Dual-wire contact collet jaws

A chuck jaw, line contact technology, applied in the field of chuck parts, can solve the problems of affecting the clamping and positioning accuracy of the chuck jaws, unfavorable for the normal operation of the chuck, and insufficient contact strength, so as to improve the contact strength and the clamping force. Maintain positioning accuracy, share contact stress, and reduce contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

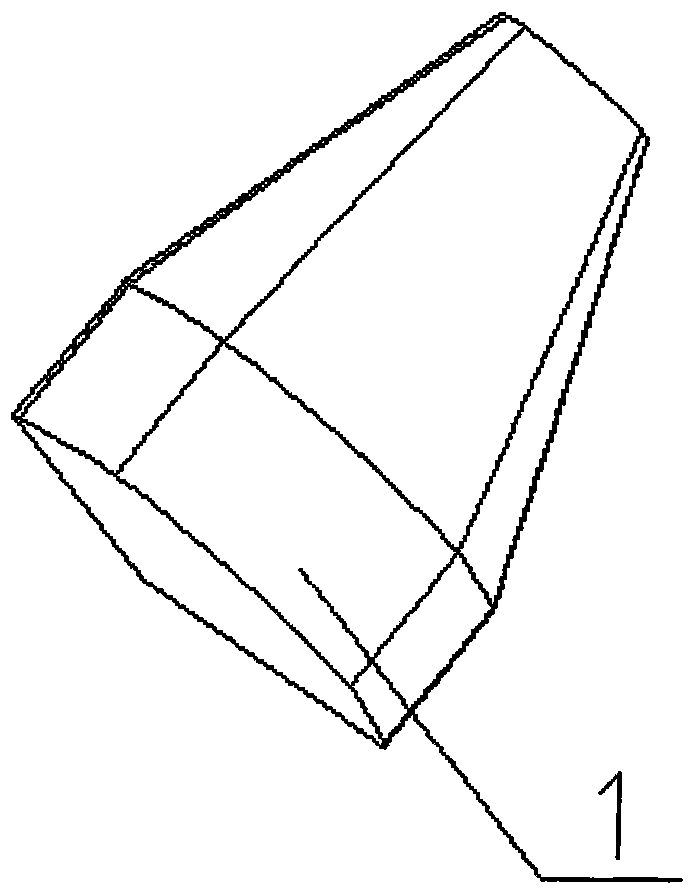

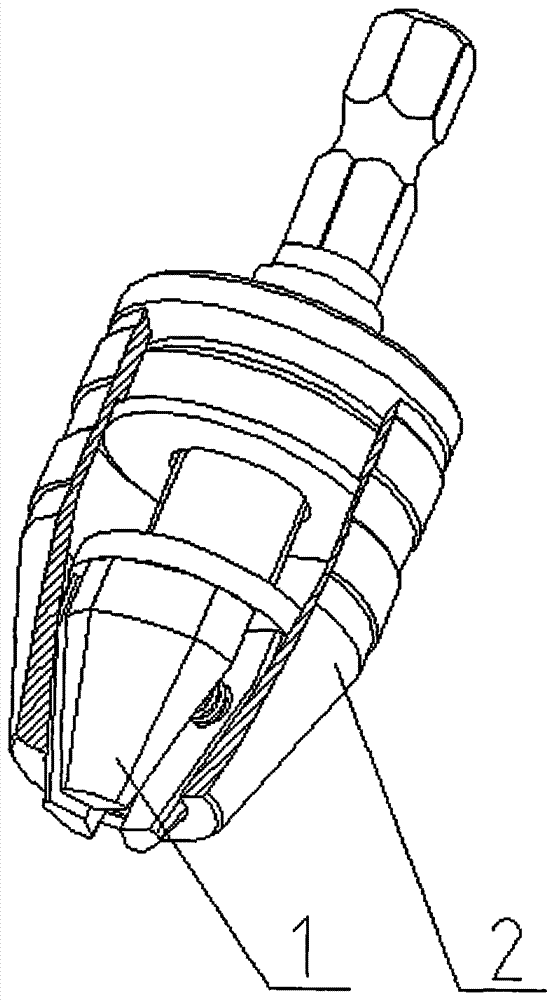

[0012] like figure 1 , figure 2 As shown, a double-line contact chuck jaw is characterized in that: the side cone surface of the chuck jaw 1 is composed of three sections of conical surfaces, forming two splicing lines, wherein the conical surfaces on both sides are the same, The conical surface in the middle section is relatively large. When the three double-line contact chuck jaws installed in the chuck shell 2 are evenly distributed to clamp the work piece with the smallest diameter, the conical surfaces on both sides are completely consistent with the inner conical surface of the chuck shell 2. Fitting, when the workpiece with the largest diameter is clamped, the conical surface in the middle of it is completely attached to the inner conical surface of the chuck shell 2. When the workpiece with a diameter in the middle range is clamped, the two splicing lines and the chuck The inner conical surface of the housing forms a two-line contact.

[0013] Working process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com