Linear oscillation motor

An oscillating motor, linear technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems that the size is difficult to meet the requirements, the precision requirements are also high, and the price of linear bearings is high, and it is convenient and difficult to replace parts. Mechanical trauma, the effect of facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

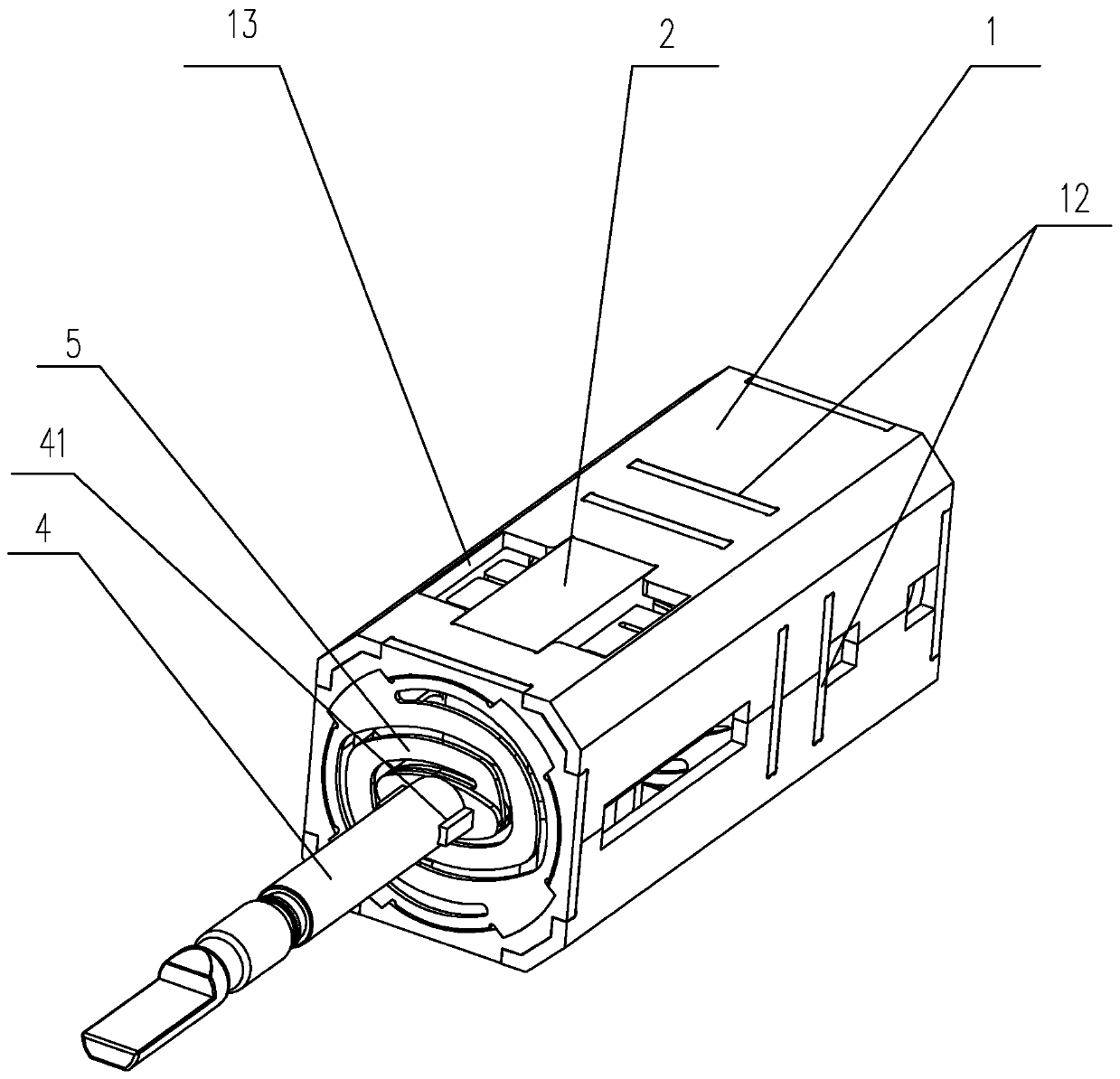

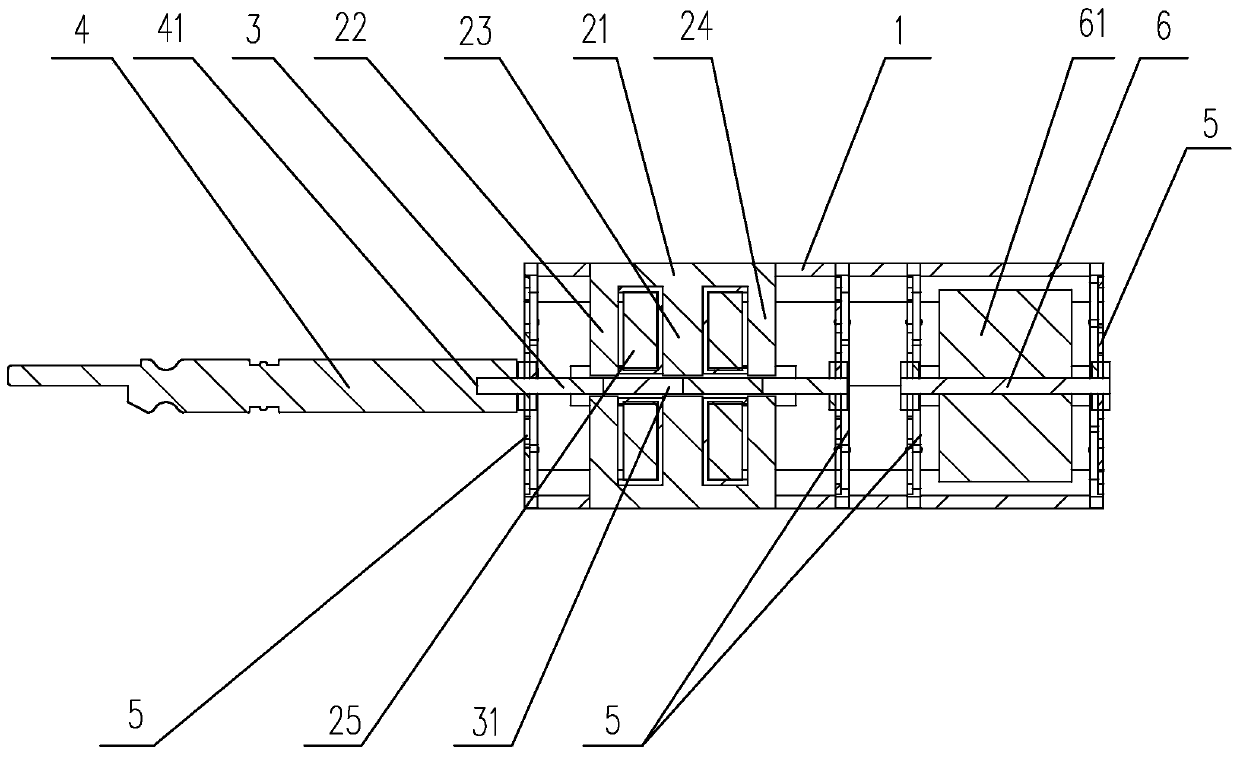

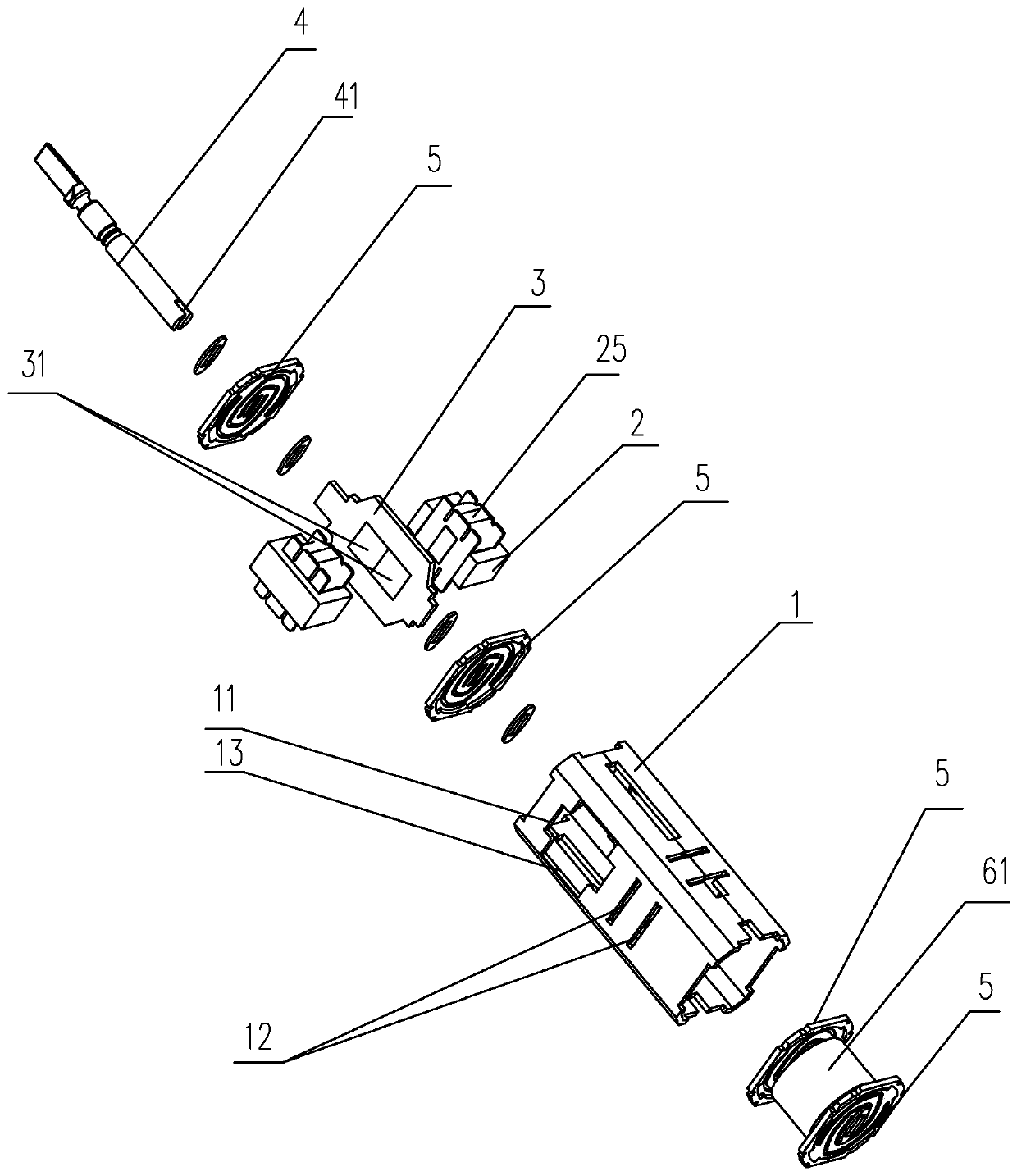

[0033] The first embodiment of the linear oscillating motor of the present invention is figure 1 , figure 2 , image 3 and Figure 4 Shown: includes a housing 1, the housing 1 is provided with a linear vibration module and a reverse vibration module, the linear vibration module and the reverse vibration module are coupled through the housing 1, and the linear vibration module includes a sliding piece 3 and a set of iron core groups, the sliding member 3 is slidably arranged in the housing 1 in the axial direction, and the sliding member 3 is extended to the outside of the housing 1 to form an output shaft 4, on which the sliding member 3 Magnetic steel 31 is provided, leaf springs 5 are provided at both ends of the sliding member 3 and are connected to the housing 1 through the leaf springs 5, and the iron core group includes two E-shaped The iron core 2 is provided with a winding on the E-shaped iron core 2 , and the reverse vibration module is arranged in the casing 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com