Roller line and workstation for hub deburring

A technology of deburring and roller table, which is applied in the field of surface treatment of parts, can solve the problems affecting the precision of deburring processing of hub workpieces, affecting the accuracy of clamping and positioning of hub workpieces, and reducing processing efficiency, etc., to achieve clamping and fixing stability, The effect of reducing vibration and improving the positioning accuracy of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

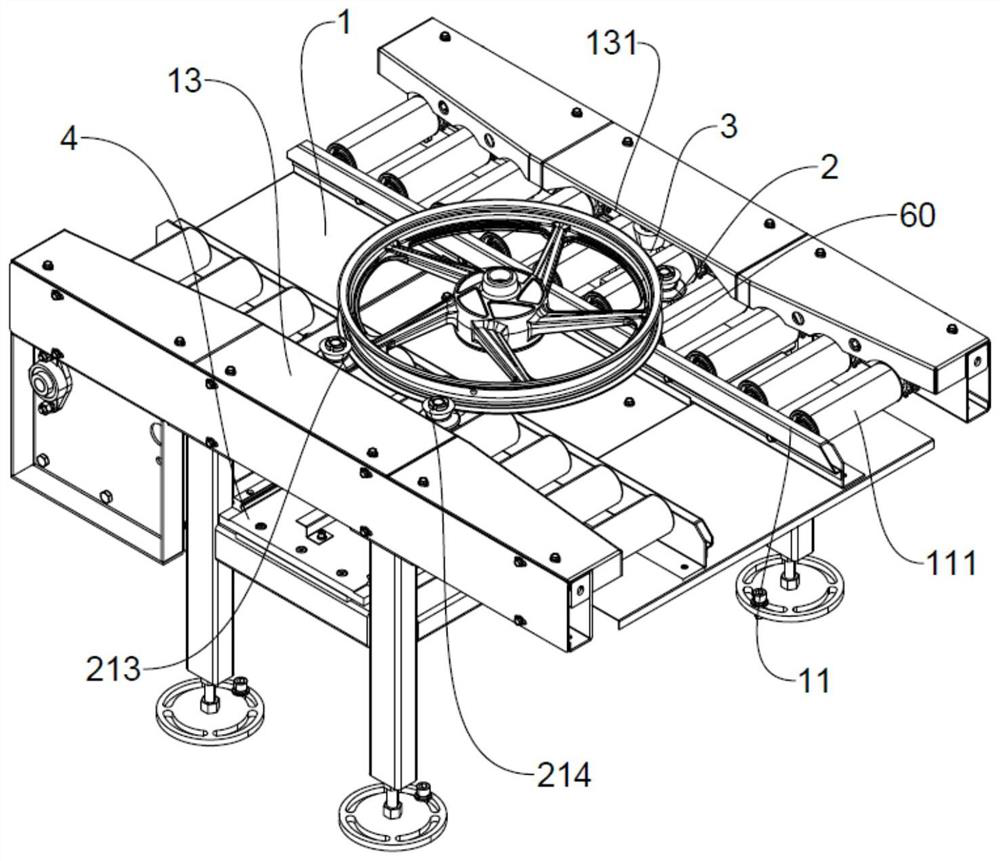

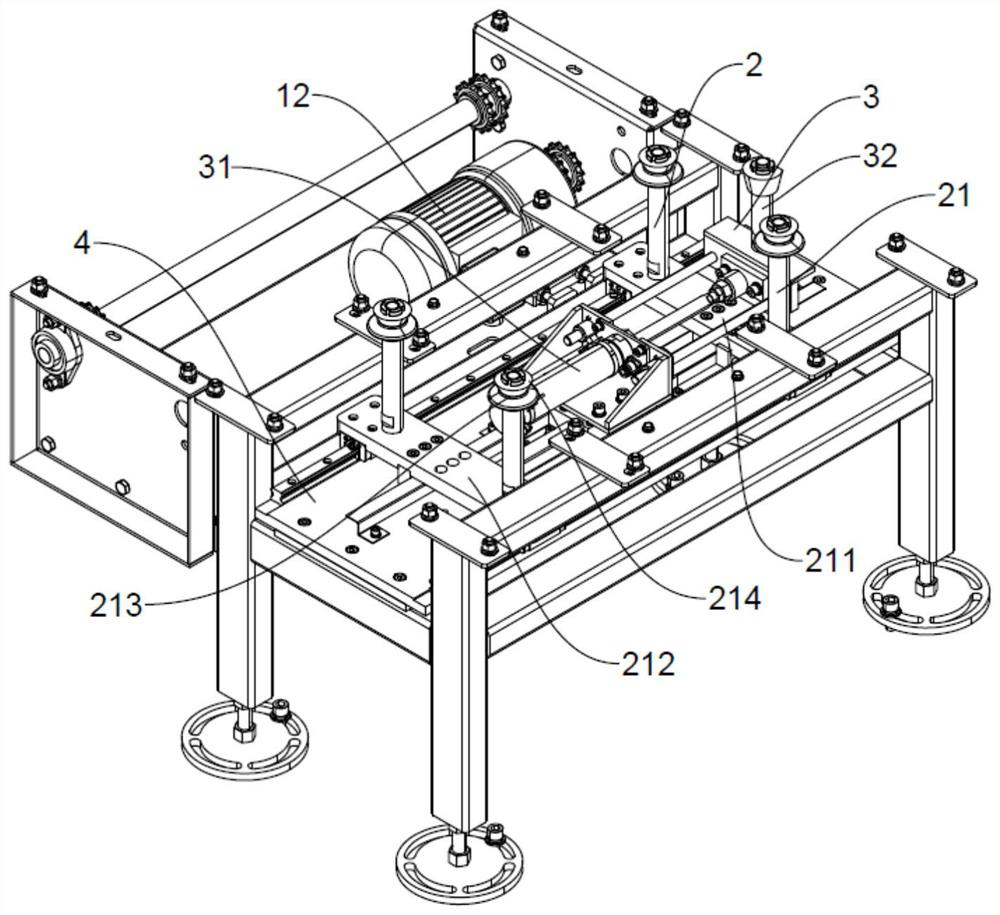

[0035] Depend on Figure 1-5 As shown, a roller table line for deburring a wheel hub includes a first support plate 1, a clamping mechanism 2 for clamping and positioning the workpiece of the hub, and a tensioning mechanism 3 for eliminating the transmission gap of the clamping mechanism 2, The first support plate 1 is provided with a roller table 11 , and a first driver 12 for driving the rollers 111 of the roller table 11 to rotate is fixed at the first support plate 1 .

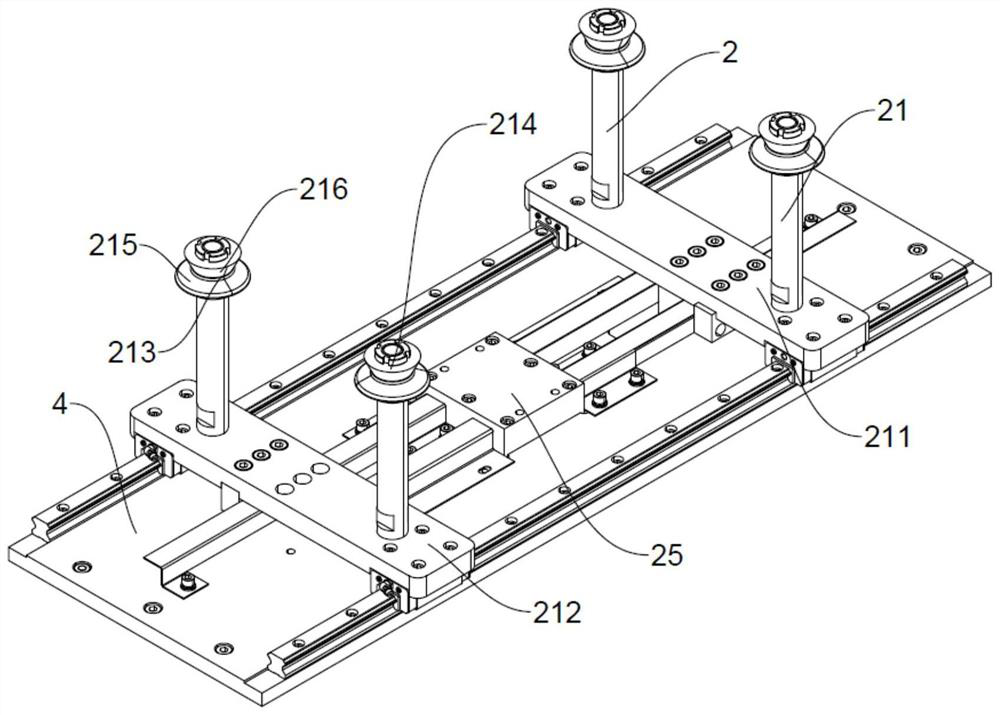

[0036] Depend on Figure 3-5 As shown, the clamping mechanism 2 includes a clamping block 21 located between the adjacent rollers 111 of the roller table 11 and a second driver 22 for driving the clamping block 21 to move in the left-right direction. The clamping block 21 includes a first clamping block 211 and a second driving block 22. Two clamping blocks 212 , a second supporting plate 4 provided below the first supporting plate 1 , the first clamping block 211 is slidably fitted on the right side of t...

Embodiment 2

[0052] Depend on Figure 1-5 As shown, a gear 23 is provided between the first clamping block 211 and the second clamping block 212, the gear 23 is rotatably arranged above the first support plate 1, and both the first clamping block 211 and the second clamping block 212 are provided with the gear 23 In the meshed rack structure 24 , the gear rotates under the action of the second driver 22 , and drives the first clamping block 211 and the second clamping block 212 to translate simultaneously through the rack structure meshing with the gear 23 .

[0053] The second driver 22 of the channel drives the gear 23 to rotate, so that the rack structure 24 moves toward each other in the left-right direction, and makes the first clamping block 211 move to the left and the second clamping block 212 to the right. The part 60 is clamped and positioned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com