Carrier rocket composite storage tank provided with honeycomb sandwich walls and machining method thereof

A composite material and launch vehicle technology, applied in transportation and packaging, space navigation equipment, space navigation vehicles, etc., can solve problems such as failure damage, performance degradation of decorative parts, long manufacturing cycle, etc., and reduce the complexity of structural assembly properties, improve the axial compression buckling strength, and reduce the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

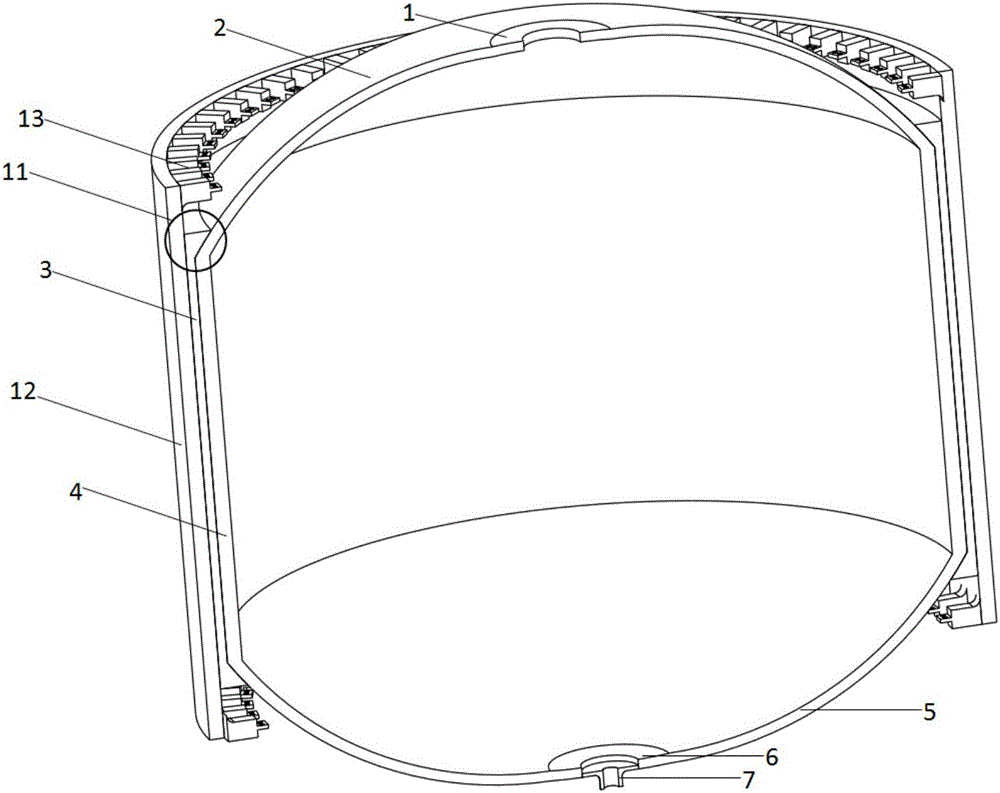

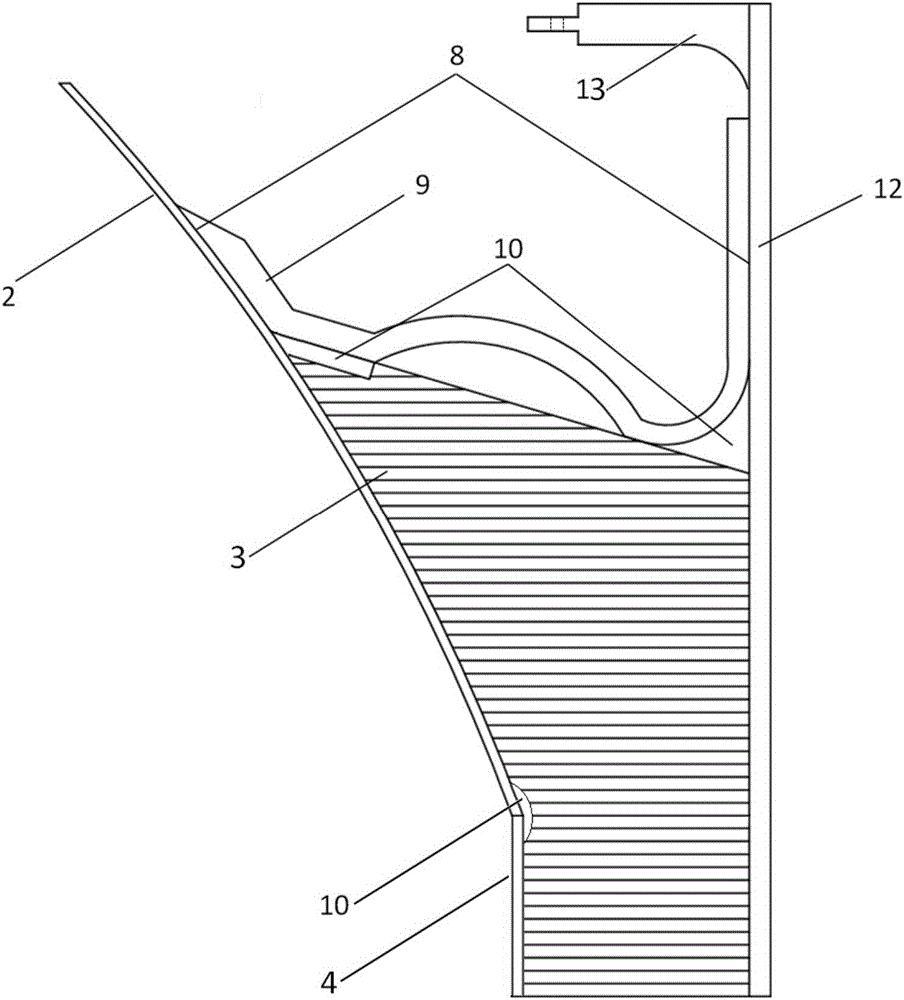

[0050] The winding molding process and laying molding process in the fiber winding molding of the storage tank combined with fiber laying molding, bonding and co-curing overall molding process are as follows: Winding molding process: first, select the core mold of the shape of the tank head, the head mold The number is 1.54, the diameter of the mandrel is 2m-5m, and there is a pole hole at the top, and the diameter of the pole hole is 0.2m-0.5m. Then, under the condition of controlling fiber tension and predetermined line type, select 12K single-bundle carbon fiber to start from the pole hole circumference, bypass the head along the curve tangent to the pole hole on the surface of the head, until the surface of the mandrel is evenly distributed. Until the fibers are full, the winding angles are the same as those in the layup, which are 55° and 35° respectively. When winding, the mandrel rotates at a constant speed around its own axis, and the guide wire reciprocates along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com