An adaptive underactuated picking end effector and method

An end-effector and self-adaptive technology, which is applied to harvesting machines, applications, agricultural machinery and implements, etc., can solve problems such as difficulty in grasping, low picking accuracy, cumbersome control, etc., so as to improve the accuracy of clamping and positioning and avoid fruit picking. damage, a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

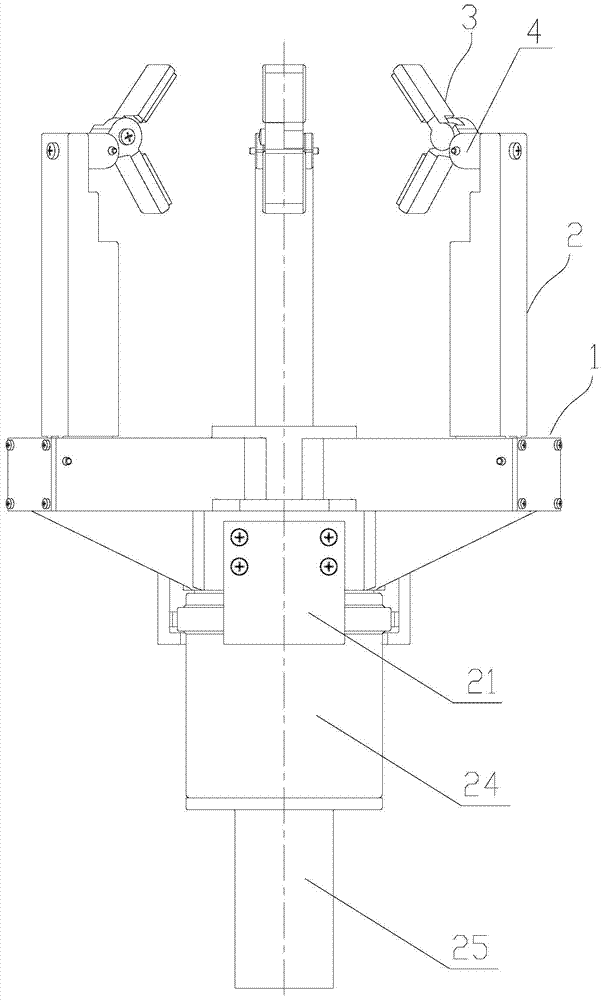

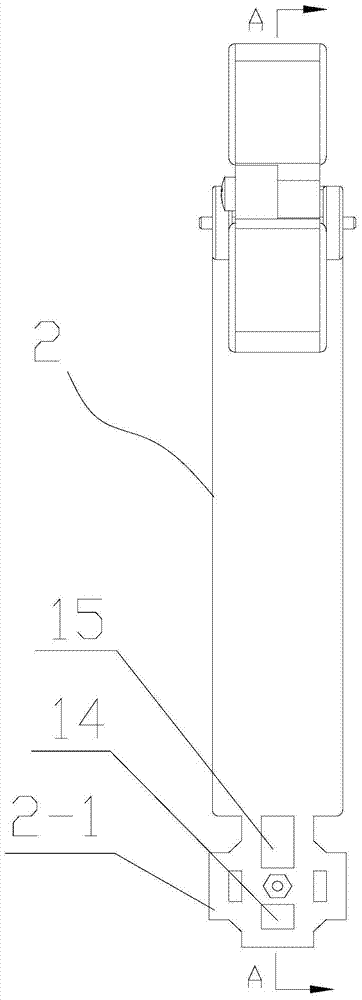

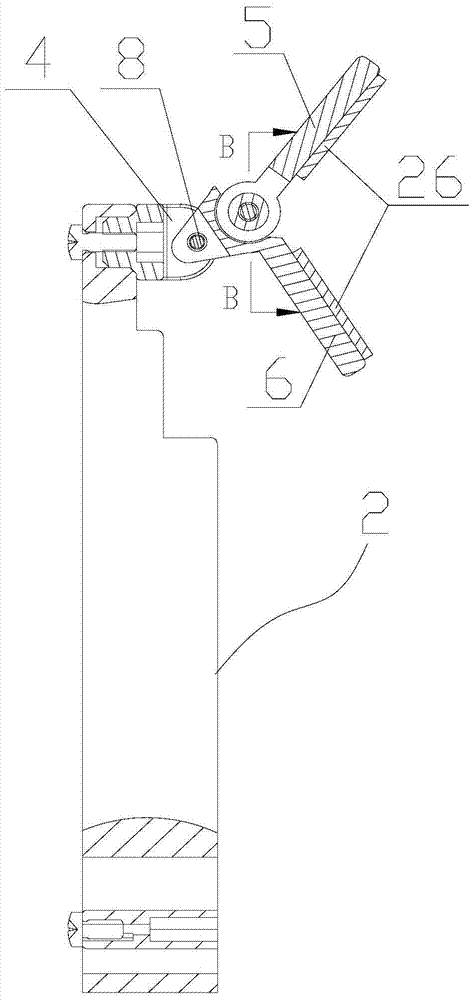

[0041] In this embodiment, an adaptive underactuated picking end effector includes a hand actuator, a drive mechanism and a support assembly, and the hand actuator is connected to the drive mechanism through the support assembly, wherein, as figure 1 As shown, the hand actuator includes a palm 1 and a plurality of fingers 2, the lower ends of each finger are movably connected with the palm respectively, each finger slides along the diameter direction of the palm, and the upper end of each finger is provided with a reversible V-shaped finger end 3, such as figure 2 or image 3 As shown, the V-shaped fingertip includes a knuckle reversing button 4, a first movable knuckle 5 and a second movable knuckle 6, and an angle-adjustable fixed connection is between the first movable knuckle and the second movable knuckle. The second movable knuckle is hinged with the knuckle reversing button, and the knuckle reversing button is connected with the upper end of the finger. Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com