High thrust linear electric push rod

An electric push rod, high thrust technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of small load, damage to the needle roller of the plane bearing, and small thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

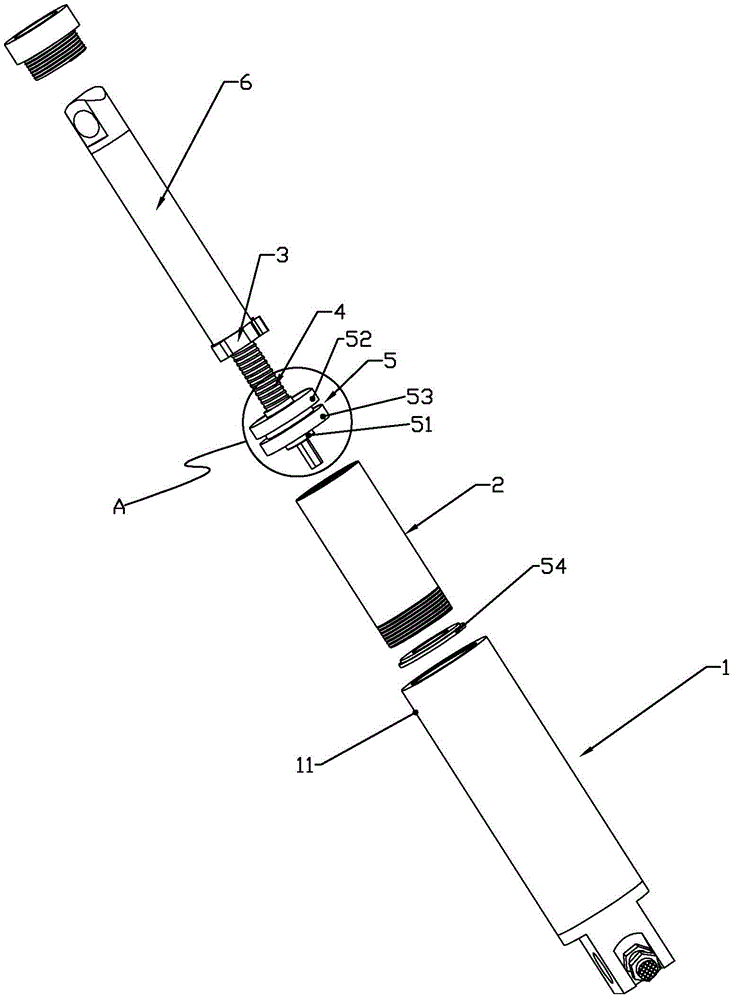

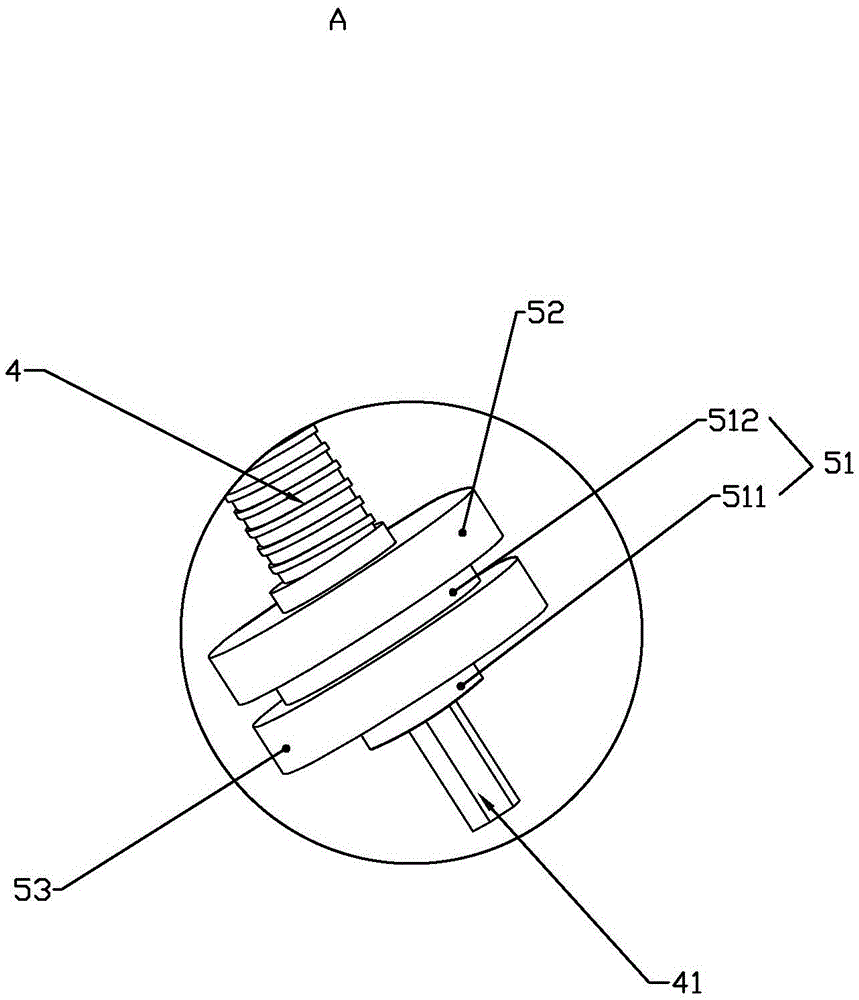

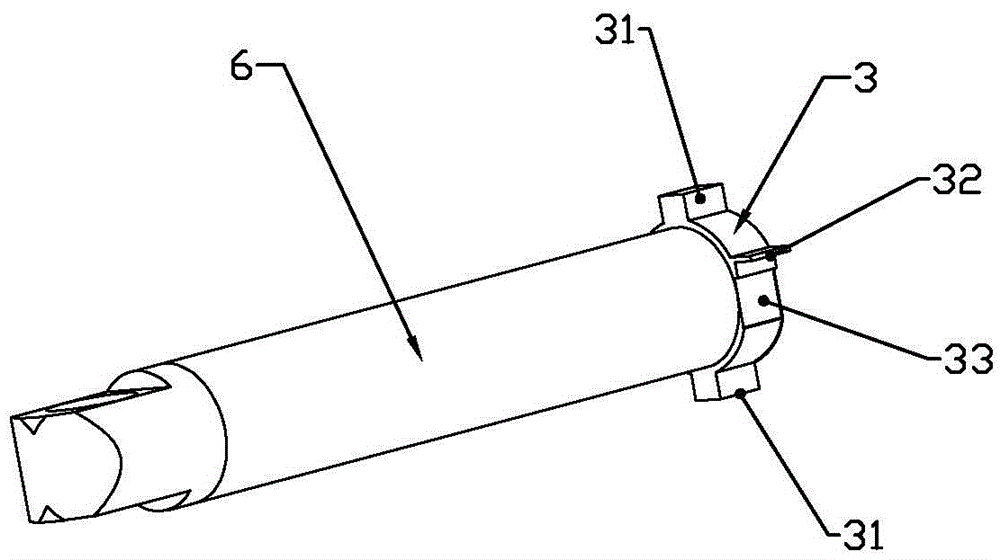

[0022] Such as Figures 1 to 5 As shown, a large-thrust linear electric push rod disclosed by the present invention includes a power unit 1, an electronic control unit, a transmission mechanism and a telescopic push rod 6, and the power unit includes a motor outer casing 11, a motor and a gear reducer (placed in The inside of the motor outer sleeve 11 is not shown, it is a conventional part of the electric push rod, so it will not be described in detail), the motor and the gear reducer are all placed in the motor outer sleeve 11, and the transmission mechanism includes a stroke sleeve 2, a nut 3, and a screw rod 4 And the bearing assembly 5, the nut 3 is screwed on the screw rod 4, the nut 3 is fixedly connected with the telescopic push rod 6, the nut 3 is dynamically fitted in the stroke sleeve 2 in an axially reciprocating sliding manner, and the telescopic push rod 6 follows the nut The movement of 3 realizes telescopic entry and exit of the stroke sleeve 2, the power input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com