A spindle tail hole top device and method capable of expanding the clamping length of a lathe

A lathe spindle, top technology, applied in the direction of tailstock/top, tool holder accessories, turning equipment, etc., can solve the problem of the maximum length limit of clamping parts, and achieve the goal of ensuring machining quality, avoiding eccentricity, expanding range and capability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below:

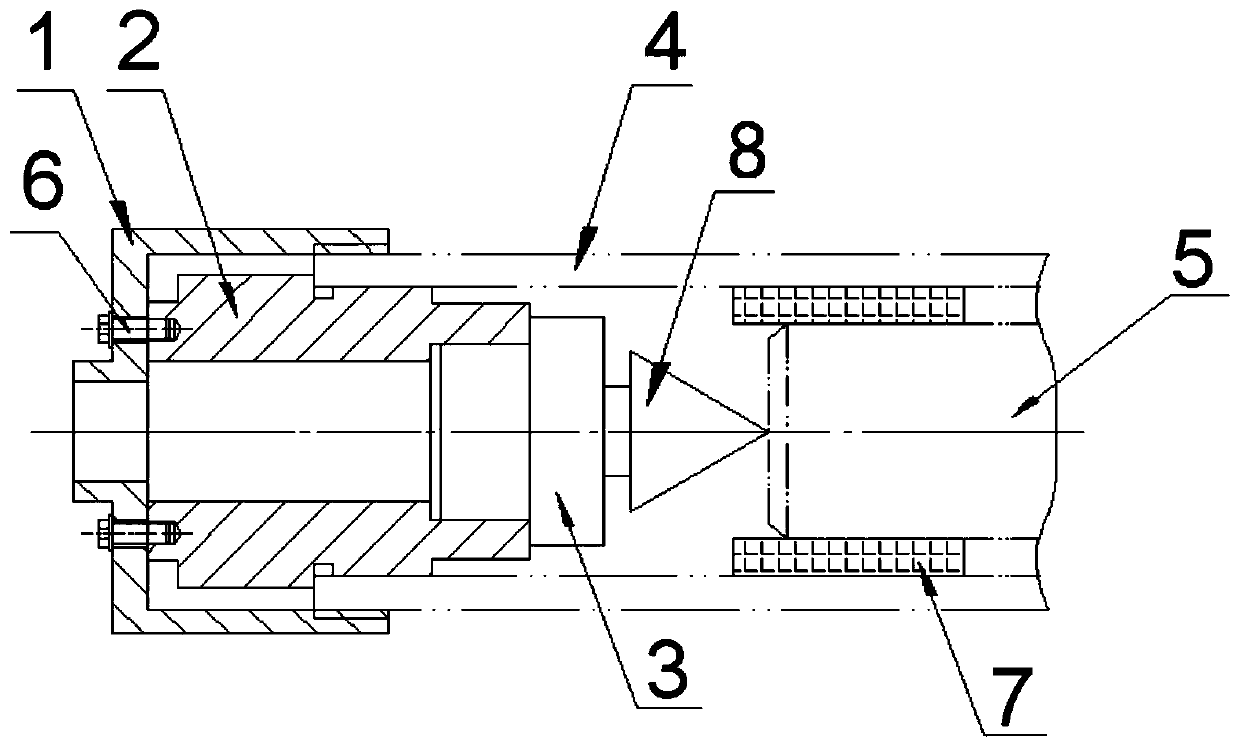

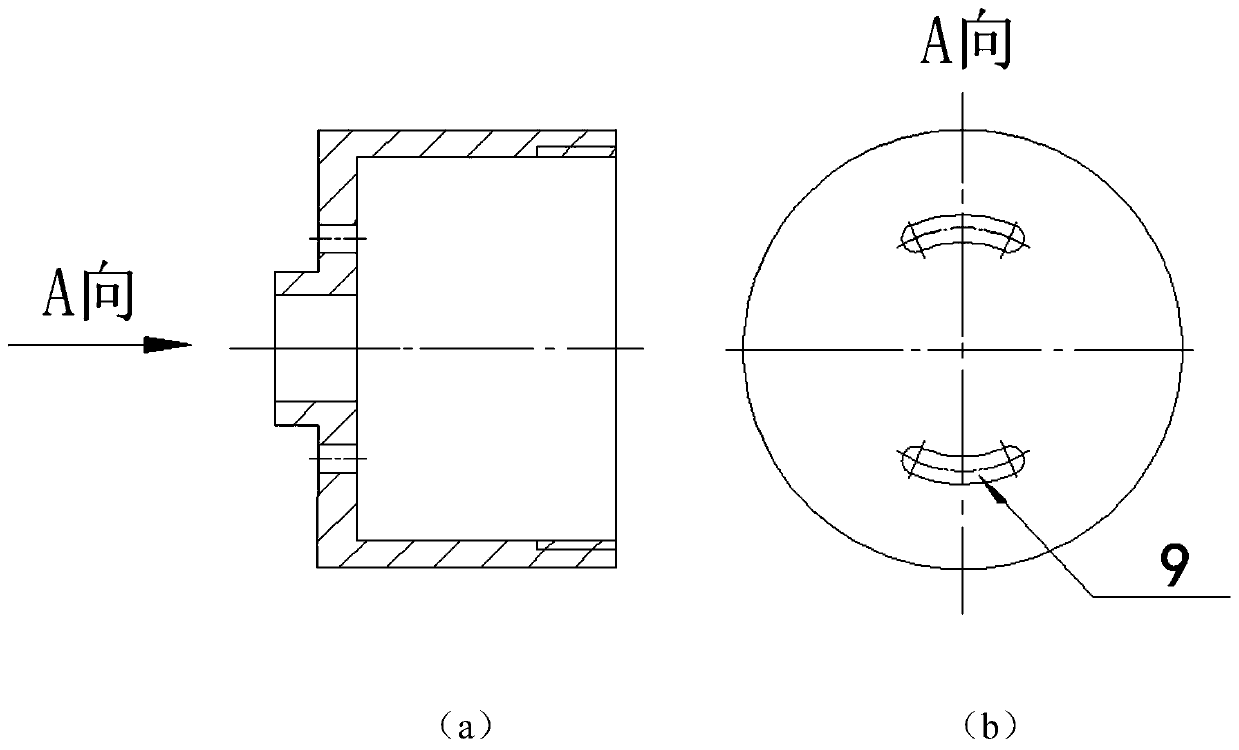

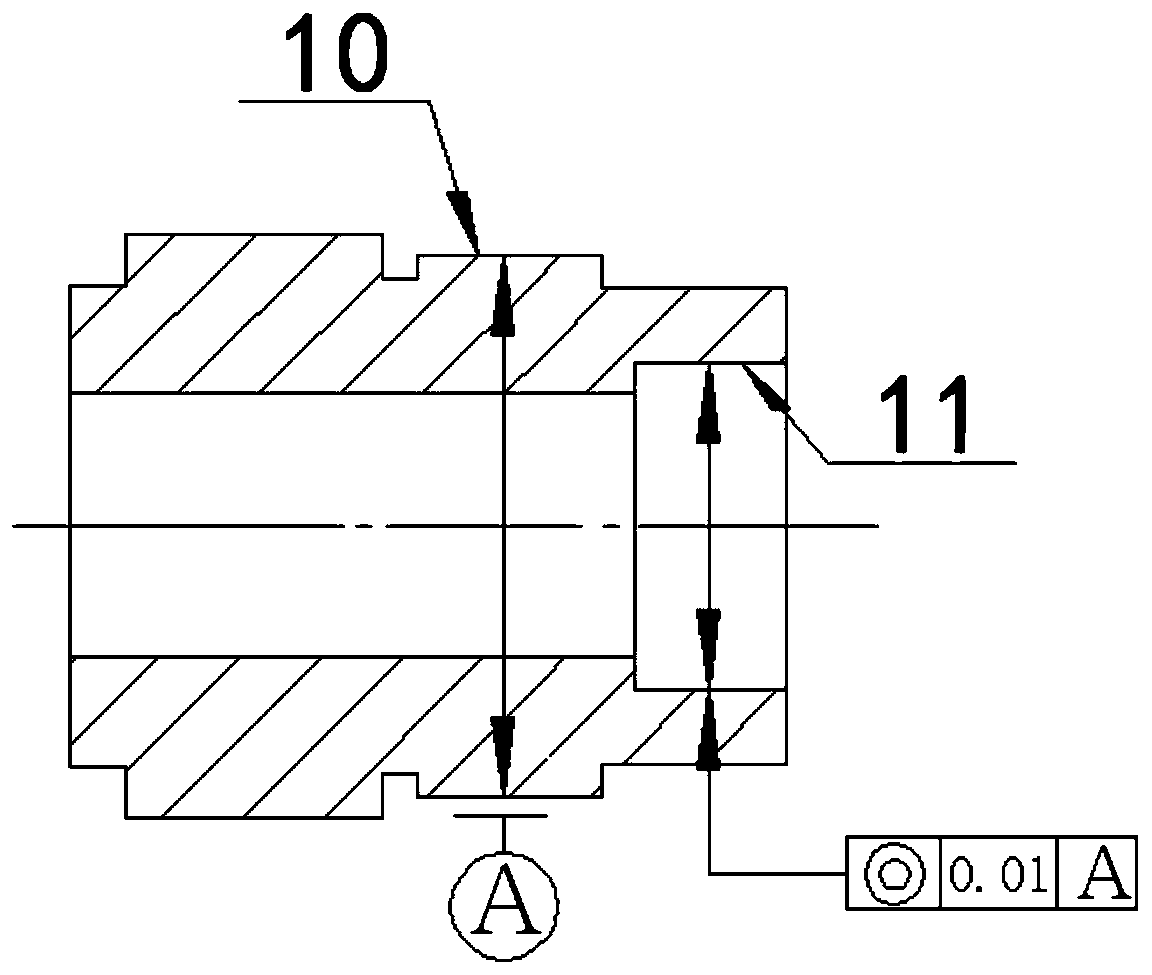

[0026] Although the traditional method can directly extend a part of the part into the spindle hole of the lathe without any centering device, so as to indirectly expand the length range of the parts that can be clamped by the lathe, but this method will cause the part to extend into the spindle hole of the lathe. Risk of eccentricity. Compared with the traditional method, the present invention designs and installs a spindle tail hole tip in the spindle hole of the lathe on the basis of the conventional method, so as to indirectly expand the length range of the clampable parts of the lathe and ensure that the long-axis part extends into the lathe The concentricity of a section of the spindle hole ensures the processing quality.

[0027] First, select a lathe with high precision such as radial runout and axial movement at the tail end of the spindle hole, and install a spindle tail hole tip device at the tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com