Hydraulic fixture for hub bracket five-axis machine tool machining

A technology of hydraulic fixtures and machine tools, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high scrap rate and rework rate, poor product processing accuracy, large equipment investment, etc., and achieve high product processing accuracy , High clamping and positioning accuracy, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

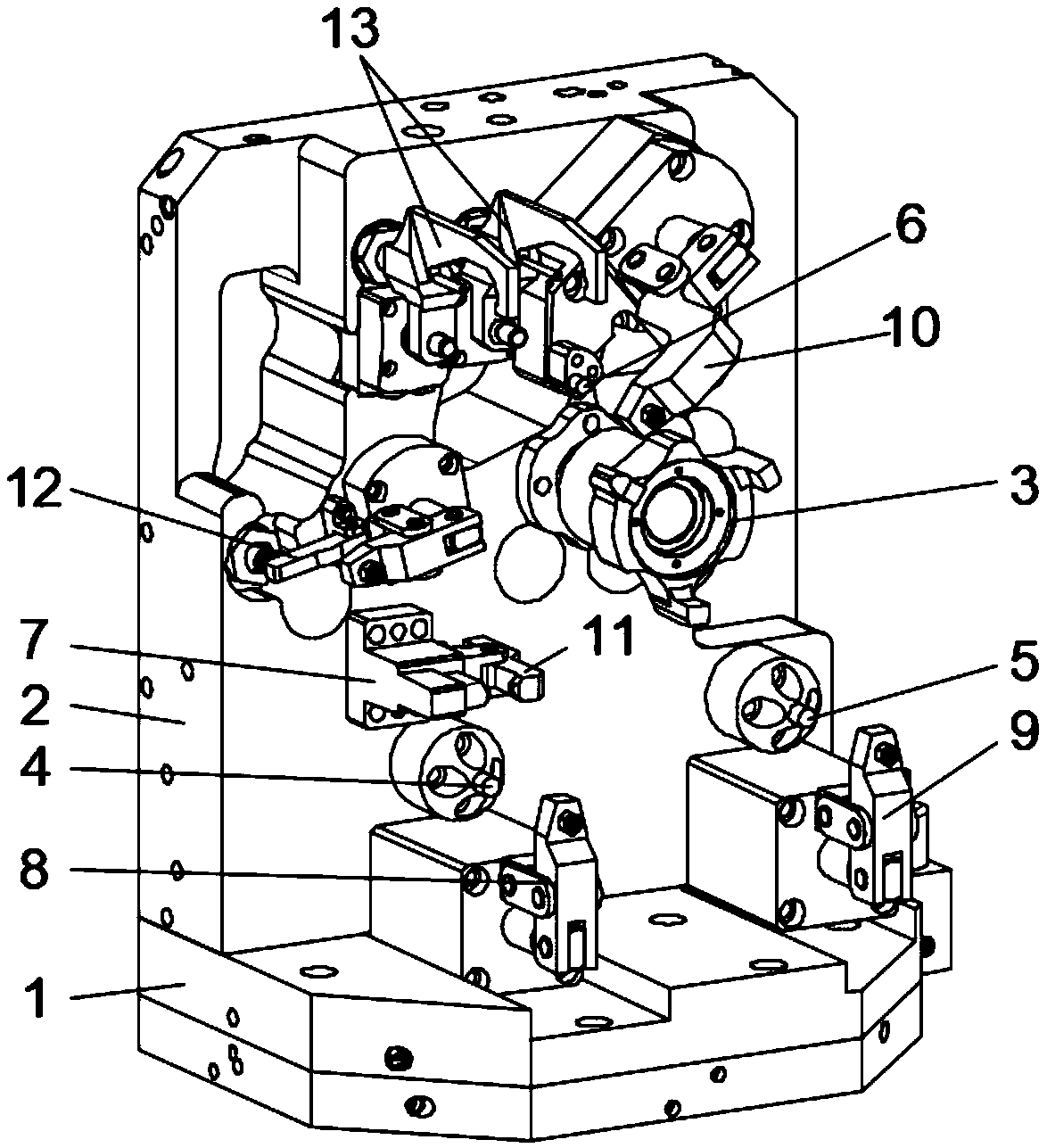

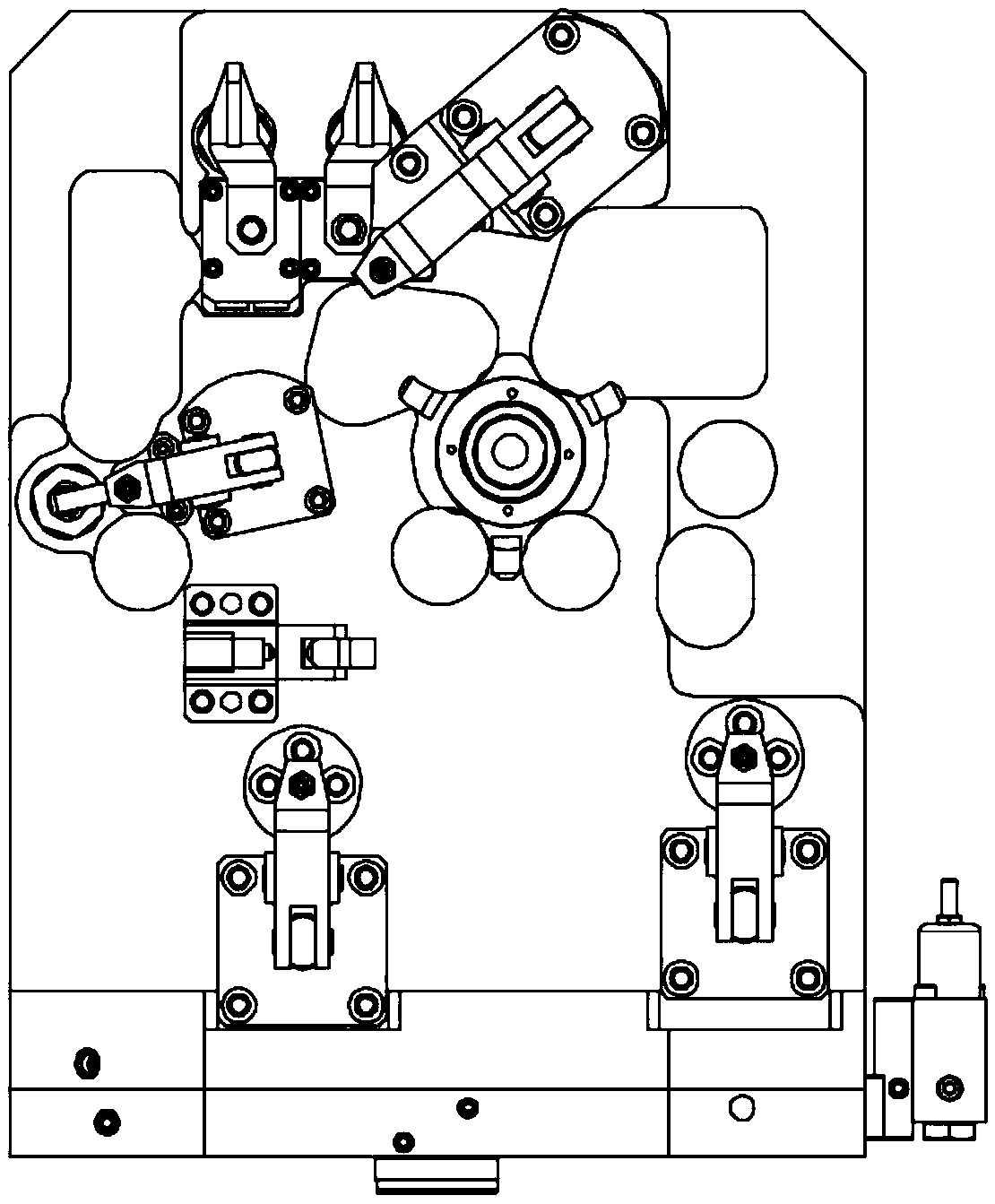

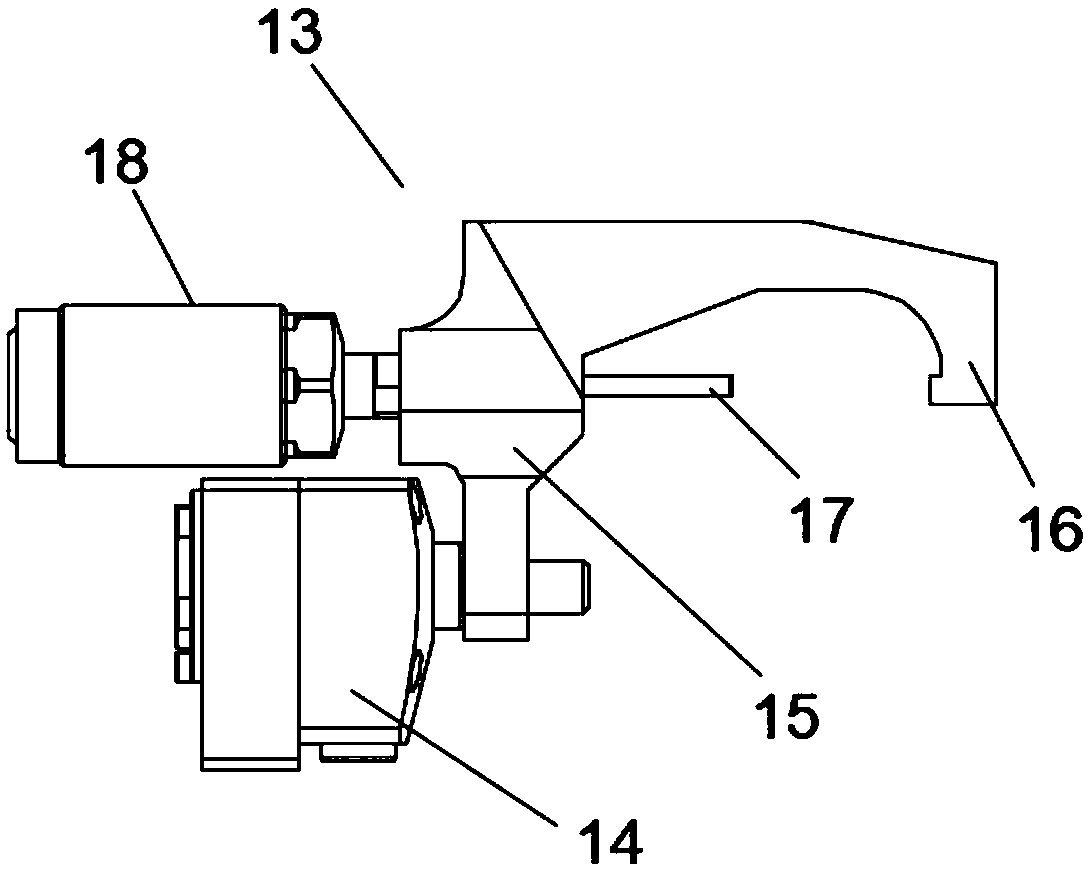

[0025] Such as Figure 1 to Figure 7 As shown, this embodiment provides a hydraulic fixture for five-axis machine tool processing of hub brackets, which includes a horizontal base 1 and a stand 2 fixed on the horizontal base 1; the position of the middle right of the stand 2 A first support seat 3 is provided; the second support nail 4 is provided at the lower left position of the first support seat 3, the third support nail 5 is provided at the lower right position, and the second support nail 5 is provided at the upper left position. Four supporting nails 6; the first supporting seat 3, the second supporting nail 4, the third supporting nail 5 and the fourth supporting nail 6 jointly form a supporting reference plane; the top of the second supporting nail 4 is provided with an angle positioning top Rod 7; the front of the second support nail 4 is provided with a first compression mechanism 8, the front of the third support nail 5 is provided with a second compression mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com