Patents

Literature

34results about How to "Improve clamping positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

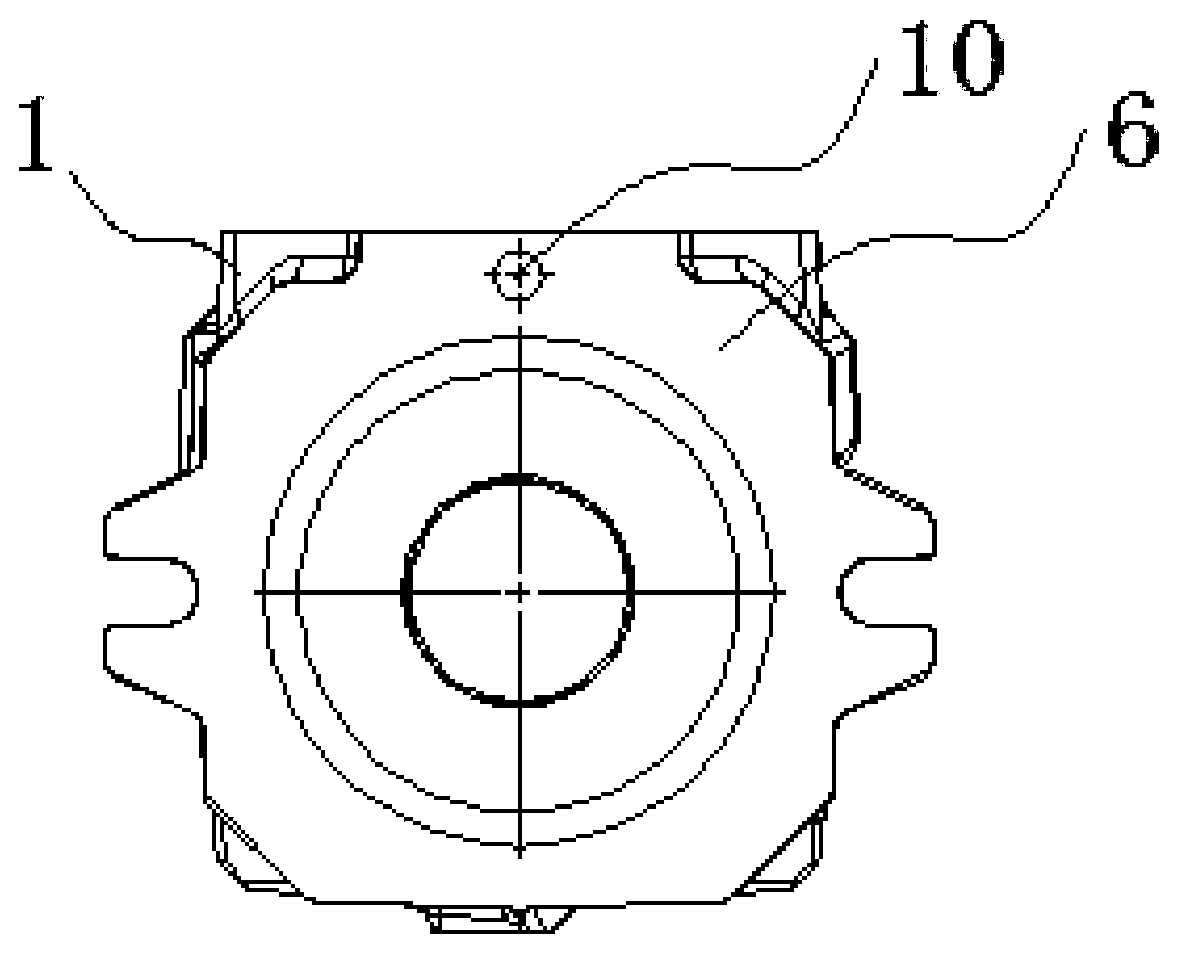

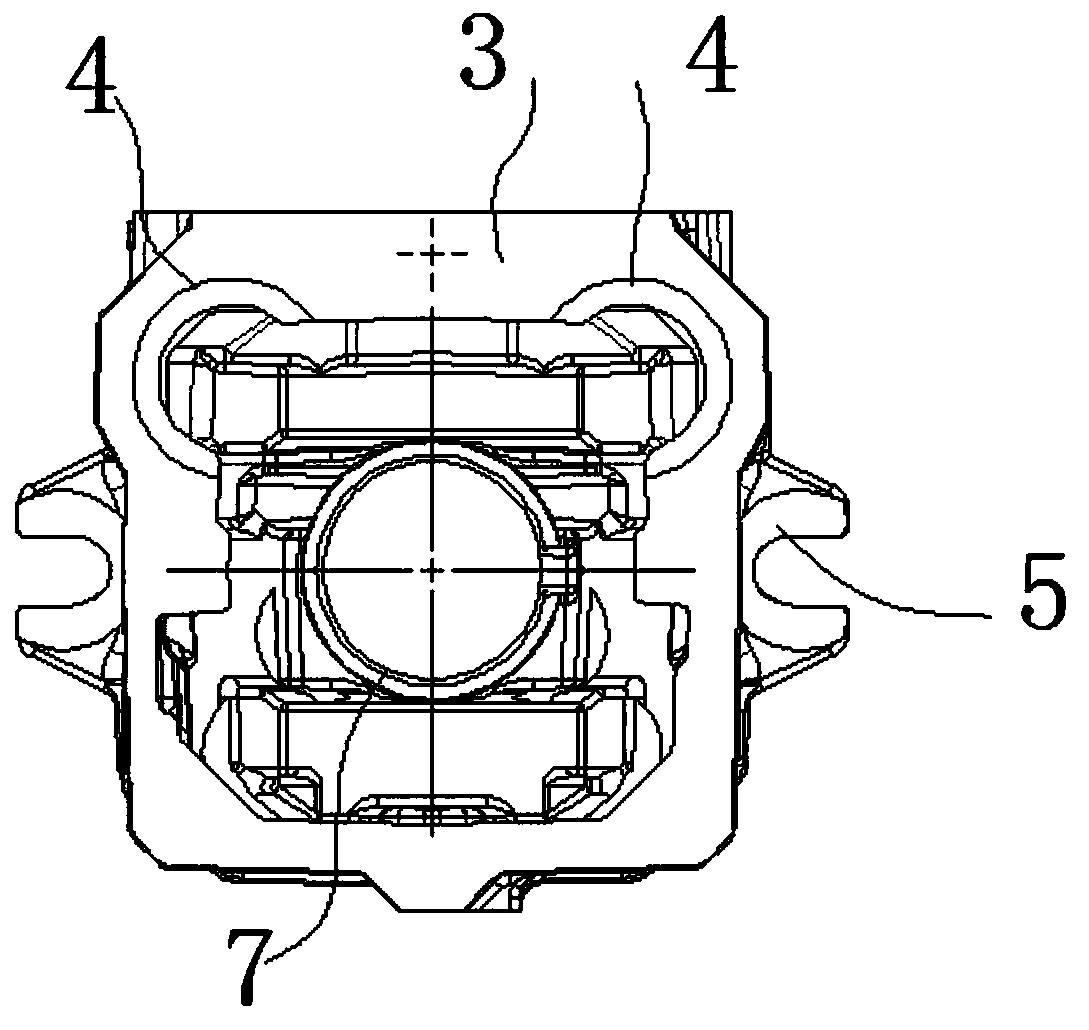

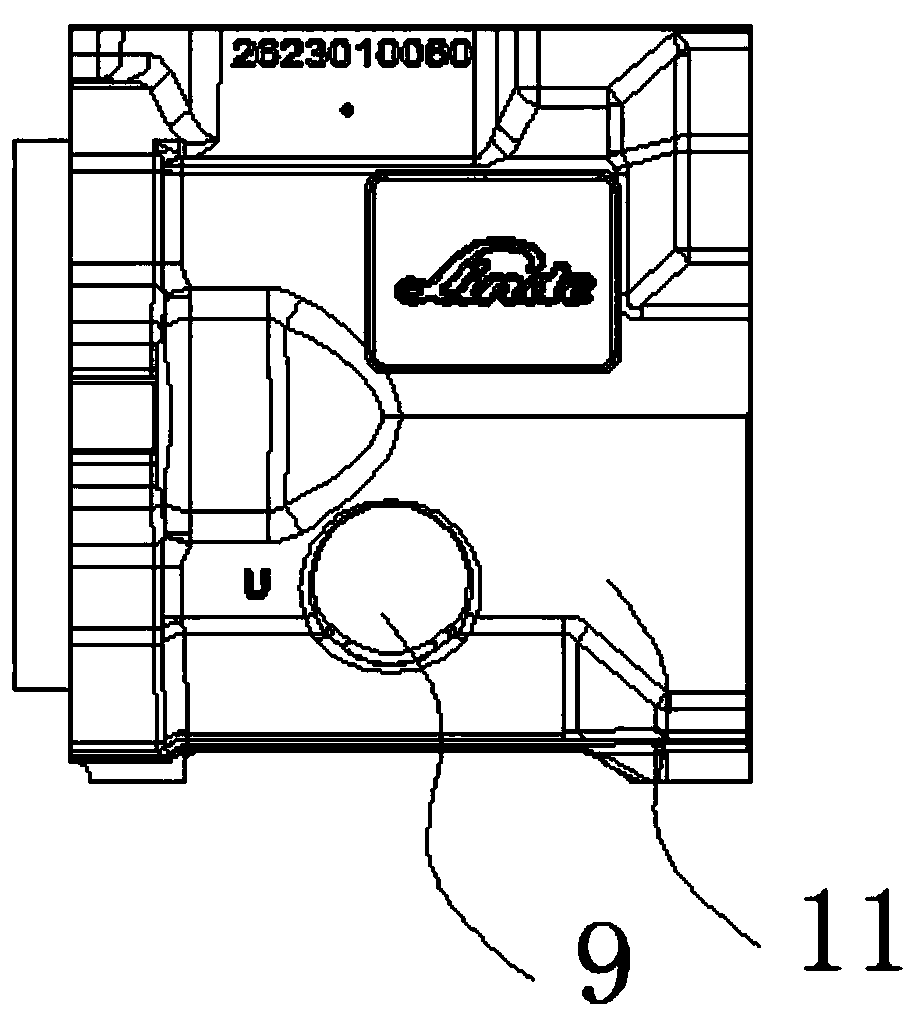

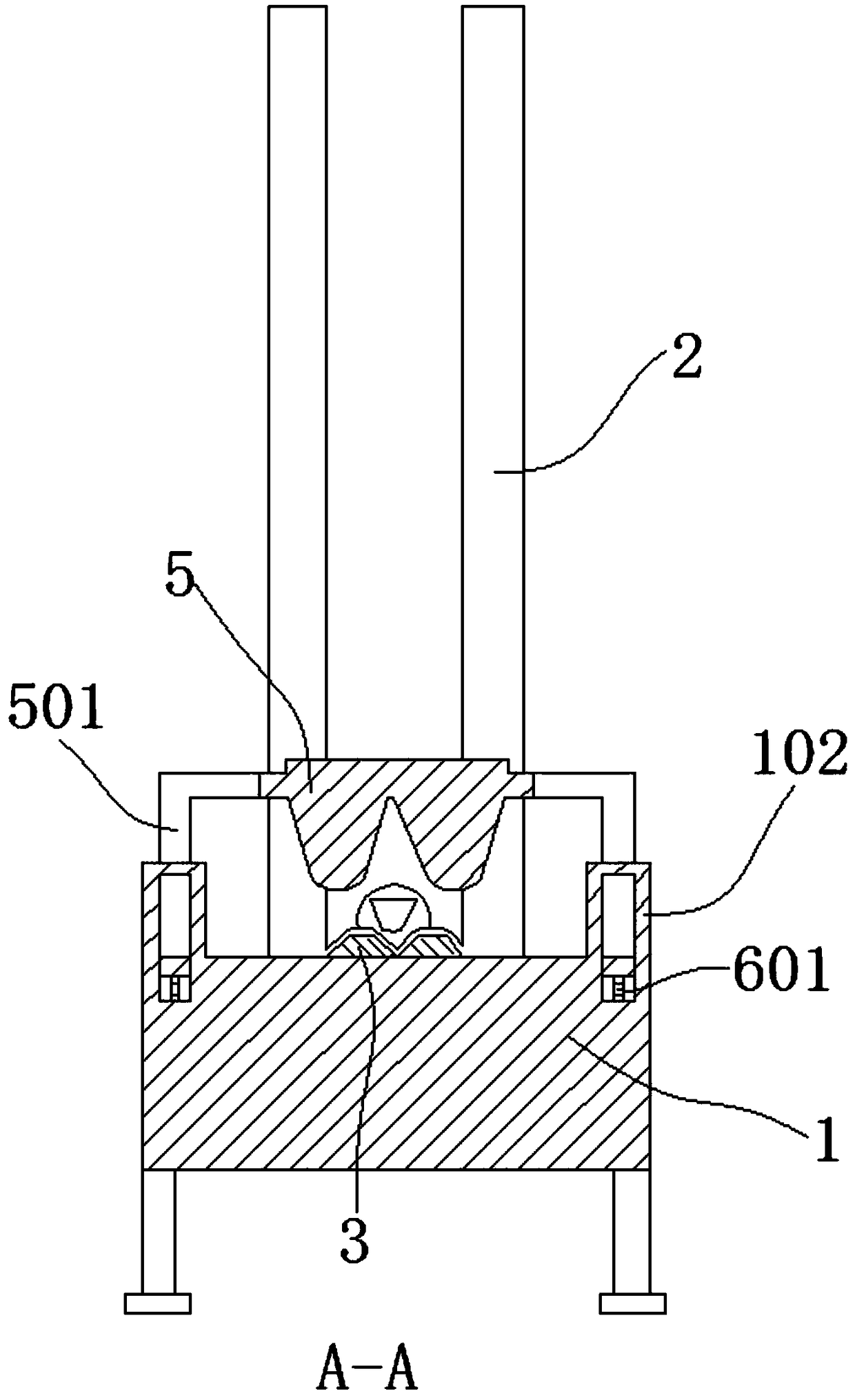

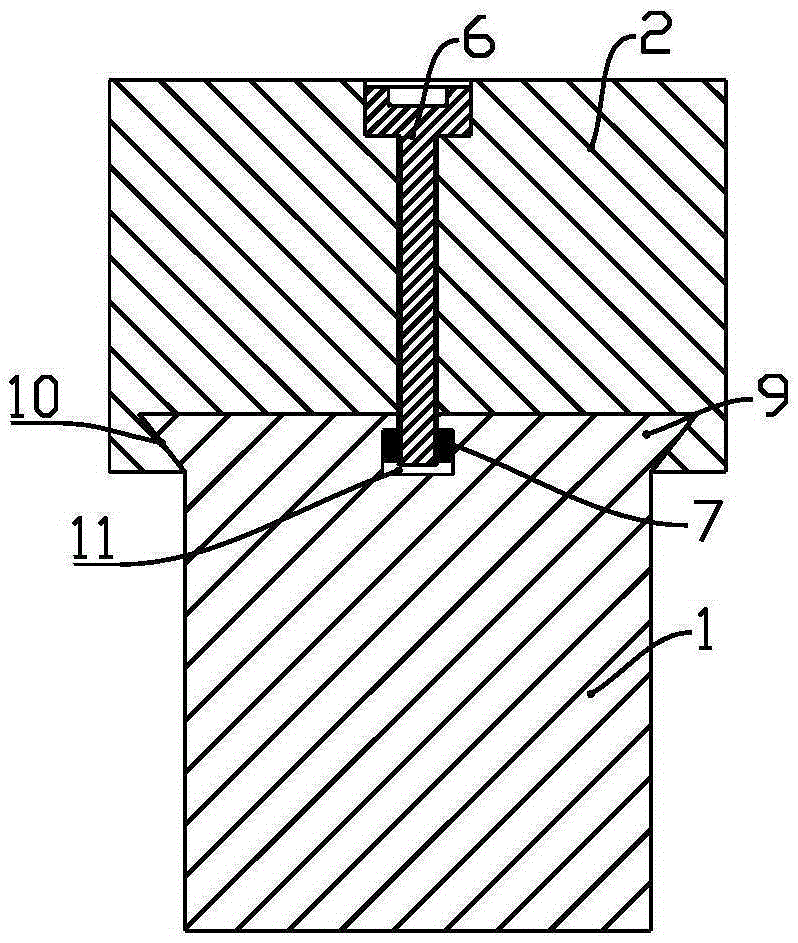

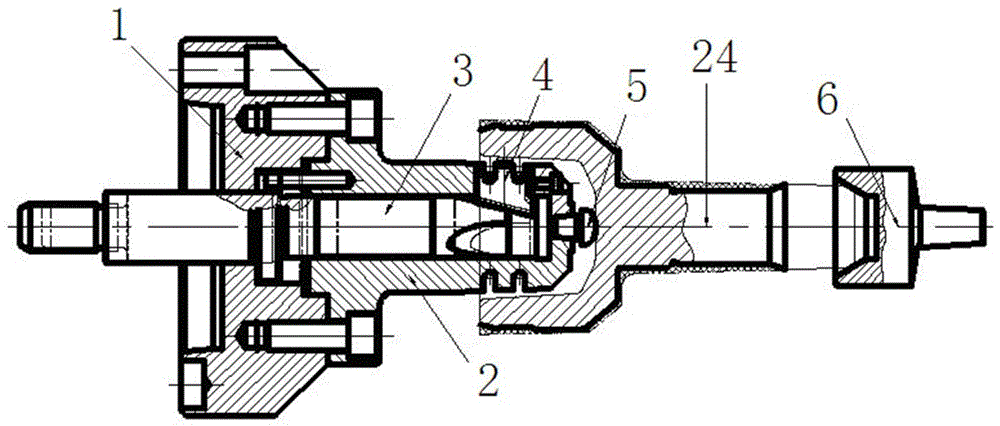

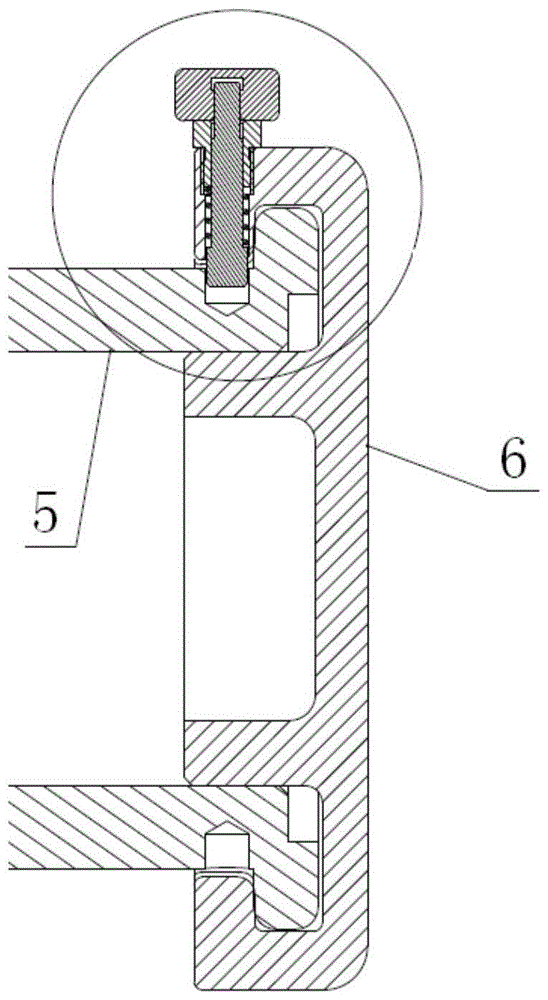

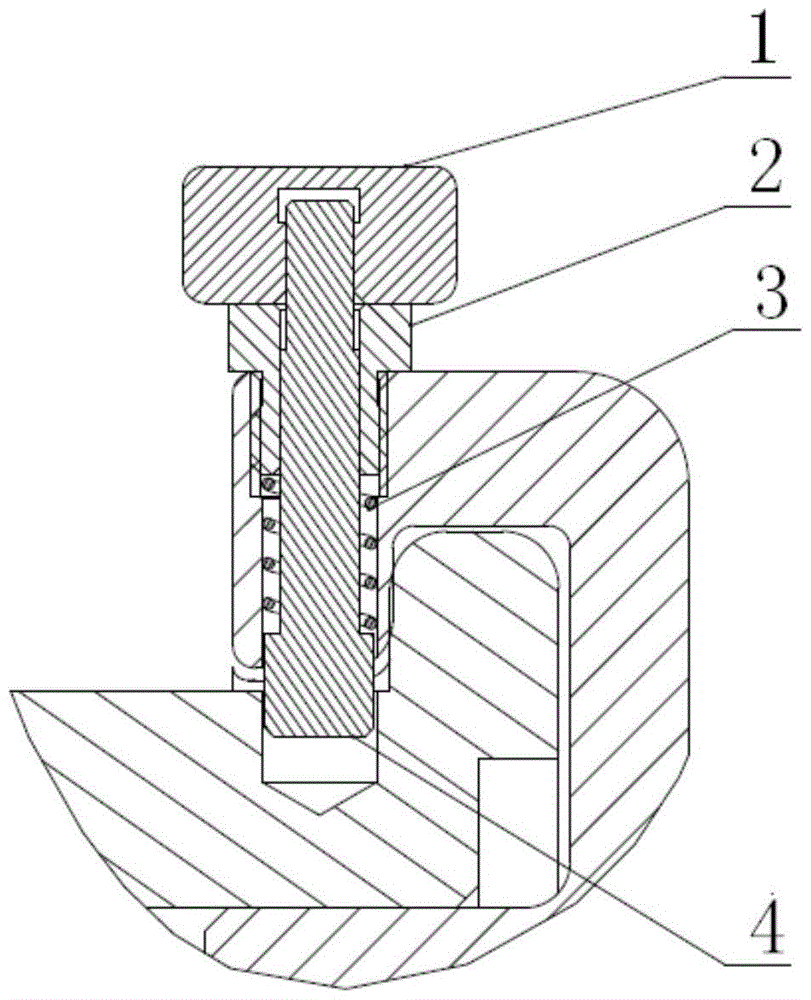

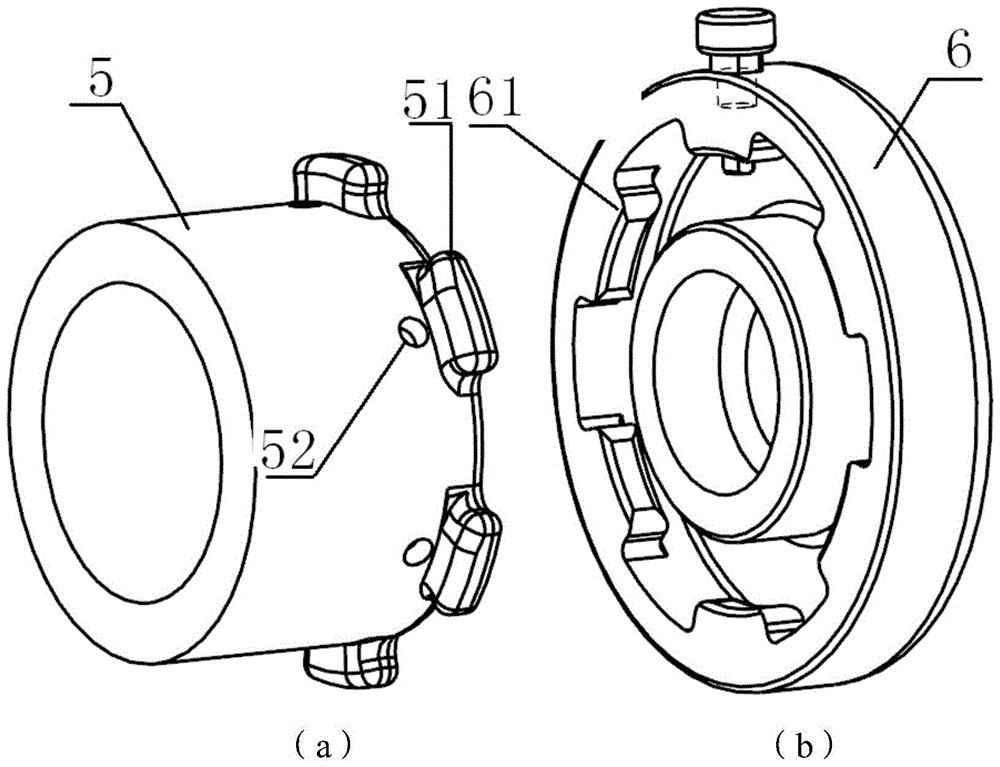

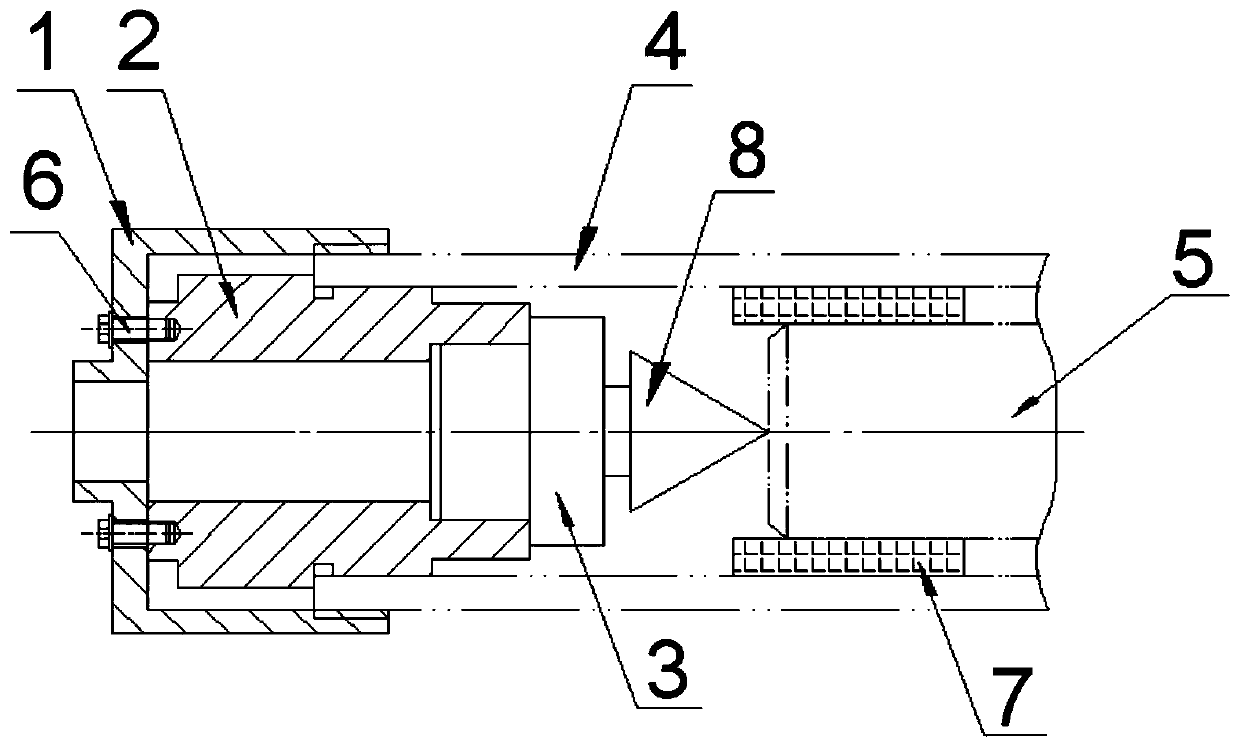

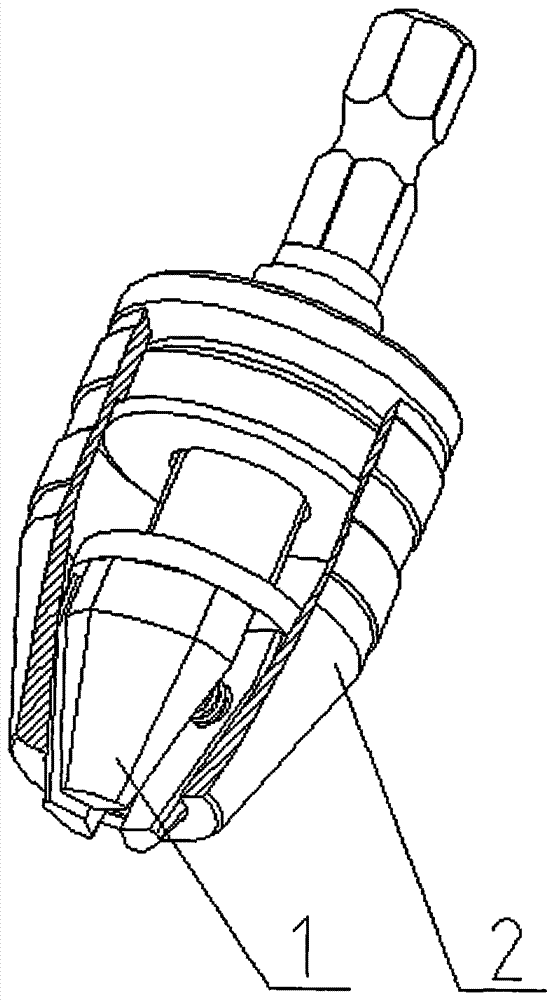

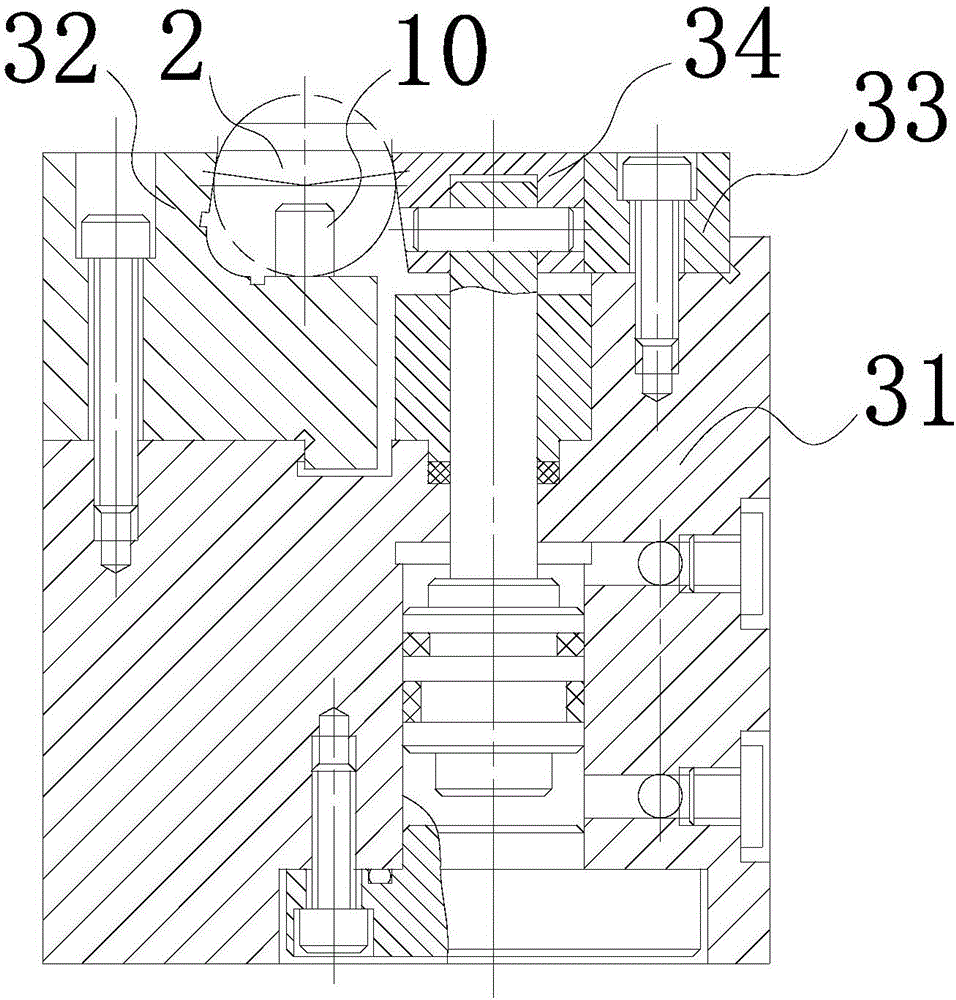

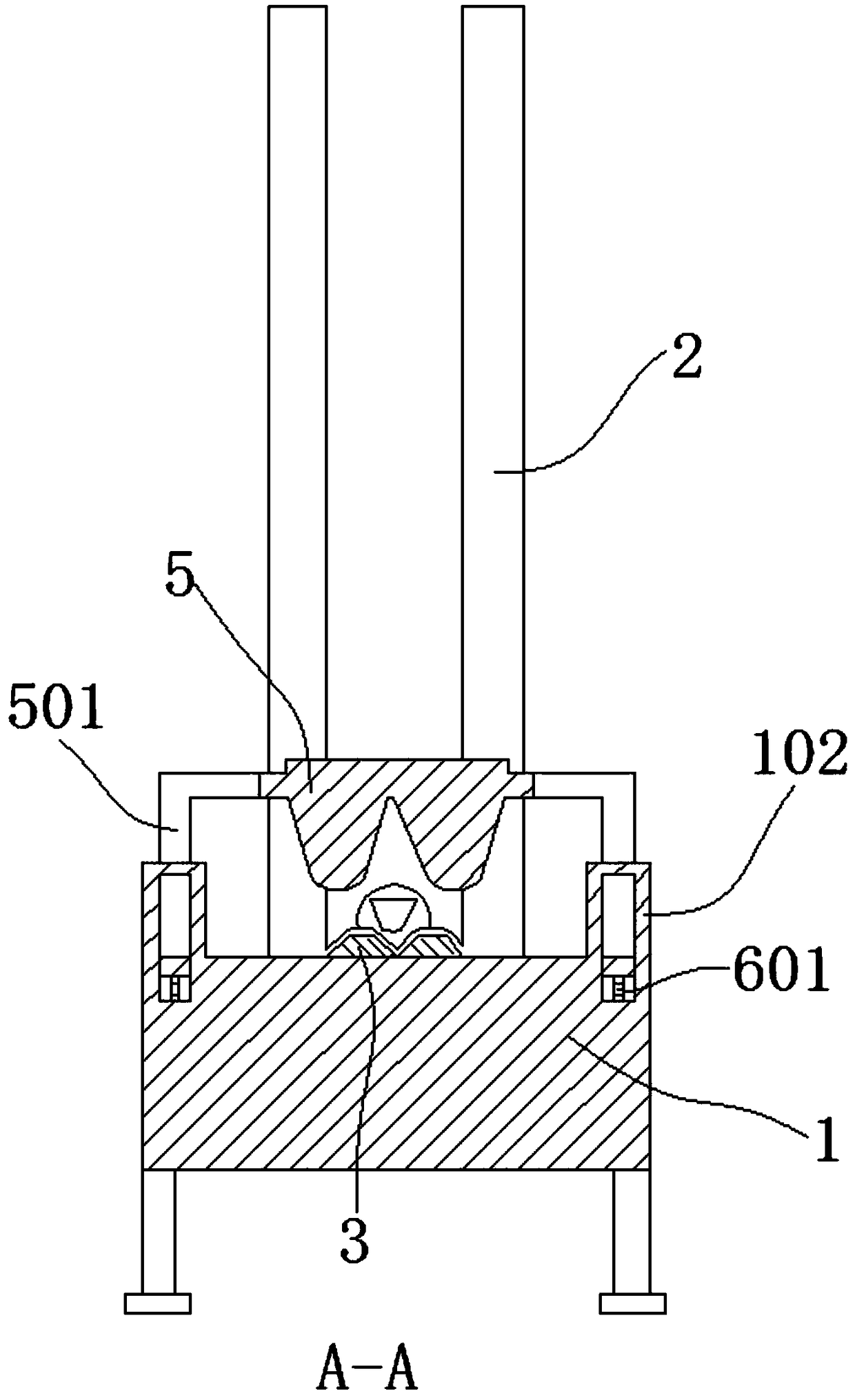

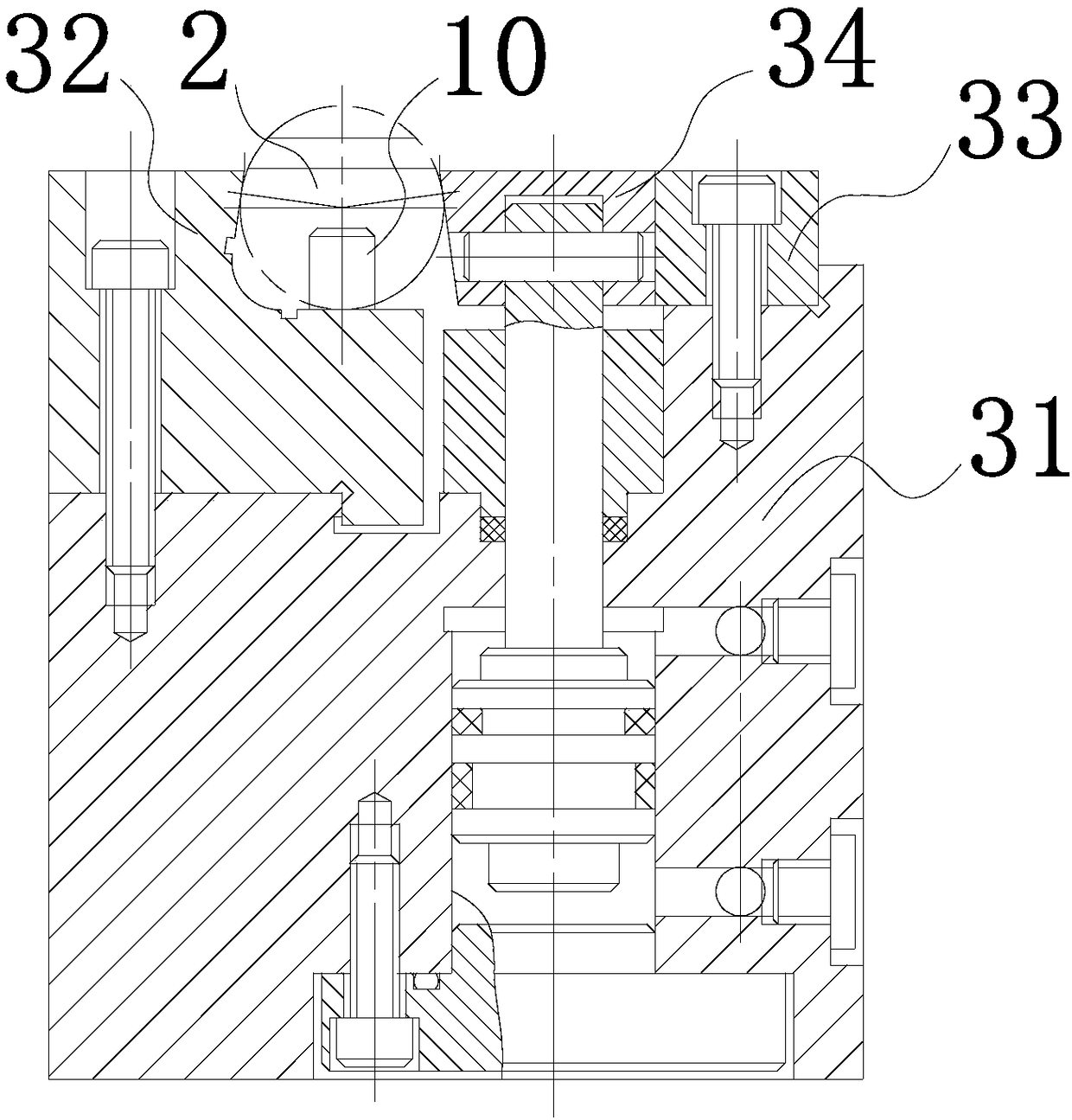

Fast clamping locking device

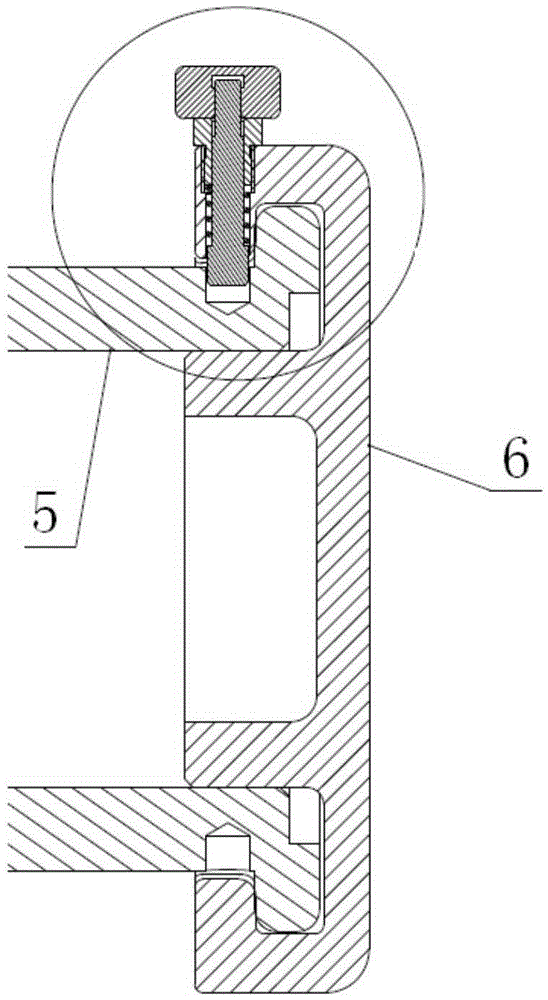

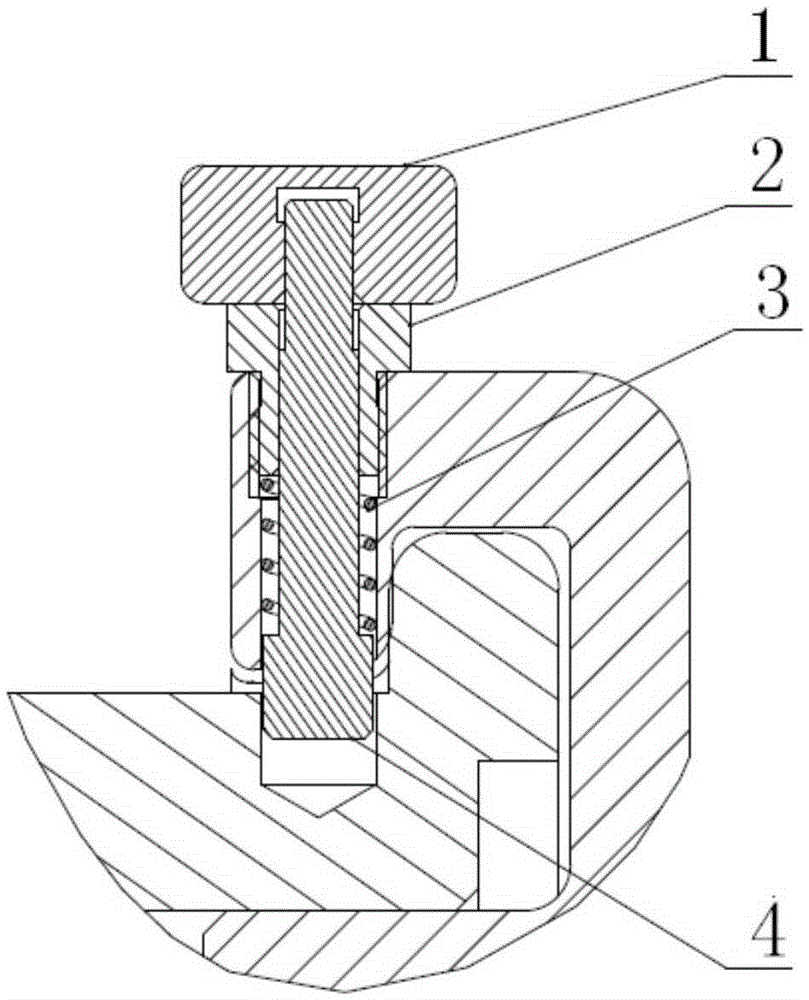

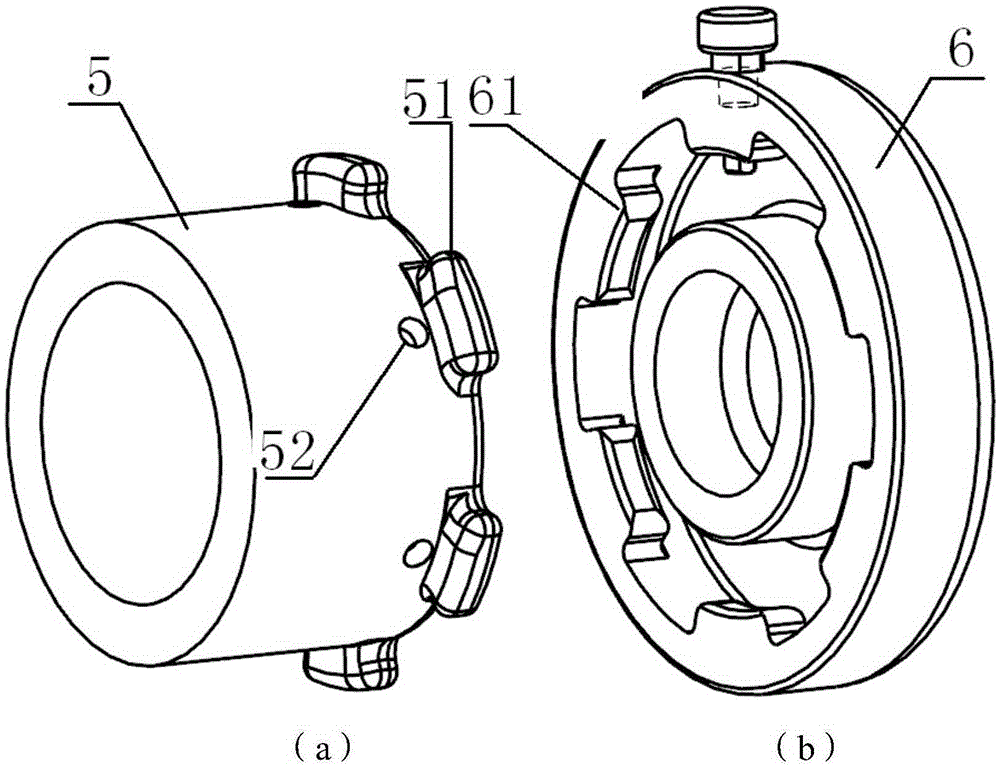

The invention provides a fast clamping locking device which comprises nuts (1), thread sleeves (2), springs (3), locking pins (4), first clamping supporting rims (61) and second clamping supporting rims (51). One end of each locking pin (4) is fixedly connected with the corresponding nut (1), and the other end of each locking pin (4) is inserted in a locking blind hole (52). Each locking pin (4) is sleeved with the corresponding thread sleeve (2). Each thread sleeve (2) is mounted in a mounting hole of an end cover (6). Each locking pin (4) is sleeved with the corresponding spring (3). One end of each spring (3) is connected with the corresponding thread sleeve (2), and the other end of each spring (3) is connected with the end, inserted in the corresponding locking blind hole (52), of the corresponding locking pin (4). The nuts (1) are pulled out or loosened, the springs (3) are driven to stretch out and draw back, the locking pins (4) are made to move in the mounting holes of the end cover (6), and therefore mounting, dismounting and locking of the end cover (6) and a shell (5) are achieved. Through the fast clamping locking device, high-precision and high-reliability connection between structures is achieved in a narrow space; the fast clamping locking device is compact in structure, easy to operate, capable of being dismounted and mounted repeatedly and good in maintainability.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

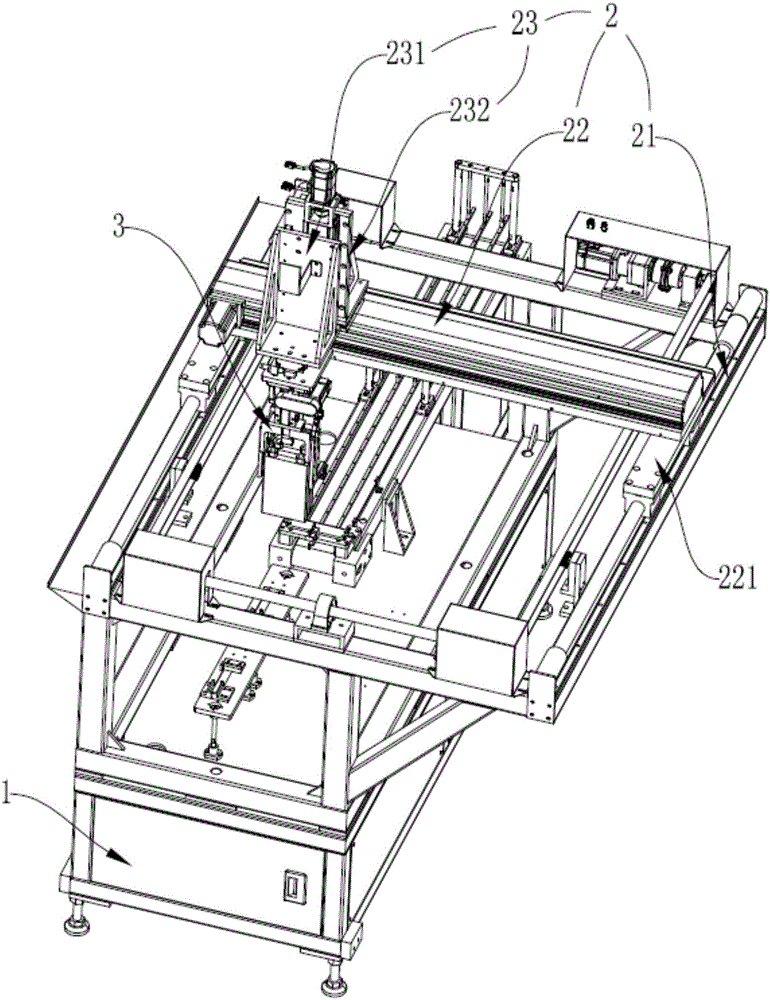

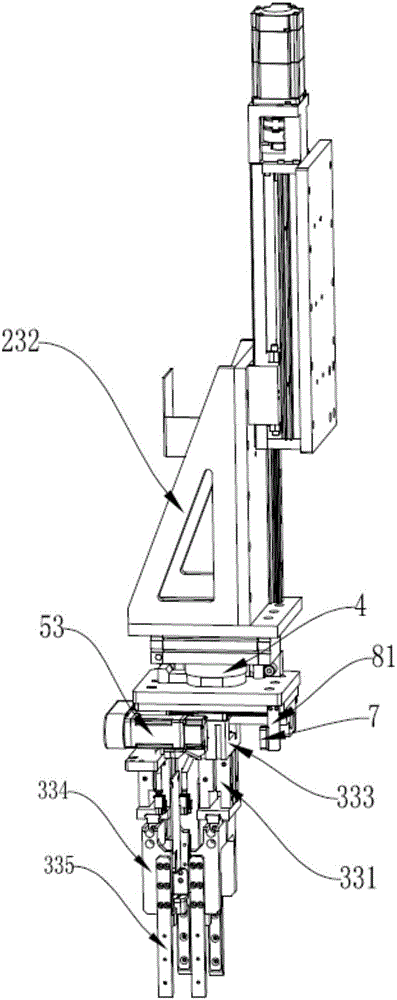

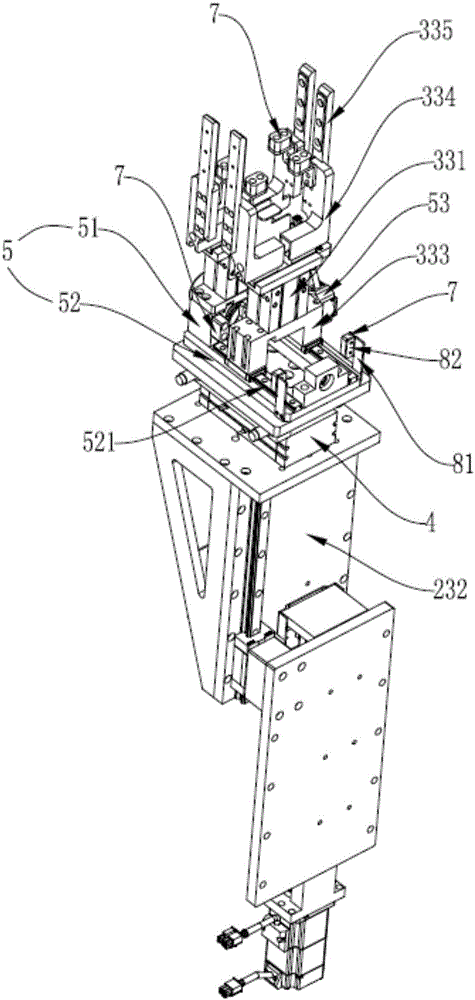

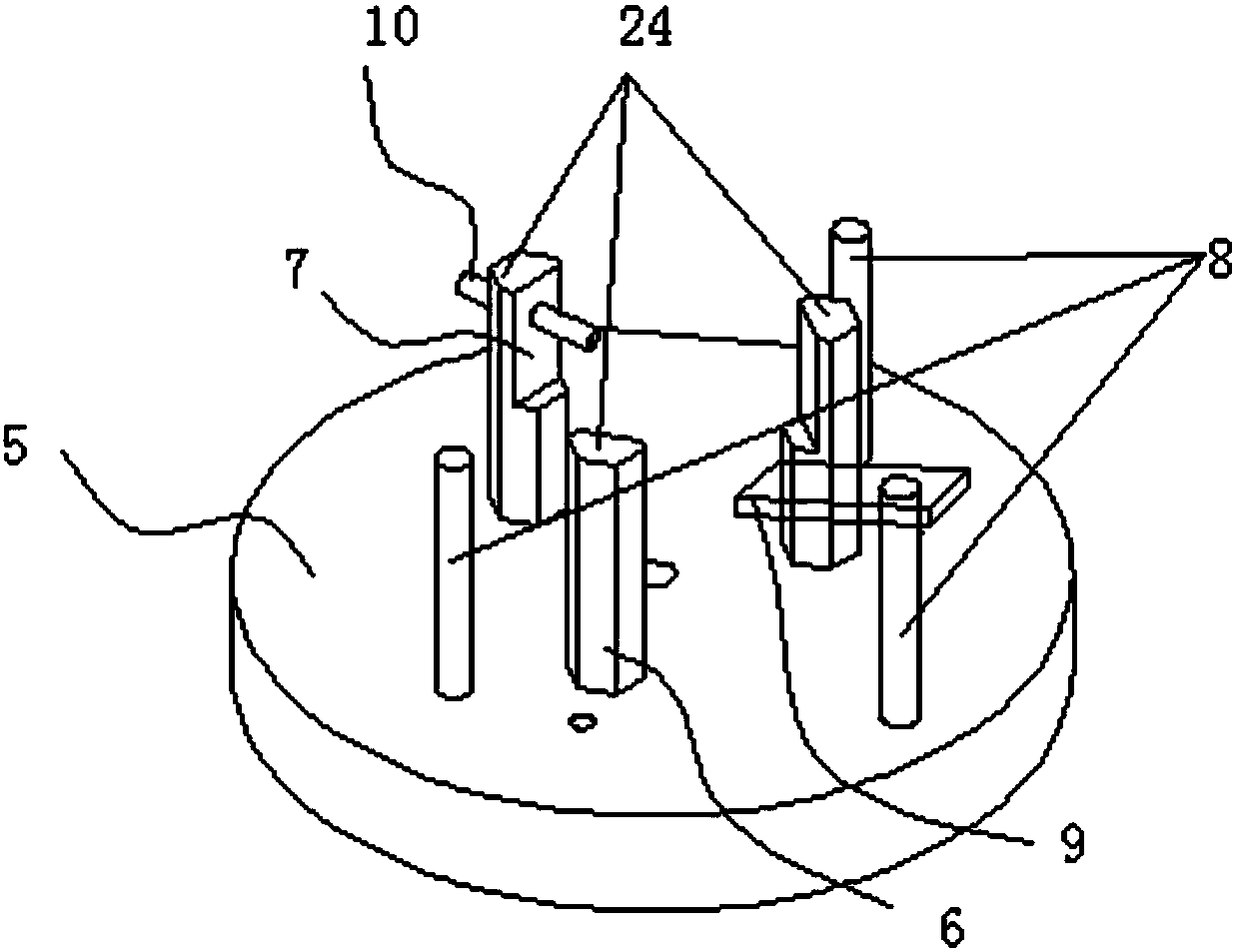

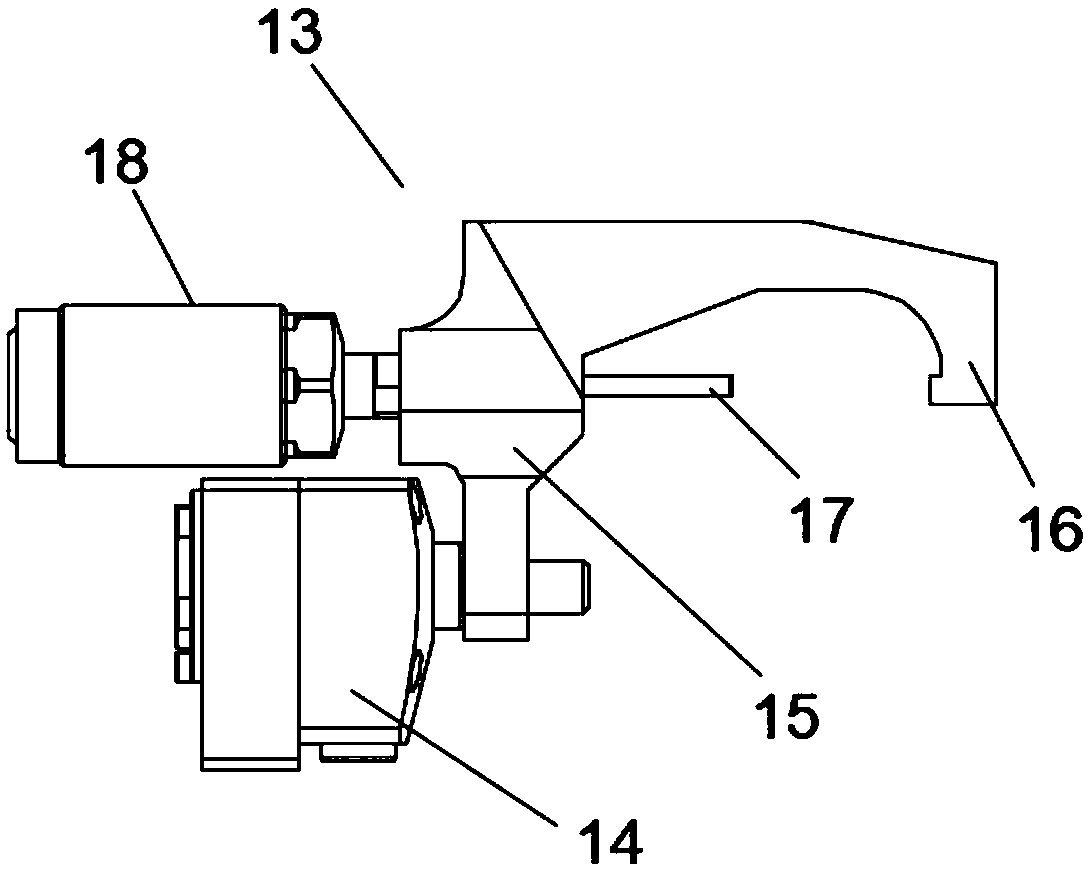

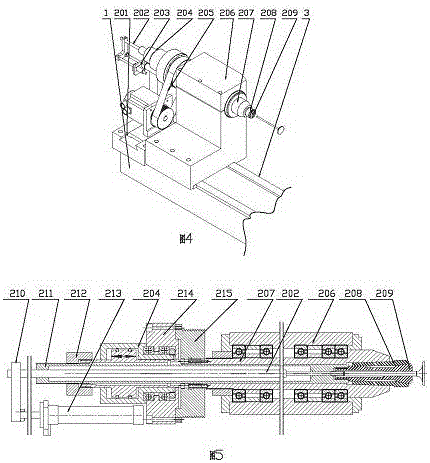

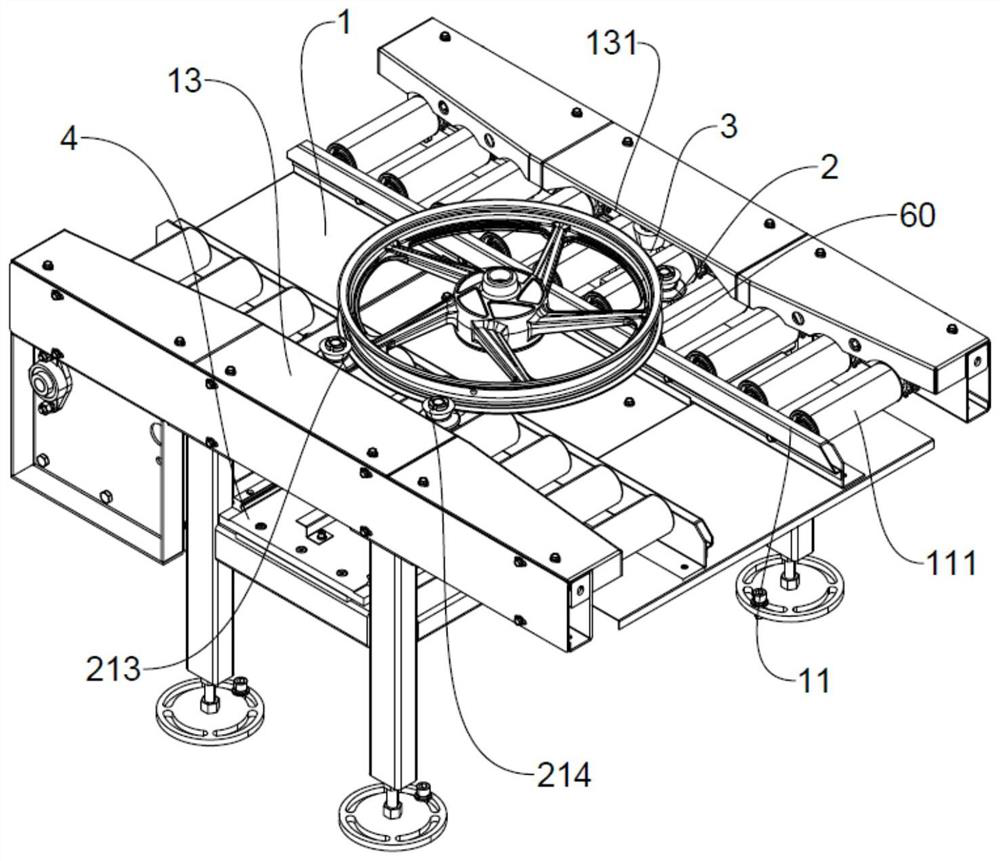

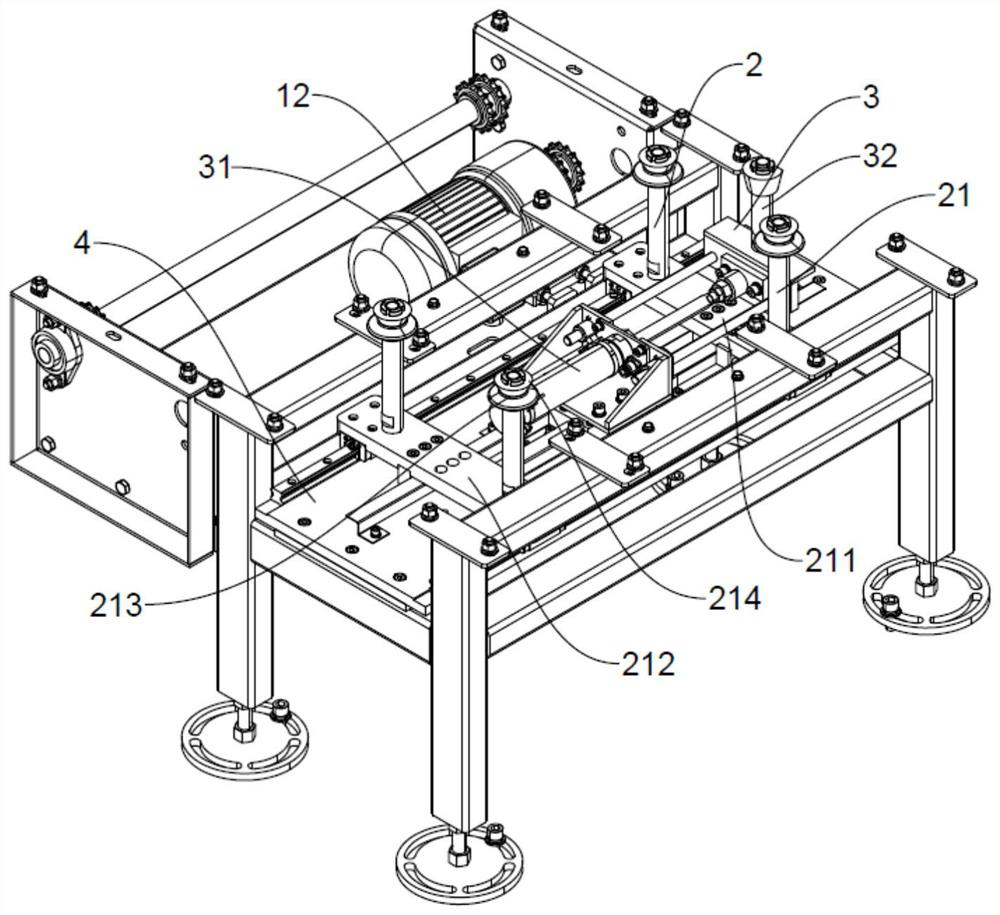

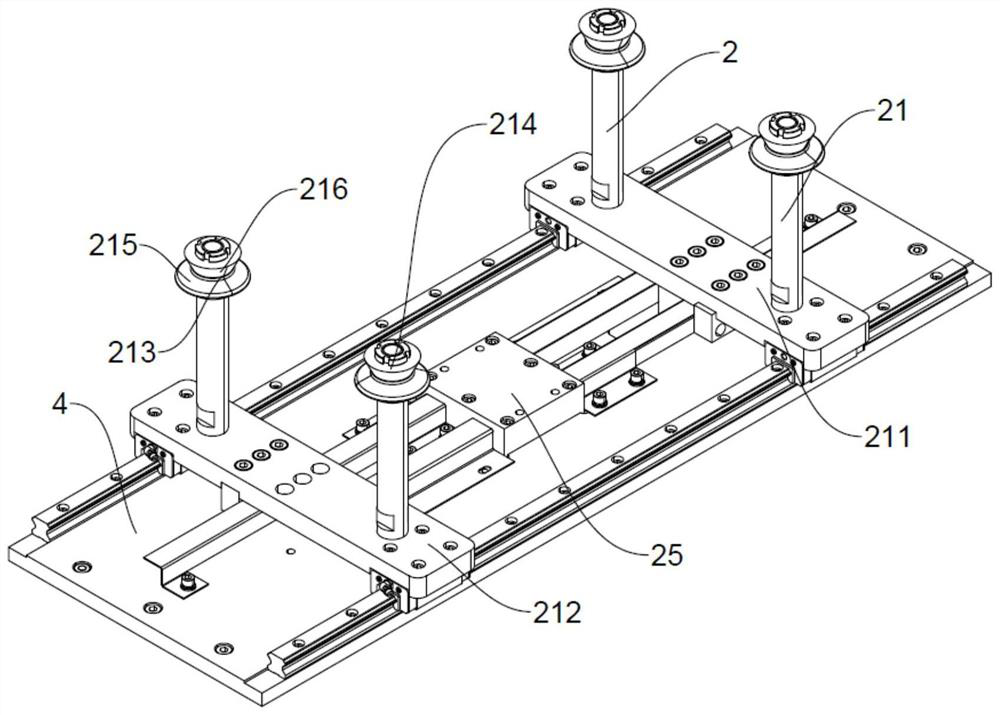

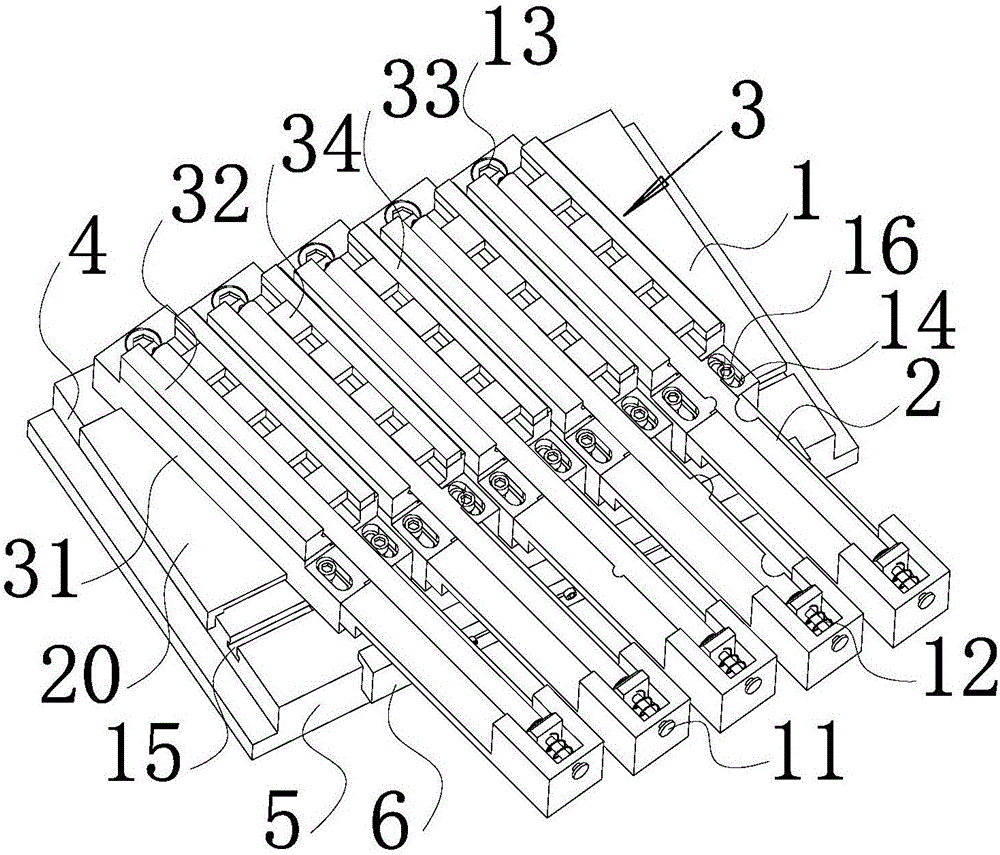

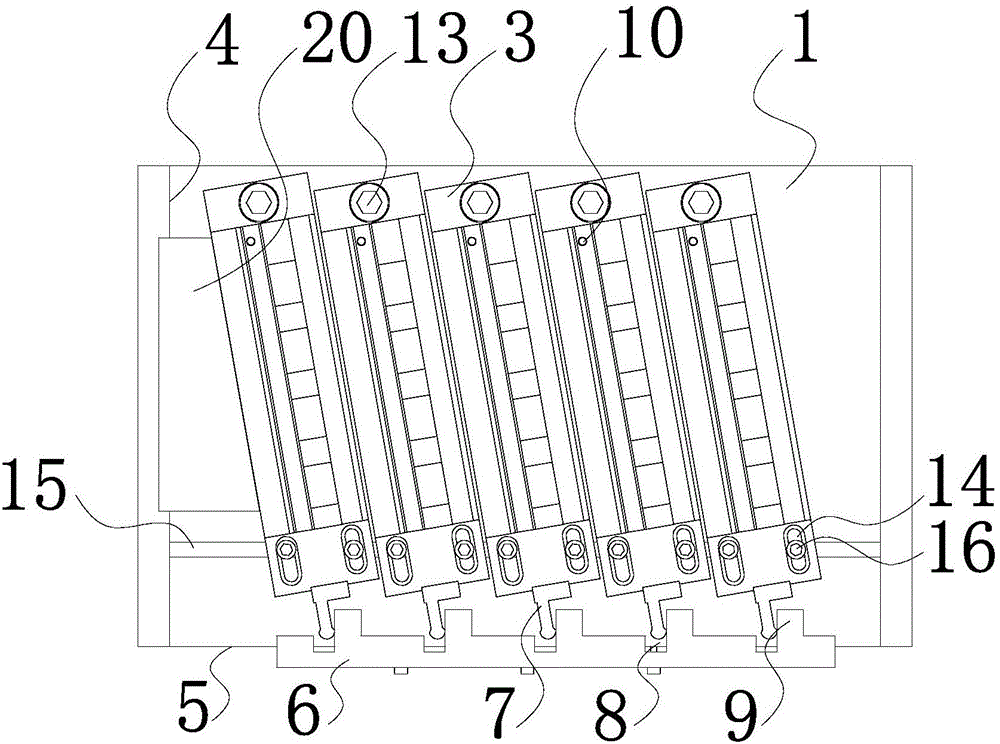

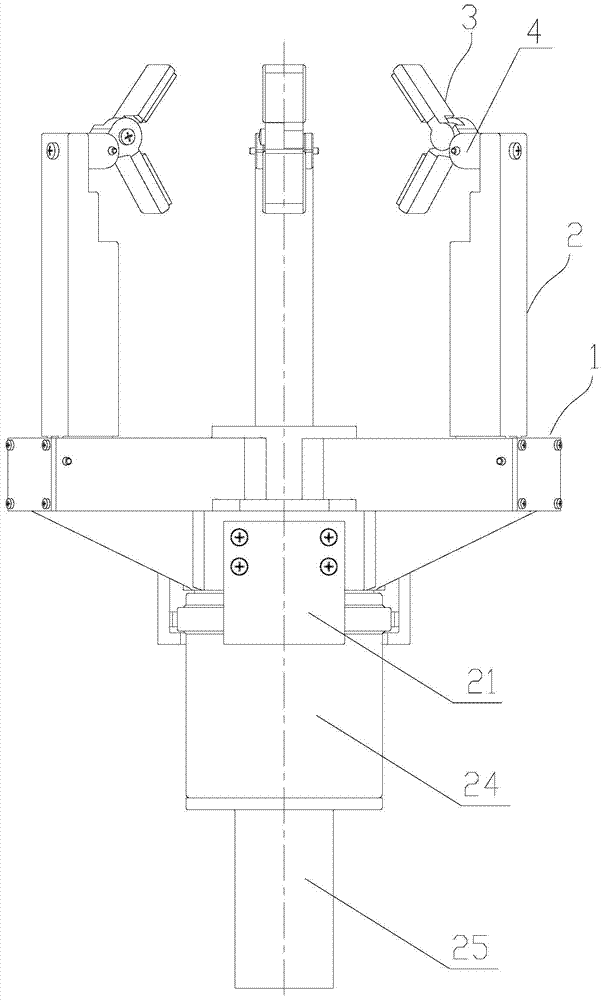

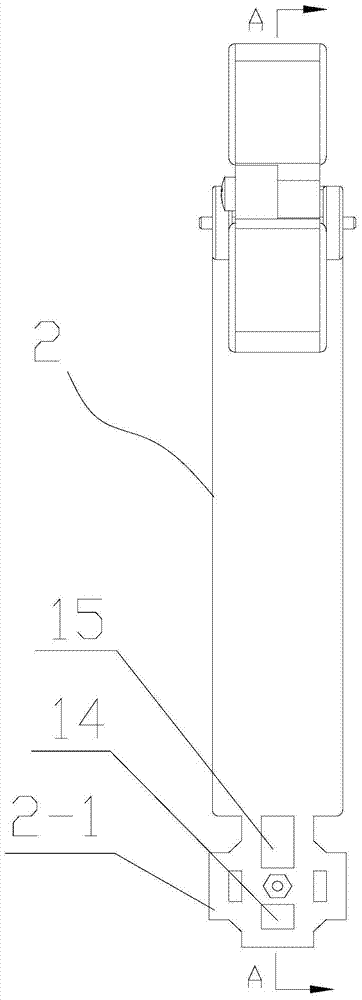

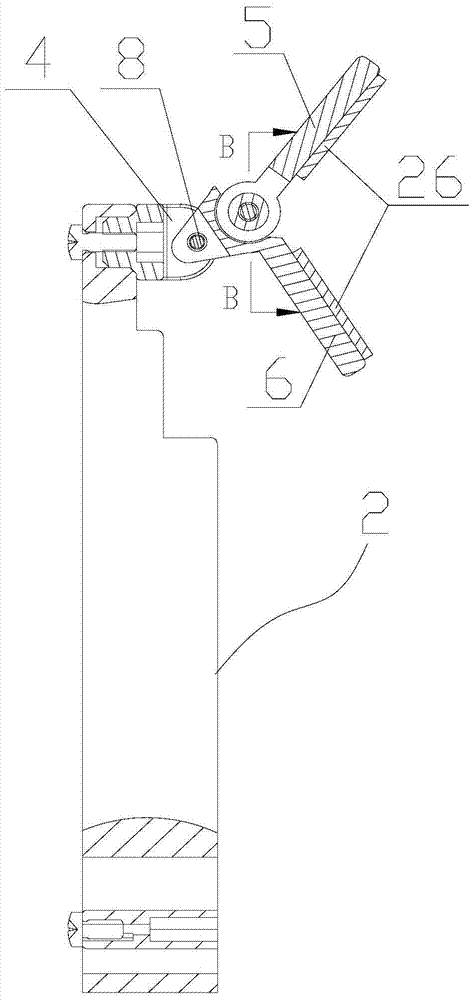

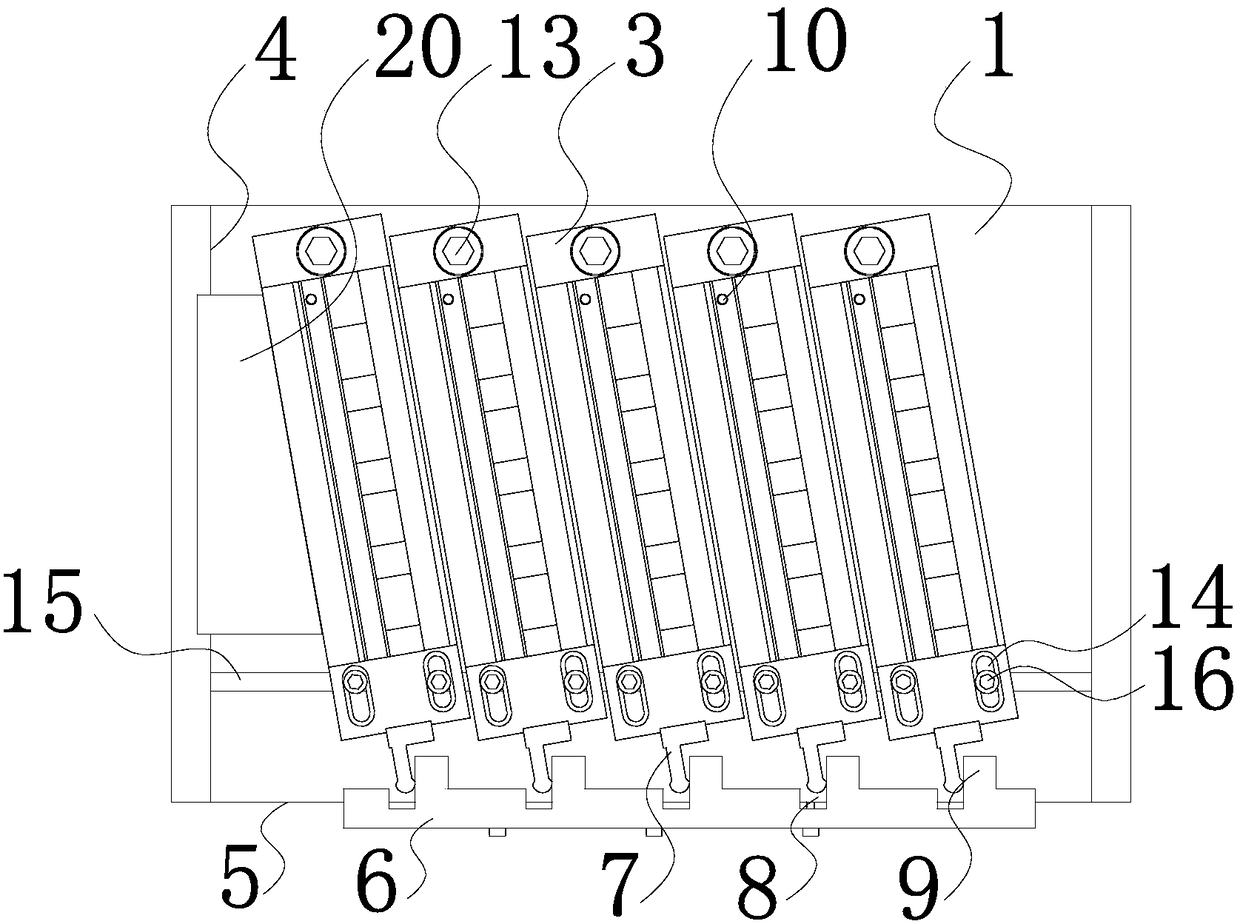

Rotary type feeding and discharging device capable of achieving three-axis transfer

InactiveCN106743613AIncrease exercise spaceImprove motor flexibilityConveyor partsEngineeringControllability

The invention discloses a rotary type feeding and discharging device capable of achieving three-axis transfer. The device comprises a machine frame, a XYZ-triaxial driving device, a clamping device and a rotating device. The fixed end of the rotating device is connected to the XYZ-triaxial driving device and driven by the XYZ-triaxial driving device to do rectilinear motion in the X-axis direction, the Y-axis direction and the Z-axis direction. The clamping device is connected to the rotating end of the rotating device and driven by the rotating device to rotate. The clamping device is composed of a plurality of clamping assemblies which are arranged at intervals through separation devices. Each clamping assembly comprises a clamping air cylinder, two clamping parts and a connection base, wherein the fixed end of the clamping air cylinder is connected to the connection base, the two clamping parts are symmetrically connected to the movement end of the clamping air cylinder, and clamping motion is completed through drive and control of the clamping air cylinder. The rotary type feeding and discharging device capable of achieving three-axis transfer can achieve multi-angle transportation and steering, and has the advantages of being high in transfer speed, good in controllability, high in clamping precision and efficiency and good in flexibility and continuity.

Owner:GUANGDONG LXD ROBOTICS CO LTD

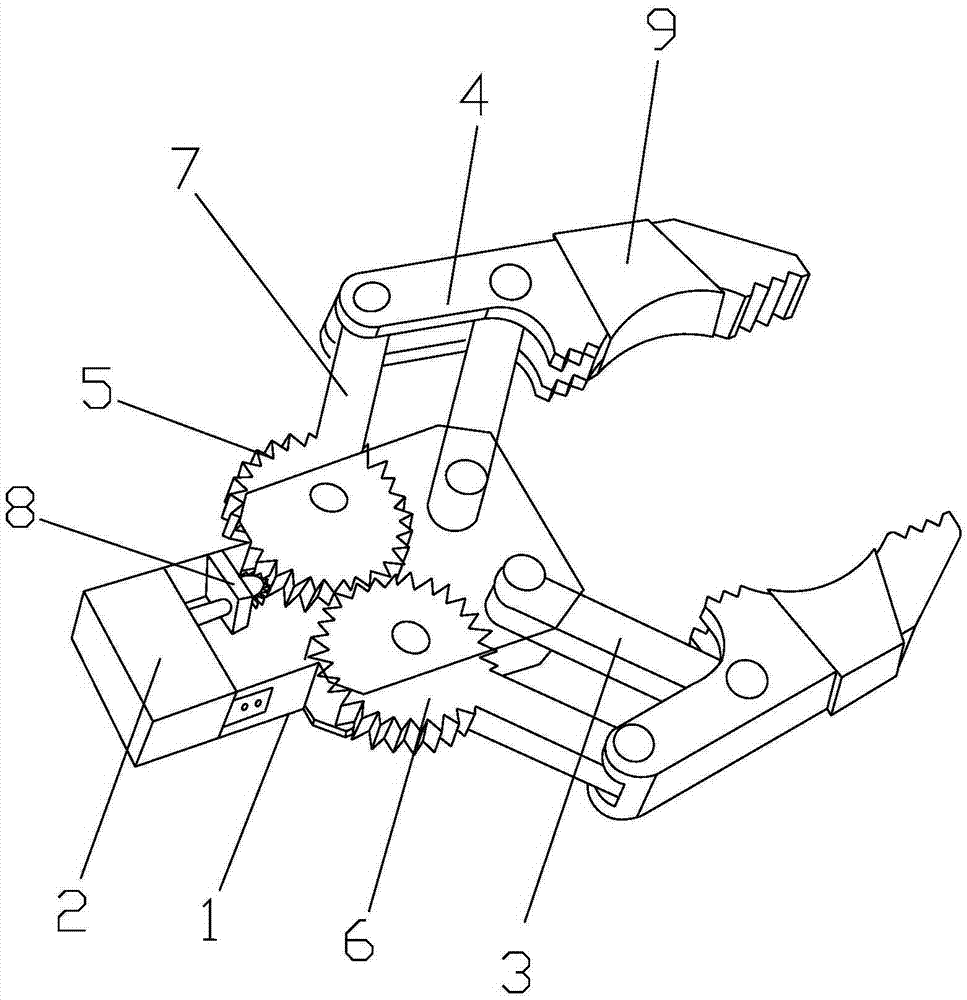

High precision manipulator

InactiveCN106926231AImprove clamping positioning accuracySimple structureProgramme-controlled manipulatorGripping headsGear wheelEngineering

The invention discloses a high precision manipulator which comprises a housing, an electromotor, rotating rods and clamping jaws, wherein a first gear and a second gear are arranged in the housing; the first gear is meshed with the second gear; both the first gear and the second gear are in rotation connection with the housing; a metal rod is arranged on each of the first gear and the second gear; the metal rod on the first gear is integrally arranged with the first gear and that on the second gear is integrally arranged with the second gear; one end of each of the metal rods is in rotation connection with the corresponding clamping jaw; a transmission mechanism is arranged in the housing; the transmission mechanism is in linkage with the first gear; the electromotor is in linkage with the transmission mechanism; one end of each of the rotating rods is mounted in the housing; the rotating rods are in rotation connection with the housing; the other ends of the rotating rods are in rotation connection with the clamping jaws. The high precision manipulator is convenient to maintain and high in clamping and positioning precision.

Owner:TIANJIN XIQING RUIBO BIOLOGICAL TECH CO LTD

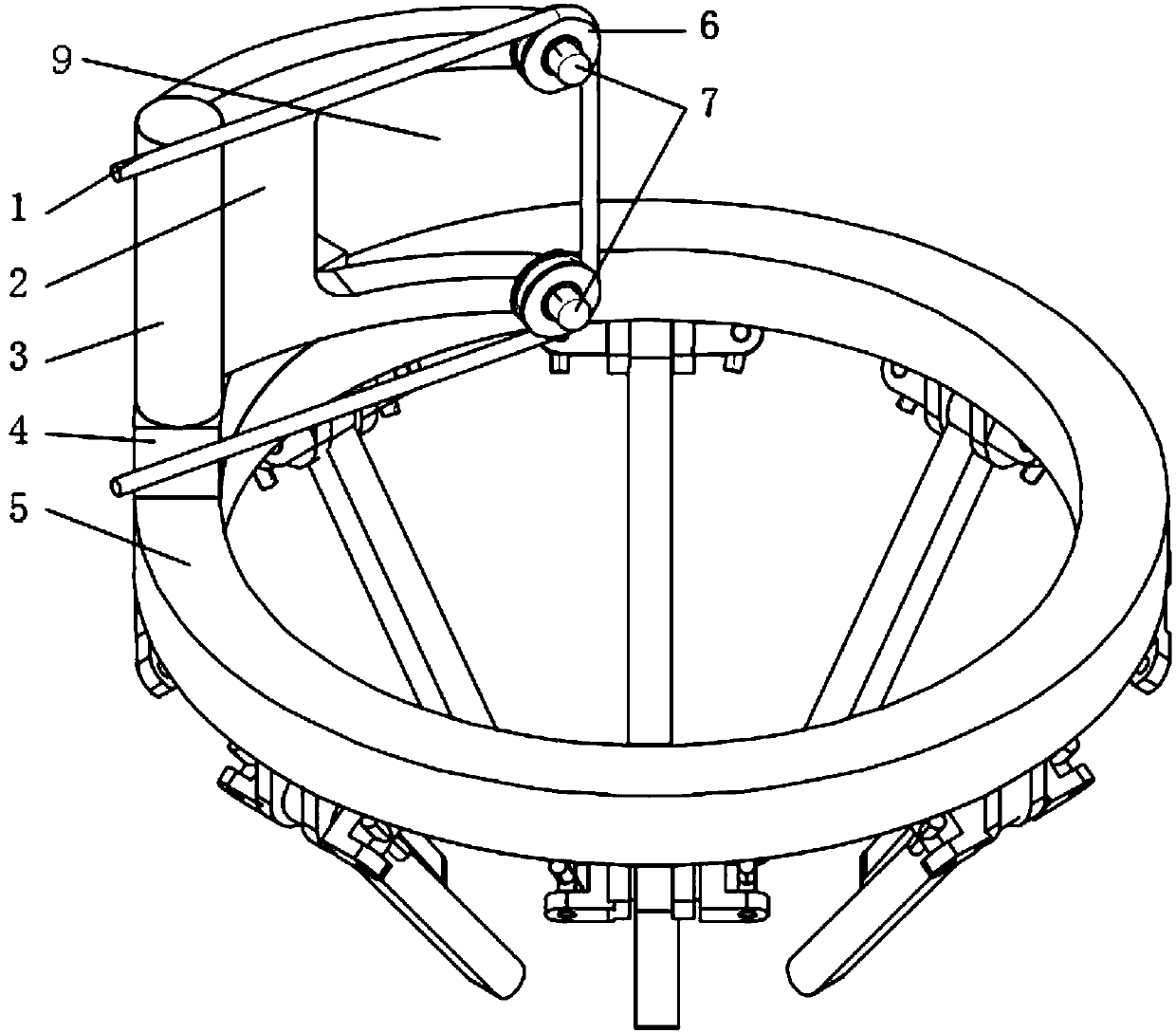

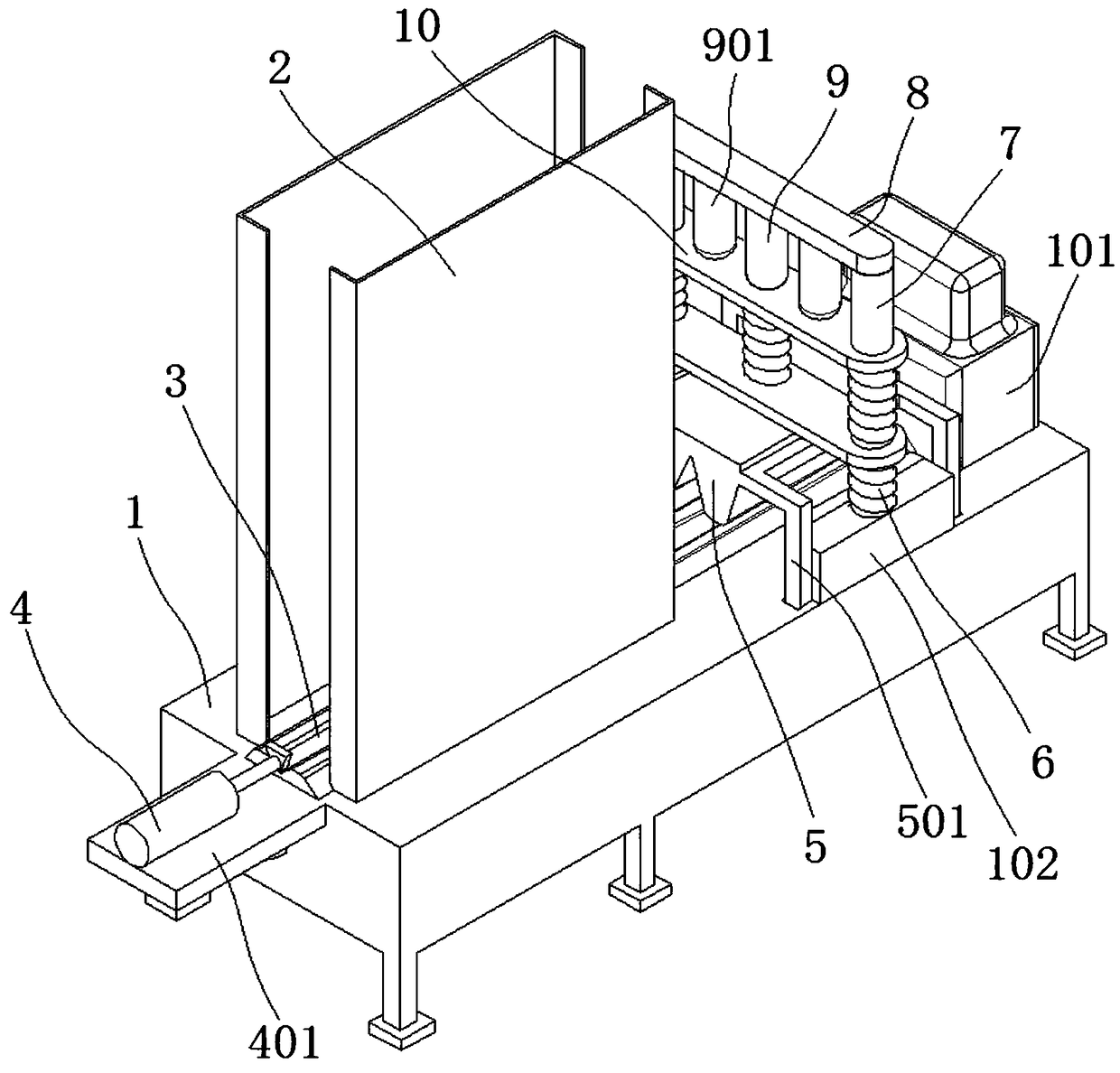

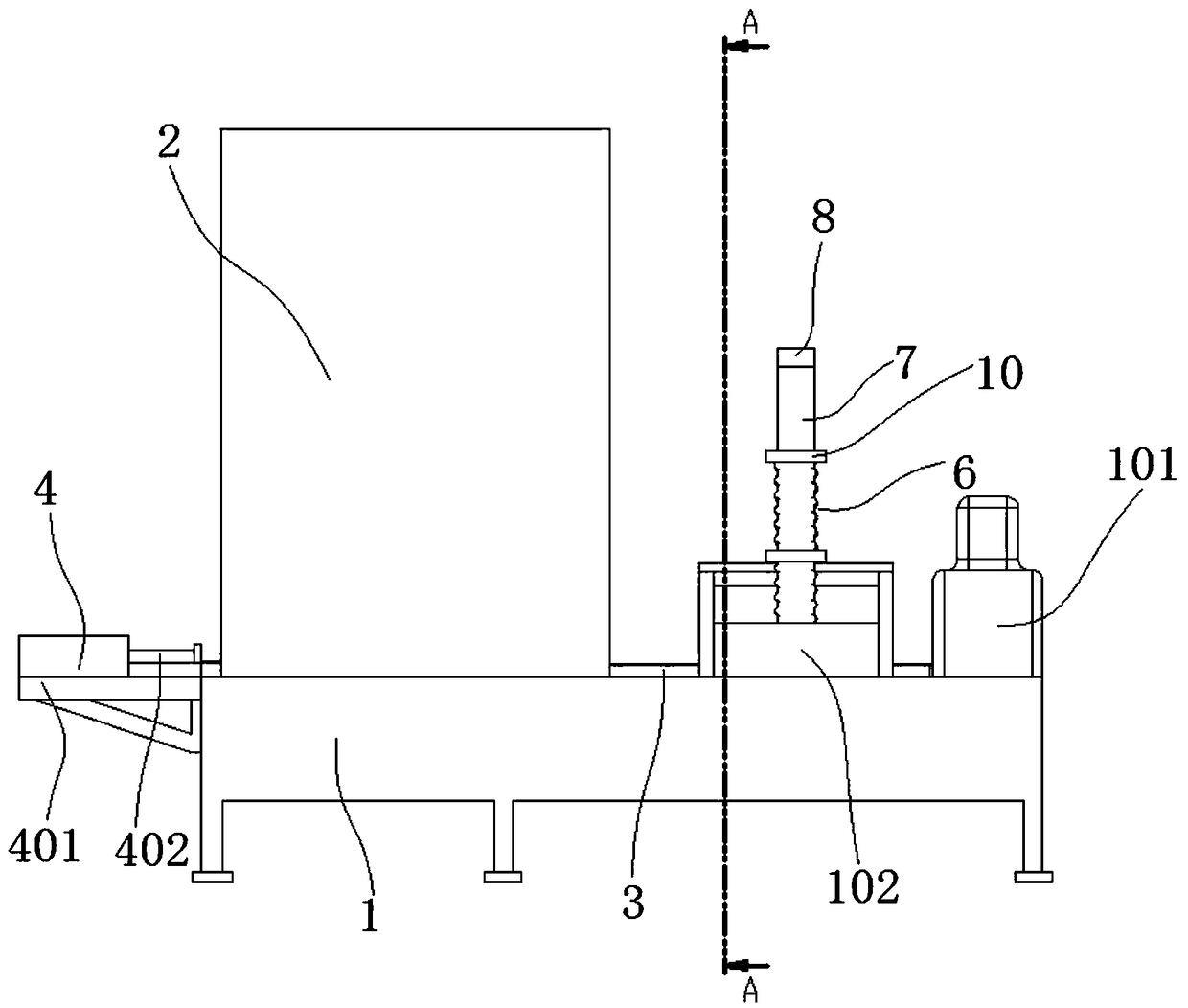

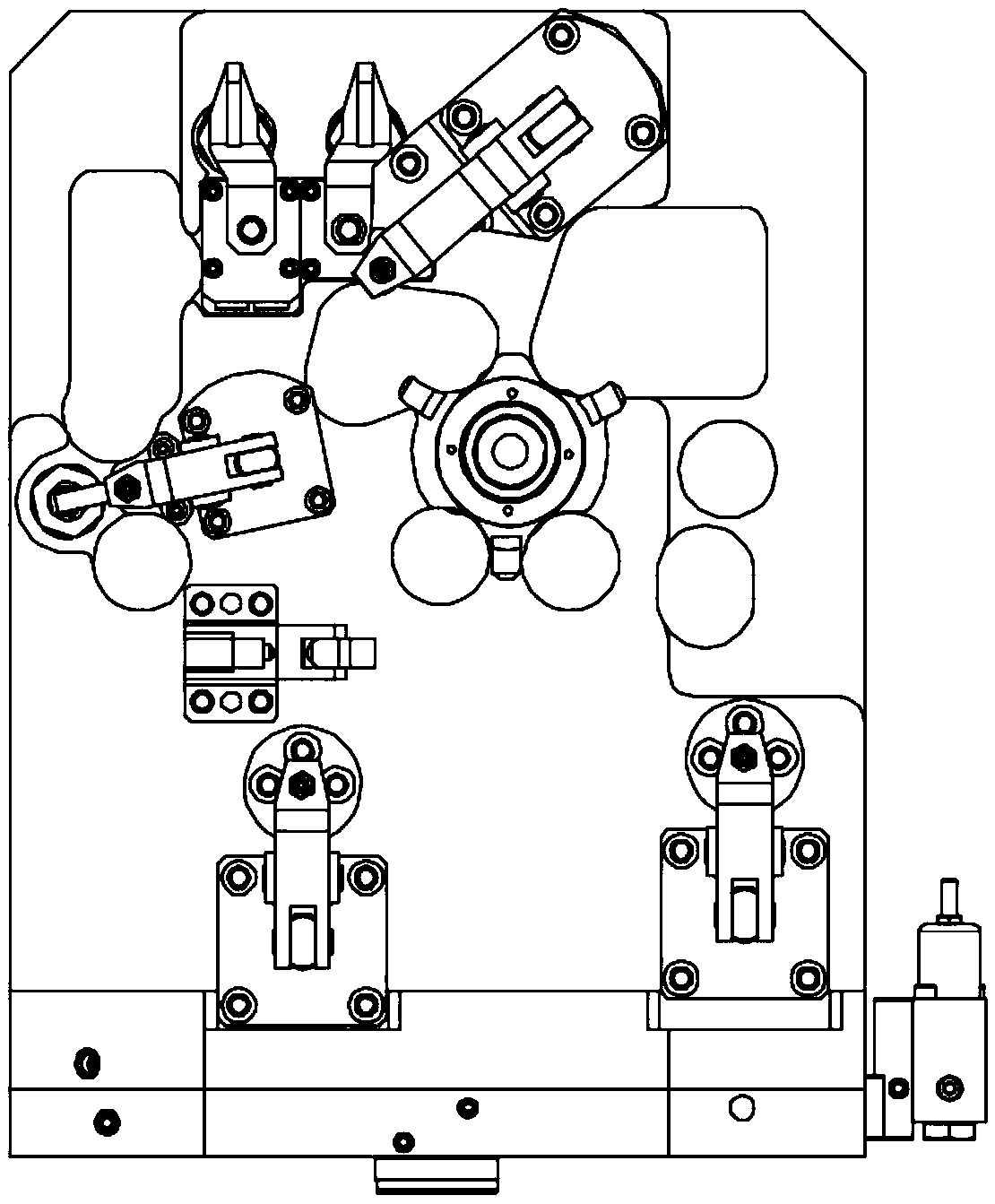

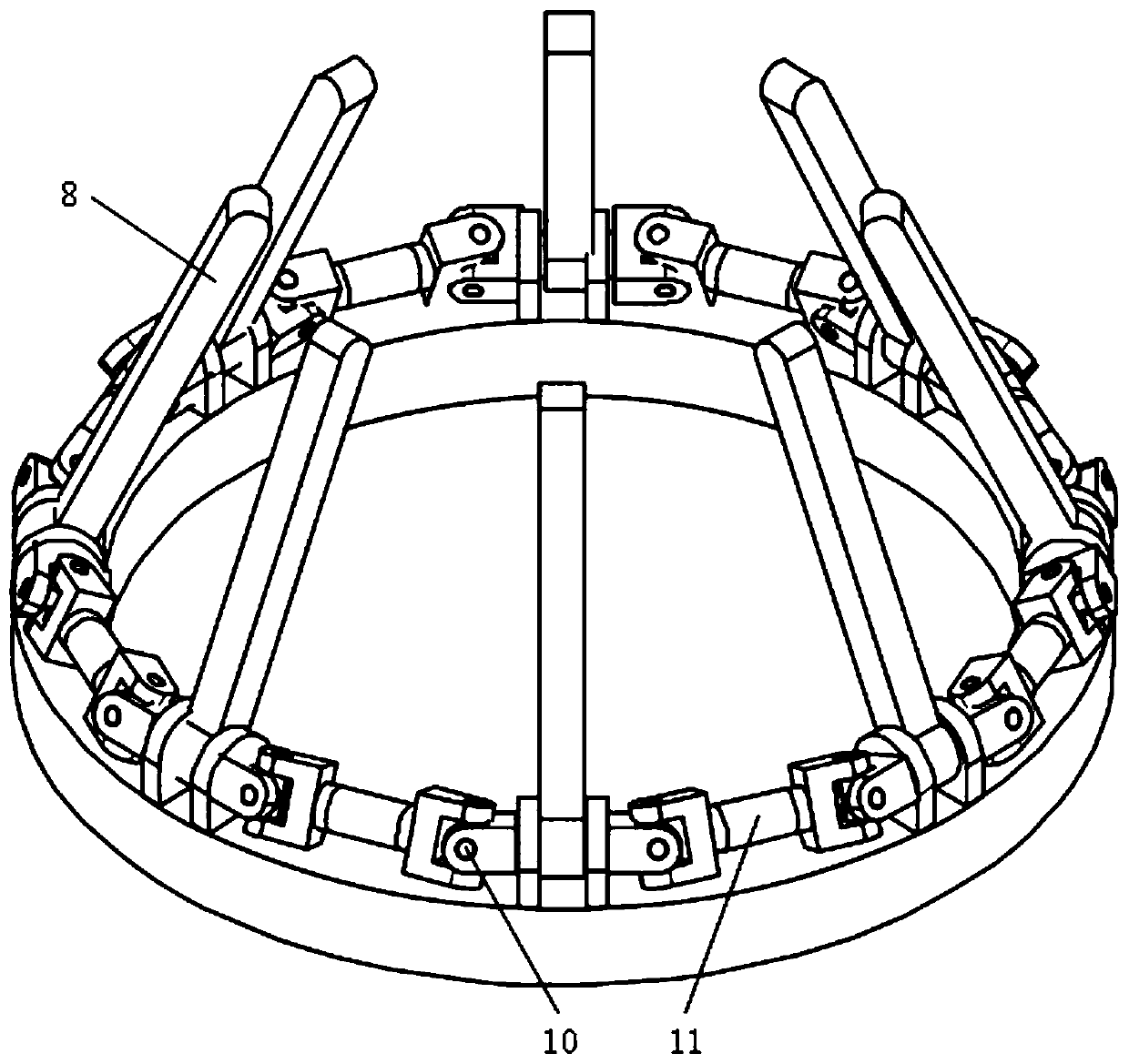

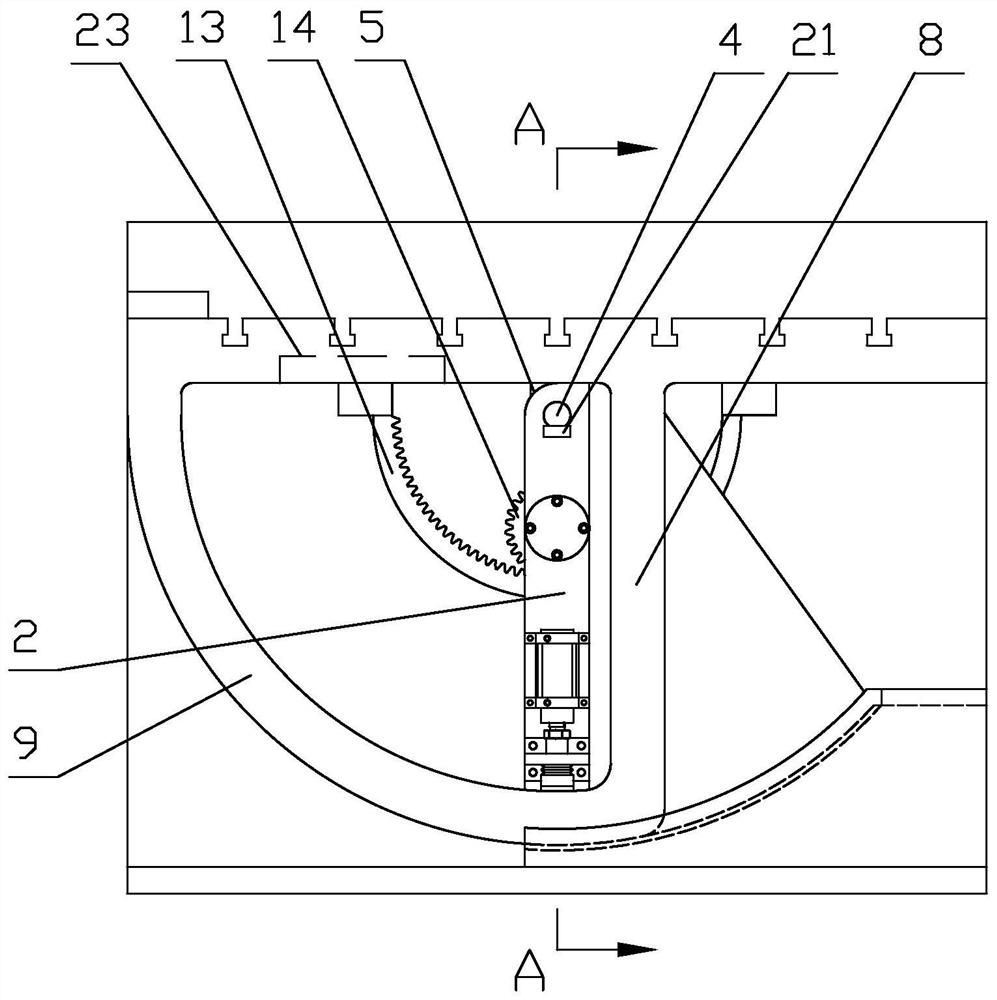

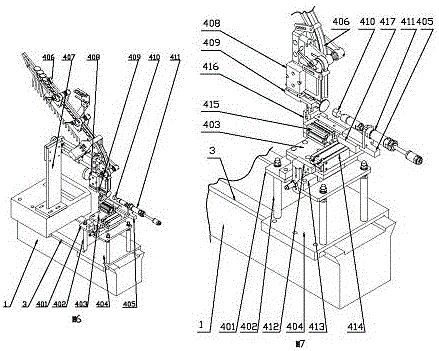

Fretsaw cutting device

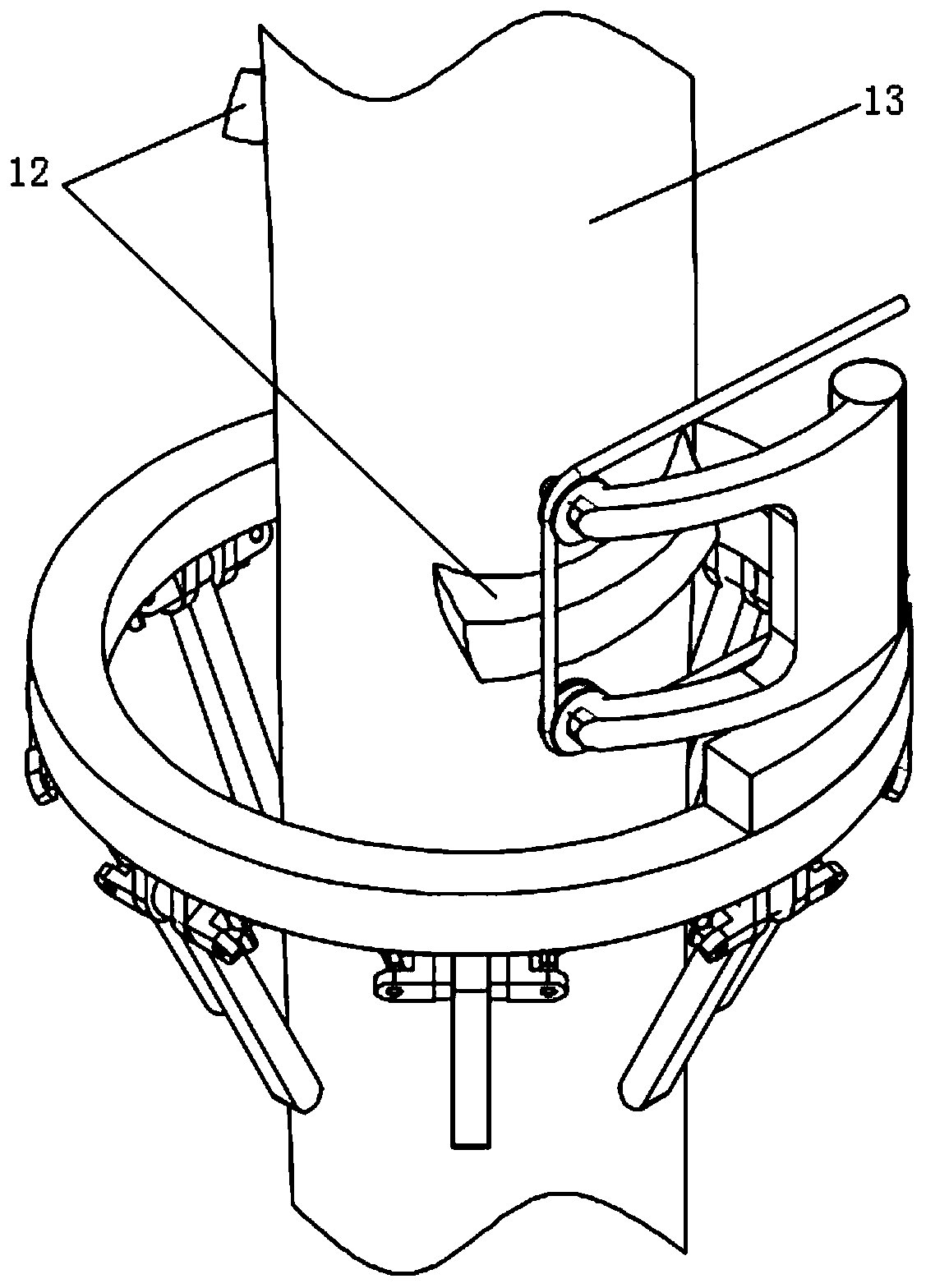

ActiveCN107637271AWide adaptability of shaft diameterReduce volumePicking devicesEngineeringWire saw

The invention discloses a fretsaw cutting device which comprises an execution portion and a positioning clamping portion. The execution portion comprises a fretsaw, a profiled supporting piece, a supporting piece rotating shaft, a movable sliding table, a fixed sliding table, a fretsaw wheel, a profiled roller and a power source, the positioning clamping portion is of a multi-jaw structure and comprises clamping jaws, a cross-shaped universal shaft and a universal shaft connecting rod. According to the device, the clamping jaws evenly distributed along the circumference are adopted for clamping an object to be cut; by adopting the movable and fixed combined sliding table mode, rotation in the circumferential direction of the object to be cut is performed; by adopting the profiled supporting piece and the profiled roller at the tail end, profiling is performed; cutting is performed by adopting the fretsaw mode. The fretsaw cutting device is well applicable to comb discharging operationof comb handles on banana stalk, and has the advantages of being small in overall size, simple in structure, wide in stalk adaptability, high in reliability, good in profiling effect, small in cut, good in cutting quality, low in energy consumption cost and the like.

Owner:SOUTH CHINA AGRI UNIV

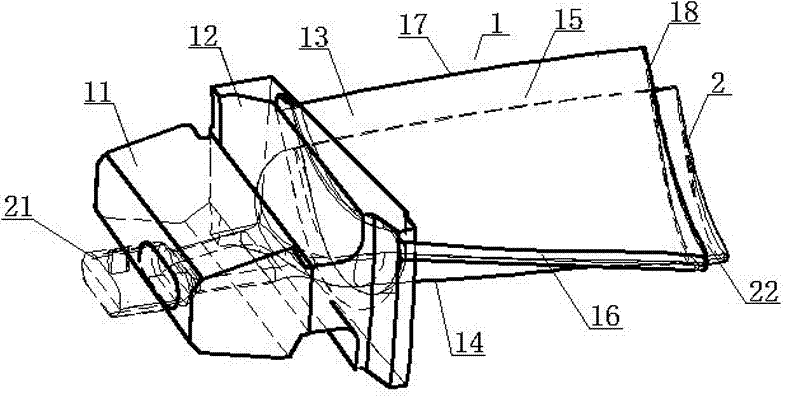

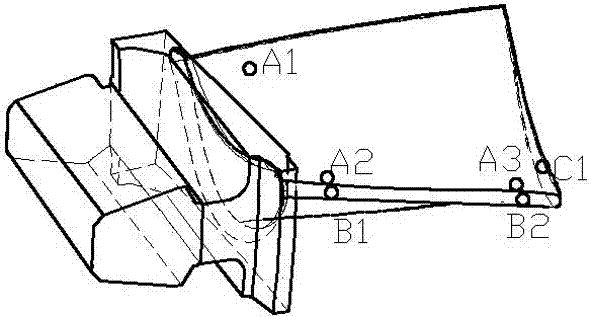

Wax mold molding method with ceramic core

ActiveCN105945220BImprove clamping positioning accuracyImprove molding qualityFoundry mouldsFoundry coresWaxSupport point

The invention discloses a method for forming a wax mold with a ceramic core. The design structure of the wax mold and the ceramic core is determined according to the designed casting. The inspection reference point is determined on the ceramic core, so that the designed casting and the inspection reference point on the ceramic core are mapped to each other; the ceramic core is manufactured according to the design structure, and the inspection reference point determined on the ceramic core is used as a supporting point. Use positioning pins to clamp the ceramic core in the wax mold; inject wax liquid into the cavity of the wax mold until the wax mold is formed, remove the positioning pins on the wax mold, and fill the positioning holes on the wax mold. The invention effectively improves the clamping and positioning accuracy of the ceramic core in the wax mold, enables the molded wax mold with the ceramic core to have good molding quality, effectively controls the reject rate, improves the qualification rate, and has good economical efficiency.

Owner:DONGFANG TURBINE CO LTD

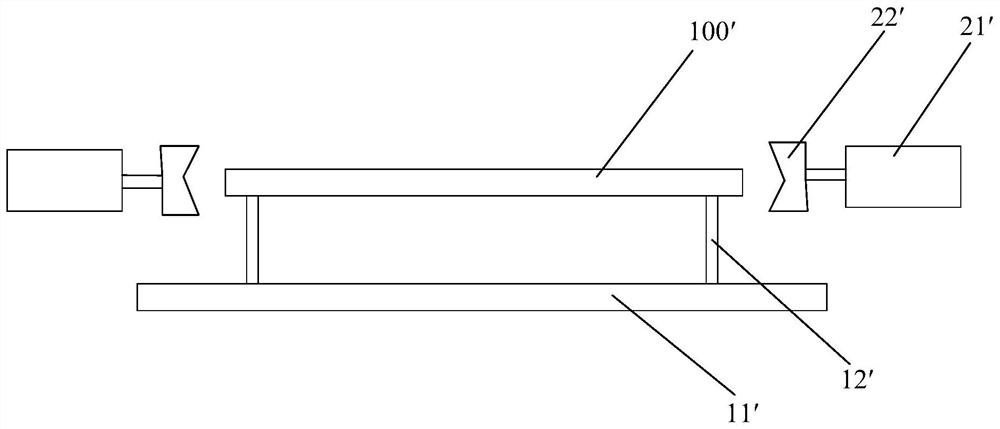

Shell machining process

InactiveCN111001997AReduce the number of clampingImprove clamping positioning accuracyPositioning apparatusMetal-working holdersEngineeringMachining process

The invention discloses a shell machining process, which comprises the steps that firstly, a blank is cast, the blank is provided with an auxiliary pressing boss, a clamp clamps the blank on the clampthrough the auxiliary pressing boss, and rough milling is conducted on the rear end face of the blank; secondly, the front end face is positioned and machined through the rear end face and at least two rear end positioning holes in the rear end face; thirdly, the positioning in the second step is adopted, and the rear surfaces of lugs on the side surfaces of the blank are milled; fourthly, the front end face and at least two front end positioning holes in the front end face are adopted for positioning, the rear end face is finely milled, and a center hole in the front end face is bored; and fifthly, the positioning in the fourth step is adopted, the first side surface is milled, and a threaded hole in the second side surface is machined. The machining in the second step and the third stepcan be carried out through one-time clamping, the machining in the fourth step and the fifth step can be carried out after the blank is dismounted and clamped again after the third step is finished,the blank clamping frequency is effectively reduced, and the precision and the machining efficiency are improved.

Owner:SHENGRUI TRANSMISSION

Elbow pipe processing technology

The invention discloses an elbow pipe processing technology. The elbow pipe processing technology is used for processing an elbow pipe with a first pipe opening and a second pipe opening, wherein thefirst pipe opening is provided with a flange plate, the opening edge of the first pipe opening is higher than the flange plate, and an axis of the first pipe opening is perpendicular to an axis of thesecond pipe opening mutually. The elbow pipe processing technology comprises the following steps: step one: fixing the elbow pipe on a first clamp and lathing a first pipe opening outer circle; steptwo: fixing the first pipe opening of the elbow pipe on a second clamp and lathing a second pipe opening inner circle; step three: fixing the elbow pipe on a third clamp, and drilling a hole in the flange plate; using the flange plate to position on the first clamp, firstly processing the first pipe opening outer circle provided with the flange plate, and using a positioning ring on the second clamp to position the first pipe opening of the elbow pipe and process the second pipe opening outer circle, using the flange plate to position, and using a drill bushing to process the hole in the flange plate. The processing sequence is optimized, the processing steps are simplified, the clamping and positioning accuracy is higher, and the production efficiency of the elbow pipes is greatly improved.

Owner:SHENGRUI TRANSMISSION

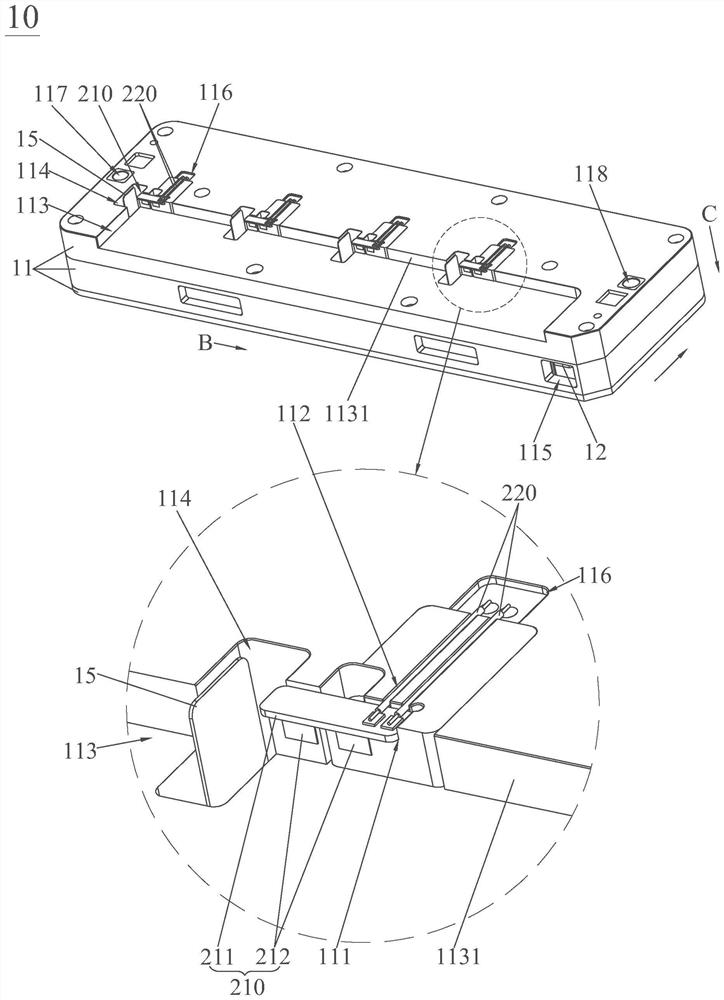

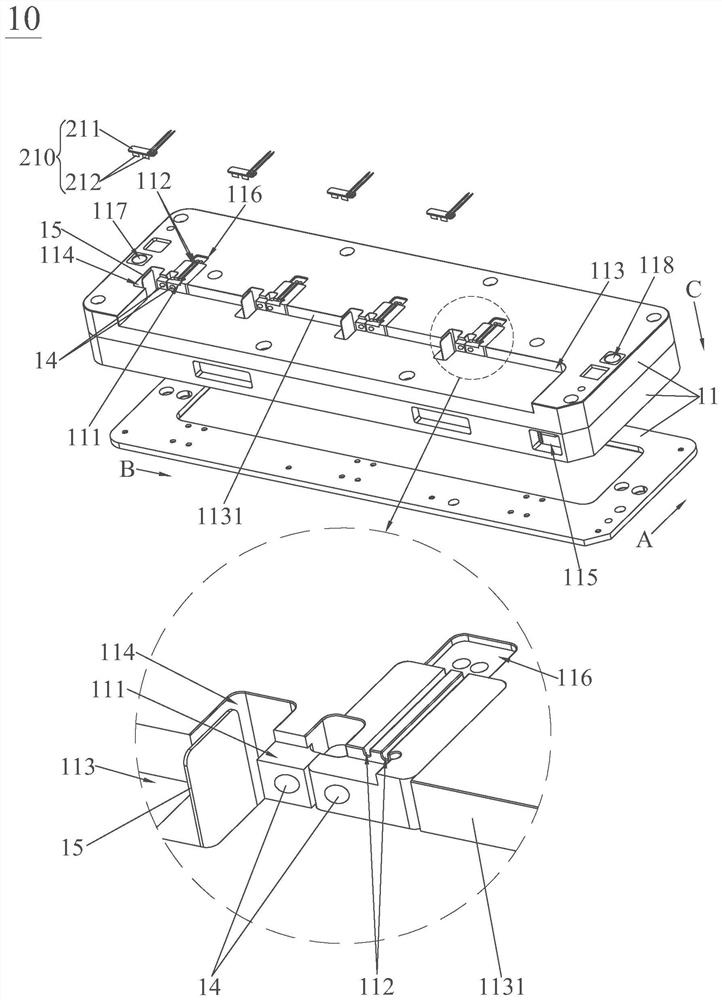

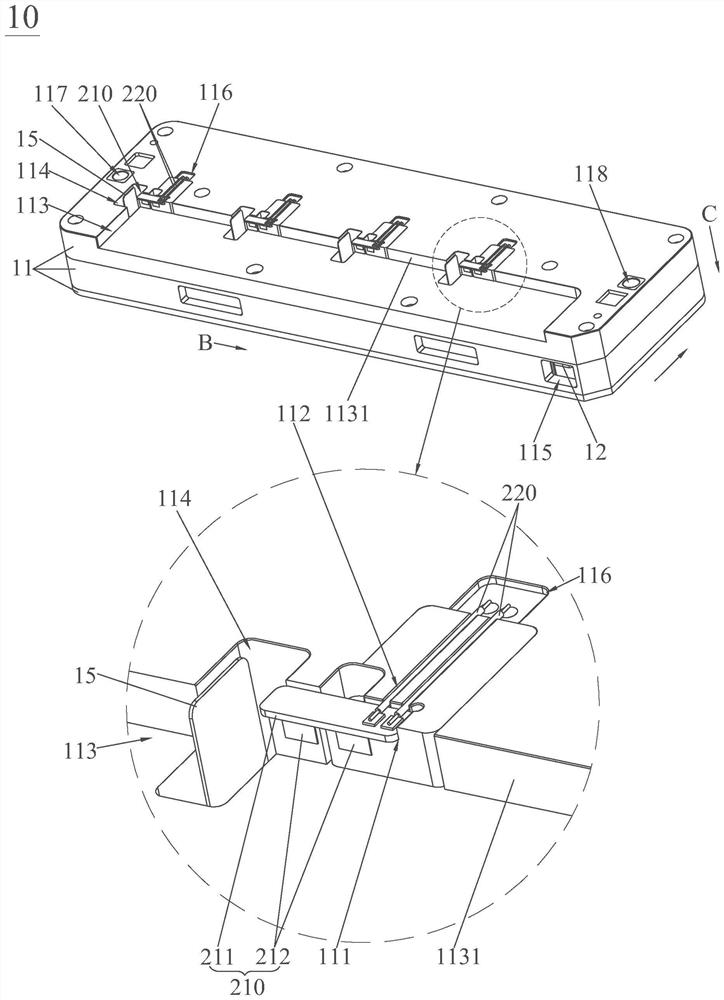

Clamping mechanism and detection device

The invention relates to the technical field of substrate detection and discloses a clamping mechanism and a detection device. The clamping mechanism is used for clamping a substrate and comprises a supporting body, at least three sets of radial abutting assemblies and axial abutting assemblies, wherein the supporting body comprises a supporting plane, the supporting plane is used for supporting abottom surface of the base plate, the at least three groups of radial pressing assemblies are arranged on the supporting body and can respectively press a peripheral surface of the substrate along the radial direction of the substrate so as to limit the position of the substrate in the supporting plane, the axial abutting assembly is arranged on the supporting body, and the axial abutting assembly can clamp the substrate to the supporting plane in the axial direction of the substrate e. The substrate clamping process of the clamping mechanism is simple, positioning precision is high, and damage to the substrate cannot be caused. According to the detection device, the substrate clamping step can be simplified and measurement accuracy of the substrate can be improved by adopting the clamping mechanism.

Owner:SHANGHAI PRECISION MEASUREMENT SEMICON TECH INC

A purple copper tube automatic feeding and clamping device for air conditioning

InactiveCN108890354AAvoid Longitudinal CracksReduce the chance of leaksPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention discloses a purple copper tube automatic feeding clamping device for air conditioning, which relates to the technical field of purple copper tube processing. Including workbenches; A guide bar is fixed on the workbench, and a fixing block is fixed on a pair of sides of the workbench; A surface of that work table is fixedly provided with a storage cylinder and an air cylinder; A pressblock is slidably arranged on the workbench; The two fixing blocks are fixedly provided with a guide column, the end of the guide column is fixed with a cross beam, and two pressure plates are sleeved on the guide column. Two first springs are arranged between the two pressure plates; A first hydraulic cylinder and two second hydraulic cylinders are fixed on the cross beam. As that material to beproces is put into the storage cylinder, By pushing the material to feed through the push rod and pressing the workpiece to be processed through the pressing block, the working efficiency is improved, the clamping positioning precision is clamped, the production cost is reduced, the damage to the purple copper pipe in the process of processing is reduced, the longitudinal cracks in the process ofprocessing the purple copper pipe are effectively avoided, the leakage probability is reduced, and the environmental pollution is reduced when the purple copper pipe is used.

Owner:芜湖辉林奥远自动化科技有限公司

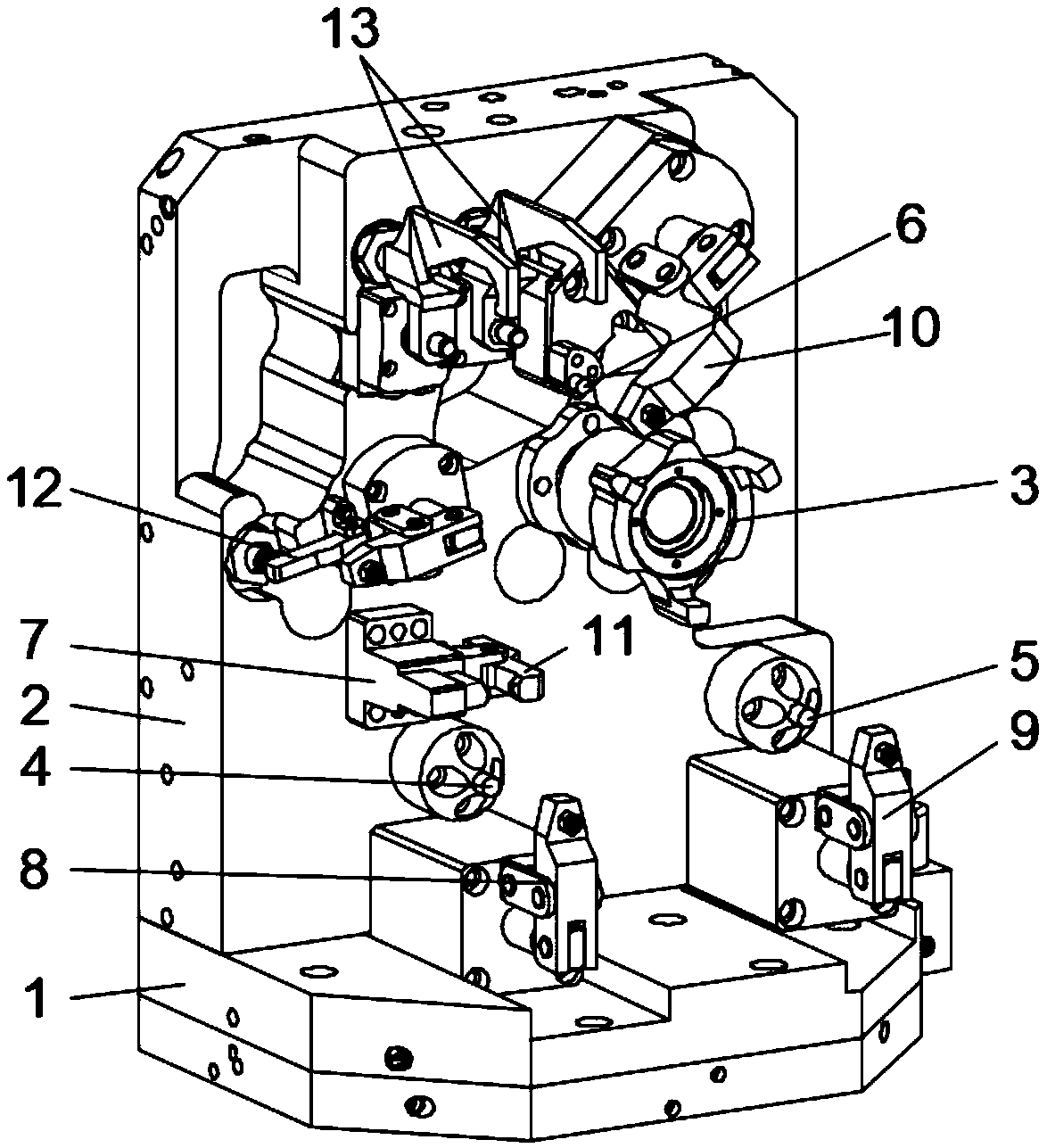

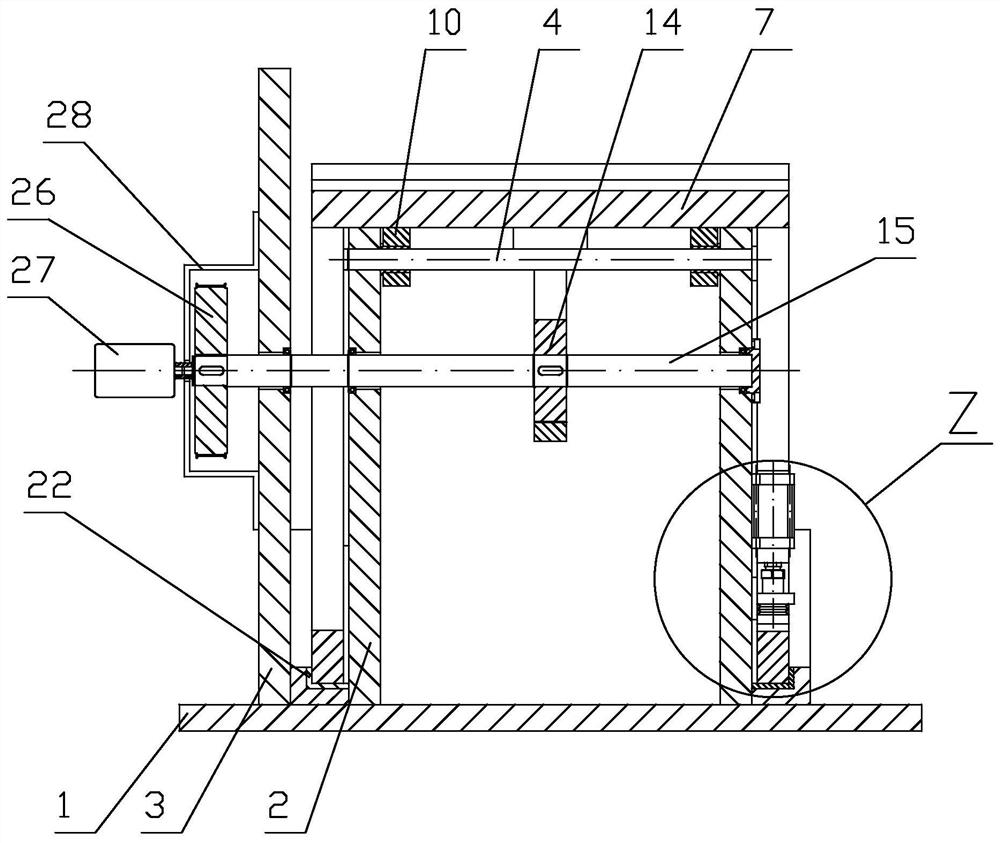

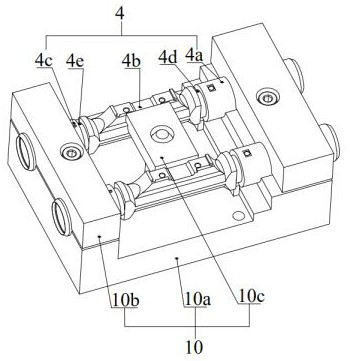

Hydraulic fixture for hub bracket five-axis machine tool machining

InactiveCN108907832AImprove stabilityImprove clamping positioning accuracyPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a hydraulic fixture for hub bracket five-axis machine tool machining. The hydraulic fixture comprises a horizontal base, and a stand base fixed on the horizontal base; and thestand base is provided with a support reference surface consisting of a first support base, a second support nail, a third support nail and a fourth support nail, an angle fixing mechanism consistingof an angle positioning ejector rod, an angle positioning pressing plate and an ejecting cylinder, a main pressing mechanism consisting of a first pressing mechanism, a second pressing mechanism and athird pressing mechanism, a first auxiliary clamping mechanism and a second auxiliary clamping mechanism. The hydraulic fixture for hub bracket five-axis machine tool machining can finish all machining procedures through once clamping, is high in stability, high in clamping and positioning precision and firm in machining, can leave enough angle and space for machining, prevents accumulated errorscaused by multiple times of clamping, is high in product machining precision, greatly reduces the product rejection rate and the rework rate, reduces the production cost, and improves the productionefficiency.

Owner:KUNSHAN YONG XIANG PRECISION MACHINERY

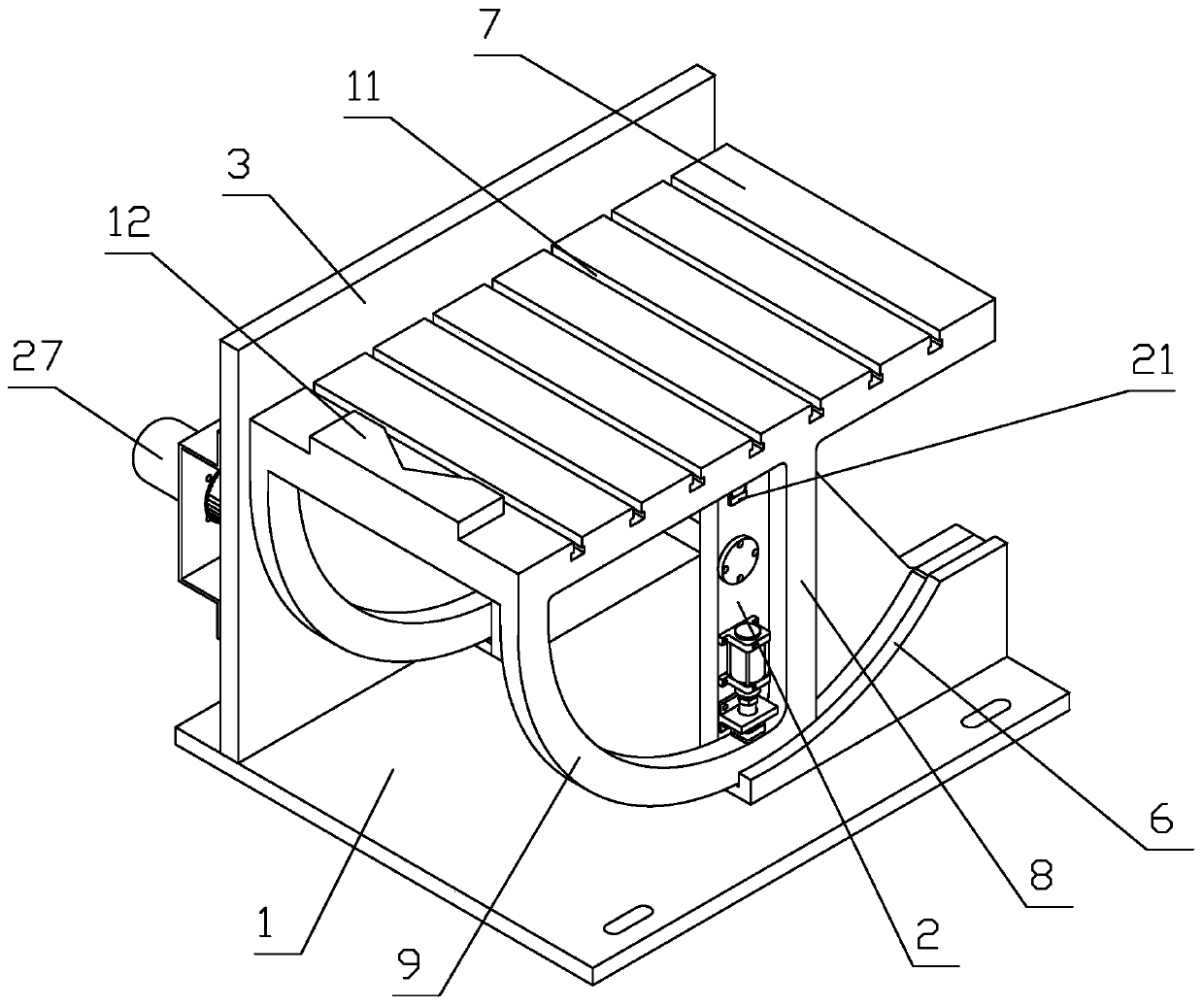

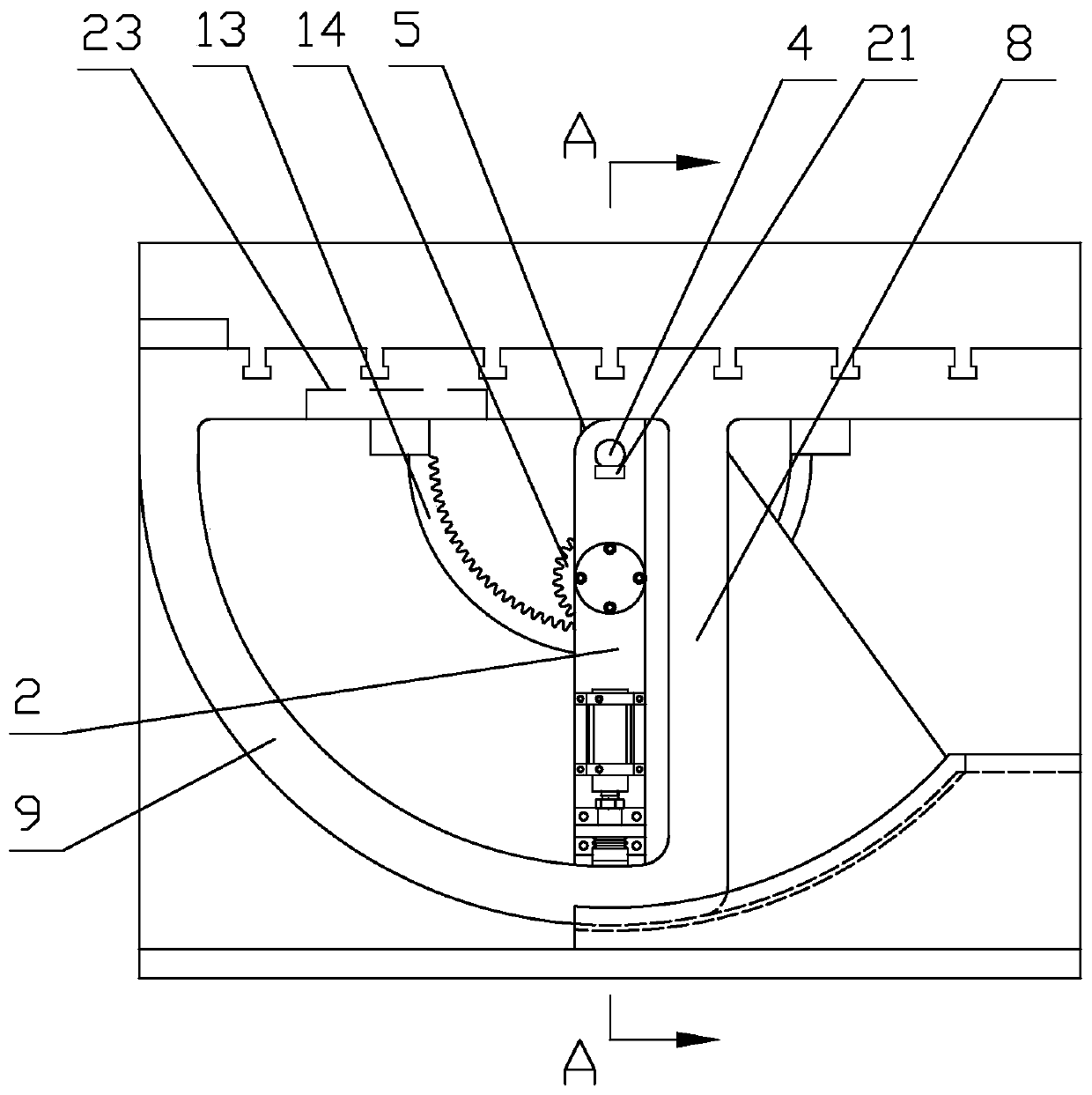

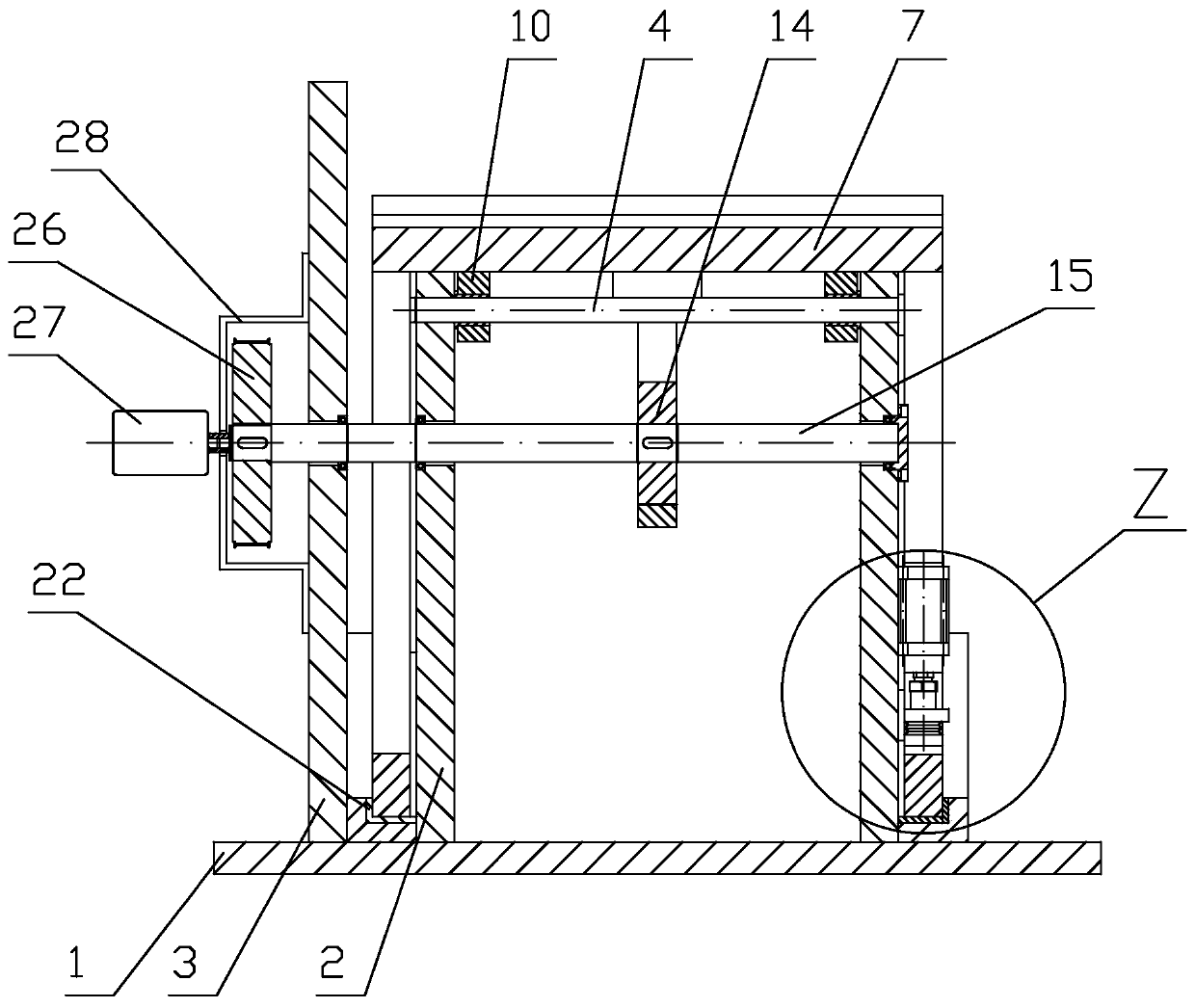

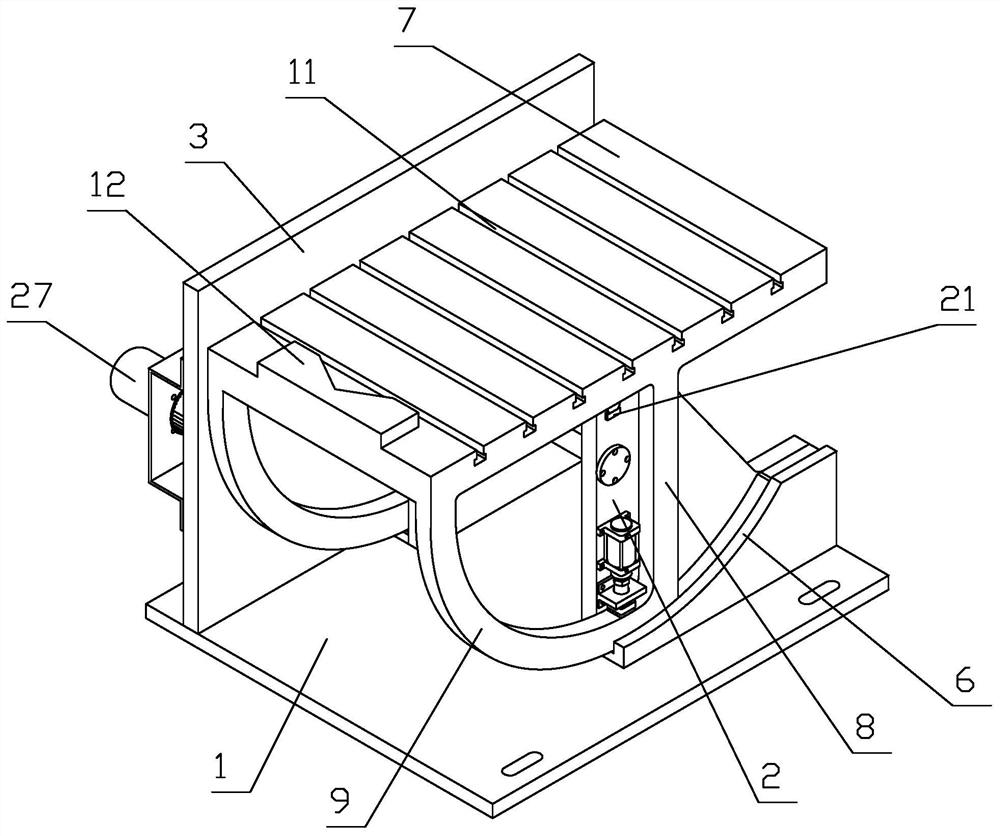

Precise machining fixture for parts of mechanical pressing machine

ActiveCN110900223AImprove processing qualityImprove processing efficiencyLarge fixed membersPositioning apparatusBrakeGear wheel

The invention discloses a precise machining fixture for parts of a mechanical pressing machine. The precise machining fixture for the parts of the mechanical pressing machine comprises a clamp body, a90-degree rotary workbench, and an internal gear pair, wherein the clamp body comprises a bottom plate, two support plates which are vertically arranged at an interval, and a side plate are arrangedon the bottom plate, a support shaft is arranged on the upper parts of the two support blocks, a 90-degree included angle is formed between the upper end surface and the front end surface of each support plate, and the upper end surface and the front end surface form circular-angle transition, and arc-surface guide rail grooves are formed in parts at the outer sides of the two support plates, of the bottom plate separately; the 90-degree rotary workbench comprises a workbench surface, a support rod and arc-shaped guide rails, the workbench surface is hinged to the support shaft through a self-lubricating shaft sleeve arranged at the bottom of the workbench surface, a trapezoidal groove is formed in the upper side of the workbench surface and a V-shaped location block is arranged at the upper side of the workbench surface, and the arc-shaped guide rails are movably installed in the arc-surface guide rail grooves; and the internal gear pair comprises a fan-shaped internal gear installedon the lower surface of the workbench surface. The precise machining fixture for the parts of the mechanical pressing machine has the advantages of being stable in structure, high in rigidity, capableof increasing the machining efficiency, high in clamping location assembly and rotary repeated location accuracy, and firm and reliable in brake, and the like, improves the part machining quality, and increases the part machining efficiency.

Owner:JIAMUSI UNIVERSITY

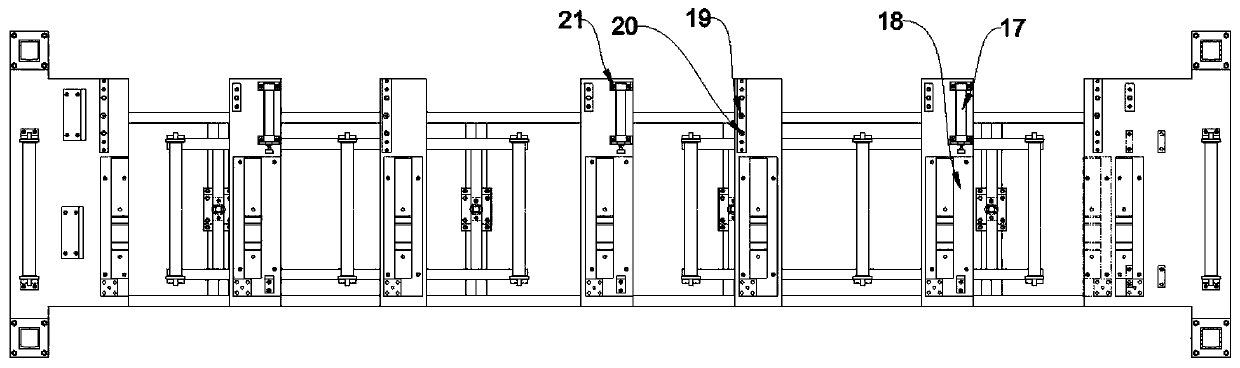

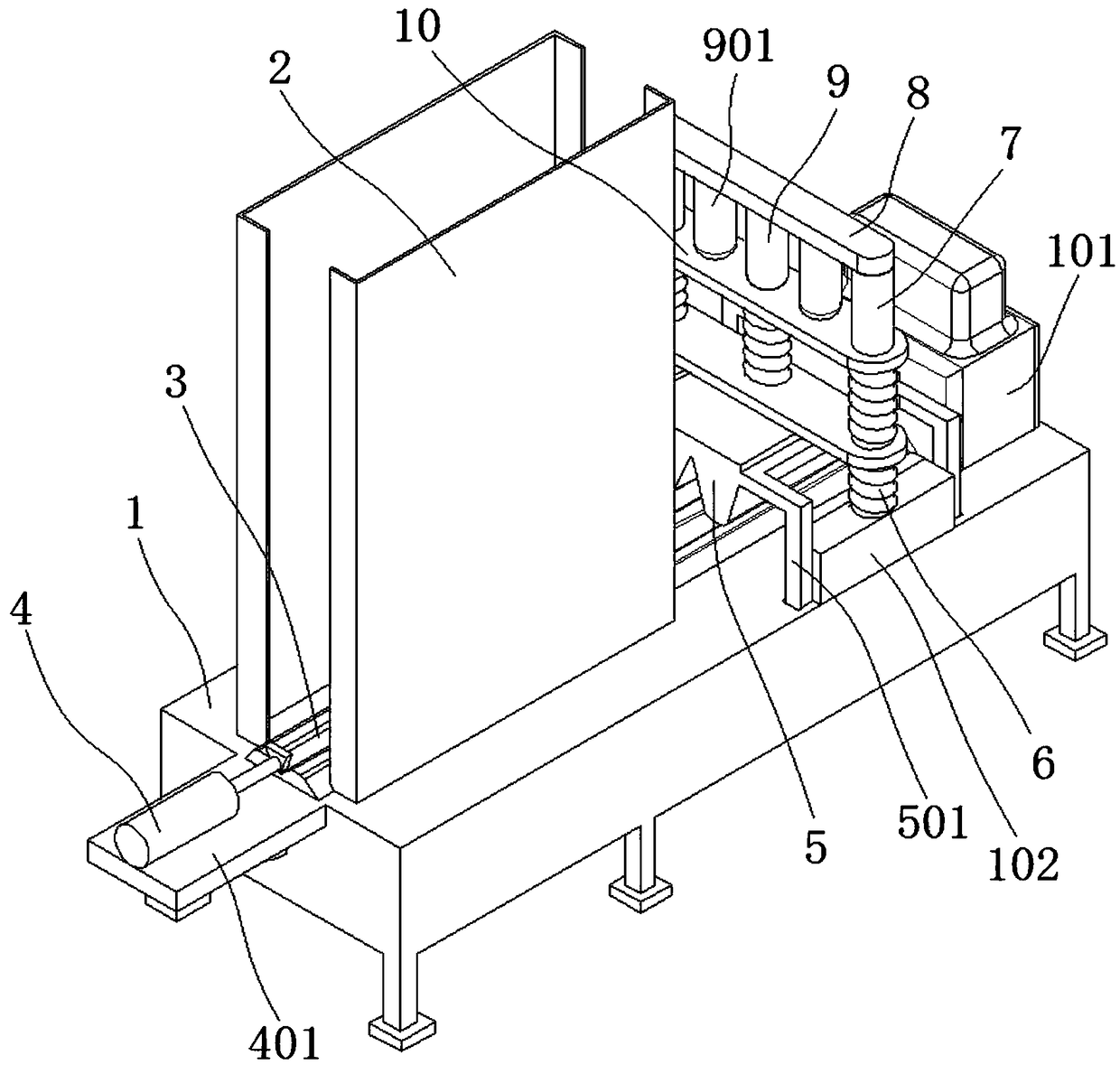

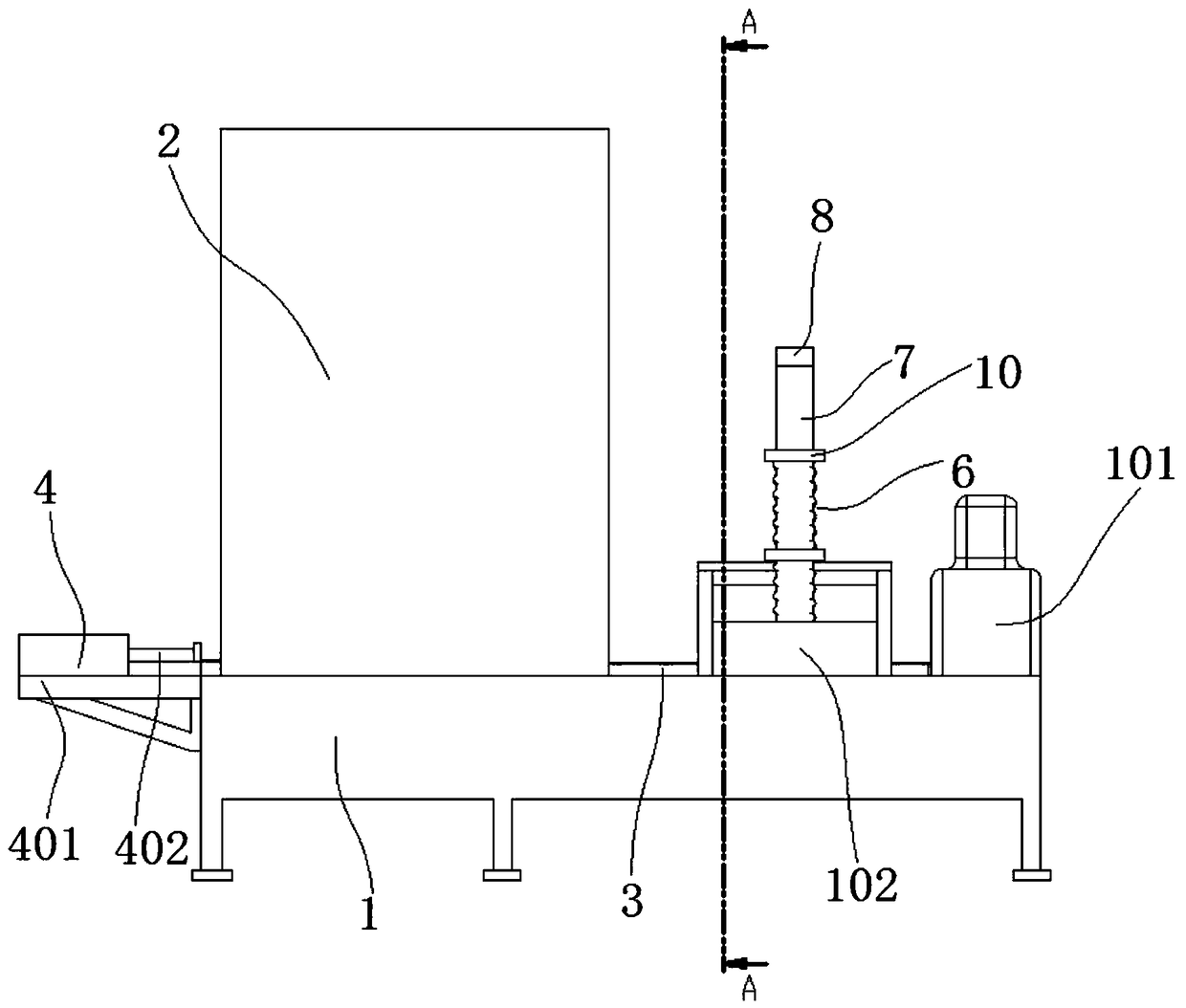

Welding tool clamp for military vehicle sideboard assembly

InactiveCN111215812AImprove the fixing strengthReduce the difficulty of operationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention discloses a welding tool clamp for a military vehicle sideboard assembly. The welding tool clamp comprises an upper pressing framework assembly and supporting legs, wherein the supporting legs are welded to the bottom side positions of a base framework assembly, the upper pressing framework assembly is arranged on the upper side of the base framework assembly in a supported mode through a stand column assembly, a plurality of upper pressing air cylinders are installed on the bottom side of the upper pressing framework assembly in an arranged mode, and an end positioning assemblystructure is welded and fixed to the end of one side of the upper side of the base framework assembly. According to the welding tool clamp for the military vehicle sideboard assembly, lower lifting air cylinders are arranged on a bottom frame body of the base framework assembly, lifting roller way assemblies are arranged at the tops of the lower lifting air cylinders, and roller structures are arranged on the lifting roller way assemblies, so that lifting adjustment of the lifting roller way assembles can be conveniently driven through lifting adjustment of the lower lifting air cylinders, then, the military vehicle sideboard is more convenient to move when being fixed, the labor intensity of workers is relieved, a workpiece is convenient to take and transfer, and potential safety hazardsin the process are eliminated.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

A wire saw cutting device

ActiveCN107637271BWide adaptability of shaft diameterReduce volumePicking devicesEngineeringEnergy consumption

The invention discloses a fretsaw cutting device which comprises an execution portion and a positioning clamping portion. The execution portion comprises a fretsaw, a profiled supporting piece, a supporting piece rotating shaft, a movable sliding table, a fixed sliding table, a fretsaw wheel, a profiled roller and a power source, the positioning clamping portion is of a multi-jaw structure and comprises clamping jaws, a cross-shaped universal shaft and a universal shaft connecting rod. According to the device, the clamping jaws evenly distributed along the circumference are adopted for clamping an object to be cut; by adopting the movable and fixed combined sliding table mode, rotation in the circumferential direction of the object to be cut is performed; by adopting the profiled supporting piece and the profiled roller at the tail end, profiling is performed; cutting is performed by adopting the fretsaw mode. The fretsaw cutting device is well applicable to comb discharging operationof comb handles on banana stalk, and has the advantages of being small in overall size, simple in structure, wide in stalk adaptability, high in reliability, good in profiling effect, small in cut, good in cutting quality, low in energy consumption cost and the like.

Owner:SOUTH CHINA AGRI UNIV

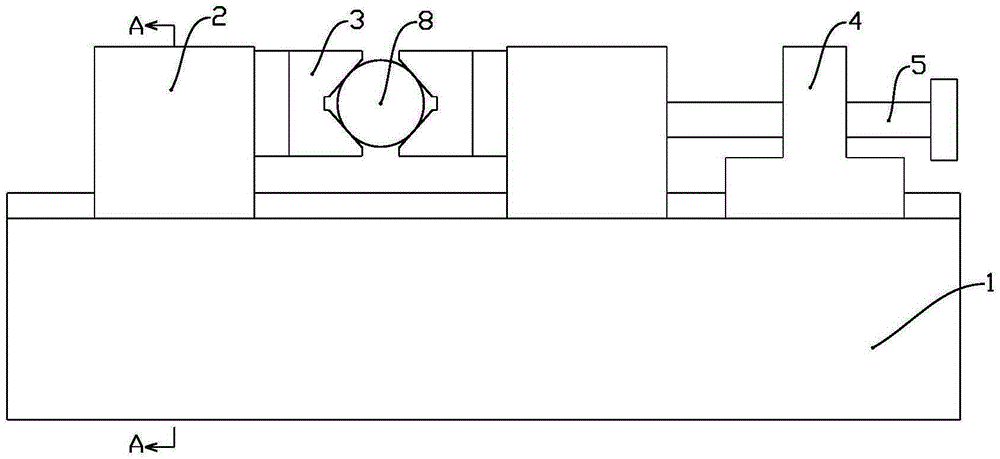

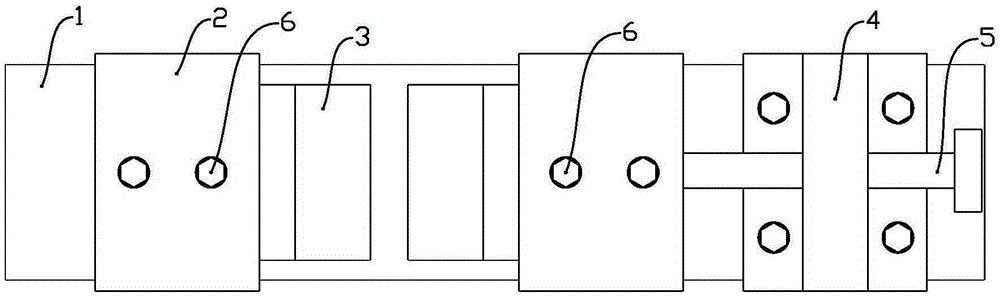

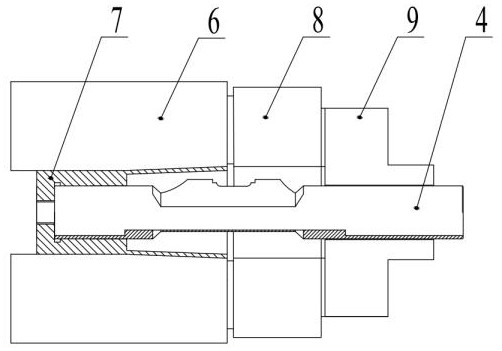

Electrospark wire-electrode cutting machining combined clamp

InactiveCN105397220AImprove versatilityImprove clamping positioning accuracyElectrical-based auxillary apparatusMechanical engineeringElectrode

The invention discloses an electrospark wire-electrode cutting machining combined clamp. The electrospark wire-electrode cutting machining combined clamp comprises a platform, an installation base and a fixing mechanism; and the installation base is fixedly installed on the platform, a V-shaped jaw is installed on the installation base, and the fixing mechanism is fixedly installed on the platform and used for exerting an abutting force on the side face of the installation base. By means of the combined clamp, a workpiece is stably clamped through the V-shaped jaw, the platform and the installation base are in sliding fit connection through a guide rail and guide groove structure, and the clamping positioning accuracy of the workpiece is increased; the installation base and the platform can be freely adjusted, and the universality of the combined clamp is improved; and meanwhile, the fixing mechanism is used for auxiliary clamping positioning on the workpiece, and the workpiece clamping machining stability is improved.

Owner:SICHUAN HANGDA ELECTROMECHANICAL TECH DEV SERVICE CENT

Precision machining tooling for mechanical press parts

ActiveCN110900223BImprove processing qualityImprove processing efficiencyLarge fixed membersPositioning apparatusMachine partsGear wheel

A precision machining tool for mechanical press parts, comprising: a card body, the card body includes a bottom plate, two support plates and a side plate arranged vertically at intervals are arranged on the bottom plate, and support shafts are arranged on the top of the two support plates, so that There is a 90° angle between the end surface and the front end surface of the support plate and the transition is through a rounded corner. The bottom plates outside the two support plates are respectively provided with arc-shaped guide rail grooves; the 90° rotating worktable, the 90° rotating workbench includes Worktable, support rods and arc-shaped guide rails. The worktable is hinged to the support shaft through a self-lubricating bushing at the bottom. There are trapezoidal grooves and V-shaped positioning blocks on the top and bottom of the worktable. The arc-shaped guide rails are movably installed on the arc In the surface guide rail groove; the internal gear pair, the internal gear pair includes a sector-shaped internal gear installed on the lower surface of the worktable. It has the advantages of stable structure, high rigidity, improved processing efficiency, high clamping and positioning accuracy, high rotary repeat positioning accuracy, firm and reliable braking, etc., which improves the processing quality and efficiency of parts.

Owner:JIAMUSI UNIVERSITY

Special grinding machine for valve cone surface

ActiveCN104128863BRealize automatic clampingAchieve relaxationGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

Owner:江苏吉斯特科技有限公司

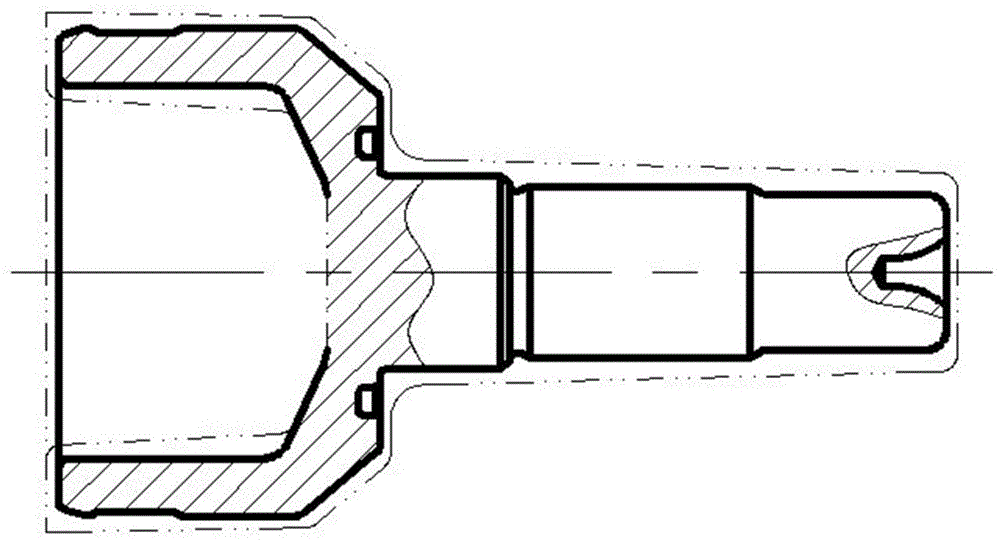

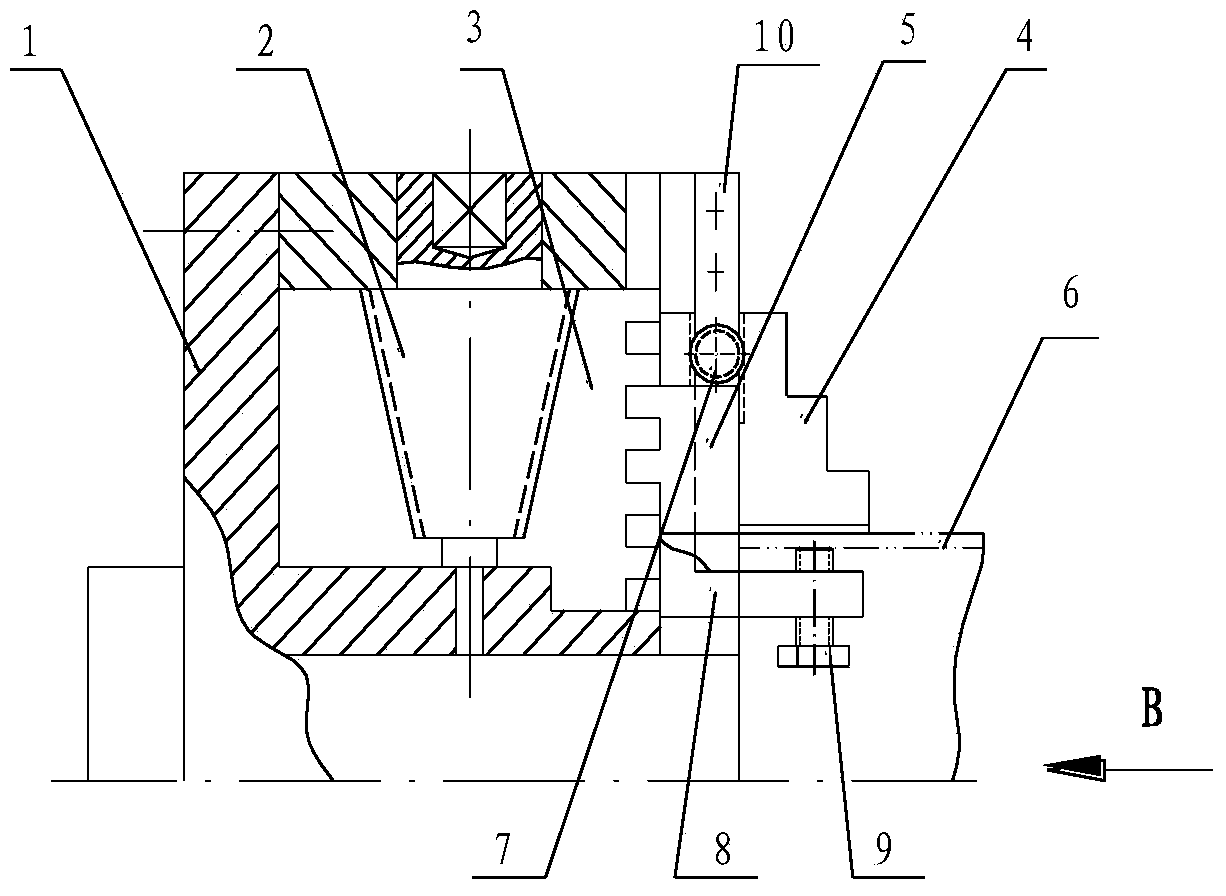

Turning method of tail end sealed type besides-star wheel of telescopic constant-velocity universal joint

ActiveCN106270558ASolve the problem of excessive wear and tearSolve quality problemsExpansion mandrelsChucksNumerical controlUniversal joint

The invention belongs to the field of machining and turning and discloses a turning method of a tail end sealed type besides-star wheel of a telescopic constant-velocity universal joint. The method includes the following steps that firstly, an inner hole serves as a clamping face by means of a jaw, the bottom of the inner hole serves as a positioning face, the end of a shaft is fixed through an apex, and the outer surface of the shaft is subjected to rough turning; secondly, the surface, subjected to rough turning, of the shaft serves as a clamping face, a middle stair face between the shaft and a blind hole serves as a positioning face, and the outer surface of the blind hole and the inner hole are subjected to finish turning; thirdly, the inner hole subjected to finish turning serves as a clamping face, the outer surface of the blind hole serves as a positioning clamping workpiece, and the outer surface of the shaft, the end face of the shaft and a center hole are subjected to finish turning. The full numerical control lathe machining technology is adopted, devices for milling planes and drilling center holes are omitted, and the problems that due to unstable factors of the plane milling and center hole drilling procedures, product quality is low and blades are excessively abraded are completely solved.

Owner:SHANGHAI CHANGRUI AUTO PARTS

Three-jaw chuck for lathe

The invention relates to a three-jaw chuck for a lathe. The three-jaw chuck for the lathe comprises a chuck body, three bevel pinions, a big bevel gear with threads, three movable clamping jaws and a clamping jaw installation base. The three-jaw chuck for the lathe is characterized in that the three-jaw chuck for the lathe further comprises three L-shaped top jaws and pinions; the three L-shaped top jaws are installed on three clamping grooves in the chuck body respectively and form sliding pairs with the clamping grooves; clamping groove convex edges are arranged on the two sides of each clamping groove in the chuck body, arrangement holes used for installing the pinions are formed in the clamping groove convex edges, the pinion is installed between the two convex edges of each clamping groove, one side of each pinion is meshed with racks of the movable clamping jaws, and the other sides of the pinions are meshed with the L-shaped top jaws; the positions, extending outwards, of the L-shaped top jaws are opposite to the corresponding movable clamping jaws, and spaces for clamping parts are formed between the positions, extending outwards, of the L-shaped top jaws and the movable clamping jaws. According to the three-jaw chuck for the lathe, thin-wall parts can be clamped conveniently, the clamping and locating accuracy is high, the parts do not deform, clamping is reliable, due to the fact that adjusting bolts are arranged on the outward-extending ends of the top jaws, parts of different thicknesses can be clamped, and the application range is wide.

Owner:SHAANXI AVIATION ELECTRICAL

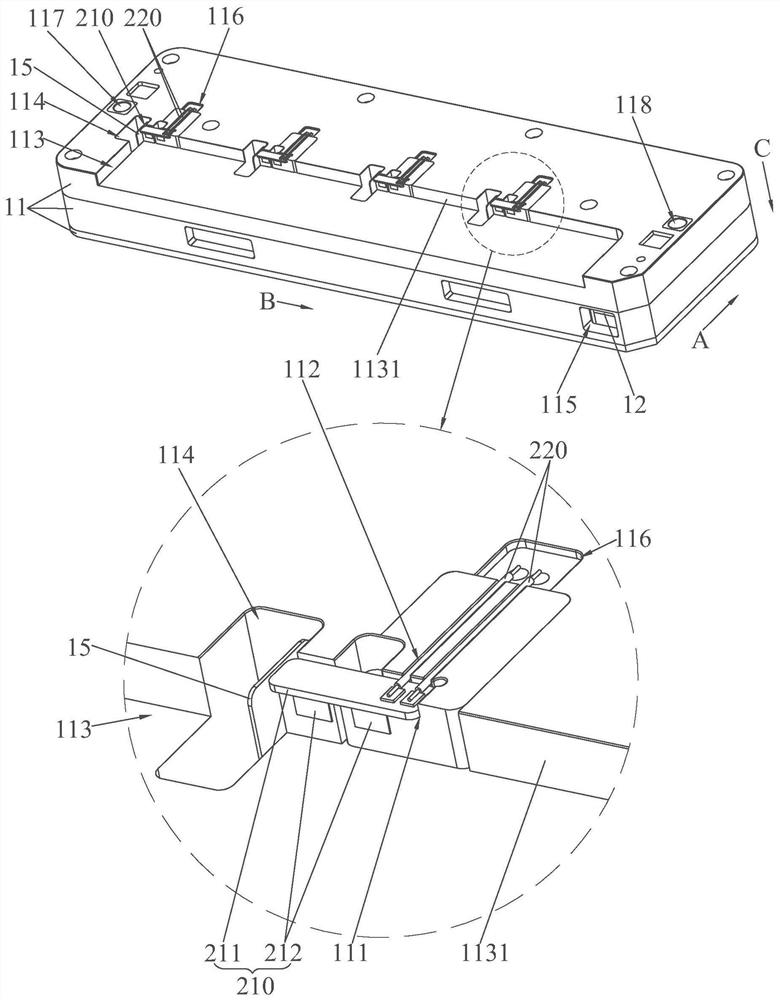

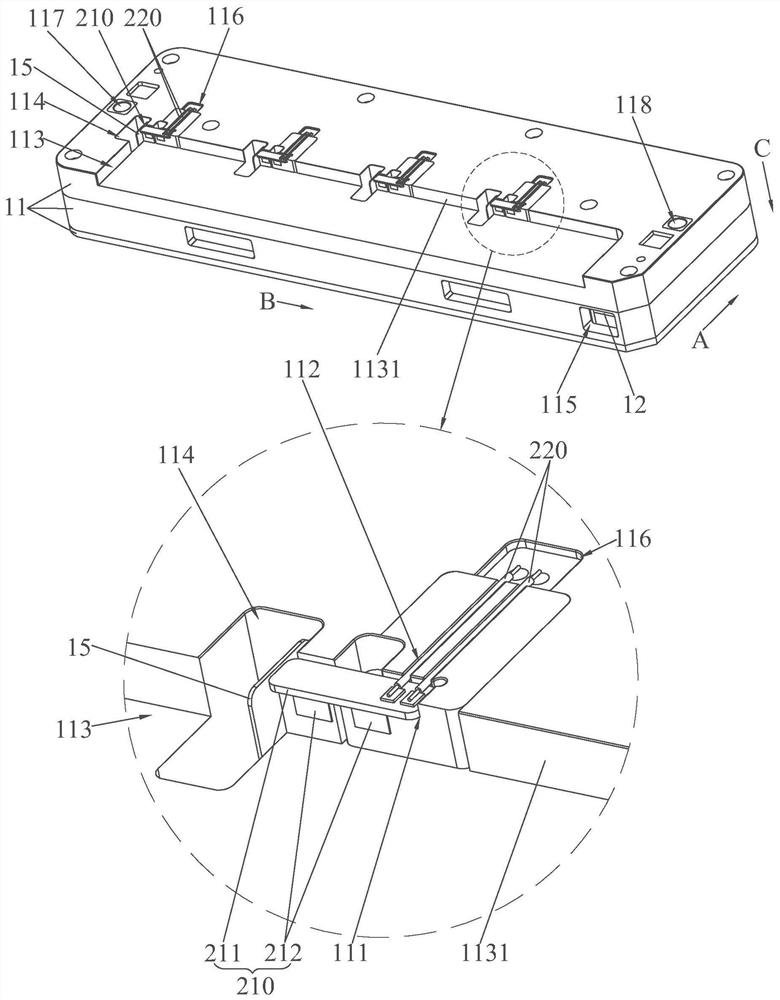

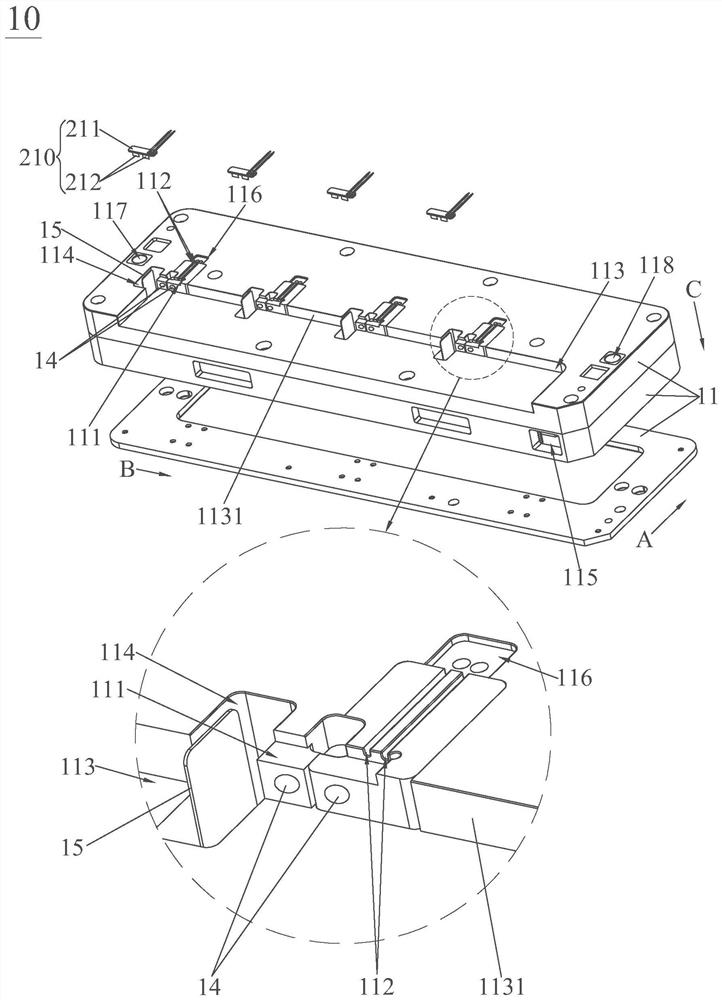

Needle-piercing mechanism and its carrier

ActiveCN113359009BReduce usageLow costPrinted circuit testingMeasurement instrument housingWire rodEngineering

The invention discloses a carrier, comprising a carrier body, a sliding rod, an elastic piece, a magnet and a push piece. The top of the carrier body is provided with a PCB positioning slot, a wire positioning slot, a sinking avoidance cavity and a movable cavity; the sinking avoidance cavity is located directly in front of the PCB positioning slot, and the wire positioning slot is located directly behind the PCB positioning slot; the movable cavity is located on the PCB On the left or right side of the positioning groove, the sliding rod is slidably arranged on the carrier body along the left and right directions of the carrier body and can be slidably switched between the first position and the second position. The rod is assembled and connected; the elastic piece is set between the sliding rod and the carrier body, and the elastic piece always has the tendency to drive the sliding rod and the push piece to slide to the second position, and the magnet is assembled on the side cavity wall behind the sinking escape cavity , when the push piece is in the second position, the PCB board in the PCB positioning slot is pressed tightly; in order to achieve the purpose of precise positioning and clamping. In addition, the present invention also discloses a supporting needle sticking mechanism.

Owner:GUANGDONG TOPSTAR TECH

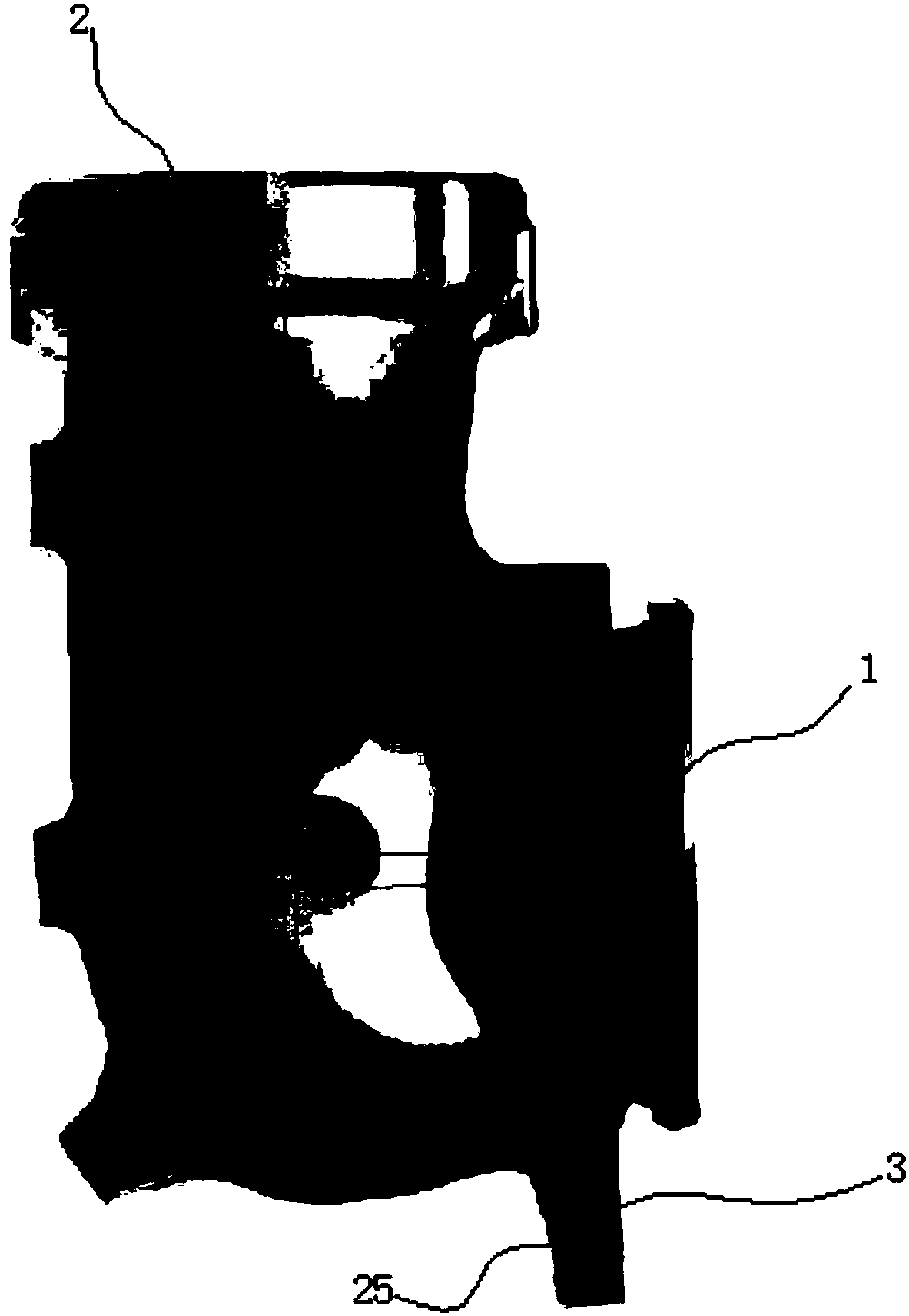

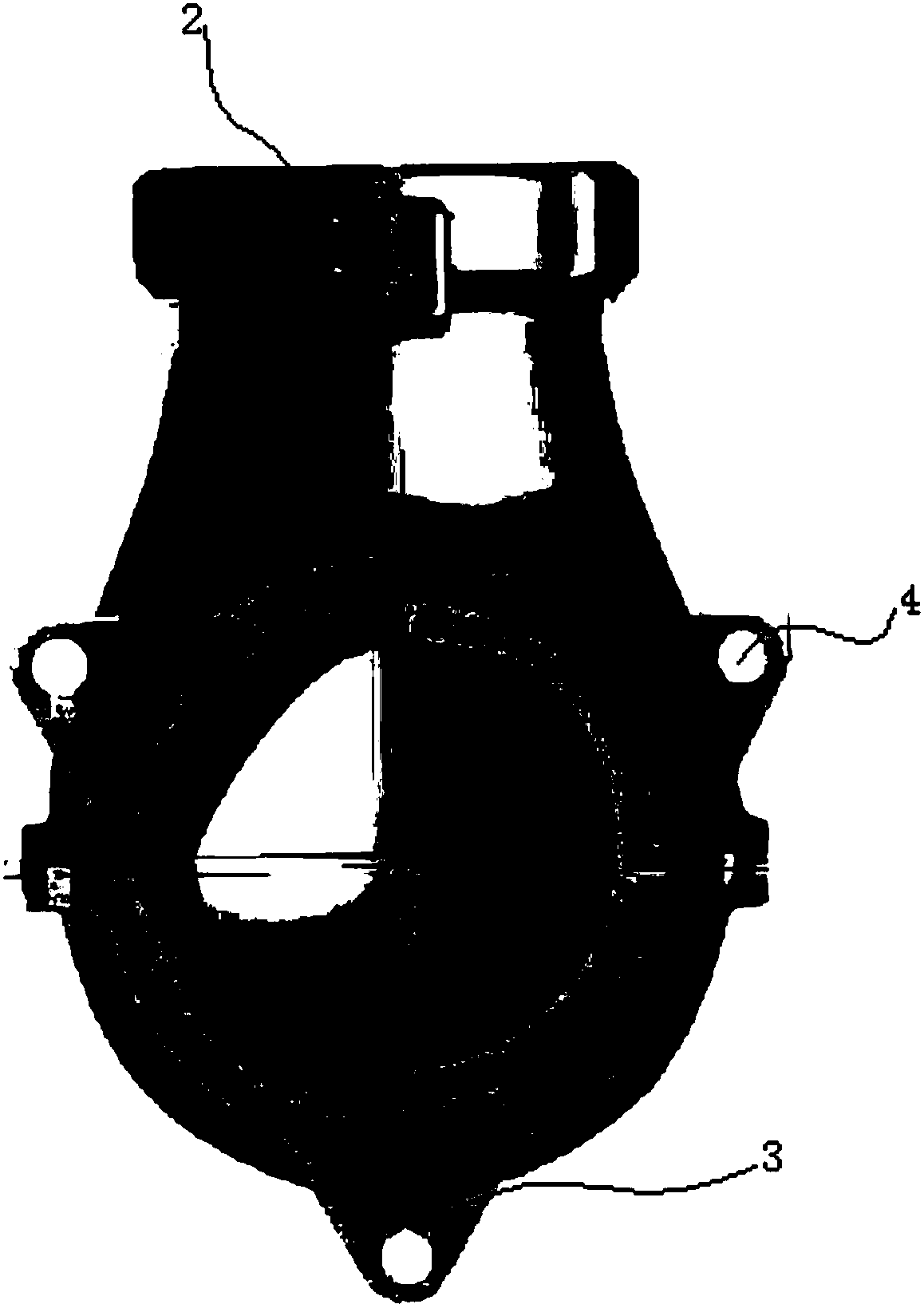

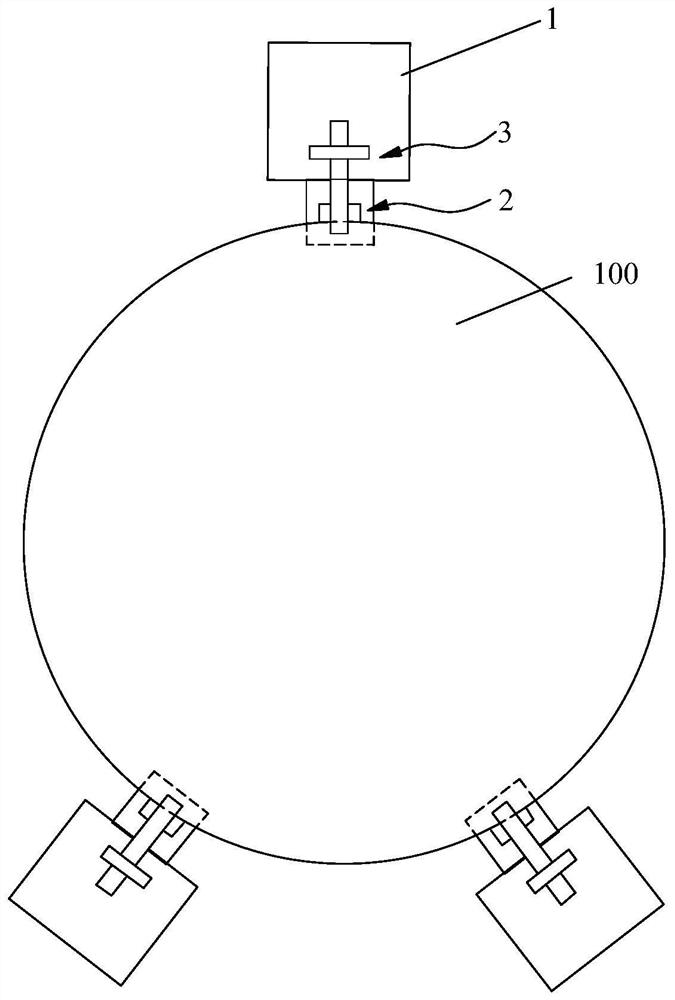

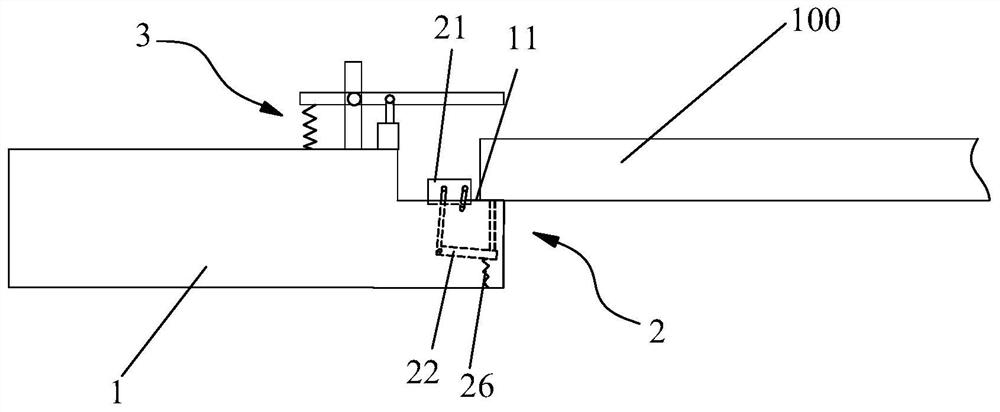

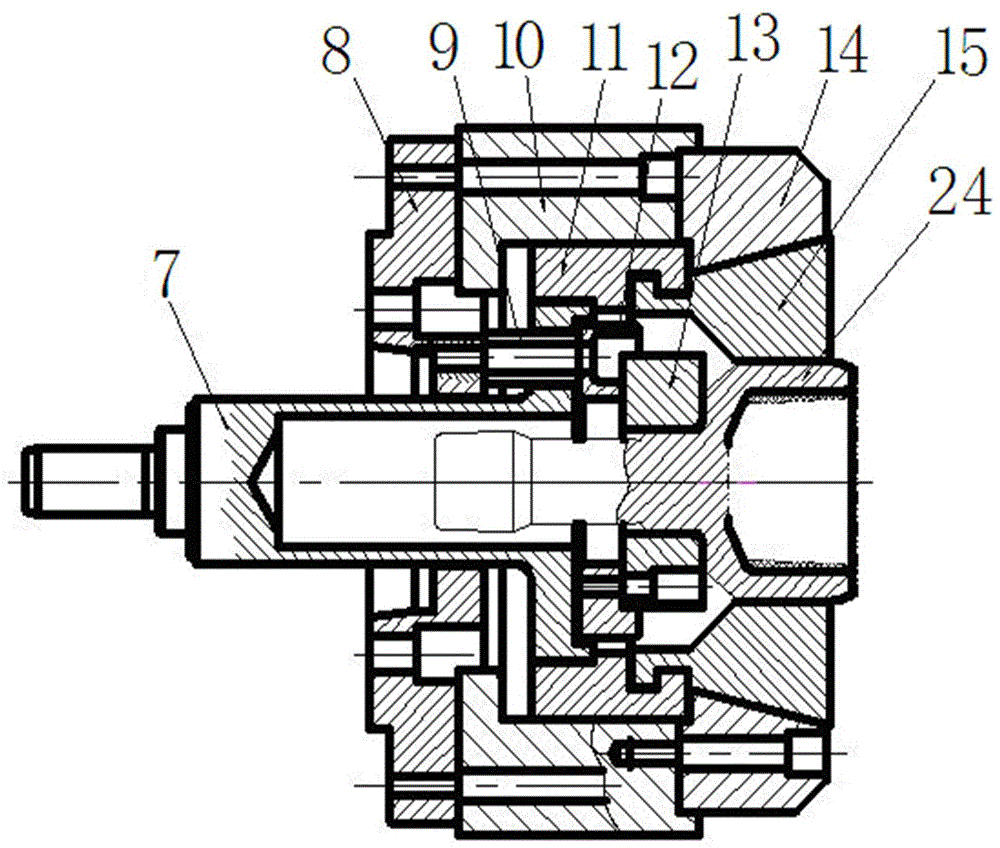

A quick locking device

The invention provides a fast clamping locking device which comprises nuts (1), thread sleeves (2), springs (3), locking pins (4), first clamping supporting rims (61) and second clamping supporting rims (51). One end of each locking pin (4) is fixedly connected with the corresponding nut (1), and the other end of each locking pin (4) is inserted in a locking blind hole (52). Each locking pin (4) is sleeved with the corresponding thread sleeve (2). Each thread sleeve (2) is mounted in a mounting hole of an end cover (6). Each locking pin (4) is sleeved with the corresponding spring (3). One end of each spring (3) is connected with the corresponding thread sleeve (2), and the other end of each spring (3) is connected with the end, inserted in the corresponding locking blind hole (52), of the corresponding locking pin (4). The nuts (1) are pulled out or loosened, the springs (3) are driven to stretch out and draw back, the locking pins (4) are made to move in the mounting holes of the end cover (6), and therefore mounting, dismounting and locking of the end cover (6) and a shell (5) are achieved. Through the fast clamping locking device, high-precision and high-reliability connection between structures is achieved in a narrow space; the fast clamping locking device is compact in structure, easy to operate, capable of being dismounted and mounted repeatedly and good in maintainability.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

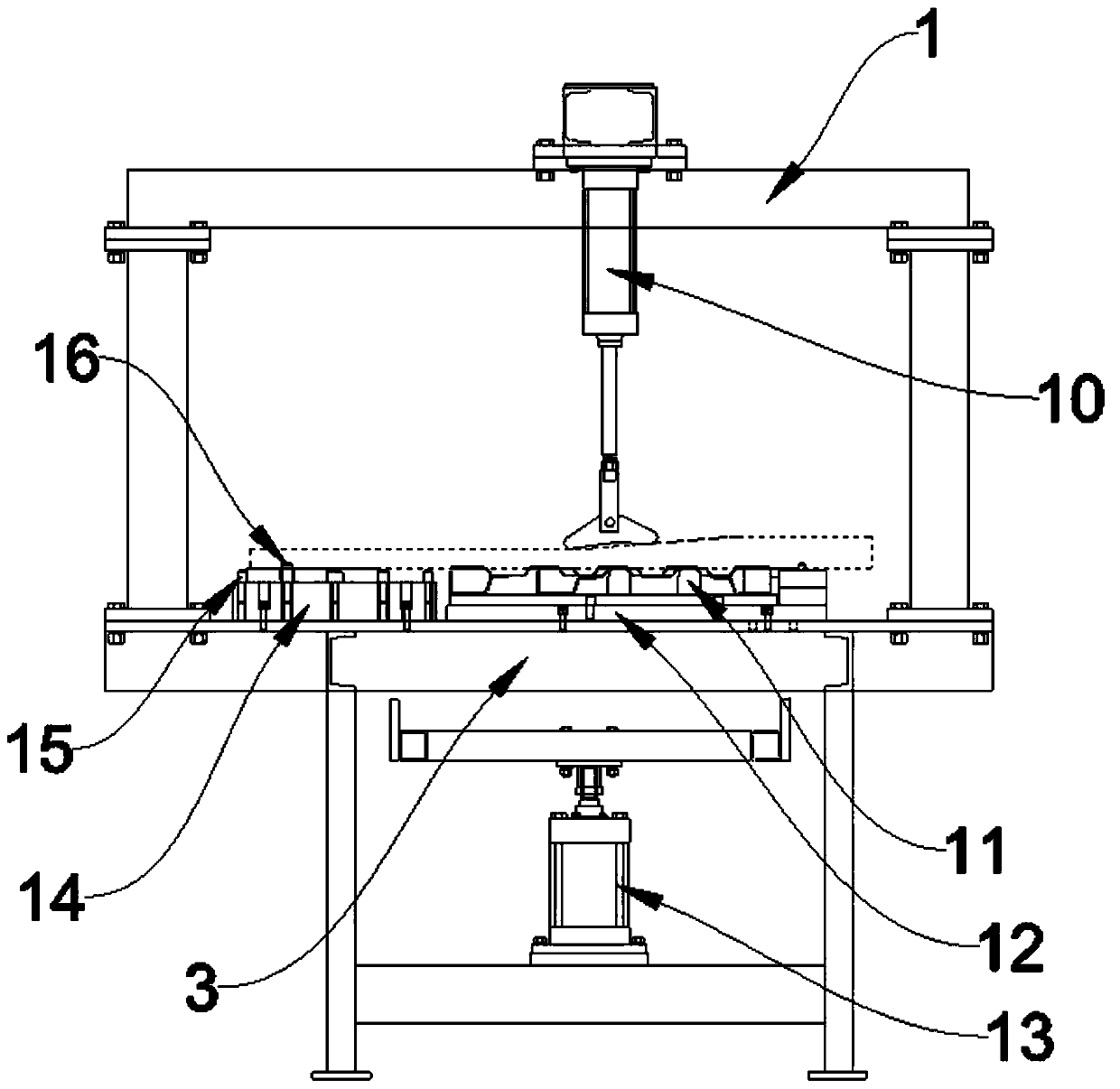

Roller line and workstation for hub deburring

PendingCN114770275APrevent looseningImprove clamping positioning accuracyEdge grinding machinesGrinding drivesStructural engineeringVision sensor

The invention relates to the field of part surface treatment, in particular to a roller line and a workstation for hub deburring. The clamping mechanism is used for clamping and positioning a hub workpiece, the tensioning mechanism is used for eliminating a transmission gap of the clamping mechanism, a roller way is arranged on the first supporting plate, and a first driver used for driving rollers of the roller way to rotate is fixed to the first supporting plate. The hub deburring device has the advantages that a hub workpiece can be directly deburred on the roller way; the error of a transmission gap of the clamp can be eliminated, and the hub workpiece is prevented from loosening after being clamped; the clamping block body can clamp a hub workpiece more stably, and vibration of the hub workpiece in the machining process is reduced; through the visual sensor, different machining parts can be judged, and the path of the deburring head is automatically adjusted; and the position of the visual sensor can be adjusted, so that the accuracy of the position of the visual sensor is ensured.

Owner:浙江今飞机械有限公司 +2

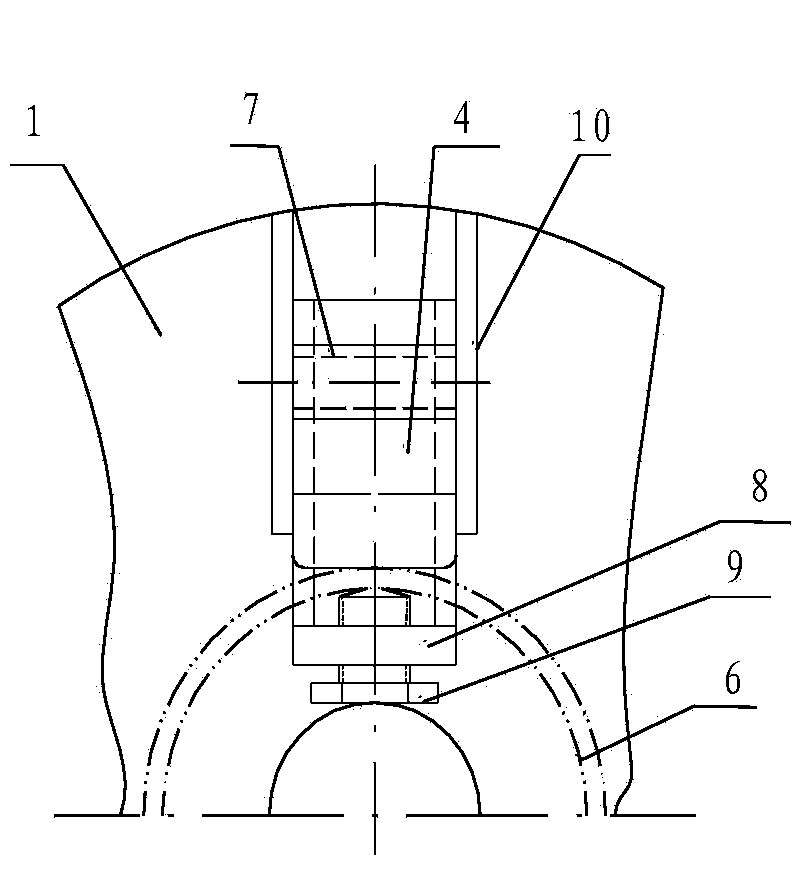

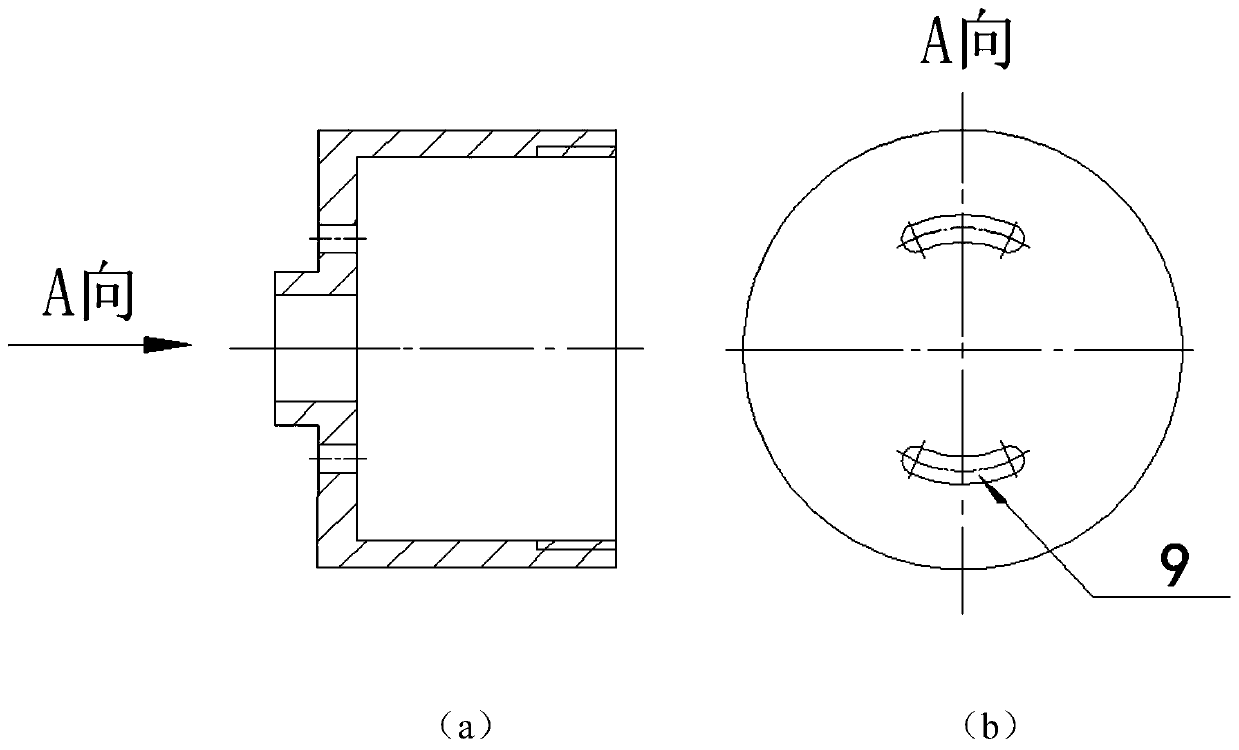

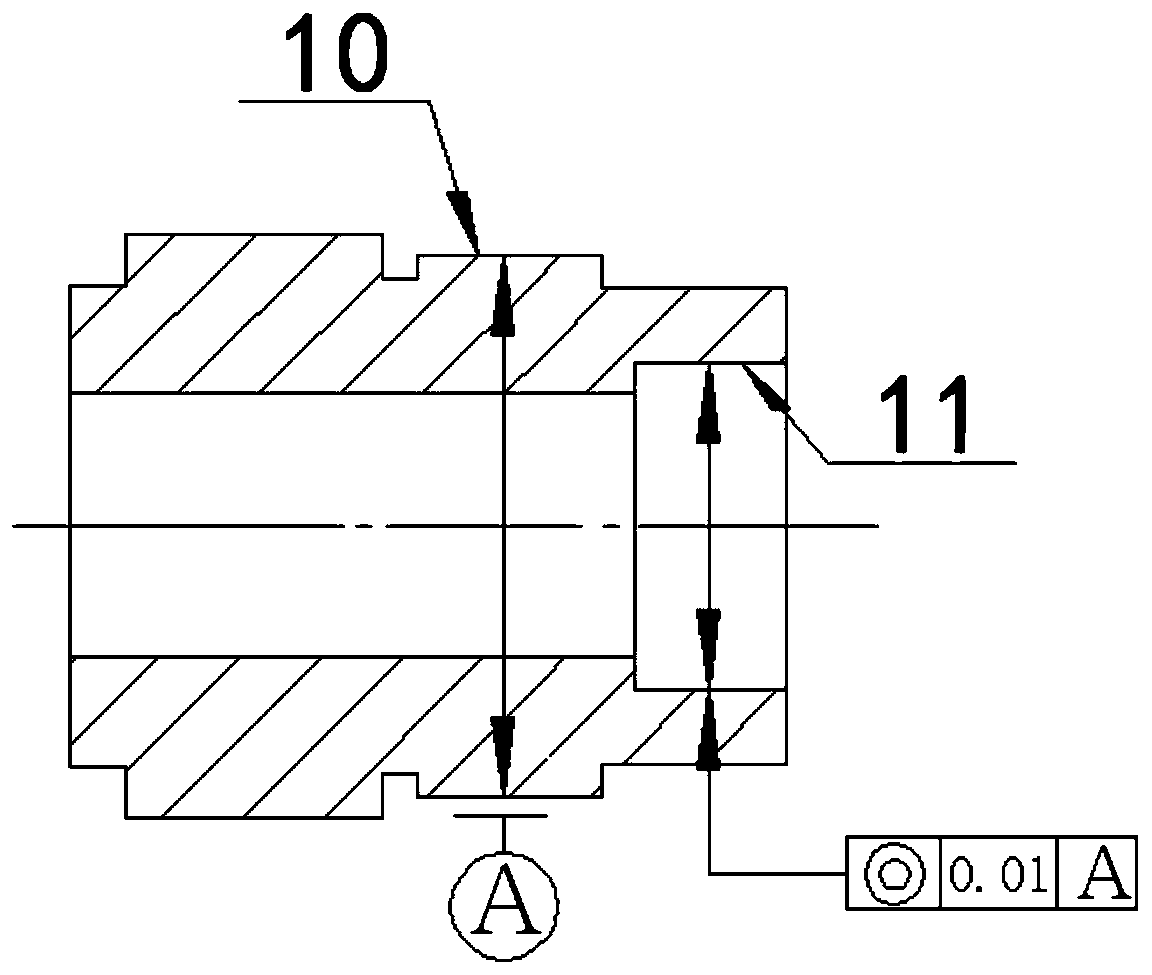

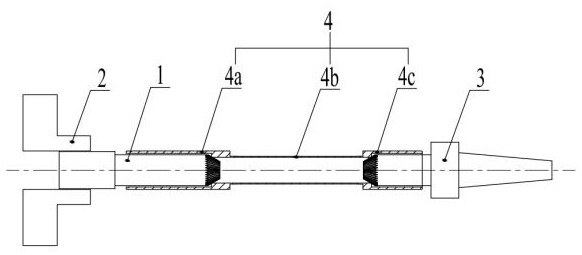

A spindle tail hole top device and method capable of expanding the clamping length of a lathe

ActiveCN109663934BGuaranteed concentricityGuarantee processing qualityTailstocks/centresEngineeringScrew thread

The invention discloses a main shaft tail hole tip device and method capable of enlarging the clamping length of a lathe. The device comprises a locating sleeve connected to a main shaft of the lathe.One end of the locating sleeve is inserted into a tail end inner hole of the main shaft of the lathe in a penetrating manner, and an adjusting and fixing ring is connected to the other end of the locating sleeve. A hole opening of the adjusting and fixing ring and an outer circle of the tail end of the main shaft of the lathe are fastened by the adoption of threads. A tip body is installed in thelocating sleeve in an inserted manner. The free end of the tip body is connected with a tip. The tip and a long shaft part inserted into the tail end inner hole of the main shaft of the lathe are aligned and abut against each other. A center hole is machined in the end face of one end, aligned to and abutting against the tip, of the long shaft part. The device can ensure that clamping of the longshaft part is concentric, and on the premise of meeting the machining quality, the problem that due to limitation of the specification of the lathe, the maximum length of the part capable of being clamped by the lathe is limited is solved.

Owner:AECC AVIATION POWER CO LTD

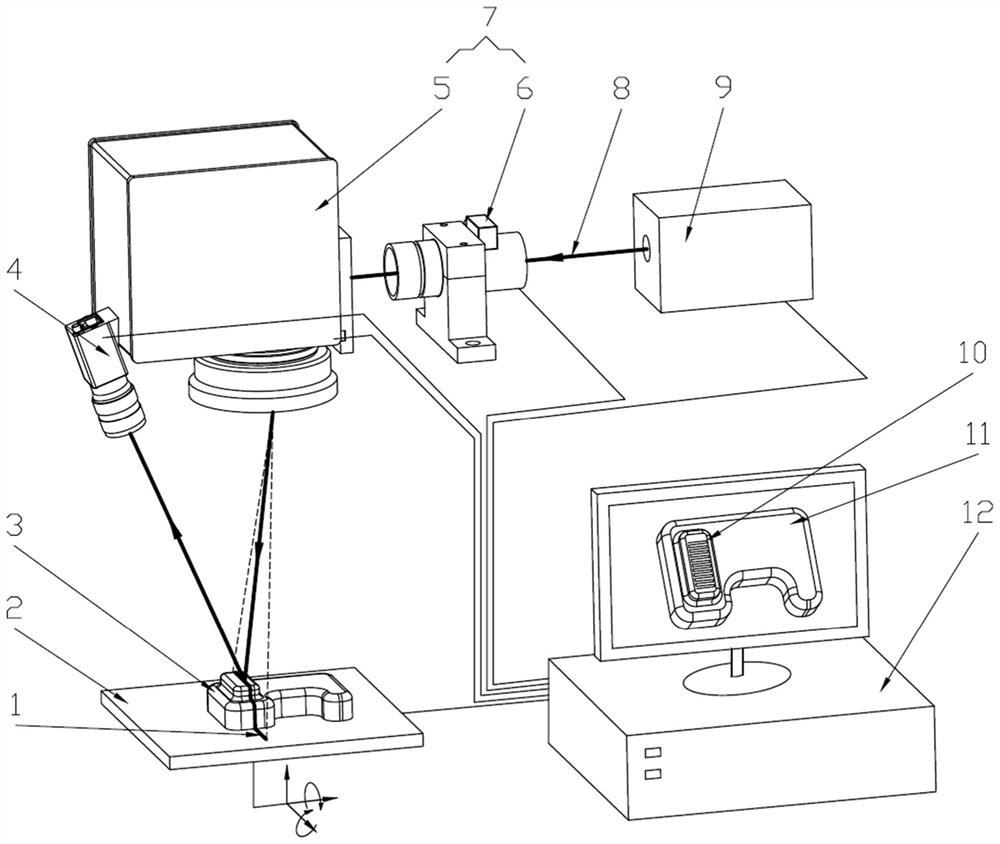

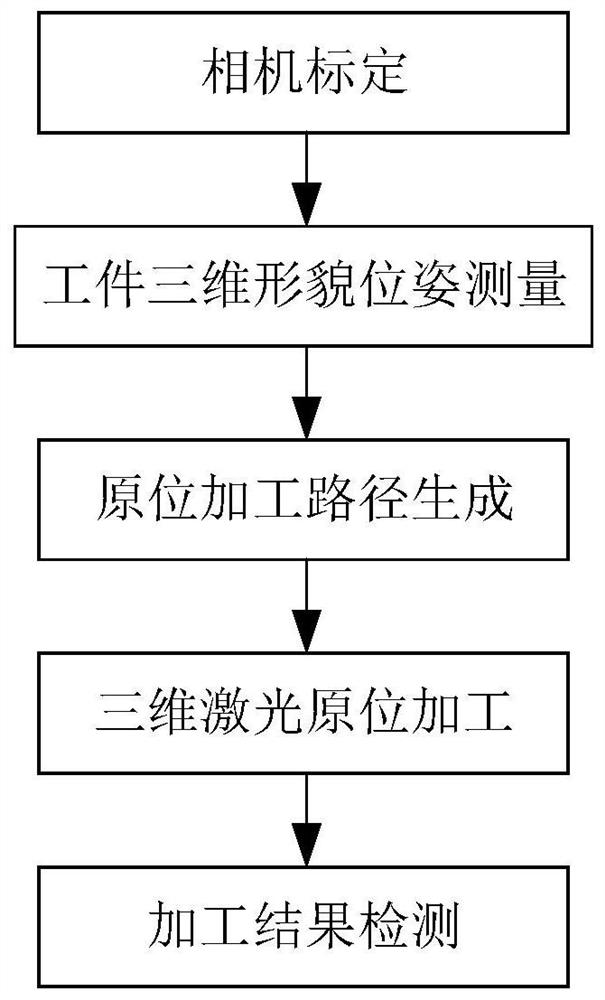

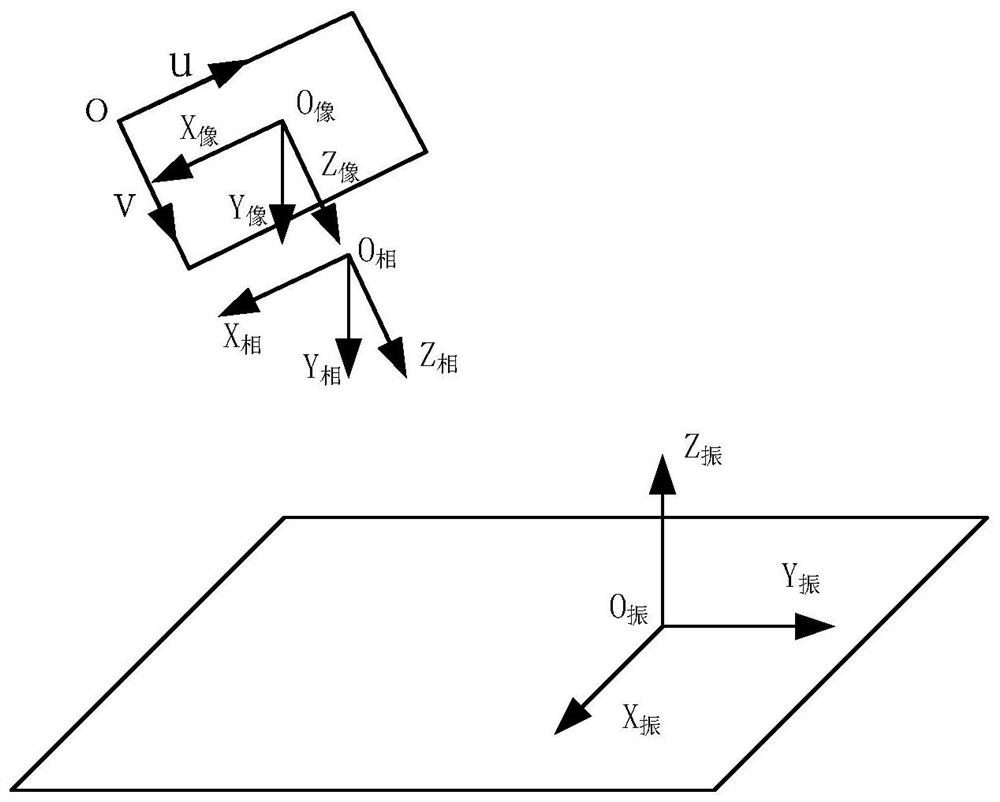

Laser in-situ processing equipment and method based on scanning galvanometer

ActiveCN109903342BMeet processing needsMeet the needs of industrial processing freedomImage analysisImage data processing detailsPath generationGalvanometer

The invention discloses a laser in-situ processing equipment and method based on a scanning galvanometer. The equipment includes an industrial camera, a five-axis motion platform, a laser, an industrial control computer, and a three-dimensional galvanometer composed of a two-dimensional galvanometer and a dynamic focusing mirror. The method includes the steps of: camera calibration, three-dimensional shape and pose measurement of the workpiece, in-situ processing path generation, three-dimensional laser in-situ processing, and processing result detection. The present invention adopts the hardware design of a three-dimensional galvanometer plus a five-axis motion platform, which fully meets the needs of the industry. The laser emits laser light or indicates light to scan the laser line on the workpiece through the three-dimensional galvanometer, and uses the principle of three-dimensional structured light to generate the three-dimensional shape of the workpiece online. Laser in-situ three-dimensional processing is performed after the in-situ processing path is generated. Therefore, the laser in-situ processing equipment and method based on the scanning galvanometer provided by the present invention realizes the integration of three-dimensional modeling, processing and detection in the laser three-dimensional processing process, and improves the positioning accuracy of the workpiece and the convenience of operation. .

Owner:XI AN JIAOTONG UNIV

Dual-wire contact collet jaws

ActiveCN104999287BReduce contact stressImprove clamping positioning accuracyWork holdersPositioning apparatusMaximum diameterCircular cone

The invention belongs to chucks, and particularly relates to a dual-line contact chuck clamping jaw. The dual-line contact chuck clamping jaw is characterized in that a lateral conical surface is formed by splicing three sections of conical surfaces, and two spliced lines are formed, wherein the conical surfaces located on the two sides are the same, and the conical surface located in the middle section is larger. When a work piece with the minimum diameter or the maximum diameter is clamped by three dual-line contact chuck clamping jaws evenly distributed in a chuck outer shell, the lateral conical surface and the conical surface in the chuck outer shell are in a face contact, so that the contact stress is small, and the clamping accuracy is high; and when a work piece with the diameter in the middle range is clamped, the two splicing lines and the inner conical surface of the chuck outer shell are in dual-line contact, so that the contact stress is effectively shared, and the contact intensity and the clamping positioning accuracy are improved.

Owner:金华市臣星科技有限公司

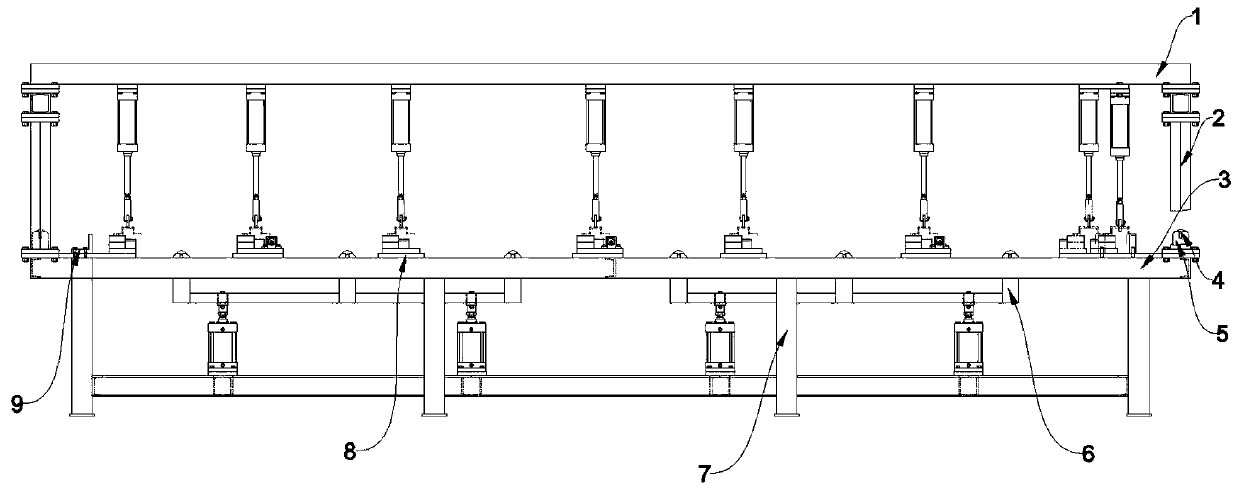

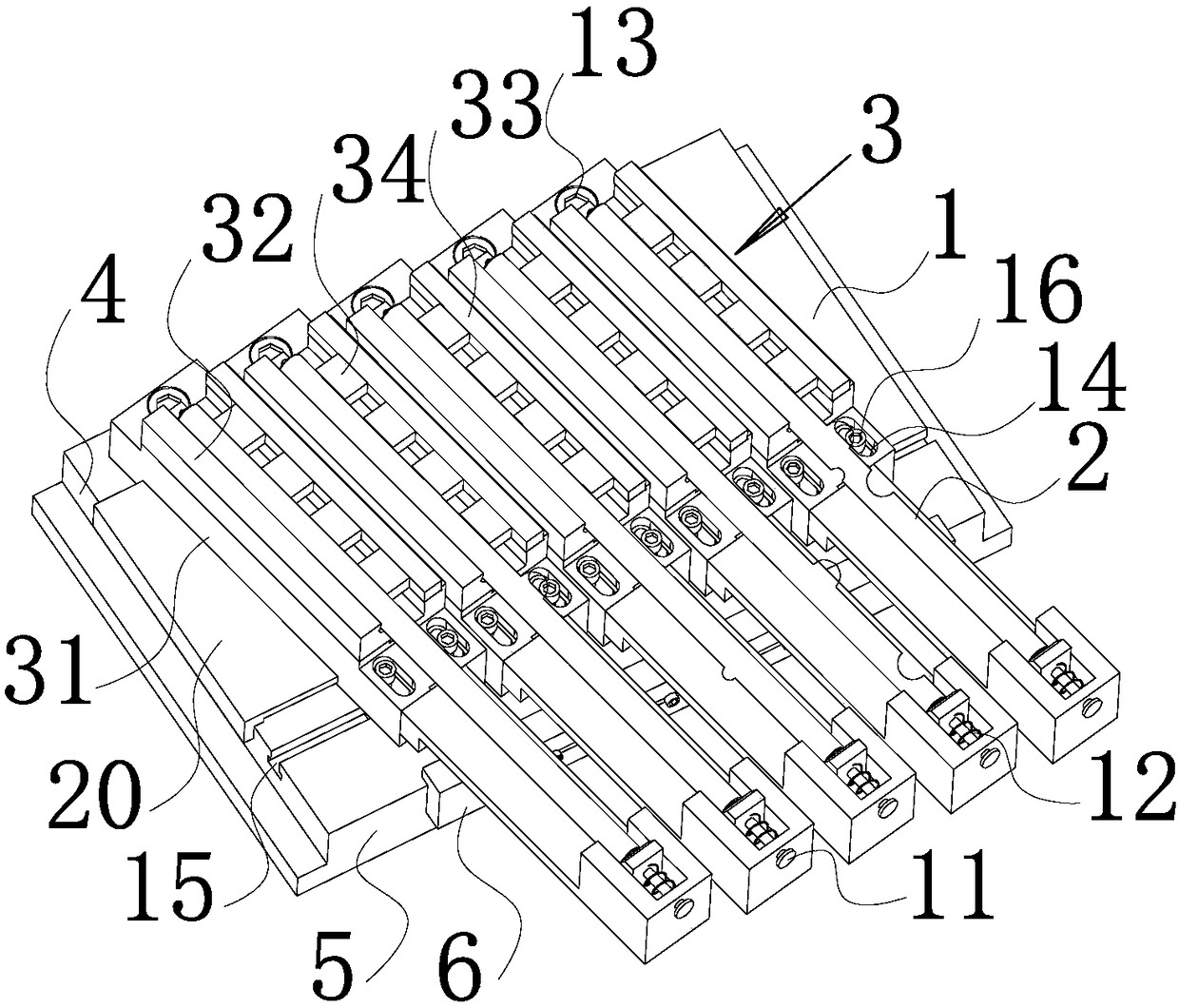

Full compliant motor steering rack grinding fixture

ActiveCN106624194ALow costShort adjustment timeGear-cutting machinesGear teethMechanical engineeringMultiple Models

The invention discloses a grinding fixture which provides a full compliant motor steering rack grinding fixture has the advantages of clamping several workpieces at one time, being applied to a variety of workpieces process, having a high accuracy of clamped positioning and saving the cost of production. The full compliant motor steering rack grinding fixture solves the existing technical problems of needing multiple model fixture to meet processing needs, having high frock cost, having low production efficiency and further increase of production cost due to a change process of fixture is wasted time and energy. The full compliant motor steering rack grinding fixture comprises a square supporting platform. Several substrates which clamps the workpiece to keep horizontal are disposed on the supporting platforms in parallel. Two ends of the substrate are connected with the supporting platform and the substrate can spin around one of fixed end. When one of substrates spin around the fixed end, others substrates can be driven to spin parallelly and synchronously.

Owner:浙江杭机股份有限公司

Bearing needling mechanism and carrier thereof

ActiveCN113359009AReduce usageLow costPrinted circuit testingMeasurement instrument housingWire rodEngineering

The invention discloses a carrier which comprises a carrier body, a sliding rod, an elastic piece, a magnet and a pushing piece. A PCB positioning groove, a wire positioning groove, a sinking avoiding cavity and a movable cavity are formed in the top of the carrier body; the sinking avoiding cavity is located right in front of the PCB positioning groove, and the wire rod positioning groove is located right behind the PCB positioning groove. The movable cavity is located on the left side or the right side of the PCB positioning groove, the sliding rod is arranged on the carrier body in a sliding mode in the left-right direction of the carrier body and can be switched between a first position and a second position in a sliding mode, and the pushing piece is located in the movable cavity and connected with the sliding rod in an assembling mode. The elastic piece is arranged between the sliding rod and the carrier body, the elastic piece constantly has the trend of driving the sliding rod and the pushing piece to slide to a second position together, the magnet is assembled on the cavity wall of the rear side of the sinking avoiding cavity, and the pushing piece tightly presses the PCB in the PCB positioning groove when the pushing piece is located at the second position; the purposes of accurate positioning and clamping are achieved. In addition, the invention further discloses a needle bearing mechanism.

Owner:GUANGDONG TOPSTAR TECH

Automated feeding and clamping device for pipe fitting machining

InactiveCN109048434AAvoid Longitudinal CracksReduce the chance of leaksPositioning apparatusMetal-working holdersPipe fittingEngineering

The invention discloses an automated feeding and clamping device for pipe fitting machining, and relates to the technical field of copper pipe machining. The automated feeding and clamping device forpipe fitting machining comprises a workbench; a guiding strip is fixed to the workbench, and fixing blocks are fixed to the opposite sides of the workbench; a storing cylinder and an air cylinder arefixed to one surface of the workbench; a pressing block is slidably arranged on the workbench; and a guiding column is fixed to each fixing block, a cross beam is fixed to the ends of the guiding columns, and two pressing plates are connected to the guiding columns in a sleeving mode. According to the automated feeding and clamping device for pipe fitting machining, to-be-machined materials are put into the storing cylinder, the materials are pushed by a pushing rod for feeding, a to-be-machined workpiece is pressed by the pressing block, therefore, the working efficiency and the clamping andpositioning precision are improved, the production cost is reduced, damage to a red copper pipe in the machining process is reduced, the condition that longitudinal cracks are generated in the red copper pipe machining process is effectively avoided, the leakage probability in the using process is decreased, and environmental pollution is reduced.

Owner:芜湖辉林奥远自动化科技有限公司

Machining method for thin-wall long pipe casting

ActiveCN112658763AIncrease frictionAffect machining accuracyPositioning apparatusMetal-working holdersConventional castingEngineering

The invention belongs to the technical field of machining, and particularly relates to a machining method for a thin-wall long pipe casting. The machining method comprises the following steps: step 1) installing tips, wherein a fixed tip is installed in a chuck of a machine tool, and a movable tip is installed in a conical hole of a main shaft of the machine tool; step 2) clamping and fixing the pipe casting, wherein the movable tip and the fixed tip extend into the pipe casting along pipe openings in the two ends of the pipe casting correspondingly, and the movable tip and the fixed tip respectively abut against a port of an inner hole in the middle section of the pipe casting to meet the requirement for clamping and fixing the pipe casting; step 3) respectively machining the outer circle of the long section and the outer circle of the short section of the pipe casting to meet the process requirement; step 4) respectively machining the inner hole of the long section and the inner hole of the short section of the pipe casting to meet the process requirement; step 5) respectively machining a first outer circular groove between the long section and the middle section of the pipe casting and a second outer circular groove between the short section and the middle section of the pipe casting to meet the process requirement; and step 6) respectively machining a step surface and a step hole of the middle section of the pipe casting to meet the process requirement. The machining method solves the problems that the outer circle of the long section and the outer circle of the short section of a conventional casting are machined, the two tips are adopted to abut against the port of the long section and the port of the short section correspondingly, the middle section is greatly deformed, and milling penetration is prone to occurring during machining of the middle section.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

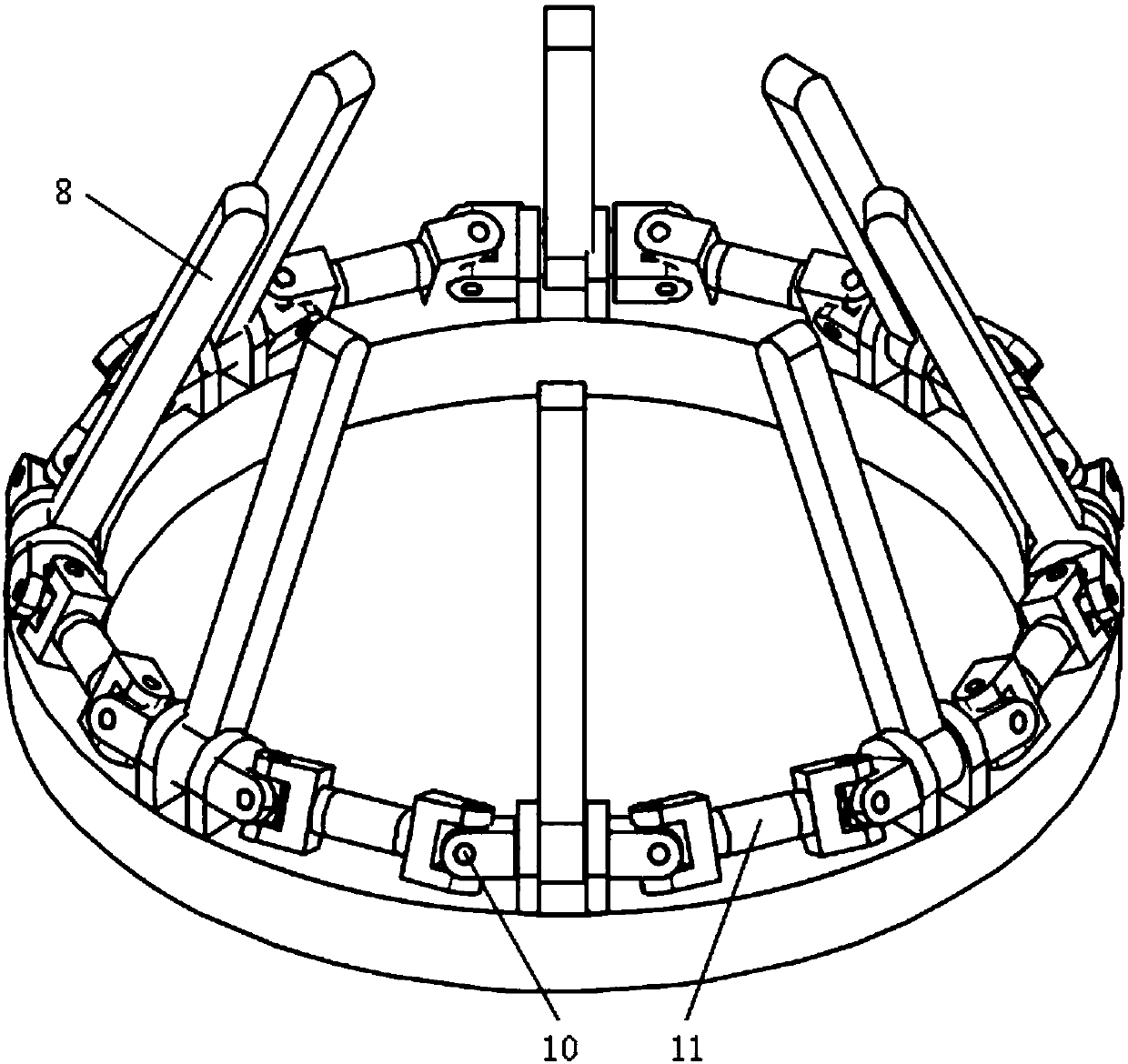

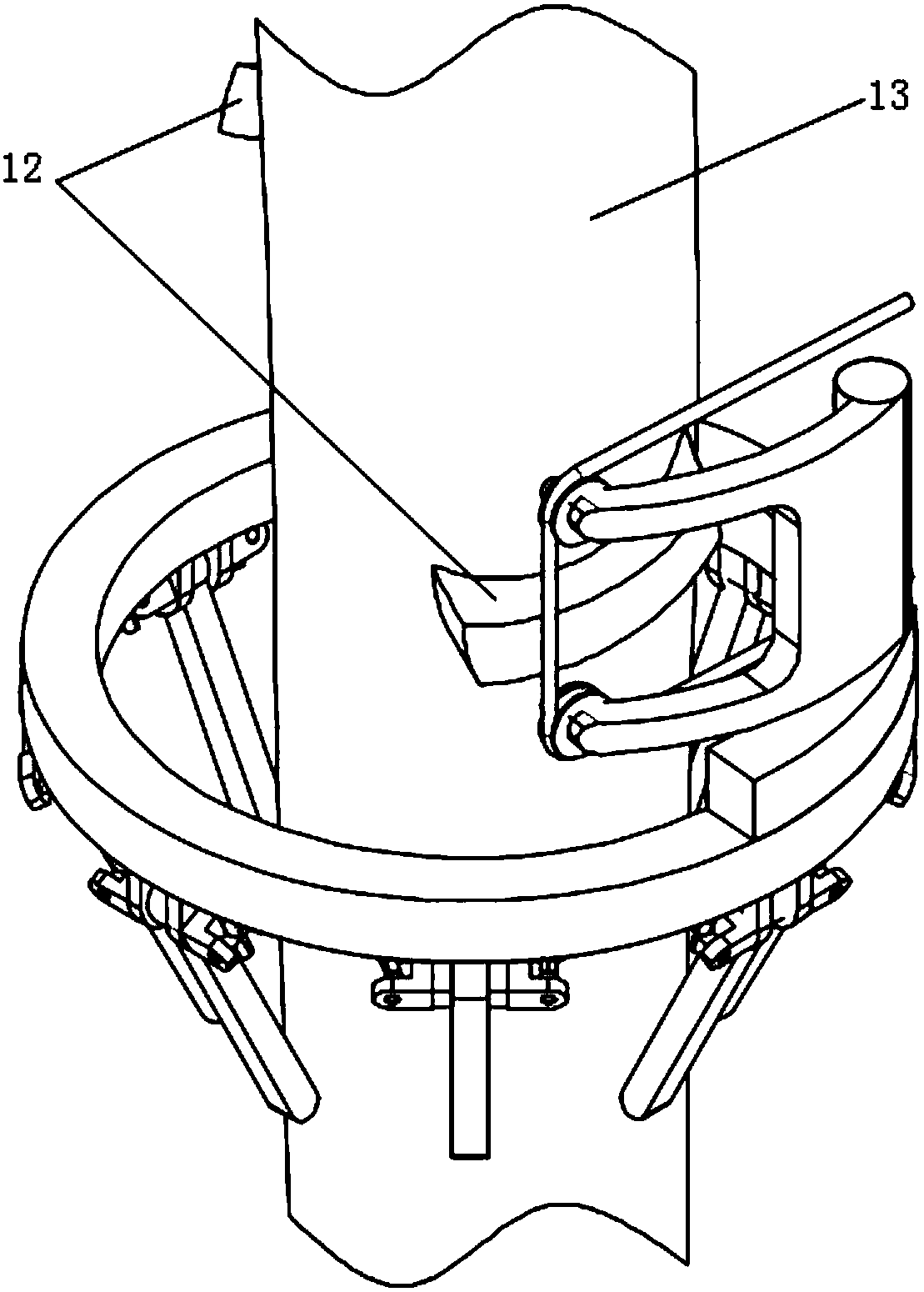

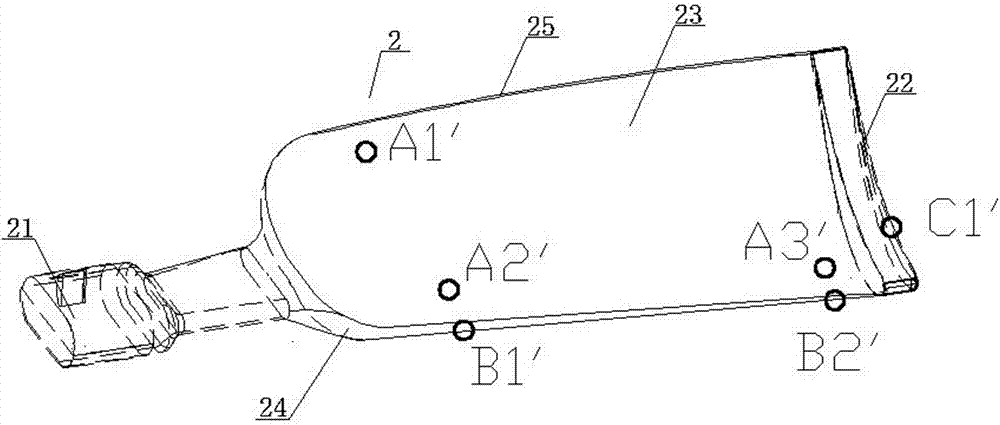

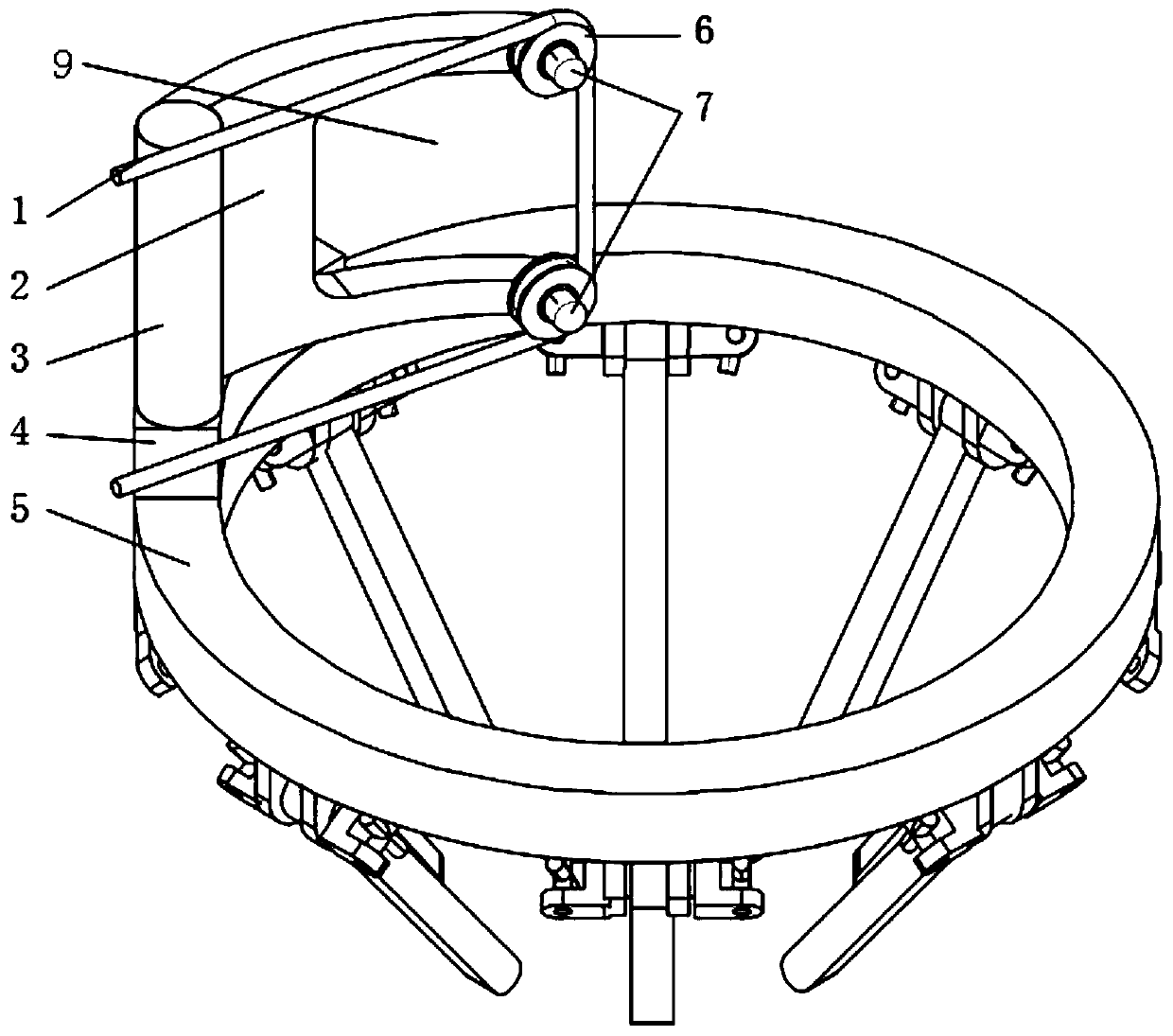

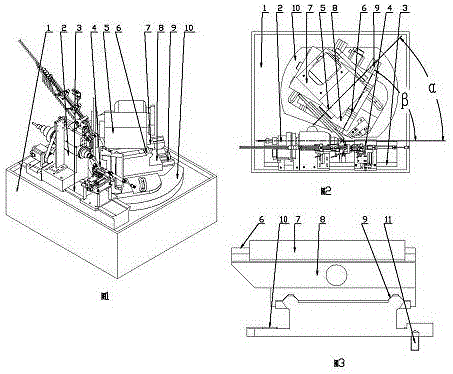

An adaptive underactuated picking end effector and method

ActiveCN105580561BAvoid damageAdapt to the current situation of agriculturePicking devicesSelf adaptiveConductor Coil

The invention discloses a self-adaption under-actuation picking tail end executing device and method. A hand executing mechanism in the device comprises a palm and multiple fingers. The lower ends of the fingers are movably connected with the palm respectively. The fingers slide in the diameter direction of the palm. The upper ends of the fingers are provided with reversible V-shaped finger tips. Each V-shaped finger tip comprises a knuckle reversing button, a first movable knuckle and a second movable knuckle, wherein the first movable knuckle and the second movable knuckle are fixedly connected in an angle-adjustable mode, and the second movable knuckle is hinged to the knuckle reversing button which is connected with the upper end of the finger. According to the method, a winding reel in the palm drives the fingers to get close to a fruit or release the fruit through two steel wire ropes with opposite winding directions and drives the V-shaped finger tips, the fingers and the palm to rotate at the same time so that fruit can be twisted to be separated. The device can adapt to the irregular appearance of the fruit by itself and keep making six-point stable contact with the fruit, is high in grasping and positioning precision and easy to control and can effectively prevent the fruit from mechanical damage.

Owner:SOUTH CHINA AGRI UNIV

Fully flexible automotive steering rack grinding fixture

ActiveCN106624194BLow costShort adjustment timeGear-cutting machinesGear teethMechanical engineeringMultiple Models

The invention discloses a grinding fixture which provides a full compliant motor steering rack grinding fixture has the advantages of clamping several workpieces at one time, being applied to a variety of workpieces process, having a high accuracy of clamped positioning and saving the cost of production. The full compliant motor steering rack grinding fixture solves the existing technical problems of needing multiple model fixture to meet processing needs, having high frock cost, having low production efficiency and further increase of production cost due to a change process of fixture is wasted time and energy. The full compliant motor steering rack grinding fixture comprises a square supporting platform. Several substrates which clamps the workpiece to keep horizontal are disposed on the supporting platforms in parallel. Two ends of the substrate are connected with the supporting platform and the substrate can spin around one of fixed end. When one of substrates spin around the fixed end, others substrates can be driven to spin parallelly and synchronously.

Owner:浙江杭机股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com