Resistance-increasing and pressure-relieving system for filling slurry pipeline transportation and using method thereof

A technology for pipeline transportation and filling slurry, which is applied to filling materials, earth square drilling and mining equipment, etc. It can solve the problems of high sealing requirements, low safety factor, easy wear of valves, etc., and achieve low cost and long service life , Reduce the effect of impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

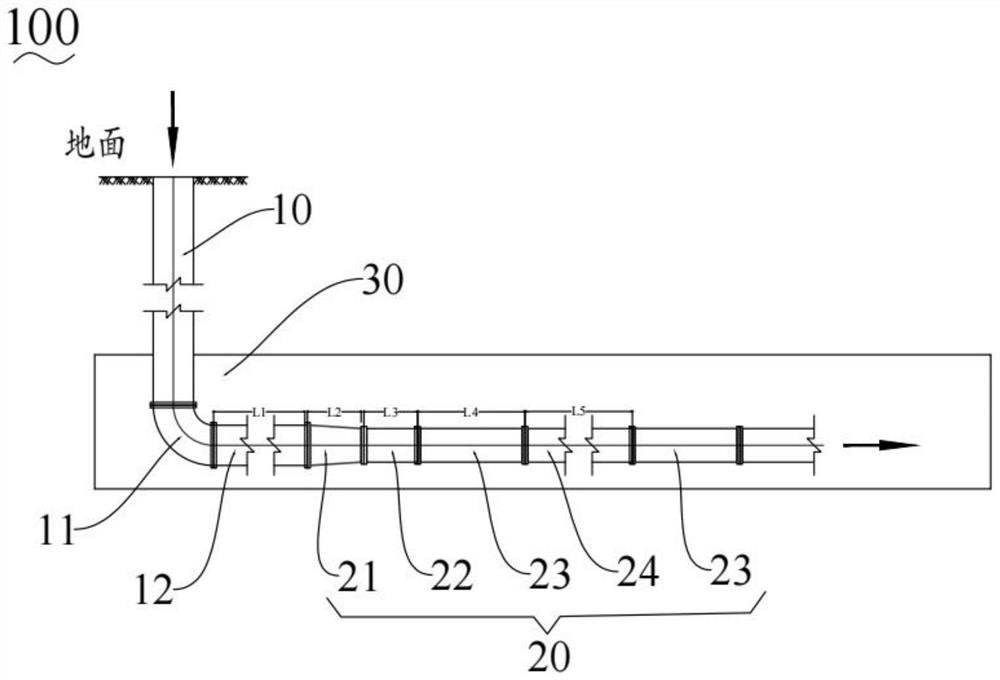

[0038] The resistance increasing and pressure relief system 100 conveyed by the above-mentioned filling slurry pipeline is used to fill a mine in Inner Mongolia. The vertical height from the surface filling station to the underground stope is large, the horizontal distance is small, and the ore filling multiplier is about 1.5-3.0. In the process of mine filling, due to the large potential energy of the slurry, the fast flow velocity of the filling slurry in the pipeline, and the large free fall distance in the vertical pipe, a huge impact on the inner wall of the pipeline is formed. The horizontal pipeline often occurs due to high pressure and fast wear. Pipe burst accidents restrict the operation efficiency of mines. By adding a resistance-increasing and pressure-relieving device 20 at the horizontal pipe 12 near the filling standpipe 10, and adding a resistance-increasing ceramic composite pipe 23 at an interval of 60 m on the horizontal pipe 12, after the filling slurry pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com