Bearing needling mechanism and carrier thereof

A carrier and body technology, applied in the field of testing equipment, can solve the problems of increased cost, troublesome PCB board clamping and positioning operations, etc., and achieve the effects of high clamping and positioning accuracy, convenient operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

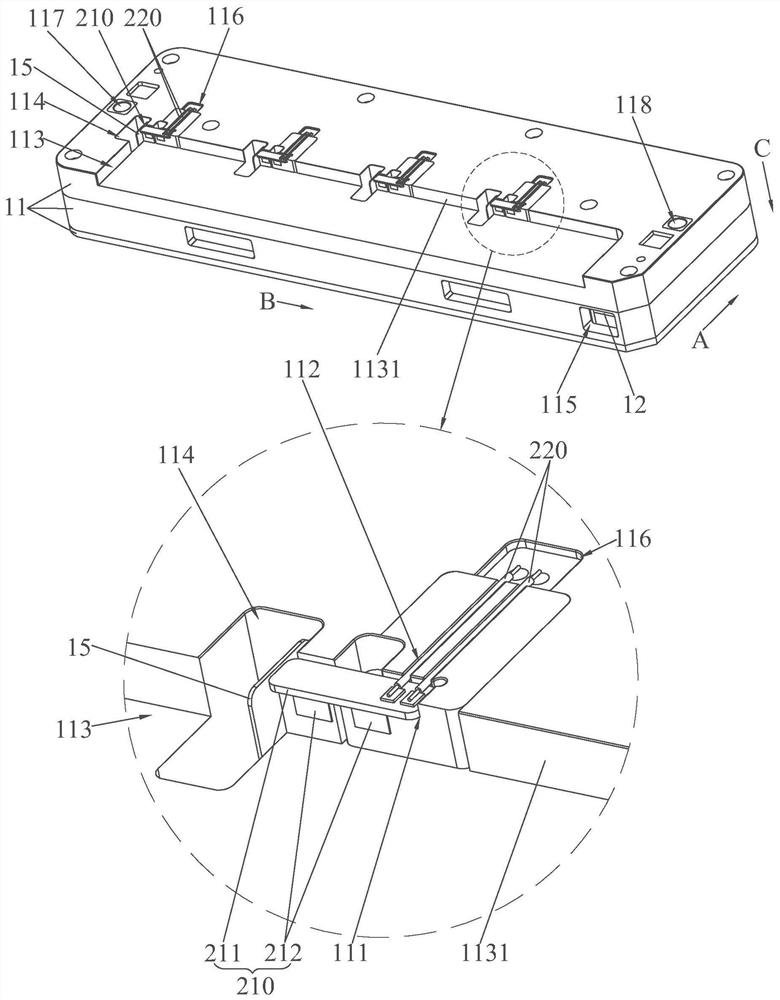

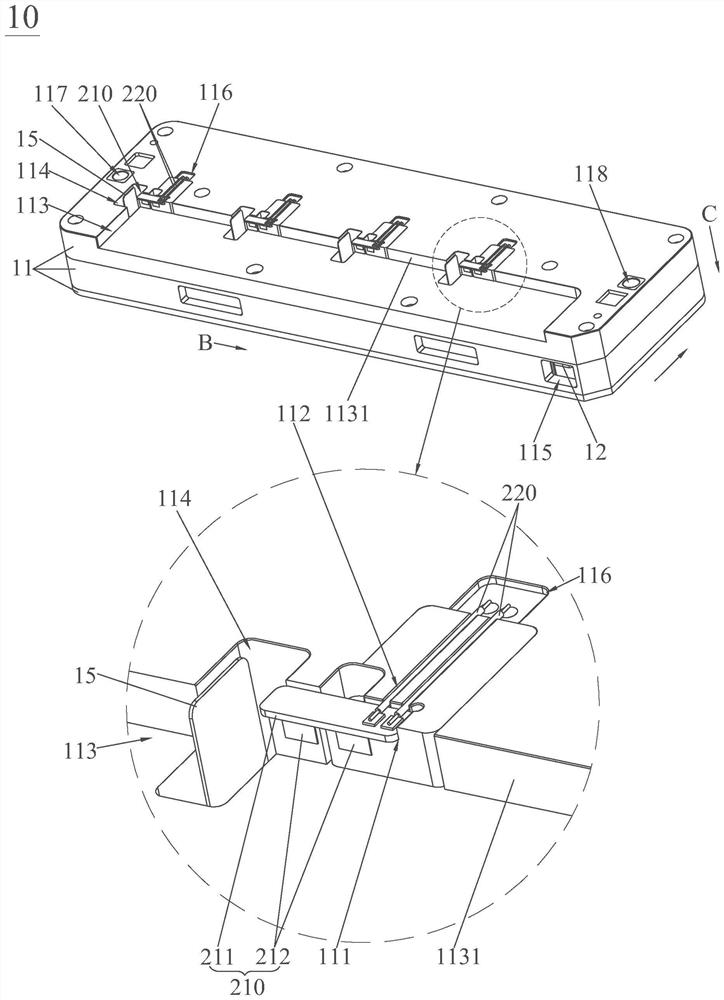

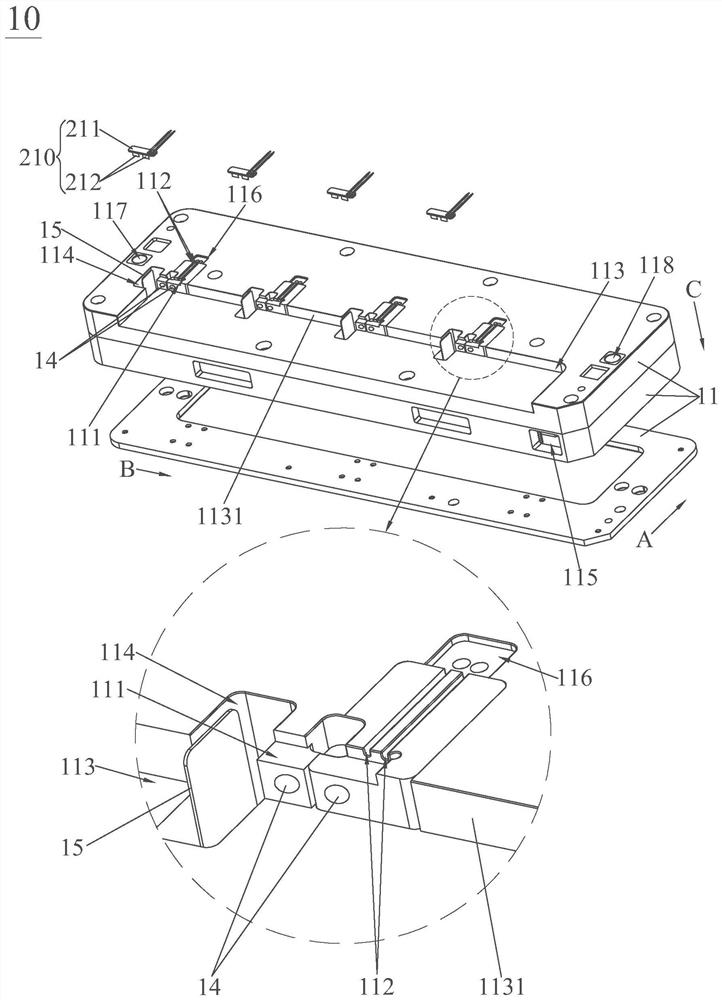

[0031] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0032] see Figure 1 to Figure 4 , The carrier 10 of the present invention includes a carrier body 11 , a slide bar 12 , an elastic member 13 , a magnet 14 and a push piece 15 . The top of the carrier body 11 is provided with a PCB positioning groove 111 for positioning the PCB board 210, a wire positioning groove 112 for positioning the connecting wire 220 welded together with the PCB board 210, and a slot for sinking the top of the carrier body 11. The sinking avoidance chamber 113 and the movable chamber 114 for the movement of the push piece 15, the sinking avoidance chamber 113 is connected and located directly in front of the PCB positioning groove 111, so that the sinking avoiding chamber 113 is located directly in front of the PCB positioning groove 111 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com