Clamping mechanism and detection device

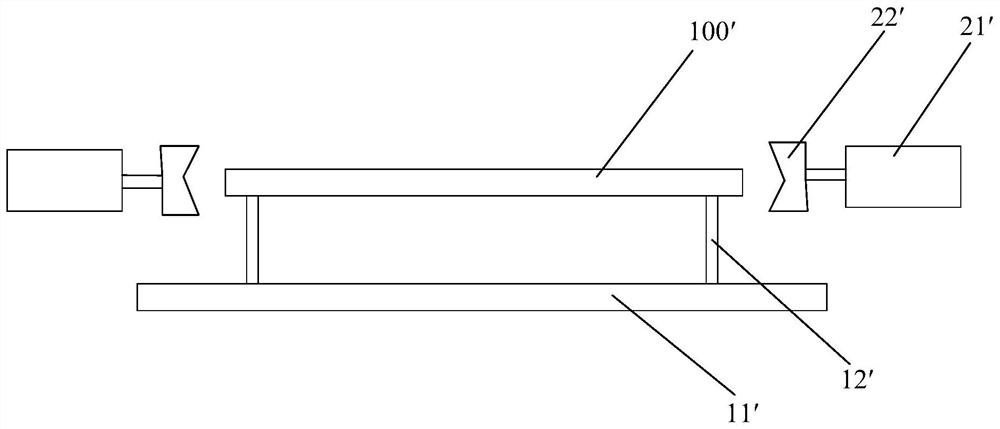

A clamping mechanism and substrate technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of large space occupation, substrate deformation, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

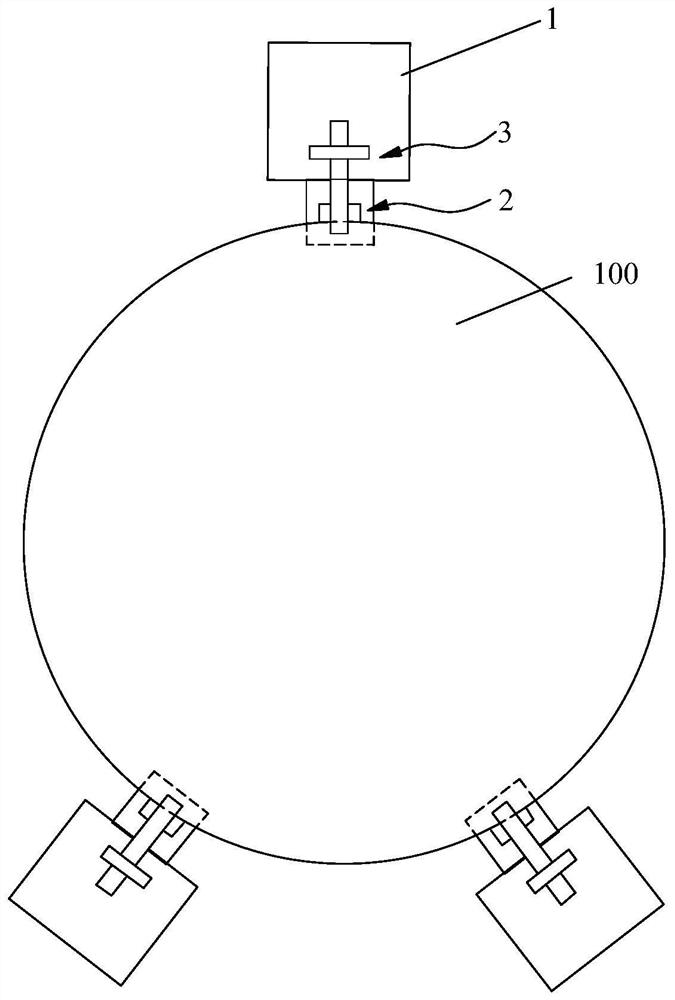

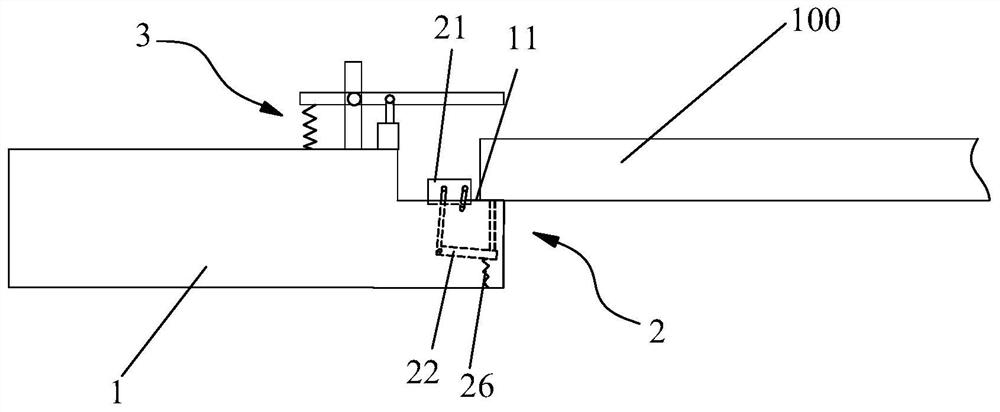

[0062] This embodiment takes the substrate as a wafer as an example for illustration, as figure 2 and 3 As shown, the clamping mechanism includes a support body 1 , an axial pressing assembly 3 and at least three sets of radial pressing assemblies 2 . Wherein, the support body 1 can be an integral plate structure, or a plurality of block structures arranged at intervals, or a frame mechanism, etc. In this embodiment, the support body 1 is a block structure, and each group of radially resisting The pressing assembly 2 is correspondingly connected with a supporting body 1 . The support body 1 includes a support plane 11, the support plane 11 can be used to support the bottom surface of the wafer 100, the radial pressing assembly 2 is arranged on the support body 1 and can respectively press the circumference of the wafer 100 along the radial direction of the wafer 100 surface, to define the radial position of the wafer 100 in the support plane 11, the axial pressing assembly ...

Embodiment 2

[0079] The difference between this embodiment and Embodiment 1 is that in order to realize the axial pressing assembly 3 pressing the wafer 100 in the axial direction, as Figure 6 As shown, the driving member 33 is a single-acting reset cylinder, and the output end of the single-acting reset cylinder is hinged to the end of the pressure rod 32 away from the base plate through a flexible hinge. In this embodiment, when the single-acting reset cylinder is in the initial state, its output end makes the pressure rod 32 in a downward position. Rotate to the avoidance position, when the wafer 100 is placed on the support plane 11, the single-acting reset cylinder is deflated, and the output end is stretched out under the action of the reset element inside it, so that the pressing rod 32 can return to compress the wafer. Circle 100 press down position.

Embodiment 3

[0081] The difference between this embodiment and Embodiment 1 lies in that, in order to realize that the radial pressing assembly 2 presses the wafer 100 in the radial direction, as Figure 7 As shown, the support body 1 includes a first support block 12 and a second support block 13, the support plane 11 is arranged on the first support block 12, and the first support block 12 and the second support block 13 are along a direction perpendicular to the support plane 11 Sliding fit; the second end of the transmission assembly 22 is provided with a bump 25, and the bump 25 is located between the first support block 12 and the second support block 13; the wafer 100 is placed on the support plane 11 so that the first support block 12 Close to the second supporting block 13 and press down the protrusion 25 . When the wafer 100 is placed on the support plane 11 of the first support block 12, under the gravity of the wafer 100, the first support block 12 slides downward relative to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com