Fully-dry connection precast concrete plate, floor and method for improving seismic performance of floor

A prefabricated concrete slab and fully dry technology, which is applied in the direction of earthquake resistance, floor slabs, building materials, etc., can solve the problems of large season and climate influence, large environmental impact, long construction period, etc., and achieve high bearing capacity and good mechanical performance , the effect of high bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

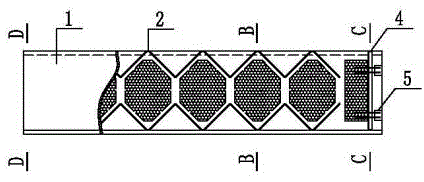

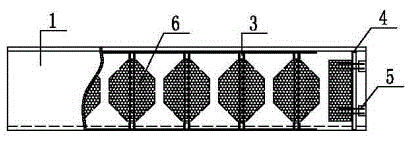

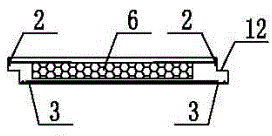

[0022] A fully dry-connected precast concrete slab, comprising a precast concrete slab 1 with tongue-and-groove forms on both sides, a row of precast slab top embedded parts 2 are pre-embedded on both sides of the top of the precast concrete slab 1, and the precast concrete slab 1 The bottom of the slab is provided with a group of slab bottom embedded parts 3, and slab end connectors 5 are respectively embedded at both ends of the precast concrete slab 1; The top anchor bar is connected with the top anchor bar, and the top anchor bar is pre-embedded in the precast concrete slab 1, and the slab top anchor plate is exposed on the side of the precast concrete slab; The longitudinal slab bottom steel bar 36 located on both sides of the bottom of the precast concrete slab 1 is connected with a pre-embedded metal plate on the longitudinal slab bottom steel bar 36, and the pre-embedded metal plate on the bottom side of the precast concrete slab 1 and the precast concrete slab The pre...

Embodiment 2

[0026] A floor constructed from the fully dry-connected precast concrete slabs, including a floor slab spliced by fully dry-connected precast concrete slabs, beams are connected around the floor, and the beams are respectively connected to the fully dry-connected precast concrete The two ends of the slab and the outer full-dry connection are connected to the precast concrete slabs, and the corresponding slab top embedded parts 2 in the adjacent fully dry-connected precast concrete slabs are connected to each other and the corresponding slab top embedded parts 2 The top anchor plate is welded and connected, and the corresponding pre-embedded metal plate in the slab bottom embedded part 3 corresponding to the position in the adjacent fully dry-connected precast concrete slab is provided with a slab bottom metal connecting plate 35. The middle part of the bottom metal connection plate 35 is provided with a through hole, and the bottom metal connection plate 35 is respectively we...

Embodiment 3

[0028]A method for improving the anti-seismic performance of a floor. First, the floor slab formed by splicing the fully dry-connected precast concrete slabs is connected to the surrounding beams. Secondly, the positions of the adjacent fully dry-connected precast concrete slabs are corresponding The top anchor plate of the slab top embedded part 2 is fully welded and welded, and then the metal plate connected by the node is adjusted by welding the slab bottom embedded part 3 corresponding to the position in the adjacent fully dry-connected precast concrete slab The size of the opening and the length of the weld make the deformation capacity of the embedded part at the bottom of the plate close to that of the embedded part at the top. In this embodiment, the welding connection of the embedded parts 3 at the bottom of the slab adopts the metal connection of the embedded metal plate covering the bottom of the slab among the two embedded parts at the bottom of the slab correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com