A quick locking device

A locking device, a fast technology, applied in the direction of fixtures, mechanical equipment, etc., can solve the problems of economic cost saving, labor cost and time cost advantages are not obvious, the number of components of the device is large, and it cannot be applied to actual needs. The effect of utilizing, improving assembly efficiency and saving assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

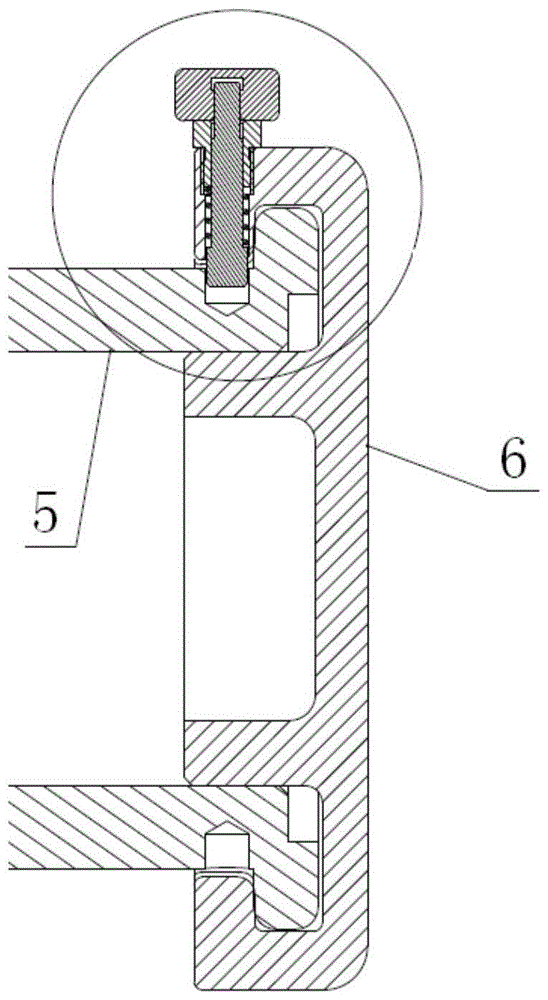

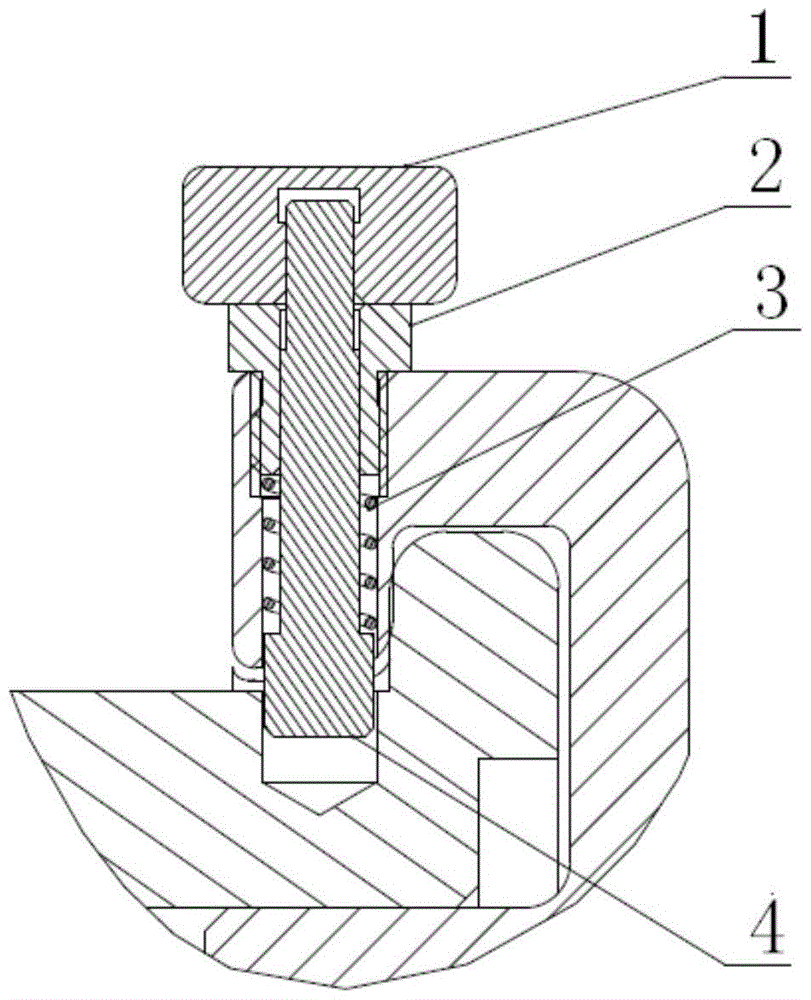

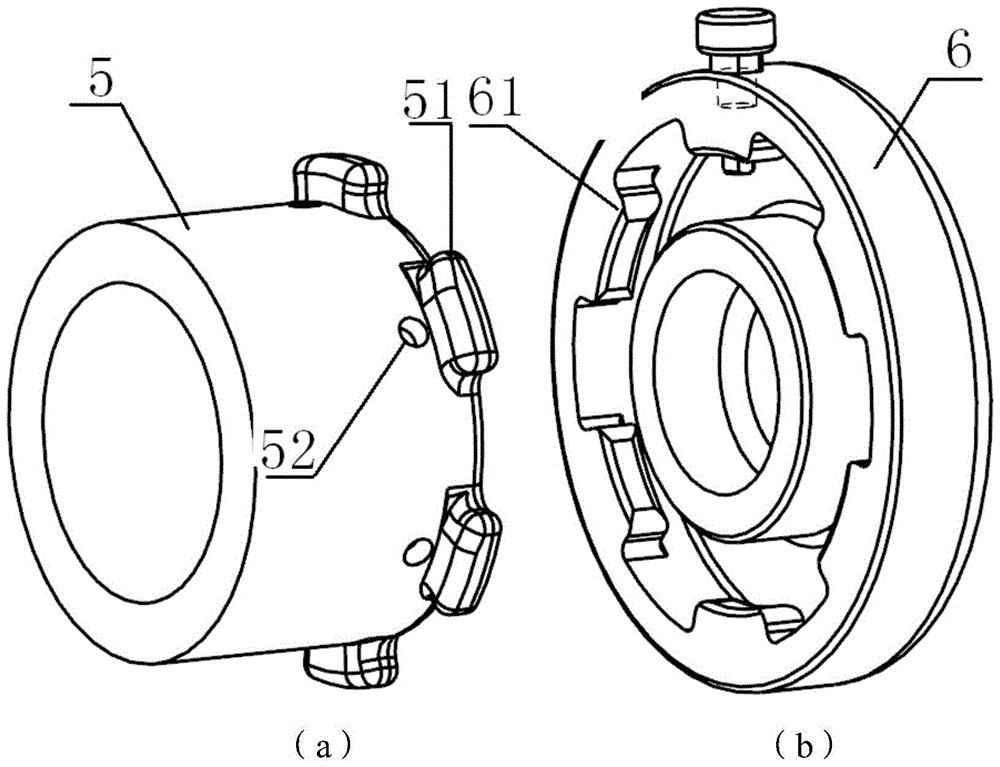

[0025] The present invention provides a fast clamping locking device, comprising: a nut 1 , a screw sleeve 2 , a spring 3 , a locking pin 4 , a first clamping opening 61 , and a second clamping opening 51 . Such as Figure 4 As shown, the nut 1 is cylindrical, and there is a mounting hole in the center of the cylindrical shape; as Figure 5 As shown, the locking pin 4 includes three sections of cylinders. The surface of the cylinder at one end is processed with threads, and the two sides of the cylinder at the other end are cut out by two planes parallel to the symmetry axis of the locking pin 4. Two symmetrical planes are cut out. The three sections of cylinders directly from the threaded end to increase sequentially; for example Image 6 , Figure 7 As shown, the screw sleeve 2 includes two cylinders with different diameters, the outer surface of the smaller diameter cylinder is processed with threads, and the center of the screw sleeve 2 has a through hole, which runs thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com