P03 discharging device for high-temperature separator of gaseous aluminum hydroxide suspension calciner

A suspension roaster and high-temperature separator technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems that the output cannot be increased due to the blockage of the feeding nozzle, the increase of production instability factors, and the temperature and heat cannot be maintained. The effect of reducing unstable factors, preventing lining damage, and preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

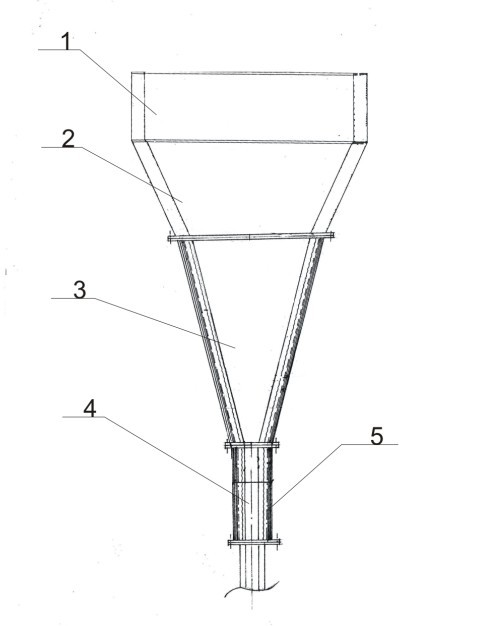

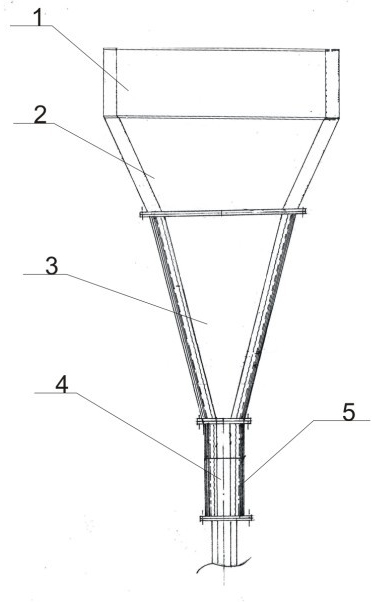

[0023] Original high temperature separator P0 3 The volume of the lower cone space is 57.73 M 3 , exit stream diversion angle a 1 about 28°. In order to increase the output per unit area and thermal efficiency and reduce wear and tear, the following measures are adopted:

[0024] 1. The double-cone settling chambers with different tapers are superimposed, and the taper of the settling chamber in the upper cone section a 1 About 28°, the taper of the settling chamber in the lower cone section a 2 about 22°. P0 3 The vertical height of the settling chamber in the cone section is extended to more than twice the vertical height of the upper cylindrical settling chamber, and the volume of the cone space is expanded to 60m 3 above.

[0025] 2. The lower part of the settling chamber adopts the same insulating furnace lining as the cone settling chamber, and the vertical height of the pipe is 1.6M, which is equivalent to one-fifth of the height of the upper cone.

[0026] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com