Special grinding machine for valve cone surface

A special grinding machine and valve cone technology, which is applied in the seat surface grinding machine, grinding machine, grinding bed and other directions, can solve the problems of inaccurate centering, inconvenient adjustment, and high operating frequency of the operator, so as to ensure the clamping accuracy and the coaxiality. effect of degree requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

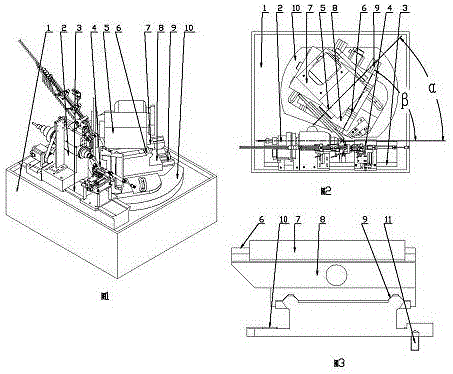

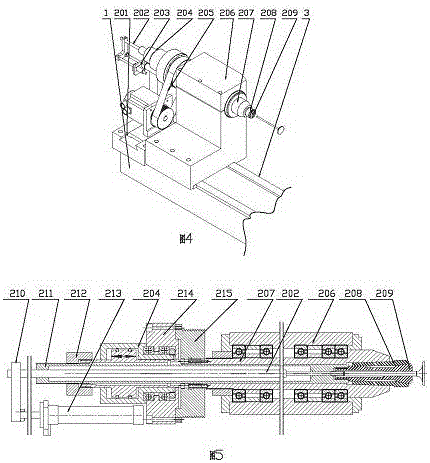

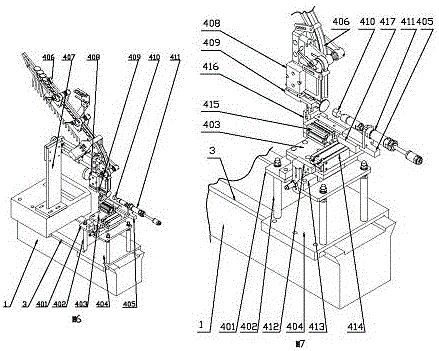

[0030] exist Figure 1 to Figure 9 In the special grinding machine for the valve cone surface shown, the frame 1 is a cuboid steel structure, the main shaft device 2, the automatic loading device 4 and the grinding head 5 are all supported on the frame 1; on the upper plane of the frame 1 The grinding head base 10 is rotatably supported by the centering pin 11. The upper and lower ends of the centering pin 11 are respectively installed in the corresponding pin holes of the grinding head base 10 and the frame 1. There are three to six holes on the grinding head base 10. With the centering pin 11 as the center arc-shaped bolt hole, after the grinding head base 10 is rotated around the centering pin 11 to adjust the angular position, the fastening bolts on it are fixedly connected with the frame 1 through the set arc bolt hole. The lower guide rail 9 is arranged on the upper plane of the grinding head base 10, the lower carriage 8 is slidingly connected with the grinding head bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com