Three-jaw chuck for lathe

A three-jaw chuck and chuck technology, used in chucks, turning equipment, accessories of tool holders, etc., can solve the problem of inconvenient clamping of thin-walled parts, and achieve a wide range of applications, high clamping and positioning accuracy, and convenience. clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

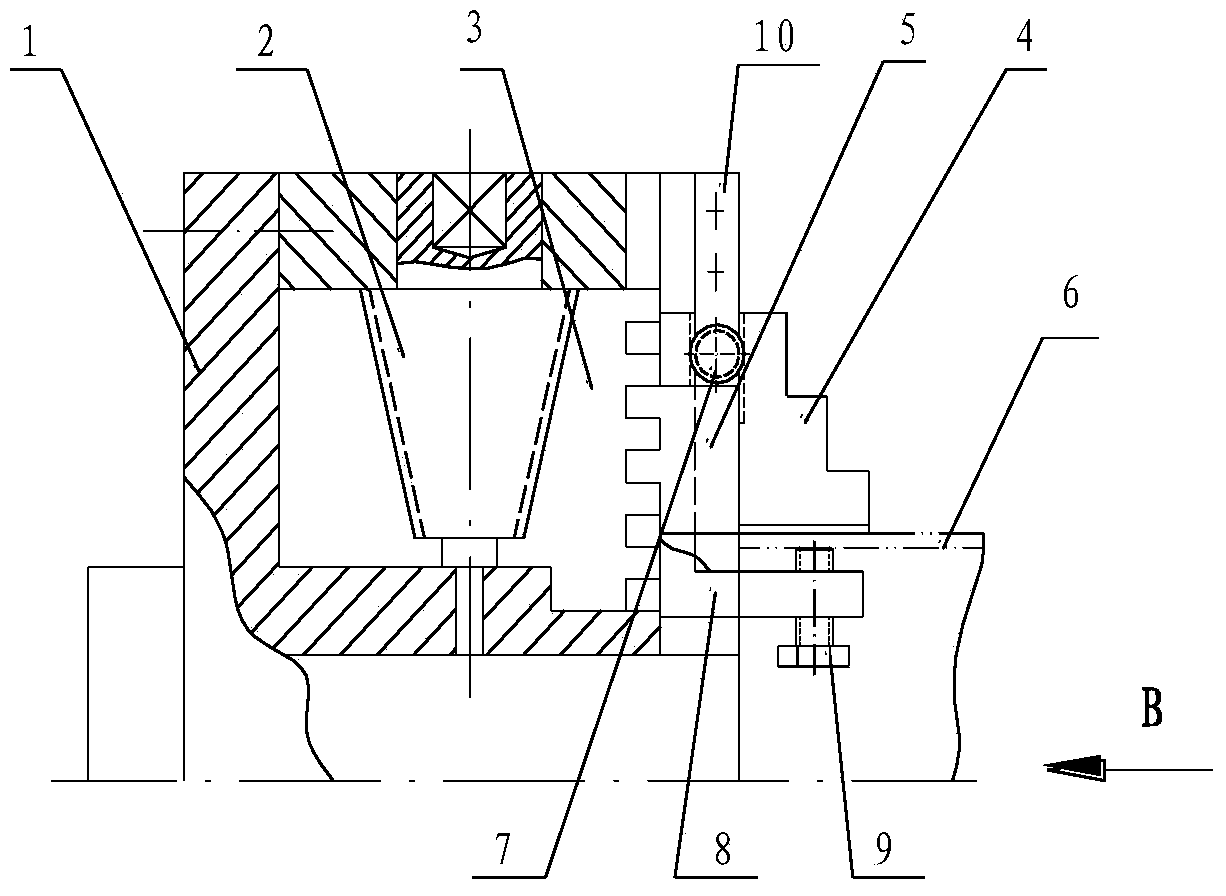

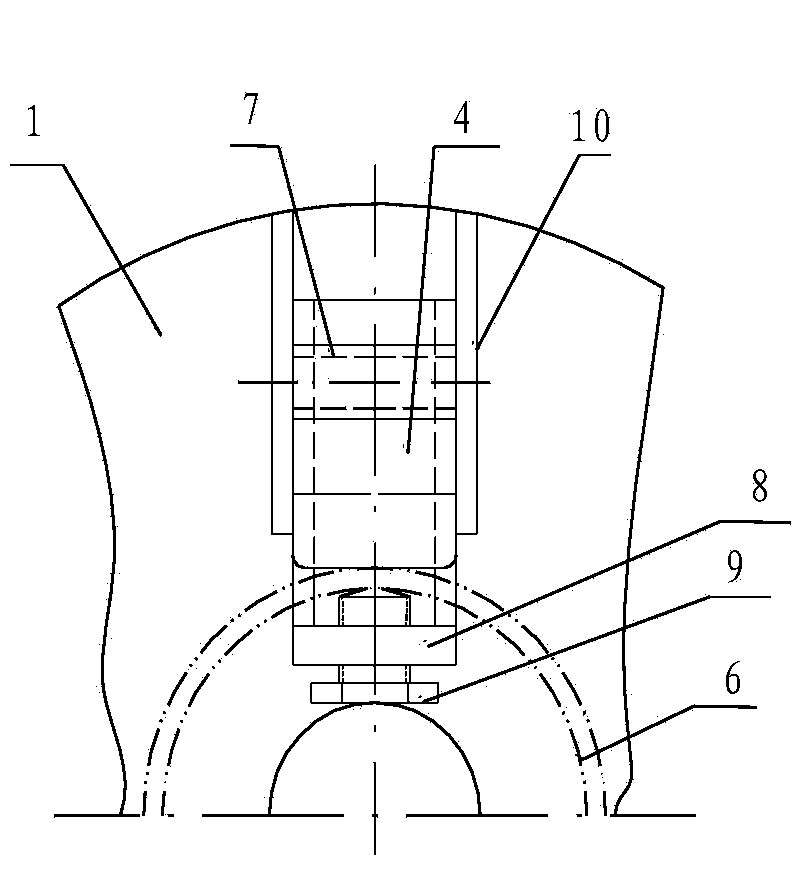

[0019] Such as figure 1 Shown is the sectional view of the structure embodiment of the present invention, figure 2 for yes figure 1 Partial schematic diagram in the middle B direction, it can be seen that the three-jaw chuck for lathes includes chuck body 1, movable jaw 4, small bevel gear 2, inner disk wire 3, pinion gear 7 and top jaw 8, in which: chuck body 1 Installed in the spindle hole of the lathe, there are three evenly distributed slots on the front end surface of the chuck body 1, and the three movable jaws 4 are respectively placed in the three slots on the front end of the chuck body 1, and The bottom of the claw 4 is fixedly connected with the claw mounting seat 5 installed in the card groove, and the claw mounting seat 5 cooperates with the card groove to form a moving pair, and the card groove guides the claw mounting seat 5, and the movable cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com