Roller bearing for supporting main shaft of wind driven generator

A technology of wind power generators and roller bearings, applied in the direction of roller bearings, etc., can solve the problems of stress concentration and large heat generation, and achieve the effects of avoiding stress concentration, prolonging working life and improving endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] The roller bearing for the main shaft support of the wind power generator of the present invention is made of high-strength alloy steel as a raw material, wherein the chemical composition ratio of the high-strength alloy steel is: carbon: 0.25-0.60wt%, silicon: 0.35-0.50wt% %, manganese: 1.2-1.70wt%, phosphorus: 0.015-0.025wt%, sulfur: 0.012-0.02wt%, chromium: 0.30-0.80wt%, molybdenum: 0.10-0.30, vanadium: 0.15-0.30wt%, nickel: 0.30~0.50wt%, copper: 0.15~0.3wt%, nitrogen: 0.015~0.05wt%, titanium: ≤0.2wt%, niobium: ≤0.06wt%, the balance is iron;

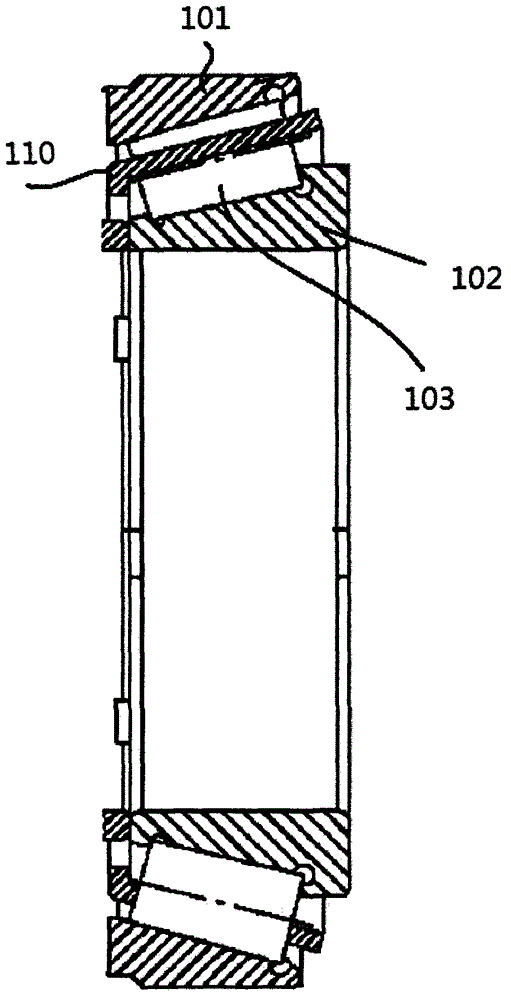

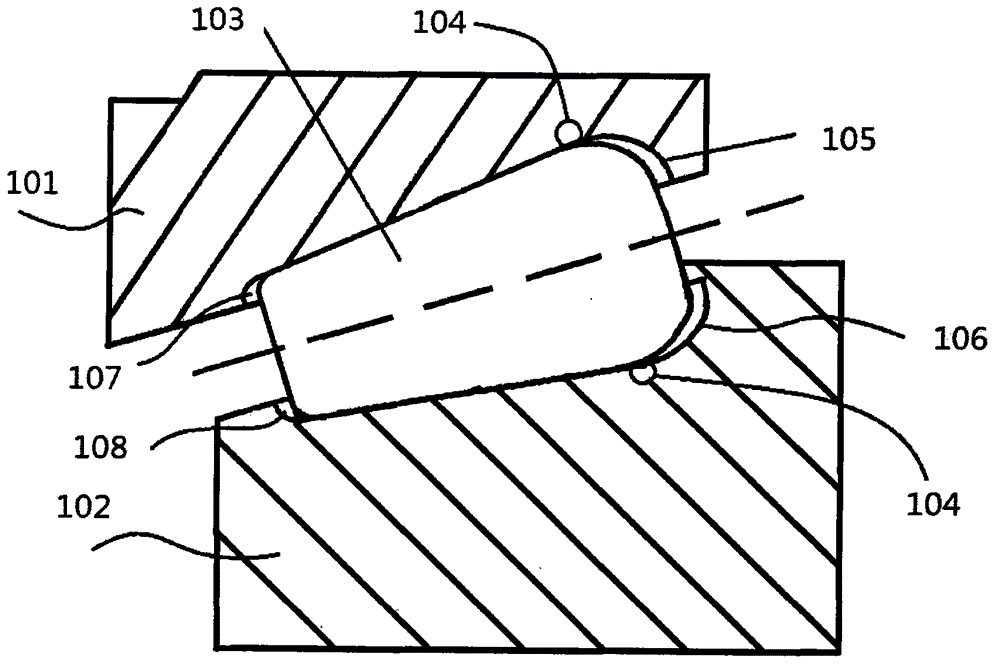

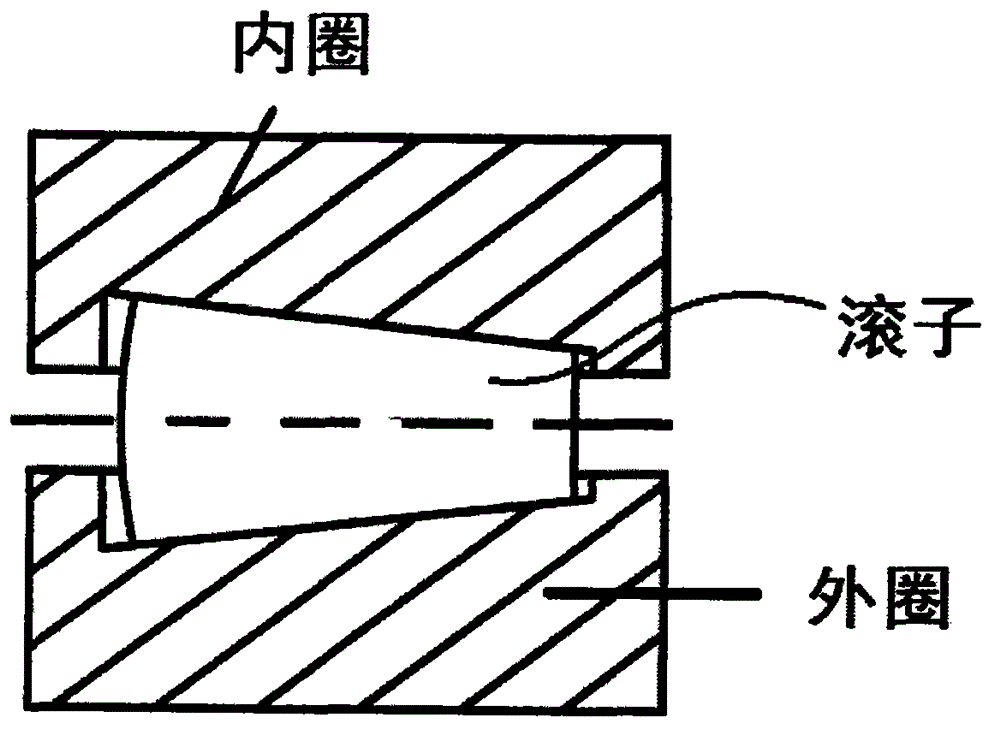

[0017] The structure of the roller bearing used for making the main shaft of the wind power generator of the present invention is a single-row structure, such as figure 1 As shown, the roller bearing includes an outer ring 101, an inner ring 102, a tapered roller 103, and a cage 110 for holding the tapered roller; as mentioned above, the tapered roller bearing is made of high-strength alloy steel, that is to say , In the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com