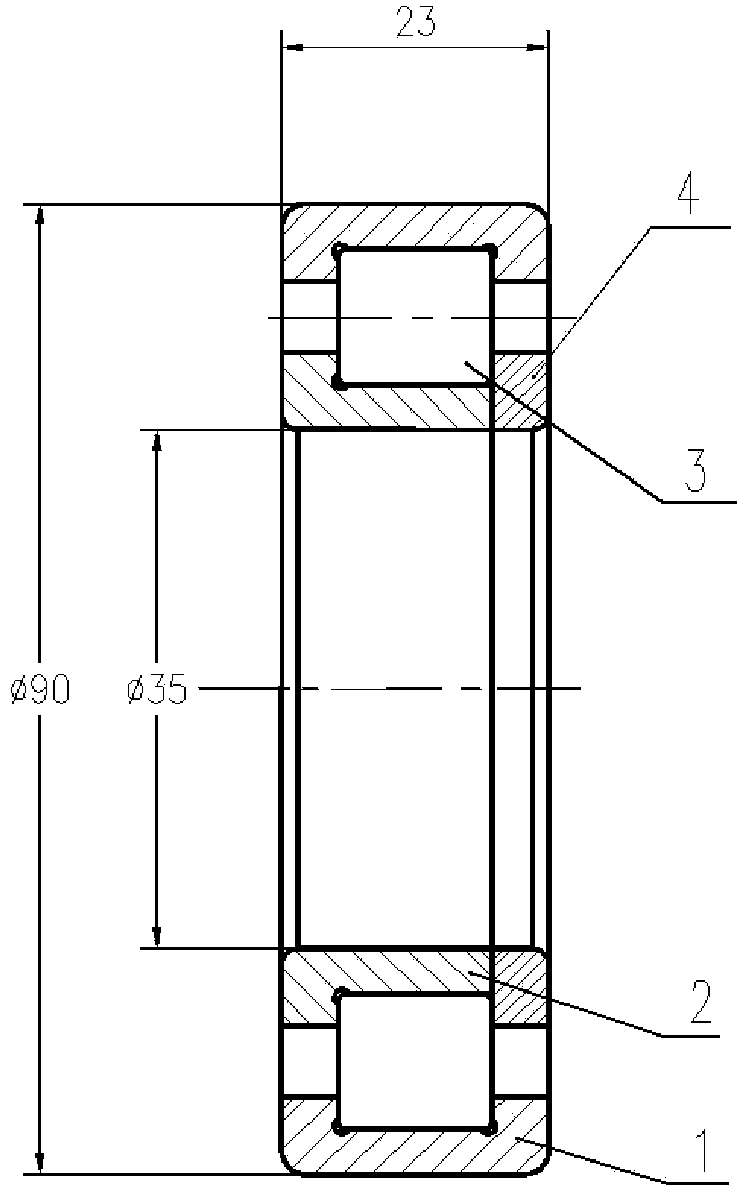

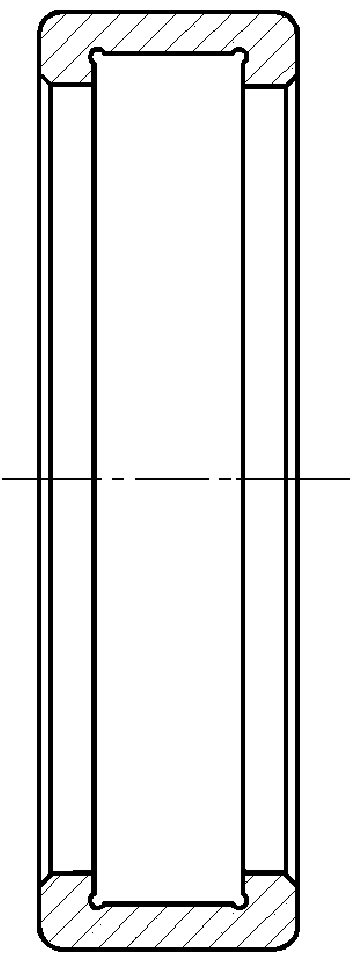

[0050] Such as Figure 6-Figure 11 Shown:

[0051]A cylindrical roller bearing with high axial load capacity provided by the present invention comprises an outer ring 1, an inner ring 2, a full complement of cylindrical rollers 3 interposed between the outer ring 1 and the inner ring 2, and a The flat retaining ring 4 on the side of the inner ring 2 and the cylindrical roller 3 is characterized in that:

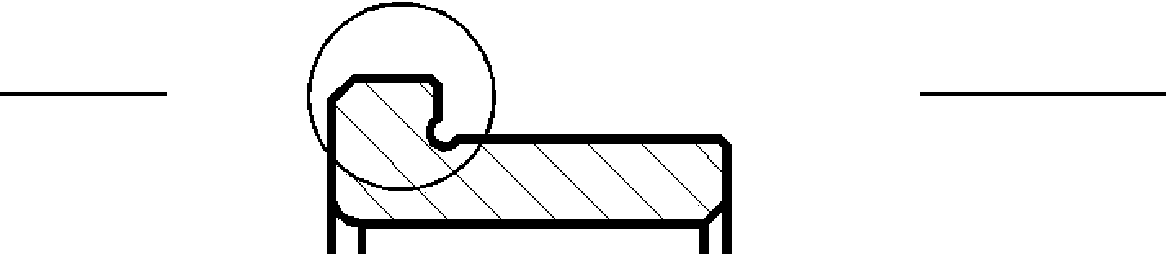

[0052] On the cross-section of the cylindrical roller bearing cut along the axis, the ribs of the outer ring 1 and the inner ring 2 are slightly convex rib arcs 2-1, located at the two ends of the rib arcs 2-1 There is a rib inclination angle α of 0°15'~0°30' between the chord line 2-2 and the longitudinal section of the cylindrical roller bearing taken along the vertical axis, and the rib arc line 2- 1 and the midpoint of the string 2-2 have a maximum vertical distance of 2-3 μm (also called convexity);

[0053] On the cross-section of the cylindrical roller bearing cut a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com