Shell machining process

A processing technology and shell technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as inconvenient clamping and positioning, inability to effectively ensure production and processing efficiency, and difficult to guarantee processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

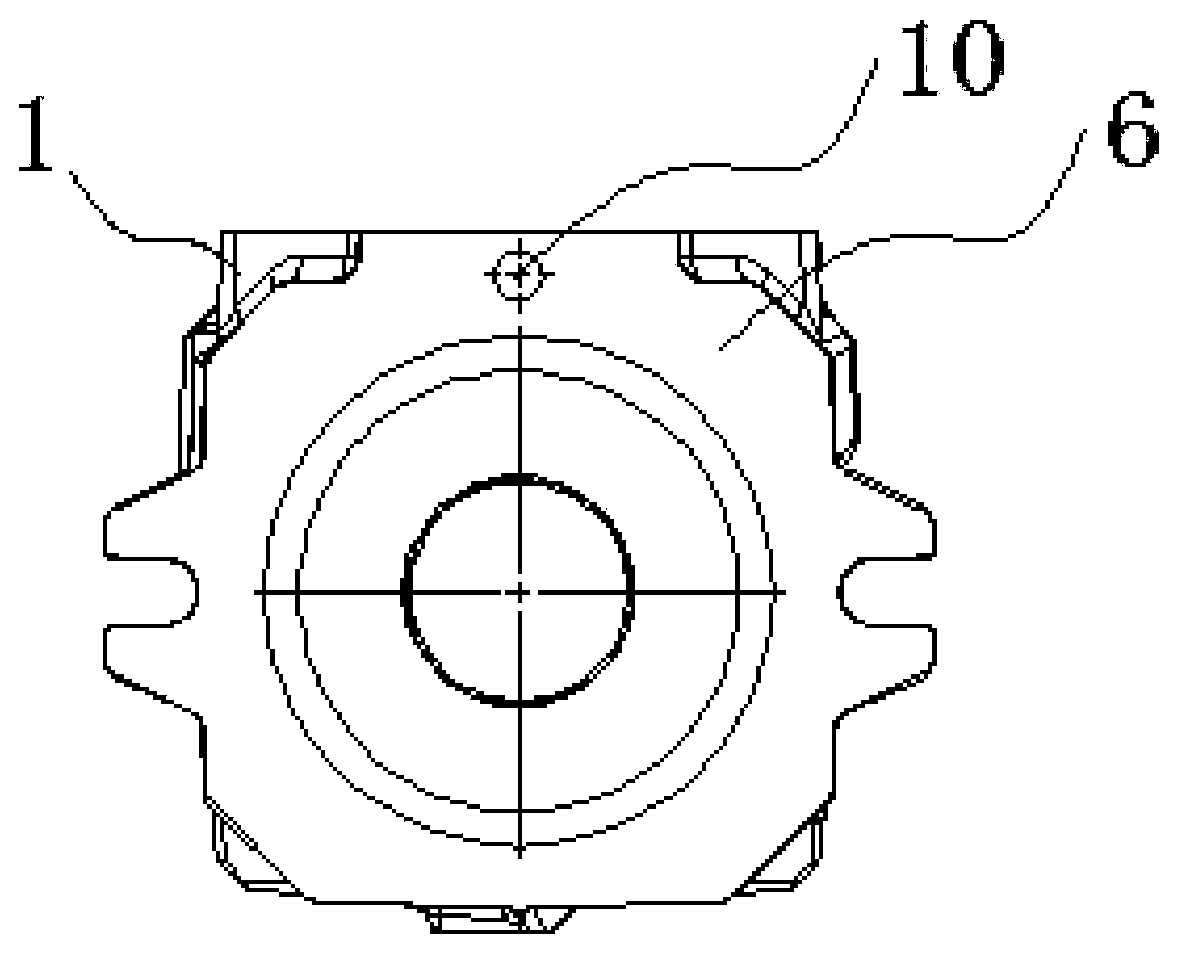

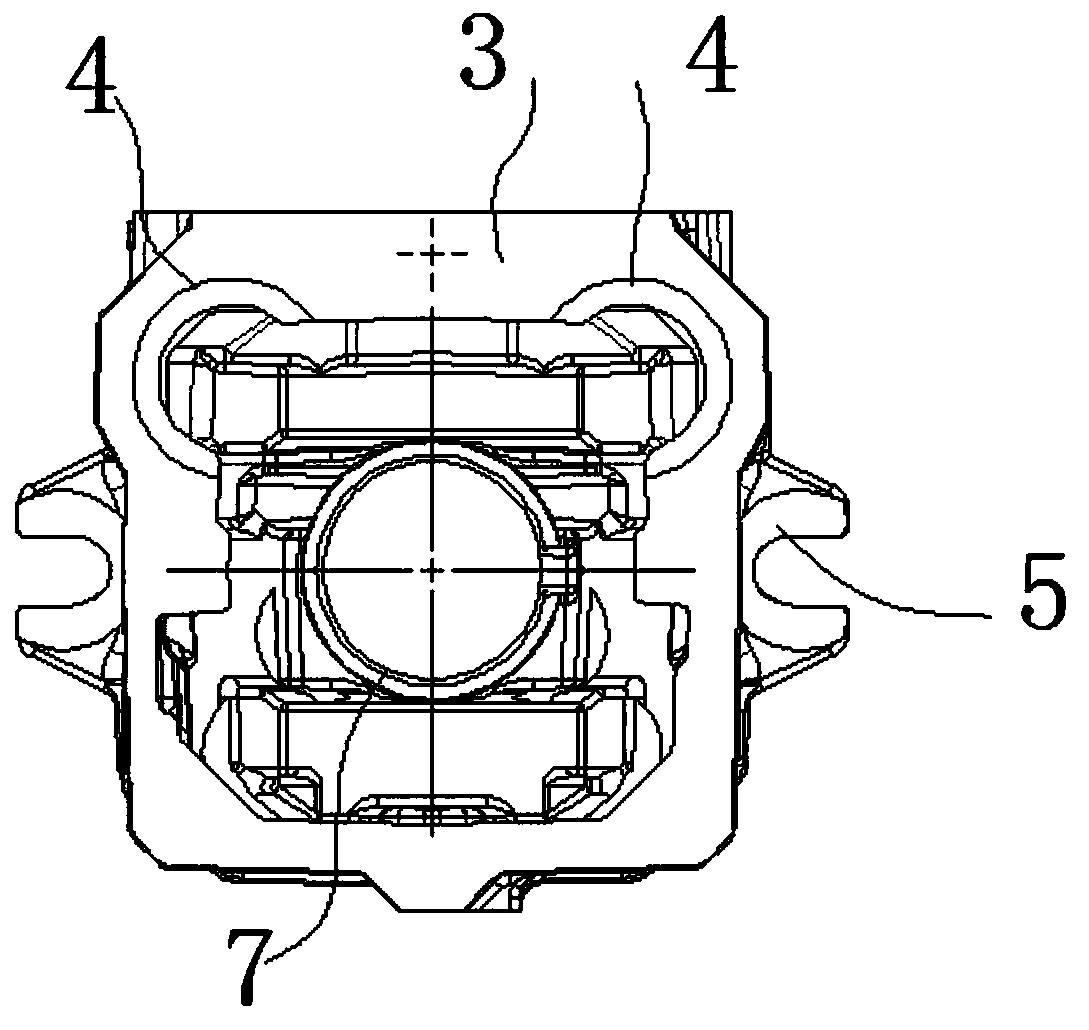

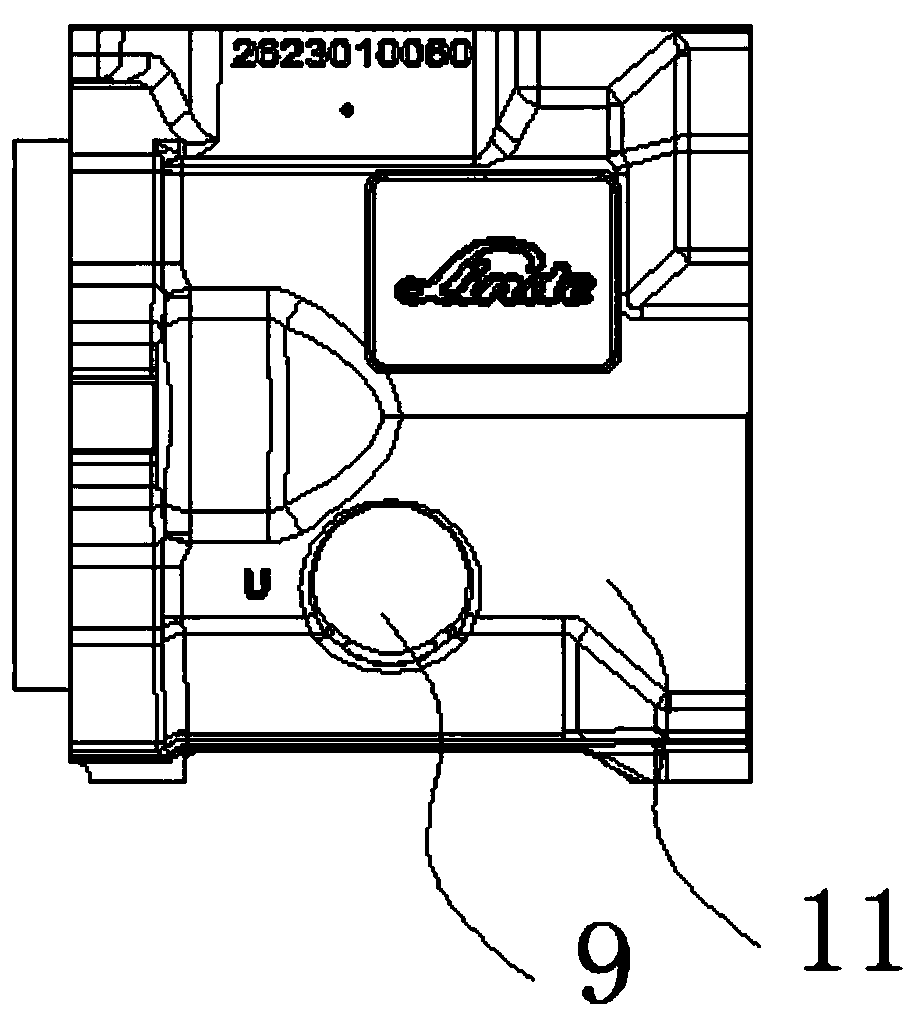

[0021] Such as figure 1 with figure 2 As shown, a shell processing technology includes the following steps:

[0022] Step 1: casting blank, such as Figure 1-Figure 5 As shown, the blank 1 has an auxiliary pressing boss 2, and the auxiliary pressing boss is arranged on the side surface between the front end surface and the rear end surface of the blank, and the clamp clamps the blank on the auxiliary pressing boss. On the fixture, perform rough milling on the rear end face 3 of the blank 1;

[0023] Step 2: use the rear end face 3 and at least two rear end positioning holes 4 on the rear end face to position and process the front end face 6;

[0024] Step 3: use the rear end face in step 2 and at least two rear end positioning holes 4 on the rear end face for positioning, and mill the rear surface of the ear 5 on the side surface of the blank;

[0025] Step 4: Use the front end face 6 and at least two front positioning holes 10 on the front end face for positioning, finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com