Turning method of tail end sealed type besides-star wheel of telescopic constant-velocity universal joint

A constant velocity universal joint and processing method technology, applied in the direction of chuck, expanding mandrel, etc., can solve the problems of violation of selection principle, large fluctuation of product quality, affecting blade life, etc., to improve clamping and positioning accuracy, automation The effect of convenient production and improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

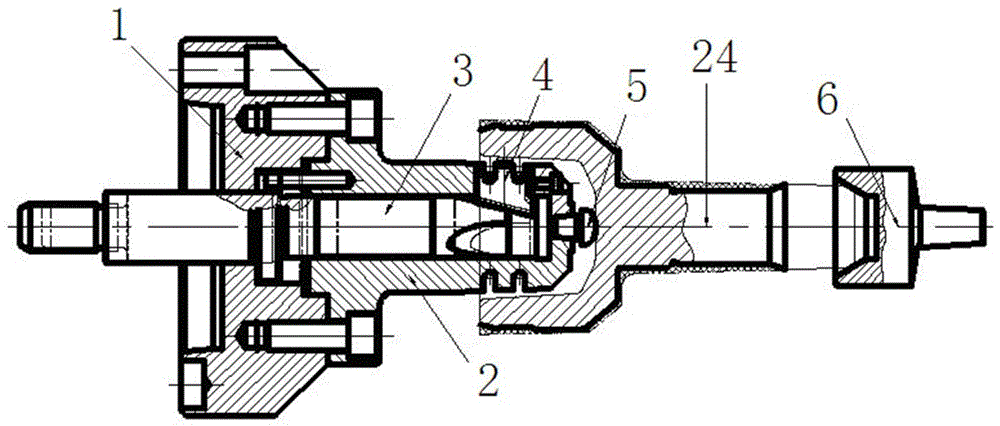

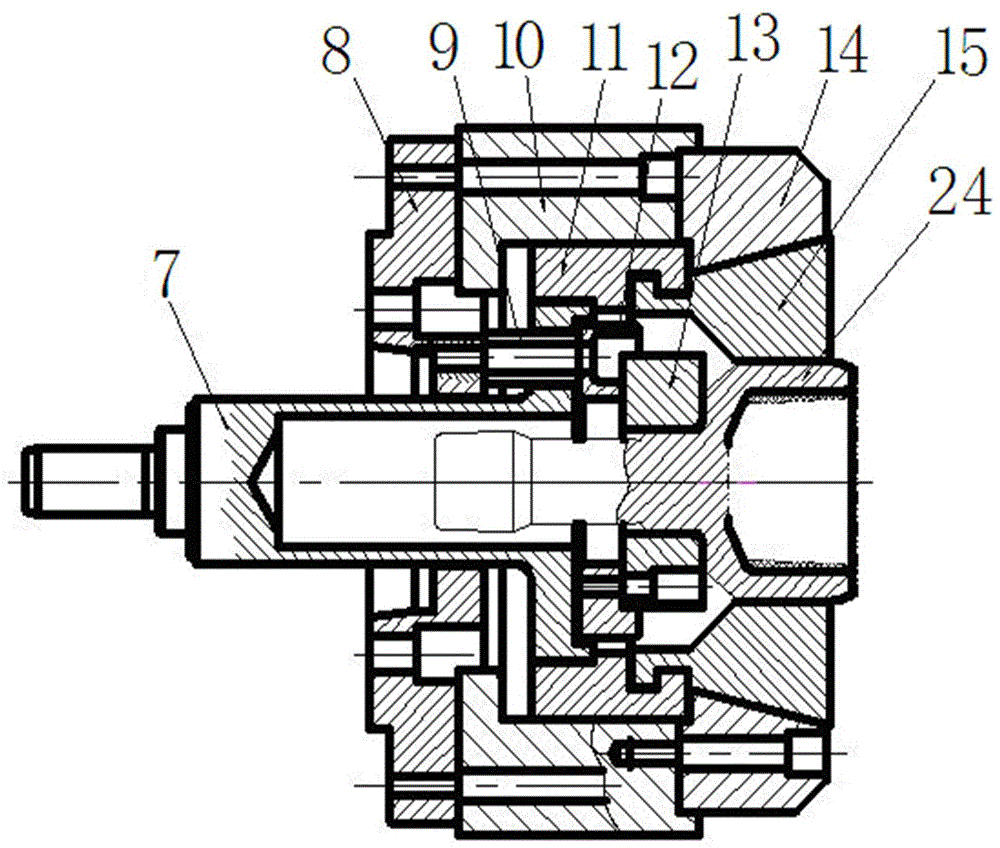

[0040] The turning processing method of the telescopic constant velocity universal joint end-closed outer star wheel of the present invention includes the following steps:

[0041] (1) Use the inner hole as the clamping surface of the claw, and the bottom surface of the inner hole as the positioning surface, fix the end of the shaft body through the top, and perform rough turning on the outer surface of the shaft;

[0042] (2) Use the surface of the rough-turned shaft body as the clamping surface, and the intermediate step surface between the shaft body and the blind hole as the positioning surface, and finish the outer surface and inner hole of the blind hole;

[0043] (3) The inner hole of the finished car is used as the clamping surface, the outer surface of the blind hole is used as the positioning and clamping workpiece, the outer surface of the finished car shaft body, the end face of the shaft body and the center hole.

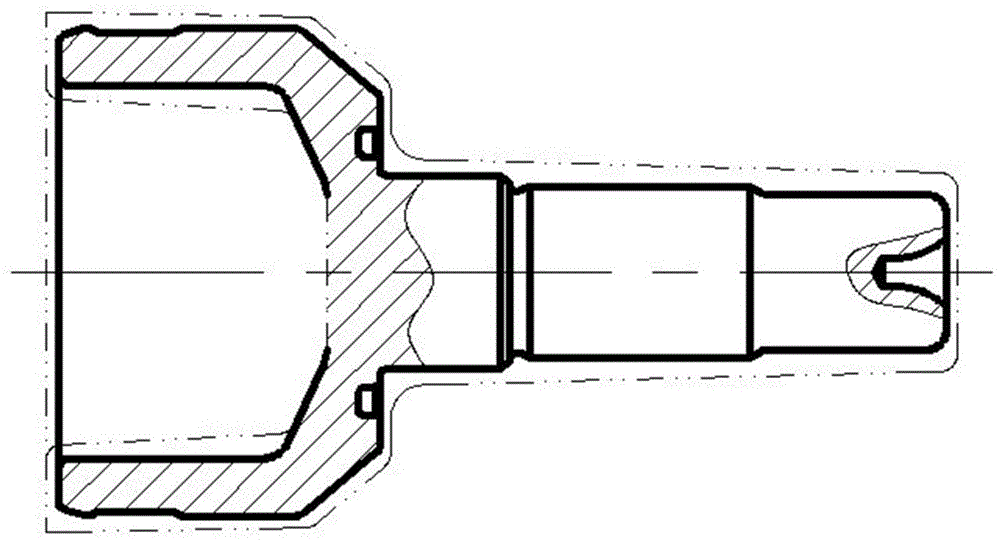

[0044] See attached figure 1 , The bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com