Variable ellipticorbit equal-thickness vibrating screen

A vibrating screen and variable ellipse technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of complex structure of the screen body, low screening efficiency, large height of the screen body of the equal thickness screen, etc., and achieve enhanced screening process, is conducive to uniform stratification, and the effect of high probability of sieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

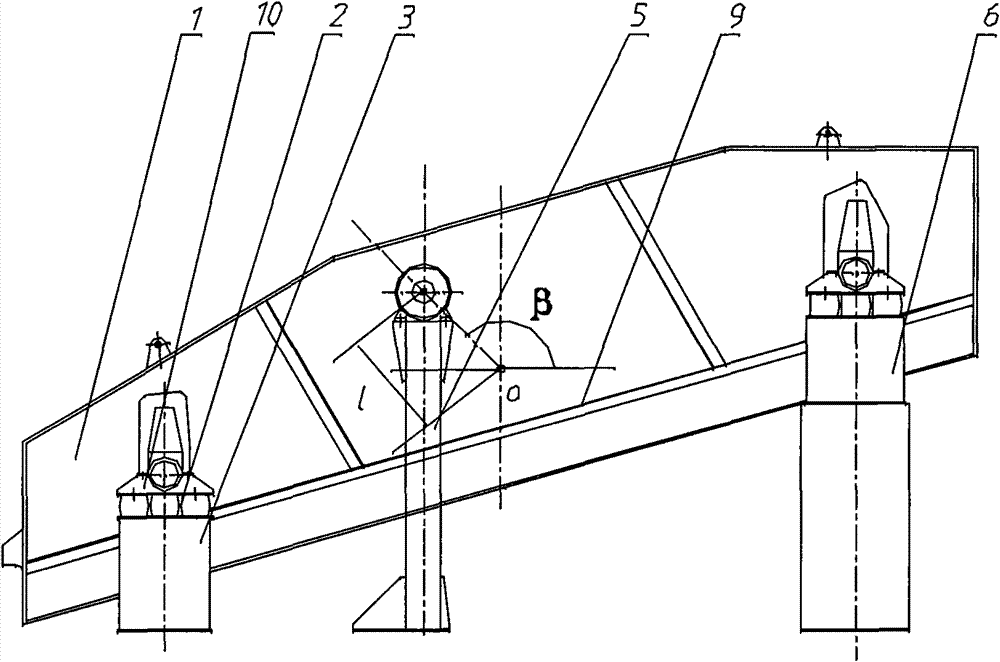

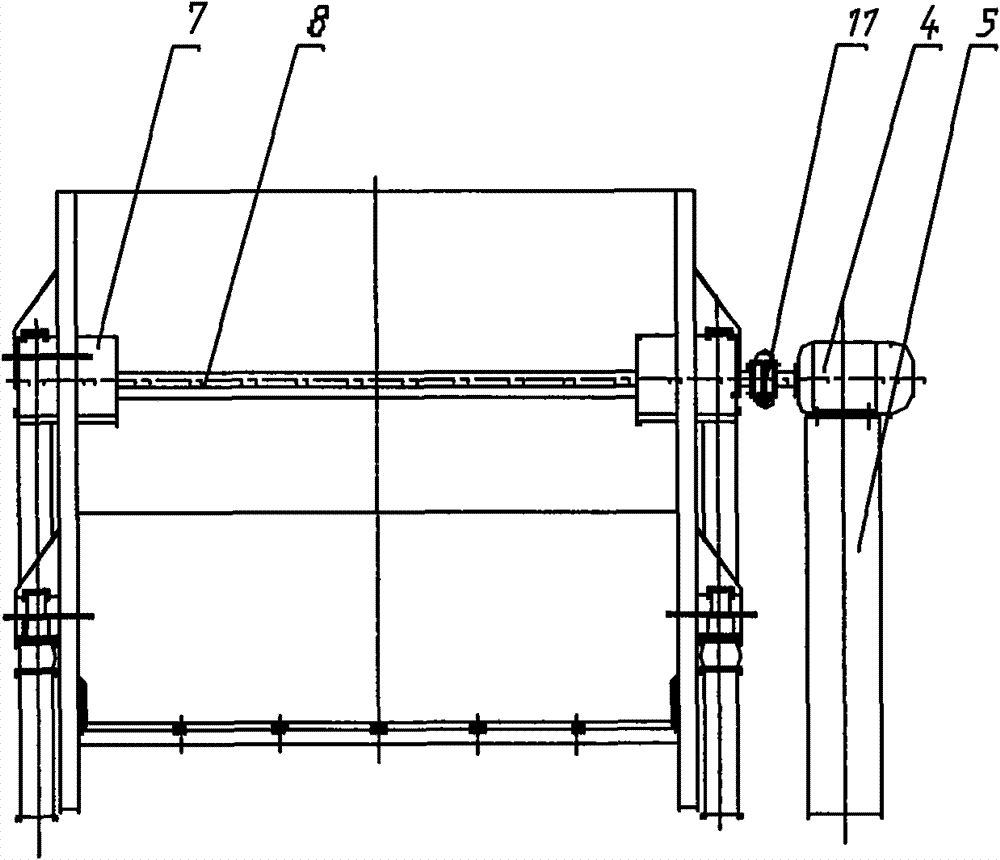

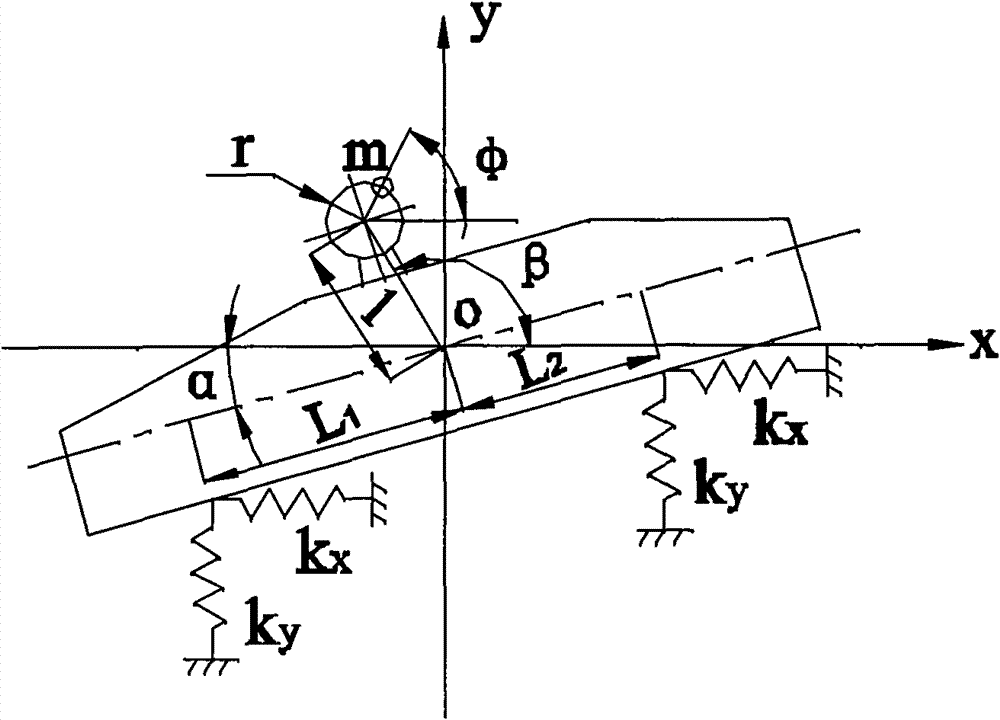

[0015] figure 1 , figure 2 As shown, the vibrating screen with variable elliptical trajectory and equal thickness of the present invention is mainly composed of a screen box, an elastic support, an exciting body, a motor 4 and a motor base 5. The screen box is composed of a sieve plate 1 and a screen mesh 9. The elastic support is composed of a front support 3 and a rear support 6. The front and rear supports are respectively provided with a rubber spring 2 and an upper support 10. The excitation body is composed of a single excitation transmission shaft. 8 and the eccentric exciter 7 symmetrically arranged thereon constitute, and the eccentric exciter 7 is made up of parts such as main eccentric block, secondary eccentric block, bearing seat, shaft, rolling bearing and gland. The front support 3 is low, the rear support 6 is high, and the screen b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com