Wax mold molding method with ceramic core

A ceramic core and molding method technology, applied in the direction of core, mold composition, casting molding equipment, etc., can solve the problem that the wax model cannot meet the design technical requirements, the clamping accuracy cannot be objectively guaranteed, and the positioning accuracy of the ceramic core is low, etc. problems, to achieve reliable molding quality, significant economic effects, and improved pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

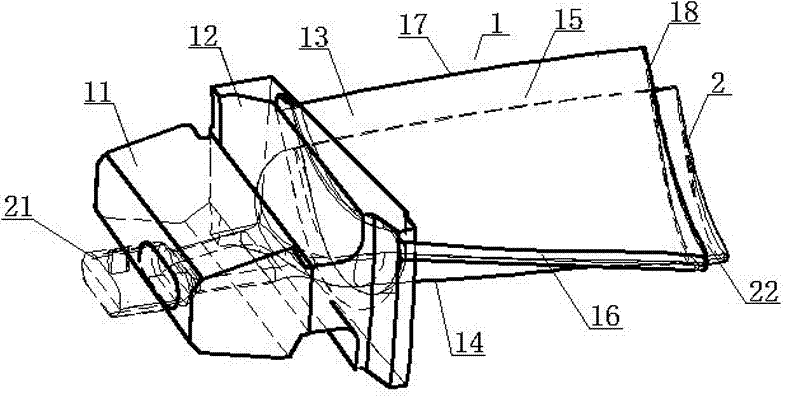

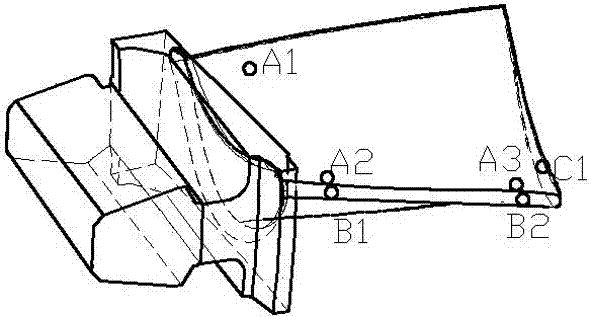

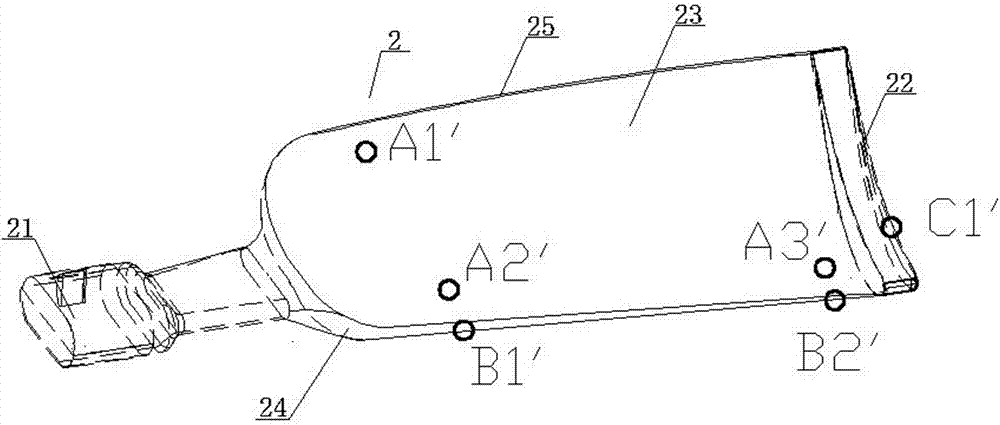

[0025] see figure 1 As shown, the wax pattern with ceramic core to be prepared and formed in the present invention is used by the lost-wax precision casting process for hollow blade castings. Therefore, the wax pattern with ceramic core should be matched to the design technical requirements of hollow blade castings, which mainly consists of matching The blade wax mold 1 of the shape structure of the hollow blade casting and the ceramic core 2 matching the cavity structure of the hollow blade casting are composed; the structural dimensions of the blade wax mold 1 and the ceramic core 2 are respectively enlarged in a certain proportion according to the design size of the hollow blade casting , the ceramic core 2 is axially wrapped in the blade wax mold 1 . The blade wax mold 1 has a wax mold leaf root 11, a wax mold blade body 13 and a wax mold leaf top 18; a wax mold tenon head 12 protruding radially between the wax mold leaf root 11 and the wax mold blade body 13; The wax mod...

Embodiment 2

[0037] The other content of this embodiment is the same as that of Embodiment 1, except that: when confirming the normal projection of the inspection reference point according to the design of the hollow blade casting, the inspection reference is only determined by the normal projection on the designed ceramic core point, no need to determine the inspection reference point on the wax mold that matches the design wax model, so that the inspection reference points on the designed hollow blade casting and the ceramic core are mapped to each other and unified with each other. When the ceramic core is clamped and positioned, with The inspection reference point determined on the ceramic core is used as a support point, and the positioning pin is used to clamp and position in the wax mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com