Welding tool clamp for military vehicle sideboard assembly

A technology for welding fixtures and assemblies, used in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient transportation and hoisting of side plate assemblies, welding deformation, and inability to guarantee dimensional accuracy. Convenience, accurate welding, and the effect of reducing labor intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

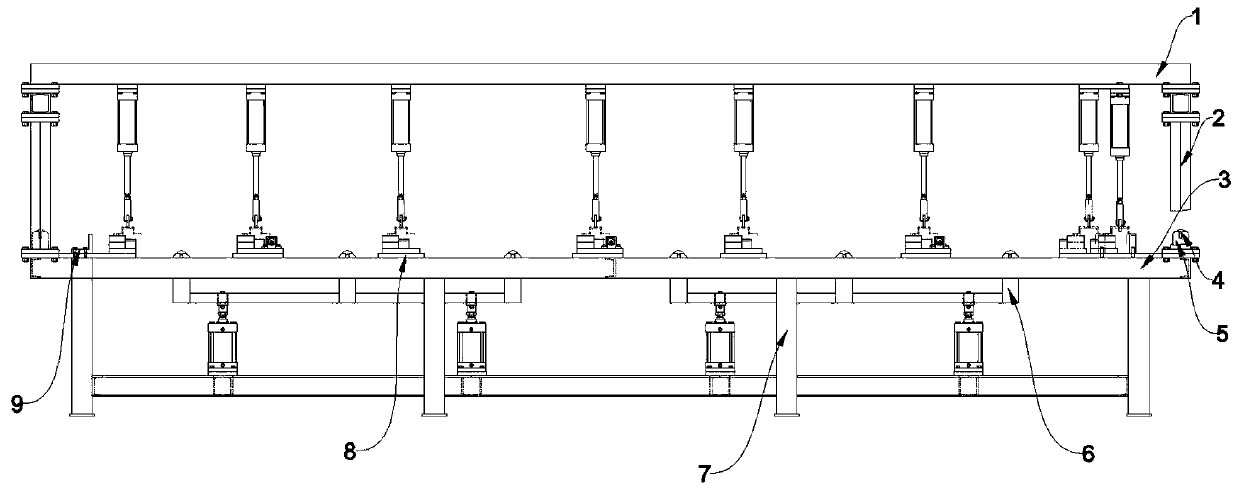

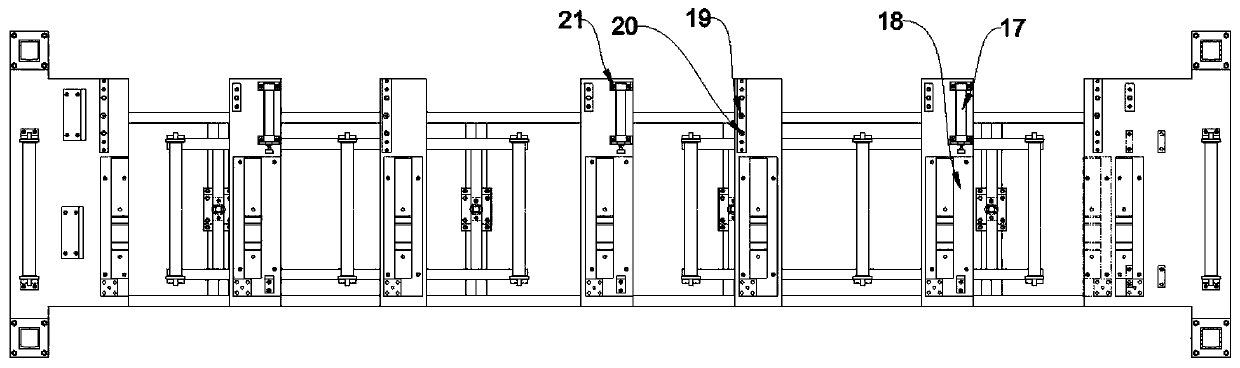

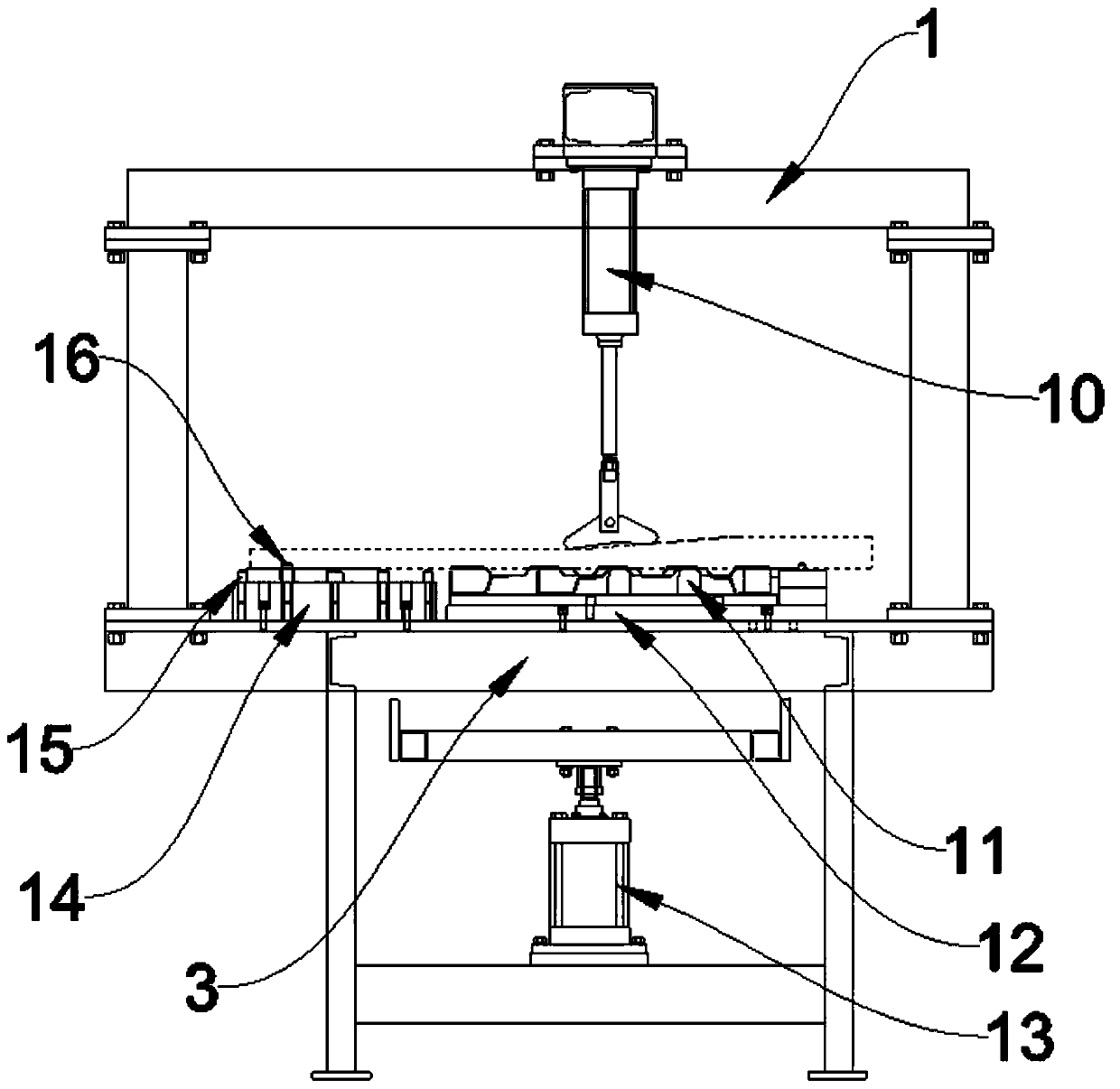

[0027] as attached figure 1 to attach Figure 4 Shown:

[0028] The invention provides a military vehicle side plate assembly welding fixture, comprising: an upper pressing frame assembly 1 and a supporting leg 7; the supporting leg 7 is welded and arranged on the bottom side of the base frame assembly 3; the upper pressing frame The assembly 1 is supported on the upper side of the base frame assembly 3 through the support of the column assembly 2; the bottom side of the upper compression frame assembly 1 is arranged and installed with multiple upper compression cylinders 10, and the bottom side of the upper compression cylinder 10 rotates A briquetting structure is installed, and the briquetting structure can also be operated laterally, and the briquetting structure is designed in a triangular structure, which is convenient for the passing rotation to better fix the side plate of the military vehicle, thereby effectively improving the fixing strength of the side plate. And ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com