Cadmium disc for inductive circuit of spark test device, and machining method for cadmium disc

A technology of spark test and processing method, applied in circuits, spark gaps, spark plugs, etc., can solve the problems of large wear of tungsten wire and cadmium disk, inconsistent angle of tungsten wire and cadmium disk, inconsistent separation angle of tungsten wire and cadmium disk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

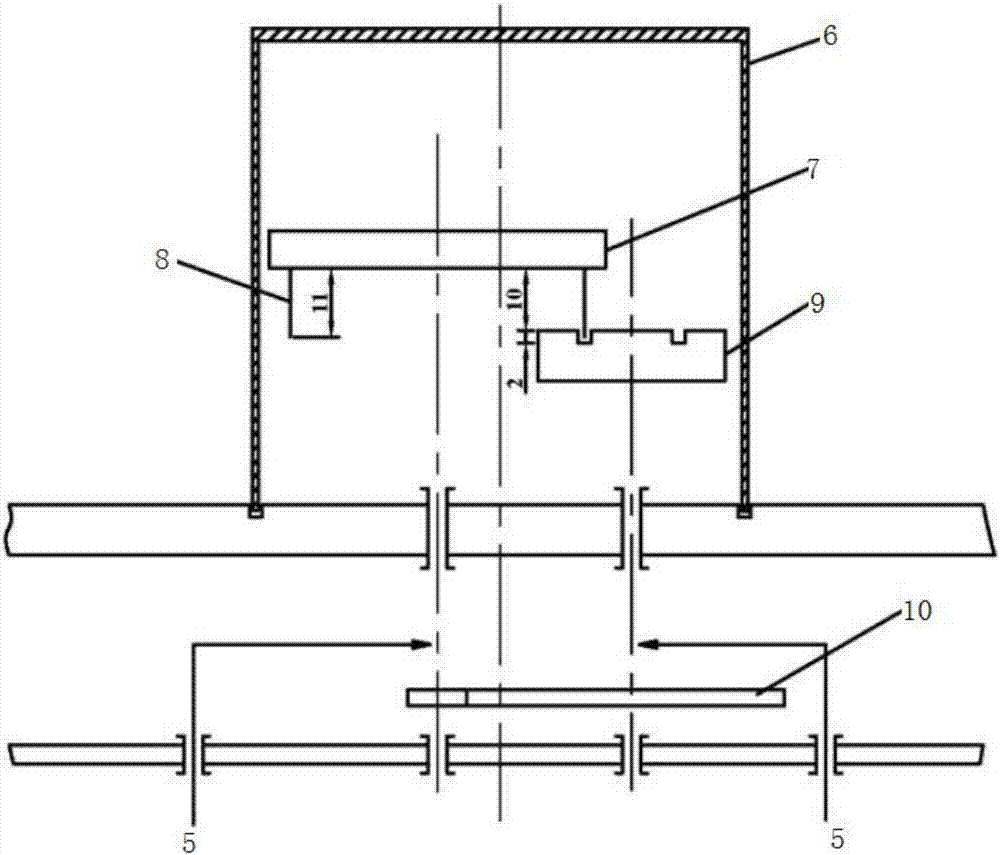

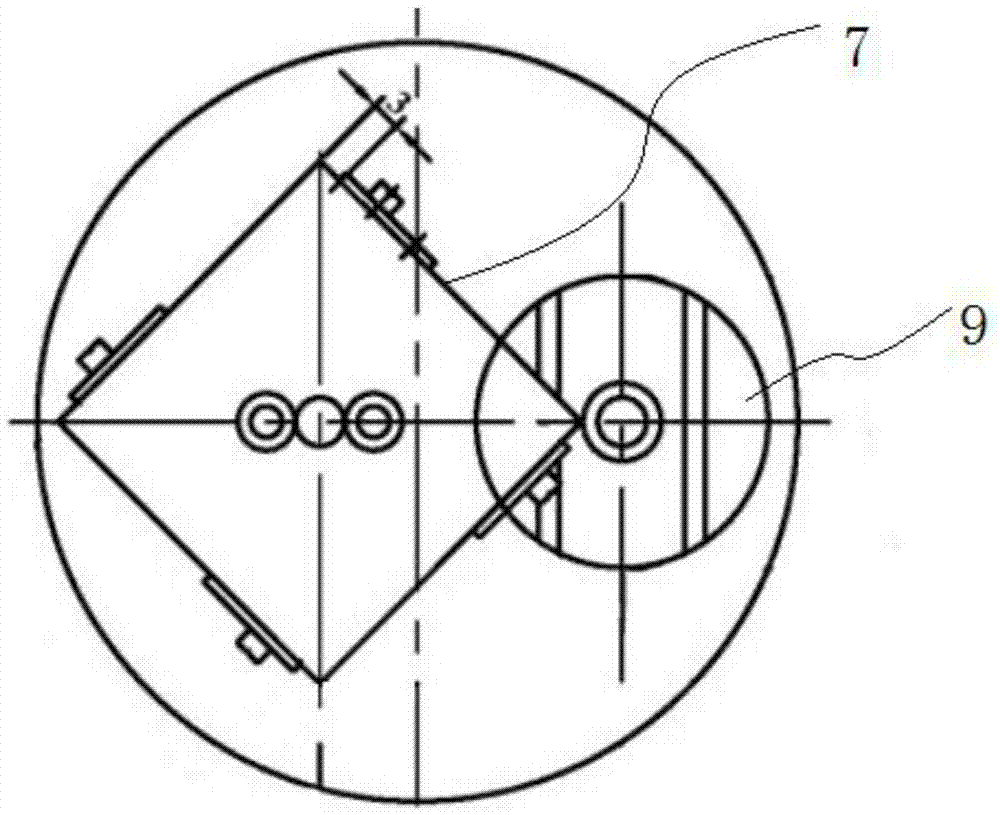

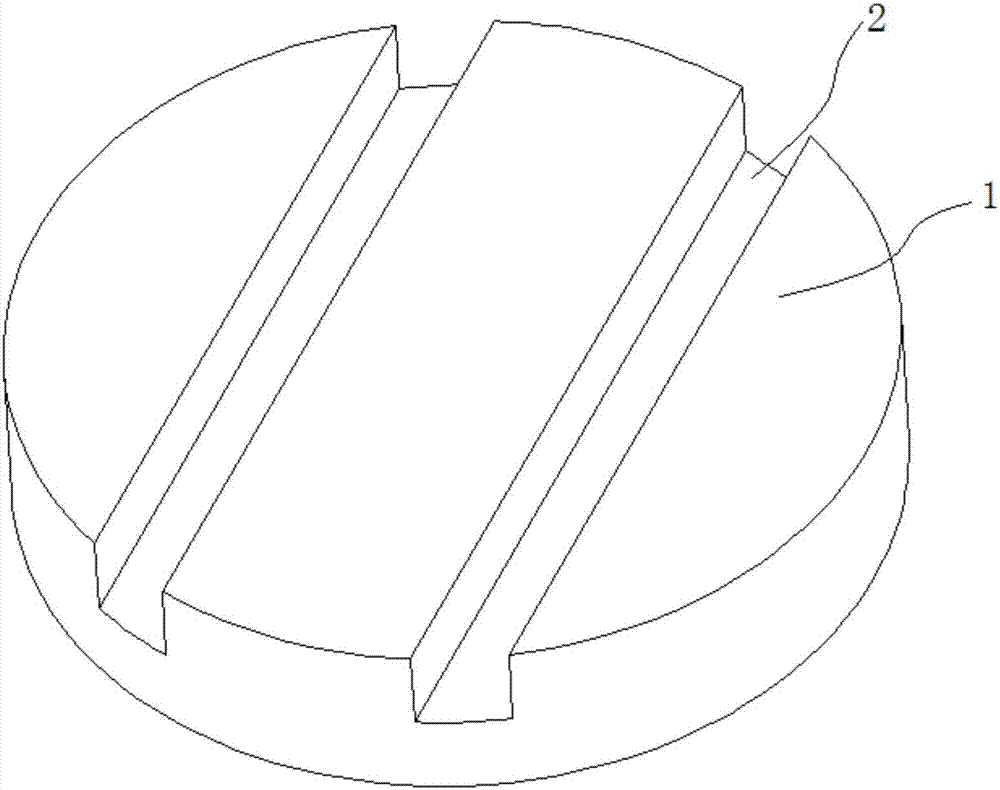

[0049] In order to enable those skilled in the art to better understand the technical solutions in this application, the technical solutions in this application will be clearly and completely described below in conjunction with embodiments.

[0050] Such as image 3 and Figure 4 As shown, the present invention discloses a cadmium disk used for the inductive circuit of the spark test device, which comprises a cadmium disk main body 1, and two grooves 2 are arranged on the cadmium disk main body 1, and the grooves between the tungsten wire and the cadmium disk main body 1 A chamfer 3 is provided at the position where the edges of the grooves 2 meet; a semicircular portion 4 is provided at the separation point between the tungsten wire and the edge of the groove 2 of the cadmium disc main body 1 .

[0051] By chamfering the groove of the cadmium disc, the problem of excessive wear of the tungsten wire and the cadmium disc during the contact process of invalid sparks can be solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com