Bearing fixing device

A fixing device and bearing technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of low reliability of bearings, poor replaceability of bearings, and inability to calibrate the axial bearing capacity of bearings, etc. Axial load capacity, the effect of improving replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

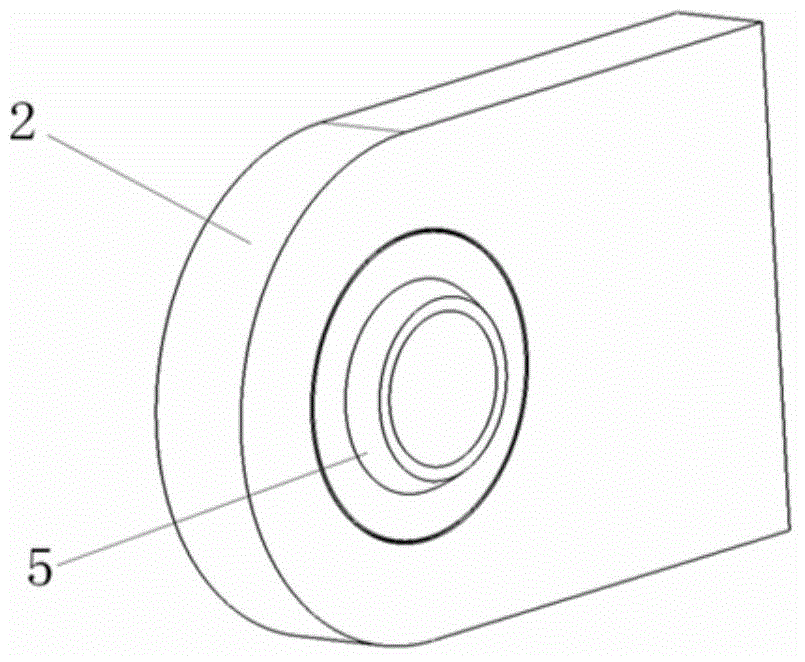

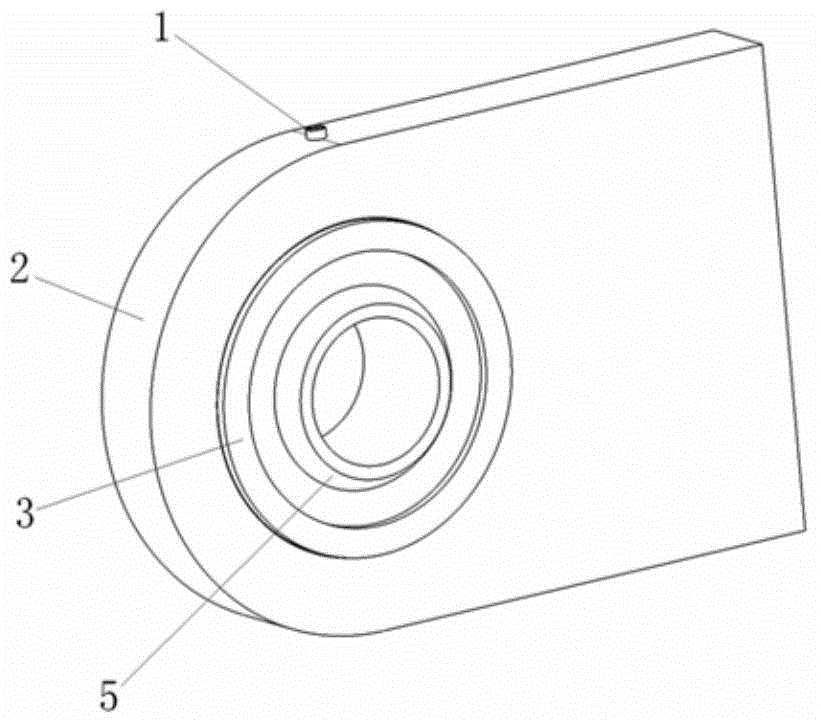

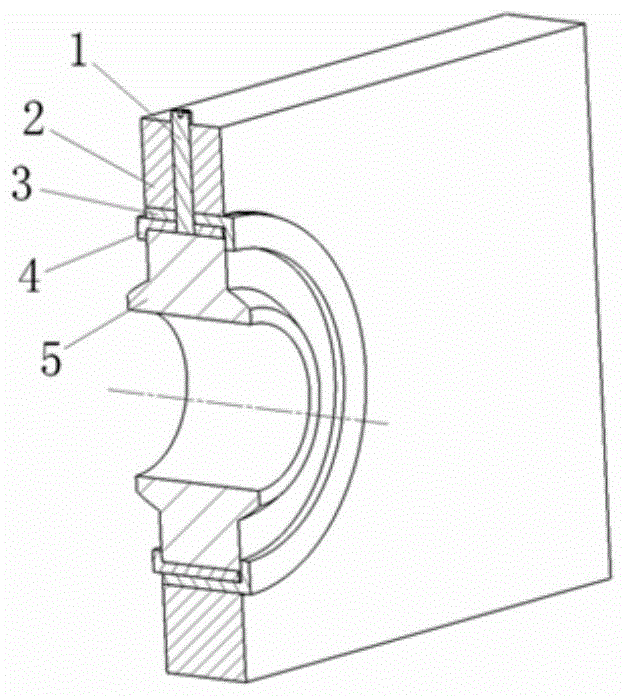

[0032] A bearing fixing device is characterized in that it includes a pin 1, a bearing support 2, an outer bush 3, an inner bush 4 and a bearing 5, the bearing support 2 is a single lug bearing support, the outer bush 3 and the inner bush There is a shoulder on one side of the bushing 4, a through hole is opened on the outer side of the bearing hole of the bearing support 2, and a through hole is opened on the outer bushing 3 and the inner bushing 4, and the bearing support 2, the outer bushing 3 and the The cross-section of the open hole of the inner bush 4 is the same, the bearing 5 is pressed into the inner bush 4, one side of the bearing 5 is in contact with the shoulder of the inner bush 4, and then the inner bush 4 is put into the outer bush 3 to ensure The inner bushing 4 is aligned with the through hole of the outer bushing 3, the bearing 5 is in contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com