Full compliant motor steering rack grinding fixture

A steering rack, fully flexible technology, applied in the field of grinding fixtures, can solve the problems of time-consuming and laborious fixture replacement process, low production efficiency, increased production cost, etc., and achieve convenient and fast fixture adjustment, fixture cost saving, and clamping positioning accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

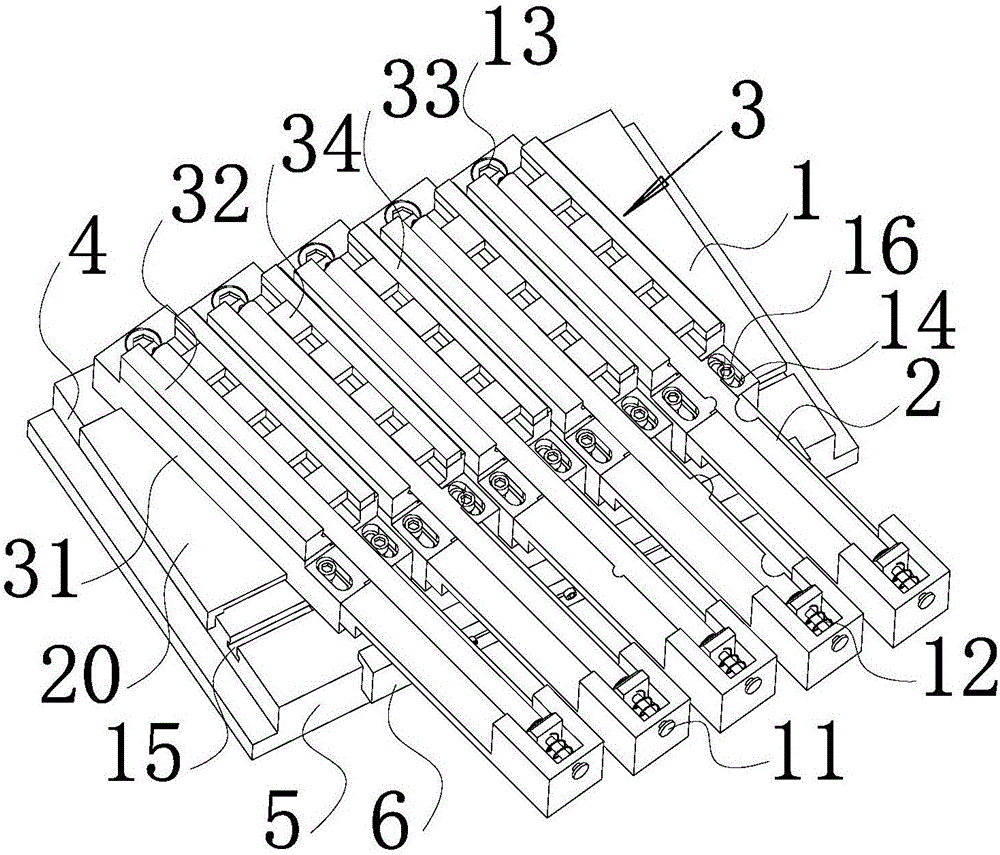

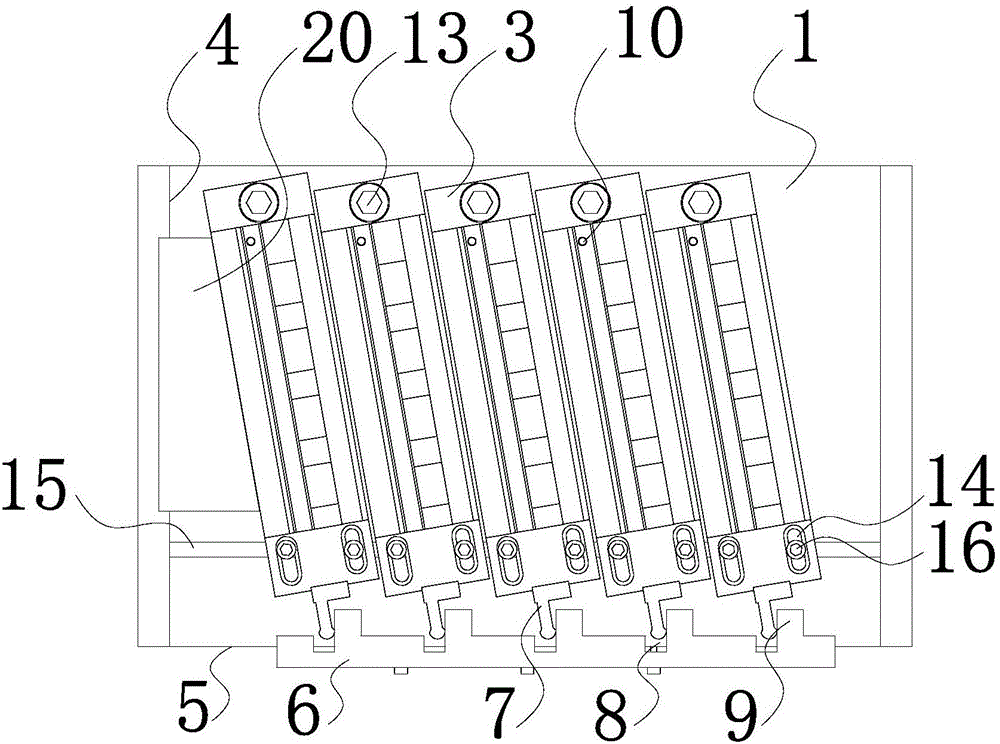

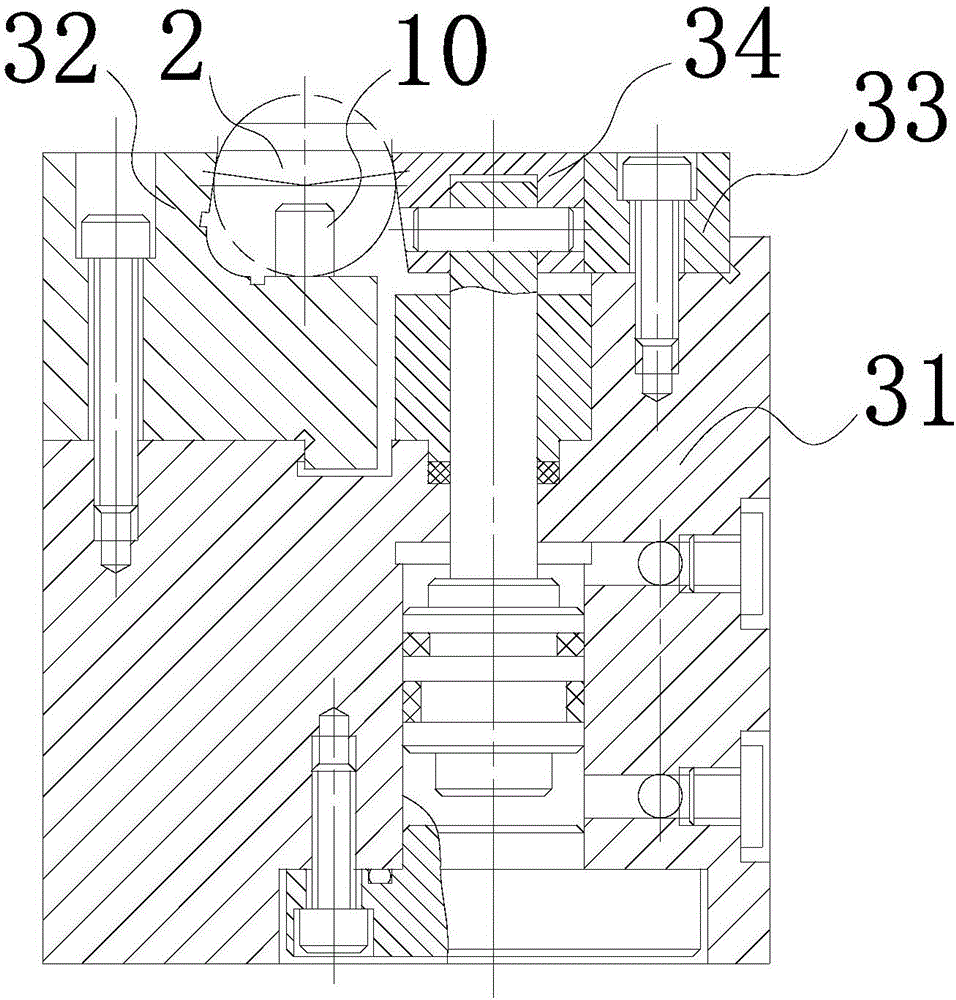

[0023] Such as figure 1 and image 3 As shown, a fully flexible automobile steering rack grinding fixture of the present invention includes a rectangular support platform 1, and five bases 3 that can hold a workpiece 2 and keep it horizontal are arranged in parallel on the support platform 1 along the length direction. , the two ends of the base 3 are kept flush with each other with a gap of 5 mm, and the base 3 includes a cuboid-shaped bottom plate 31 horizontally fixed on the surface of the support platform 1, and left and right sides are arranged on the upper surface of the bottom plate 31 along the length The clamping plate 32 and the right clamping plate 33, the base plate 31 between the left clamping plate 32 and the right clamping plate 33 has several pressure blocks 34 that can be lifted vertically, and the inner side of the left clamping plate 32 corresponding to the pressure block 34 has an axial arc. The cross section of the pressing block 34 is an inverted trapezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com