Key strengthening device for auxiliary fixation between wheel and shaft

A technology for reinforcing devices and axles, applied in hand-held tools, manufacturing tools, etc., can solve the problem of stamping equipment losing precision and achieve the effect of excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

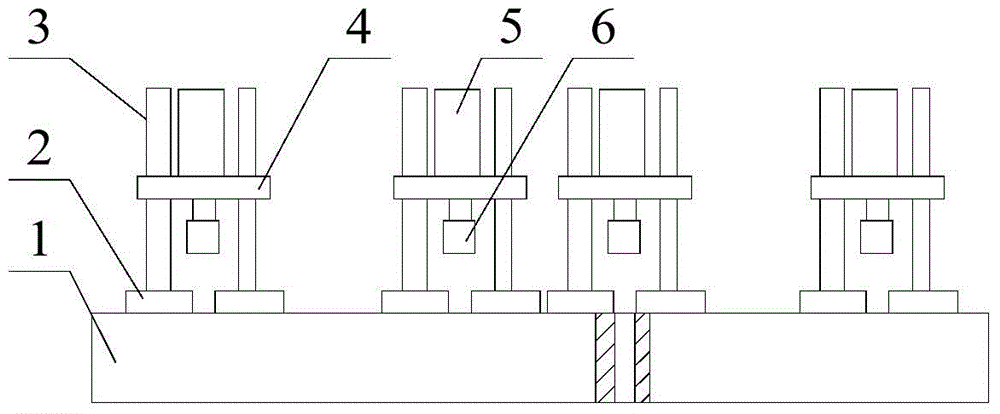

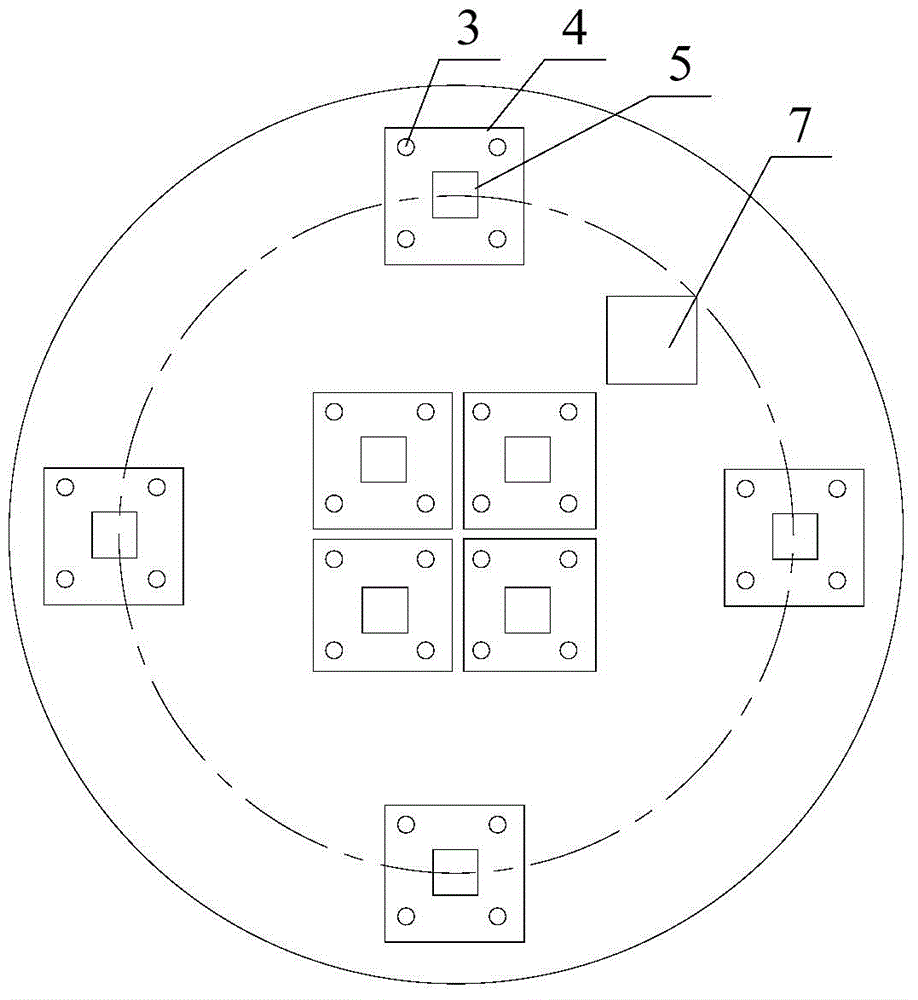

[0016] See attached figure 1 And attached figure 2 , the key reinforcement device for auxiliary fixing between axles of the present invention includes a base plate 1, a tightening device and a control unit;

[0017] The inner ring of the bottom plate 1 is evenly distributed with a plurality of threaded holes on the circumference relative to the shaft end, that is, at least two; the outer ring of the bottom plate 1 is evenly distributed with a plurality of threaded holes on the circumference relative to the wheel end surface, that is, at least two; The number of multiple threaded holes evenly distributed on the inner and outer circles of the bottom plate 1 is determined according to the actual force requirements;

[0018] A tightening device is provided at the corresponding position of each threaded hole on the base plate 1, and a screw is fixed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com